High-thermal-conductivity low-abrasion TPU material and preparation method thereof

A low-wear, high thermal conductivity technology, applied in the field of thermoplastic polyurethane elastomers, can solve the problems of material thermal conductivity, mechanics, wear resistance and other properties that cannot be taken into account at the same time, affect the overall performance of the material, affect the stability of the material and other problems, so as to solve the problem of wear and tear. The effect of fast, enhanced force, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

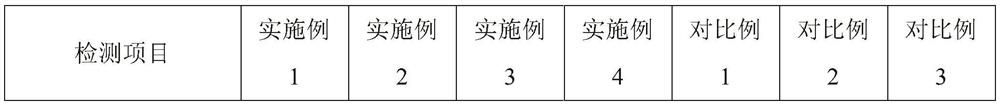

Examples

Embodiment 1

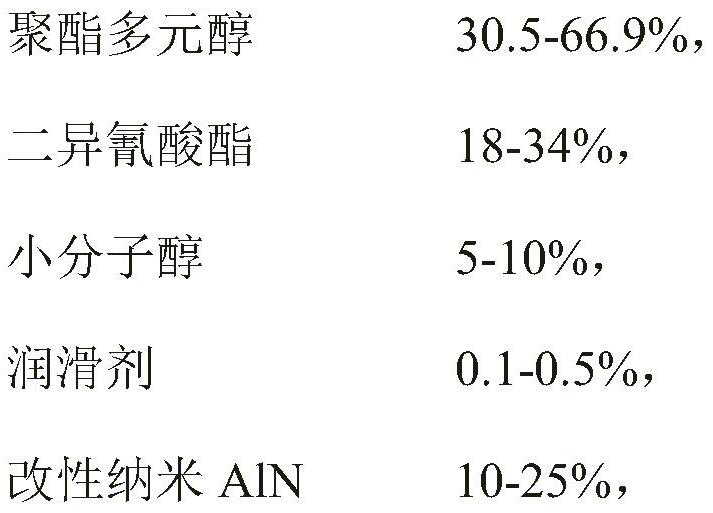

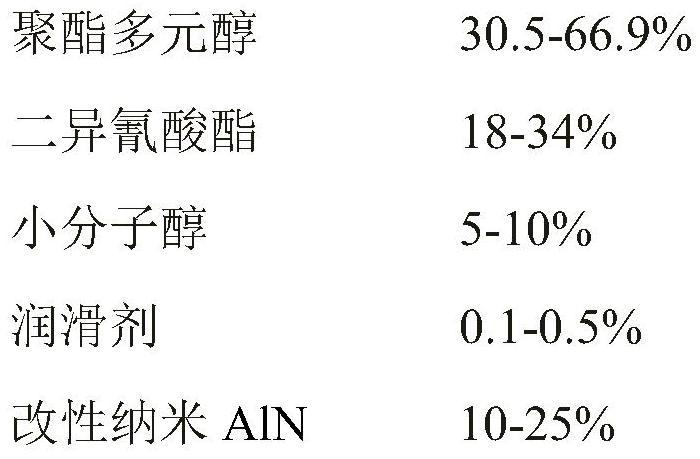

[0031] A TPU material with high thermal conductivity and low wear, made of the following raw materials in mass percentage:

[0032] Polyethylene adipate-1,2-propylene glycol ester diol (M=3000): 47.75%,

[0033] 4,4'-Diphenylmethane diisocyanate (MDI-100): 20.85%,

[0034] 1,4-butanediol (BDO): 5.94%,

[0035] Trimethylolpropane (TMP): 0.06%,

[0036] Stearic acid amide: 0.2%,

[0037] Ethylene bis-stearamide: 0.2%,

[0038] Modified nano-AlN particles: 25%,

[0039] Wherein, the consumption of catalyst stannous octoate (T-9) is 0.04% of the total mass of the raw materials used above.

[0040] The preparation method is: add polyethylene adipate-1,2-propylene glycol ester diol (M=3000), stearic acid amide, ethylene bisstearic acid amide, stannous octoate (T-9) into In reactor A with mechanical stirring and temperature control system, set the temperature to 100°C and stir; place MDI-100 in reactor B, set the temperature to 65°C; place BDO and TMP in reactor C , set the te...

Embodiment 2

[0042]A TPU material with high thermal conductivity and low wear, made of the following raw materials in mass percentage:

[0043] Polyadipate-1,4-butylene glycol ester diol (M=2000): 46.28%,

[0044] 4,4'-Diphenylmethane diisocyanate (MDI-100): 26.18%,

[0045] 1,4-butanediol (BDO): 7.12%,

[0046] Trimethylolpropane (TMP): 0.22%,

[0047] E wax: 0.2%,

[0048] Modified nano-AlN particles: 20%,

[0049] Wherein, the consumption of catalyst stannous octoate (T-9) is 0.06% of the total mass of the raw materials used above.

[0050] The preparation method is: add polyadipate-1,4-butylene glycol ester diol (M=2000), E wax, stannous octoate (T-9) into reaction kettle A with mechanical stirring and temperature control system , set the temperature at 105°C and stir; put MDI-100 in reactor B, set the temperature at 60°C; place BDO and TMP in reactor C, and set the temperature at 70°C. After the materials in each reactor are stirred evenly and the temperature is stable, through ...

Embodiment 3

[0052] A TPU material with high thermal conductivity and low wear, made of the following raw materials in mass percentage:

[0053] Polyethylene adipate-1,4-butylene glycol ester diol (M=1000): 42.31%,

[0054] 4,4'-Diphenylmethane diisocyanate (MDI-100): 33.59%,

[0055] 1,4-butanediol (BDO): 8.36%,

[0056] Trimethylolpropane (TMP): 0.44%,

[0057] Pentaerythritol Stearate: 0.2%,

[0058] Oleamide: 0.1%,

[0059] Modified nano-AlN particles: 15%,

[0060] Wherein, the dosage of the catalyst bismuth neodecanoate (C83) is 0.1% of the total mass of the raw materials used above.

[0061] The preparation method is: polyethylene adipate-1,4-butylene glycol ester diol (M=1000), pentaerythritol stearate, 10 g of oleic acid amide, and bismuth neodecanoate (C83) are added to In reactor A with mechanical stirring and temperature control system, set the temperature at 95°C and stir; place MDI-100 in reactor B, set the temperature at 55°C; place BDO and TMP in reactor C , set the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com