Flame-retardant polypropylene-nylon complex with high rigidity, high heat resistance and impact whitening resistance and preparation method thereof

A technology of flame-retardant polypropylene and high heat resistance, which is applied in the field of high rigidity, high heat resistance, shock resistance, whitening flame retardant polypropylene-nylon composite and its preparation, and can solve the problem of polypropylene toughness, stress whitening, and stress resistance. Whitening is not very good, flame retardant polypropylene stress whitening and other problems, to achieve the effect of lengthening the precipitation path, good stress whitening resistance, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

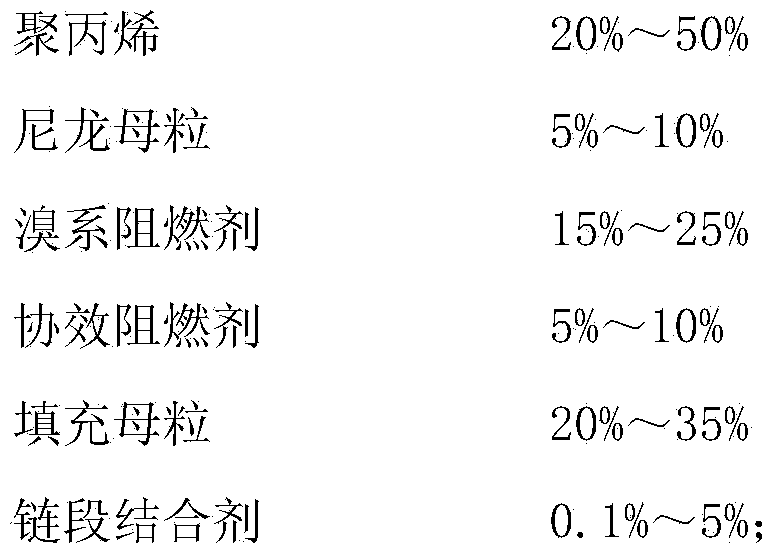

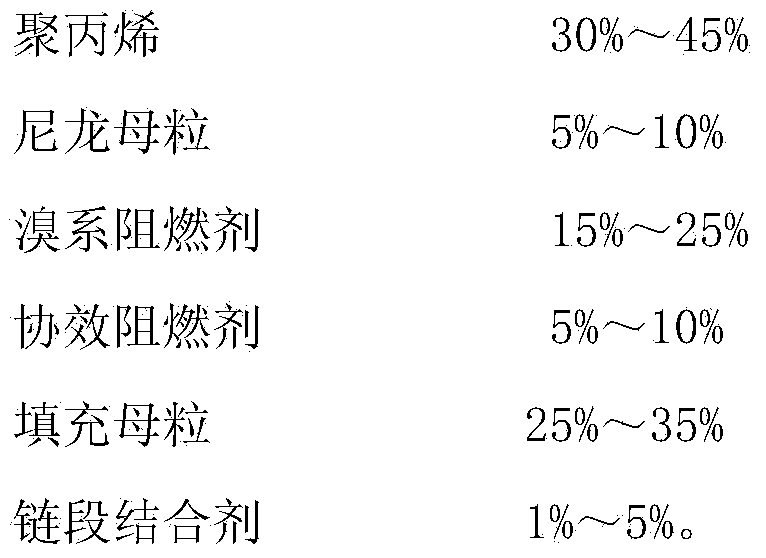

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of nylon masterbatch:

[0025] 38 parts by weight of nylon resin PA (melt index is 40g / 10min), 55 parts by weight of polypropylene resin PP (melt index is 10g / 10min), 7 parts by weight of maleic anhydride grafted POE (melt index is 2g / 10min , grafting rate of 0.8%) and 0.4 parts of processing aids were mixed evenly, extruded and granulated by a screw extruder, and the processing temperature was 210-260 °C; the prepared nylon PA masterbatch was used for the following examples use.

[0026] (2) Preparation of filler masterbatch:

[0027] 28 parts by weight of polypropylene resin (melt index is 10g / 10min), 60 parts by weight of talc powder inorganic filler (average particle size is 5 microns), 8 parts by weight of coupling agent, 10 parts by weight of maleic anhydride grafted polypropylene (The melt index is 80g / 10min, the grafting rate is 0.8%) and 0.4 parts of processing aid calcium stearate are evenly mixed, extruded and granulated by a screw extruder,...

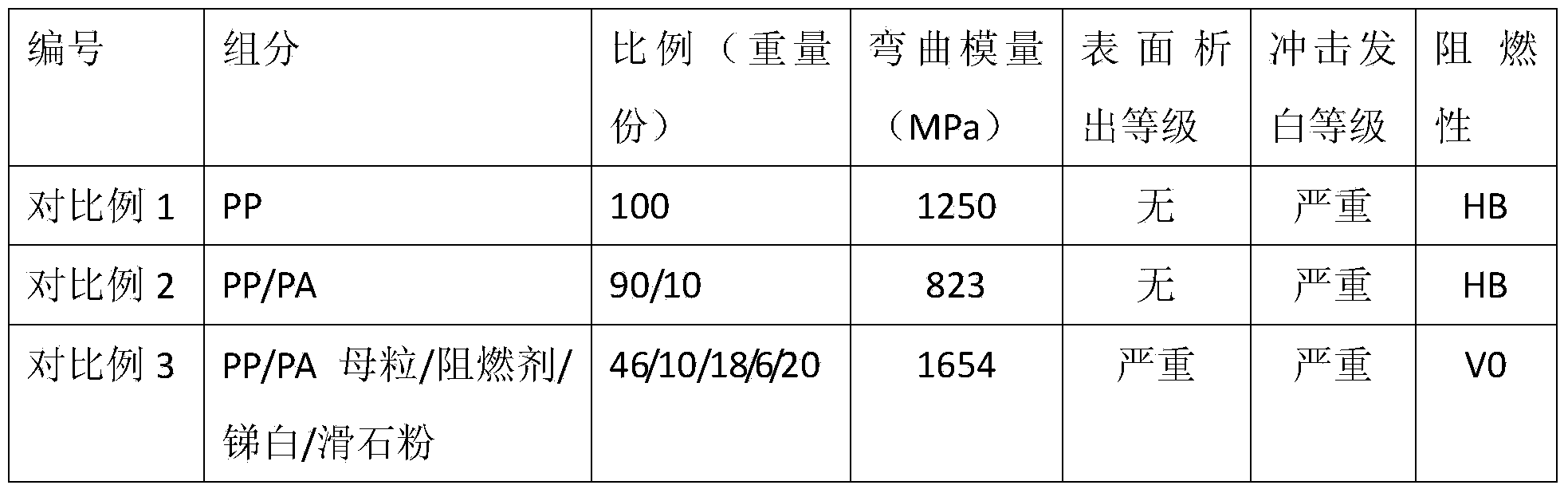

Embodiment 2

[0031] Weigh each component according to the following parts by weight: 36 parts by weight of homopolypropylene (melt index is 10g / 10min), 5 parts by weight of nylon masterbatch, 18 parts by weight of flame retardant decabromodiphenyl ether, 6 parts by weight The antimony white of weight part, the filling masterbatch of 30 weight parts, the chain linker benzoyl peroxide of 5 weight parts, the processing aid zinc stearate of the antioxidant 1010 of 0.2 weight part and 0.2 weight part; Its The preparation process is the same as in Example 1, and the performance test parameters are shown in Table 1.

Embodiment 3

[0033] Take each component by the following parts by weight:

[0034] 31 parts by weight of copolymerized polypropylene (melt index: 10g / 10min), 10 parts by weight of nylon masterbatch, 18 parts by weight of flame retardant polybrominated styrene, 6 parts by weight of antimony white, 30 parts by weight of filler Granules, 5 parts by weight of segment binders, 0.2 parts by weight of antioxidant 1010 and 0.2 parts by weight of processing aid zinc stearate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com