Application of bipyridine ester phosphite to PVC heat stabilizer

A technology of dipyridyl phosphite and heat stabilizer, which is applied in the field of application of dipyridyl phosphite in PVC heat stabilizers, can solve the problem of poor anti-separation performance and auxiliary stability performance, which limits the wide application of liquid stabilizers, Obvious problems such as pressure segregation and blooming, to achieve the effect of improving initial coloring, excellent anti-separation, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further specifically described below through specific examples.

[0024] The raw materials used in the examples are commercially available conventional raw materials.

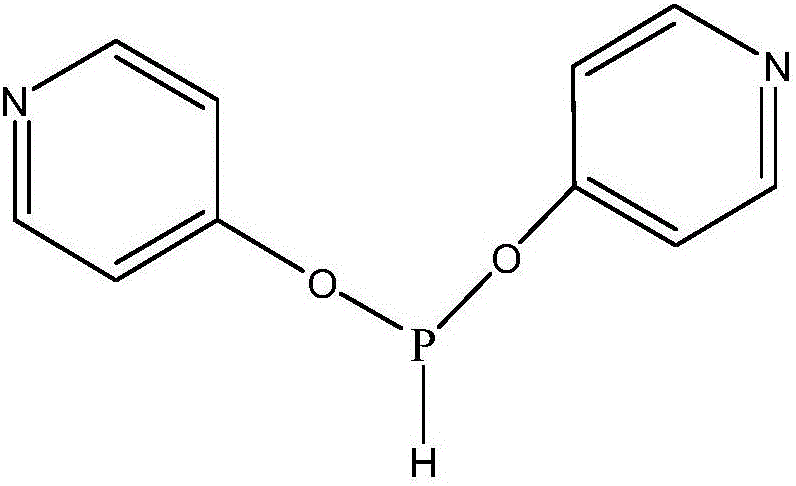

[0025] Preparation of bipyridine phosphite:

[0026] Using 68.5g of phosphorus trichloride and 150g of 2-hydroxypyridine as raw materials, add phosphorus trichloride dropwise to 2-hydroxypyridine at a temperature of 65°C and a time of 100 minutes to obtain trihydroxypyridinyl phosphite. Add 20.5 g of phosphorous acid into the above product, and react at 120° C. for 60 minutes to obtain 98.5 g of dihydroxypyridinium phosphite.

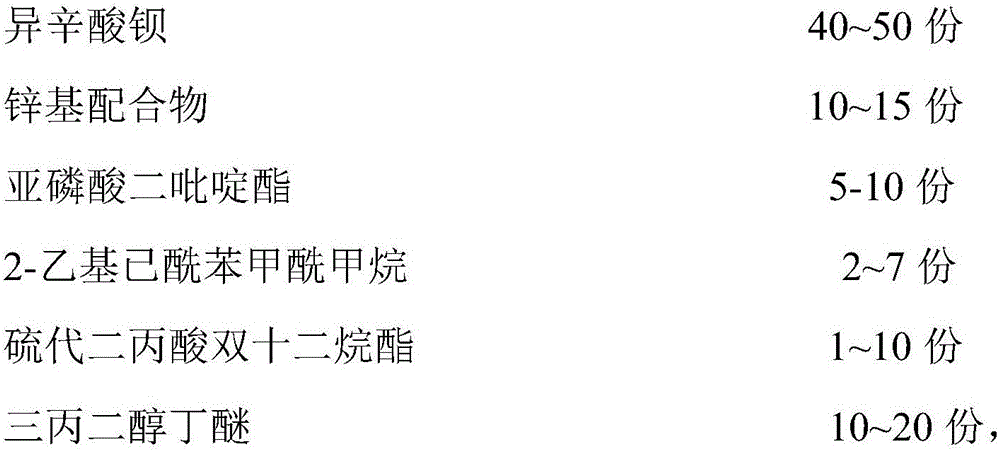

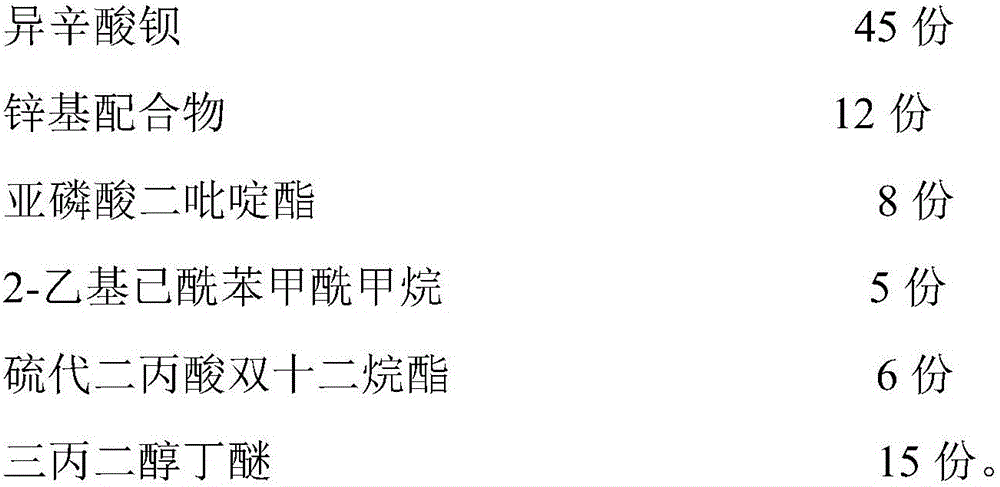

[0027] The formula composition of the liquid barium zinc stabilizer of embodiment 1-4 is as follows table:

[0028]

[0029]

[0030] The composition of the zinc-based complex in Examples 1-4 is as follows, the following raw materials are mixed according to the proportion, and then the amount used in the formula of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com