Preparation method of antistatic PBAT polymer and antistatic PBAT polymer

A kind of polymer and antistatic technology, which is applied in the field of polymer preparation, can solve the problems of limited application, and achieve the effect of improving conversion rate, increasing antistatic performance and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

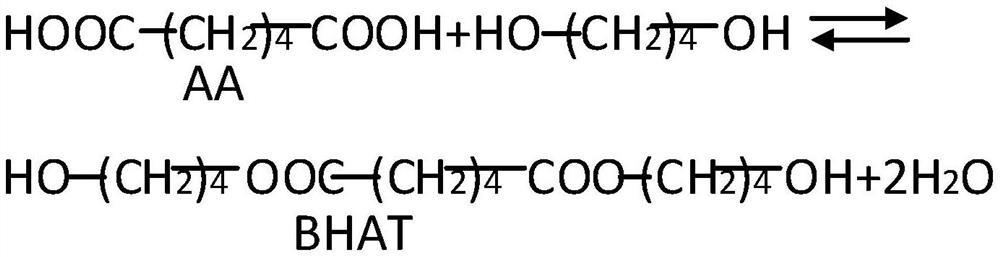

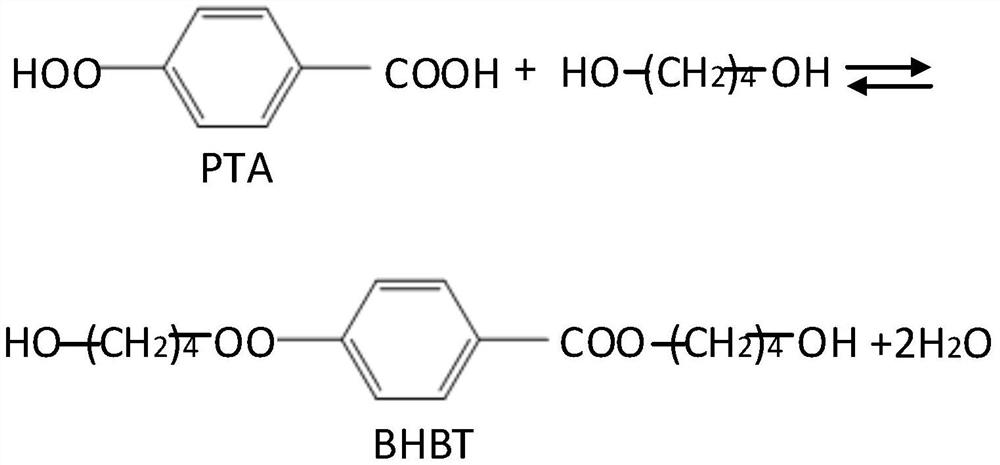

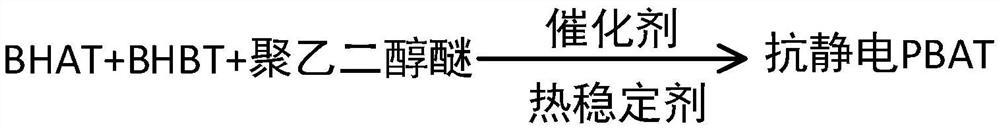

Method used

Image

Examples

Embodiment 1

[0040] In the first esterification tank, add 100 kilograms of adipic acid, the amount of butanediol added is (1.2:1 molar ratio to adipic acid), and tetrabutyl titanate catalyst is added (0.02 %), the esterification temperature is 165° C. The esterification rate reaches 99.0%, and the first product is obtained.

[0041] In the second esterification tank, add 100 kilograms of terephthalic acid, the amount of butanediol added is (the molar ratio with adipic acid is 1.3:1), and the tetraisopropyl titanate catalyst is added (the molar amount of terephthalic acid 0.02%), the esterification temperature is 250°C, the esterification rate reaches 99.0%, and the second product is obtained.

[0042] The weight ratio of the first product and the second product is 1:1 and pumped into the polymerization reactor respectively, and the molar amount of the stabilizer antioxidant 1010 added is the total molar amount of the terephthalic acid and adipic acid 0.01%. The molecular weight of the ad...

Embodiment 2

[0046] In the first esterification tank, add 100 kilograms of adipic acid, the amount of butanediol added is (1.2:1 molar ratio to adipic acid), and tetrabutyl titanate catalyst is added (0.02 %), the esterification temperature is 175° C. The esterification rate reaches 99.0%, and the first product is obtained.

[0047] In the second esterification tank, add 100 kilograms of terephthalic acid, the amount of butanediol added is (the molar ratio to succinic acid is 1.3:1), and the tetraisopropyl titanate catalyst is added (the molar amount of terephthalic acid 0.02%), the esterification temperature is 255°C, the esterification rate reaches 99.0%, and the second product is obtained.

[0048] The weight ratio of the first product and the second product is 1:1 and pumped into the polymerization reactor respectively, and the molar amount of the stabilizer antioxidant 1010 added is the total molar amount of the terephthalic acid and adipic acid 0.01%. The molecular weight of polyethy...

Embodiment 3

[0052] In the first esterification tank, add 100 kilograms of adipic acid, the amount of butanediol added is (1.2:1 molar ratio to adipic acid), and tetrabutyl titanate catalyst is added (0.02 %), the esterification temperature is 165° C. The esterification rate reaches 99.0%, and the first product is obtained.

[0053] In the second esterification tank, add 100 kilograms of terephthalic acid, the amount of butanediol added is (the molar ratio with adipic acid is 1.3:1), and the tetraisopropyl titanate catalyst is added (the molar amount of terephthalic acid 0.02%), the esterification temperature is 250°C, the esterification rate reaches 99.0%, and the second product is obtained.

[0054] The weight ratio of the first product and the second product is 1:1 and pumped into the polymerization reactor respectively, and the molar amount of the stabilizer antioxidant 1010 added is the total molar amount of the terephthalic acid and adipic acid 0.01%. The molecular weight of the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com