Reeling waste water deep treating method and apparatus

A technology for the advanced treatment of silk reeling wastewater, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problem of high frequency of backwashing (generally need backwashing once a day, operation Troublesome management, short working cycle, etc., to achieve the effect of improving treatment efficiency, large pollutant holding capacity, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

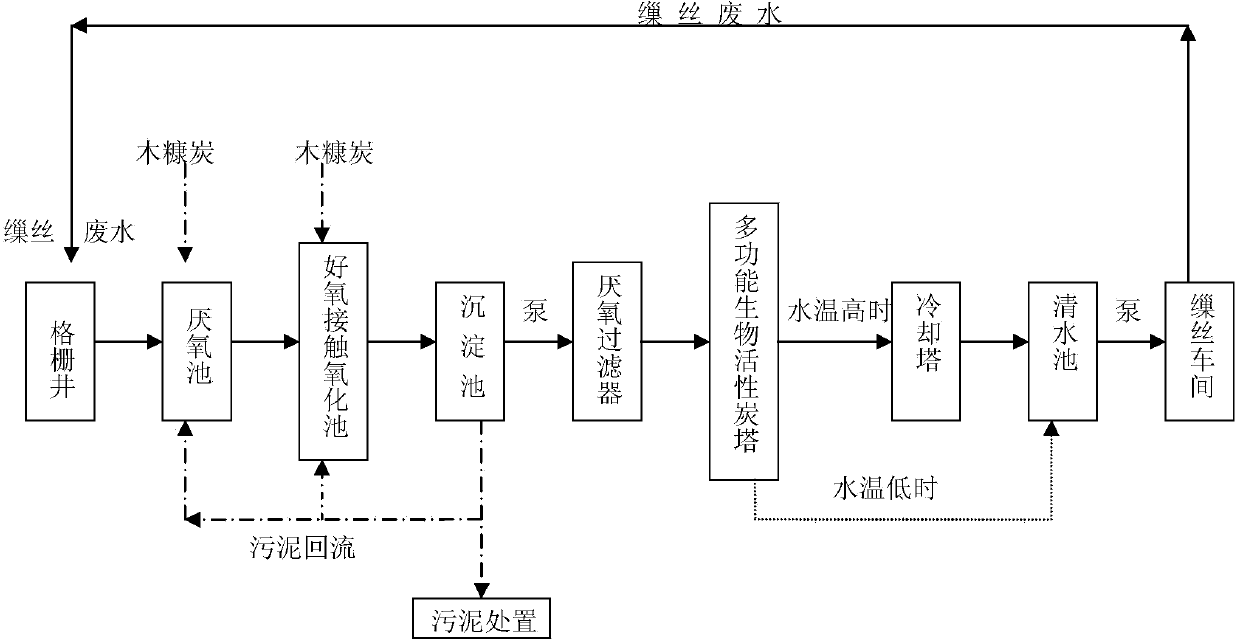

[0038] Embodiment one: a kind of silk reeling wastewater advanced treatment method, comprises the following steps:

[0039] A. The silk reeling waste water first passes through the grid well 1 to remove floating matter, and then enters the anaerobic pool 2, where wood chaff charcoal is put into the anaerobic pool, and wood chaff charcoal can be added continuously or intermittently. For: 1m 3 Add 0.05-5kg wood chaff charcoal to the silk reeling wastewater, and the wastewater enters the anaerobic tank 2 to remove nitrate nitrogen and degrade part of COD under the action of anaerobic bacteria.

[0040] B. The effluent from the anaerobic tank enters the aerobic contact oxidation tank 3. Wood chaff charcoal is put into the aerobic contact oxidation tank. The wood chaff charcoal can be added continuously or intermittently. The input amount of wood chaff charcoal is: 1m 3 Add 0.05-5kg of wood chaff charcoal to the silk reeling wastewater, and the wastewater enters the aerobic contac...

Embodiment 2

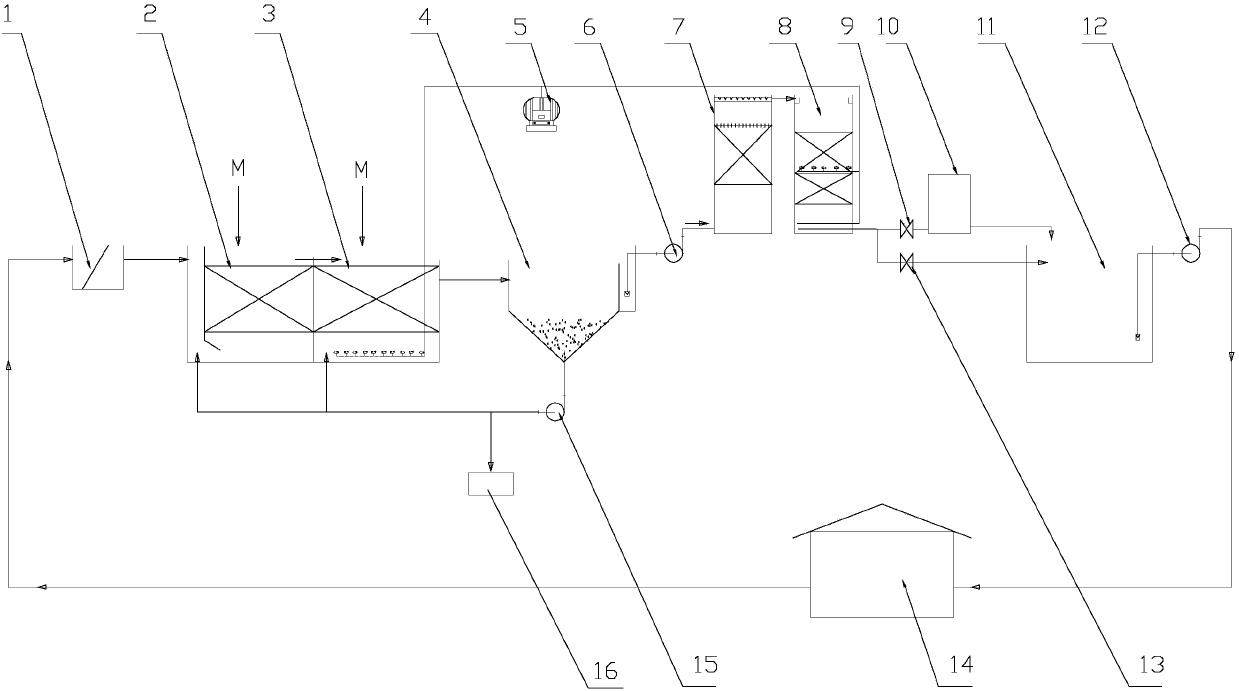

[0050] Embodiment 2: A kind of silk reeling waste water advanced treatment device, comprises grid well 1, anaerobic pond 2, aerobic contact oxidation pond 3, sedimentation pond 4, anaerobic filter 7, multi-functional biological activated carbon tower 8 connected successively And the clear water tank 11, the bottom of the sedimentation tank 4 is communicated with the sludge disposal discharge system 16 or the anaerobic tank or / and the aerobic contact oxidation tank through the sludge pump 15, and the described sedimentation tank 4 is connected with the anaerobic tank by the lift pump 6 Oxygen filter 7 communicates, and the described aerobic contact oxidation tank and the multifunctional biological activated carbon tower are provided with the aeration air distribution pipe that is supplied with oxygen by blower 5 .

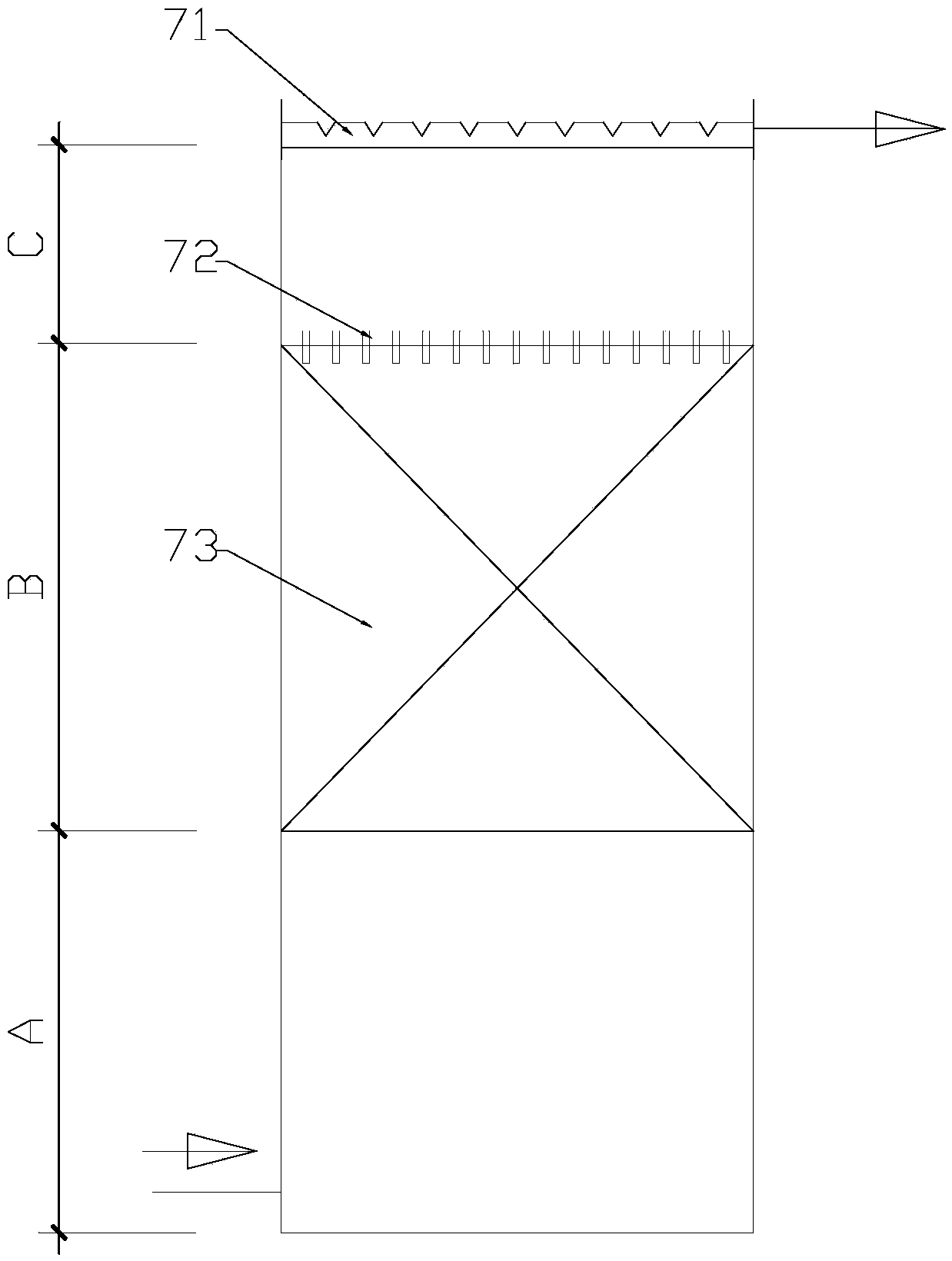

[0051] The anaerobic filter 7 includes a housing and a sump 71, a filter head 72 and a filter material 73 arranged in the housing from top to bottom in sequence. The...

experiment example

[0063]Experimental example: a scale is a silk reeling enterprise of 20 groups, and the daily reeling water consumption is 2100 tons. According to the reeling wastewater advanced treatment method and device construction recycling project of the present invention, the operating capacity is 41KW, and the daily operation is 17 hour, assuming that the electricity price is 0.6 yuan / KW.h, the running electricity cost per ton of water is only: 0.18 yuan. The water quality before and after treatment is as follows:

[0064]

[0065] The treated water is clear and transparent, which can fully meet the needs of silk reeling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com