Halogen-free flame-retardant TPU cable material as well as preparation method and application thereof

A technology for cables and flame retardants, which is applied in the field of low-smoke halogen-free flame-retardant TPU cable materials and their preparation, can solve the problems of mechanical properties, aging resistance and hydrolysis resistance of flame-retardant TPU materials, and TPU materials are flammable and very poor. It is difficult to meet the problems of cables, etc., to ensure product quality, good compatibility, and reduce uneven mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

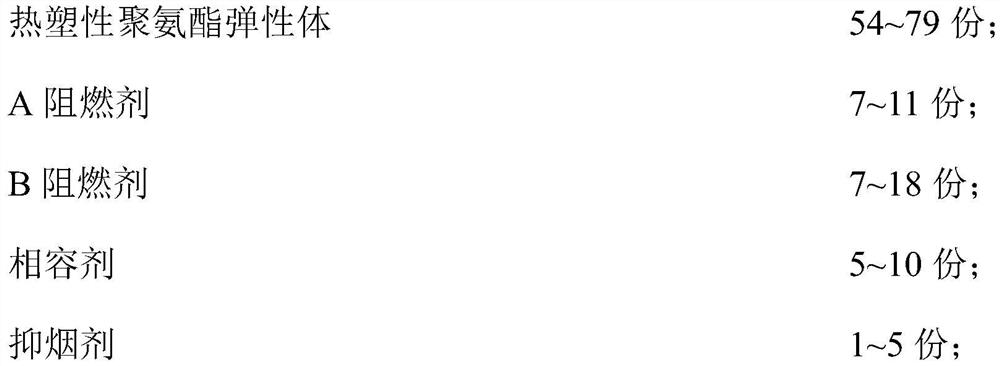

[0051] In this embodiment, a halogen-free flame-retardant TPU cable material is provided, and the preparation raw materials of the halogen-free flame-retardant TPU cable material include the following components by weight:

[0052]

[0053] Wherein the B flame retardant is aluminum hypophosphite and melamine cyanurate modified by a controlled radical silane hyperdispersant.

[0054] The preparation method of B flame retardant is:

[0055] After heating the temperature of the high mixer to 80°C, stop heating, dry aluminum hypophosphite and melamine cyanurate with a mass ratio of 4:9 in an oven at 105°C for 2 hours, then pour it into the high mixer and mix it, and pour it onto the surface of the mixture Add a hydrophobic modifier, stir and mix at 800 rpm, stop stirring when the temperature of the high mixer rises to 120°C, and discharge while hot to obtain the B flame retardant.

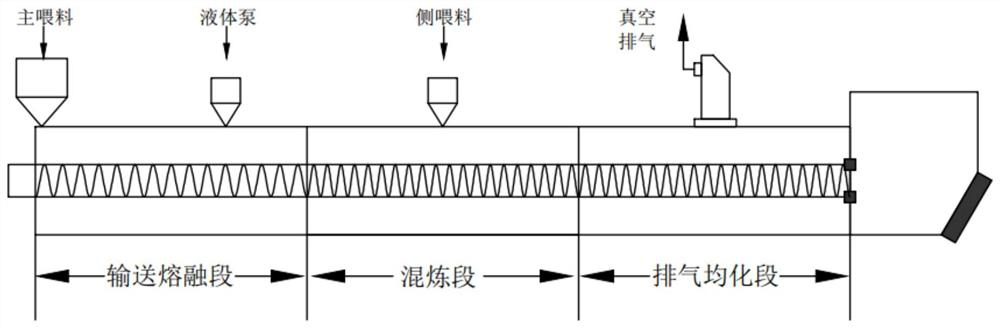

[0056] The preparation method of the halogen-free flame-retardant TPU cable material comprises ...

Embodiment 2

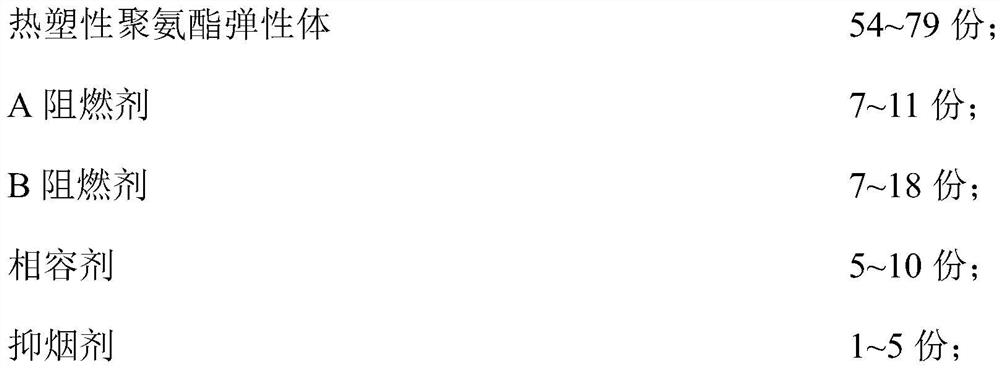

[0061] In this embodiment, a halogen-free flame-retardant TPU cable material is provided, and the preparation raw materials of the halogen-free flame-retardant TPU cable material include the following components by weight:

[0062]

[0063] Wherein the B flame retardant is aluminum hypophosphite and melamine cyanurate modified by a controlled radical silane hyperdispersant.

[0064] The preparation method of B flame retardant is:

[0065] After heating the temperature of the high mixer to 100°C, stop heating, dry the aluminum hypophosphite and melamine cyanurate with a mass ratio of 4:11 in an oven at 105°C for 2 hours, then pour it into the high mixer for mixing, and pour it onto the surface of the mixture Add the hydrophobic modifier, stir and mix at 900 rpm, stop stirring when the temperature of the high mixer rises to 120°C, and discharge while hot to obtain the B flame retardant.

[0066] The preparation method of the halogen-free flame-retardant TPU cable material co...

Embodiment 3

[0071] In this embodiment, a halogen-free flame-retardant TPU cable material is provided, and the preparation raw materials of the halogen-free flame-retardant TPU cable material include the following components by weight:

[0072]

[0073] Wherein the B flame retardant is aluminum hypophosphite and melamine cyanurate modified by a controlled radical silane hyperdispersant.

[0074] The preparation method of B flame retardant is:

[0075] After heating the temperature of the high-mixer to 90°C, stop heating, dry aluminum hypophosphite and melamine cyanurate with a mass ratio of 2:3 in an oven at 110°C for 2.5 hours, then pour into the high-mixer for mixing, and add to the mixture Add a hydrophobic modifier to the surface, stir and mix at 1000 rpm, stop stirring when the temperature of the high mixer rises to 115°C, and discharge while hot to obtain the B flame retardant.

[0076] The preparation method of the halogen-free flame-retardant TPU cable material comprises the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com