High-tearing strength, biodiesel-resistant hydrogenated acrylonitrile butadiene rubber composition for automobile hoses

A technology of hydrogenated nitrile rubber and biodiesel, which is applied in the field of rubber hose, can solve the problems of high cost, poor process performance, and poor low temperature resistance, and achieve good resistance, meet product performance requirements, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

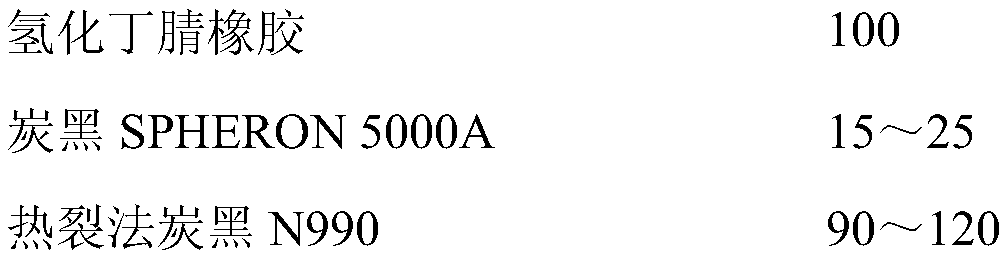

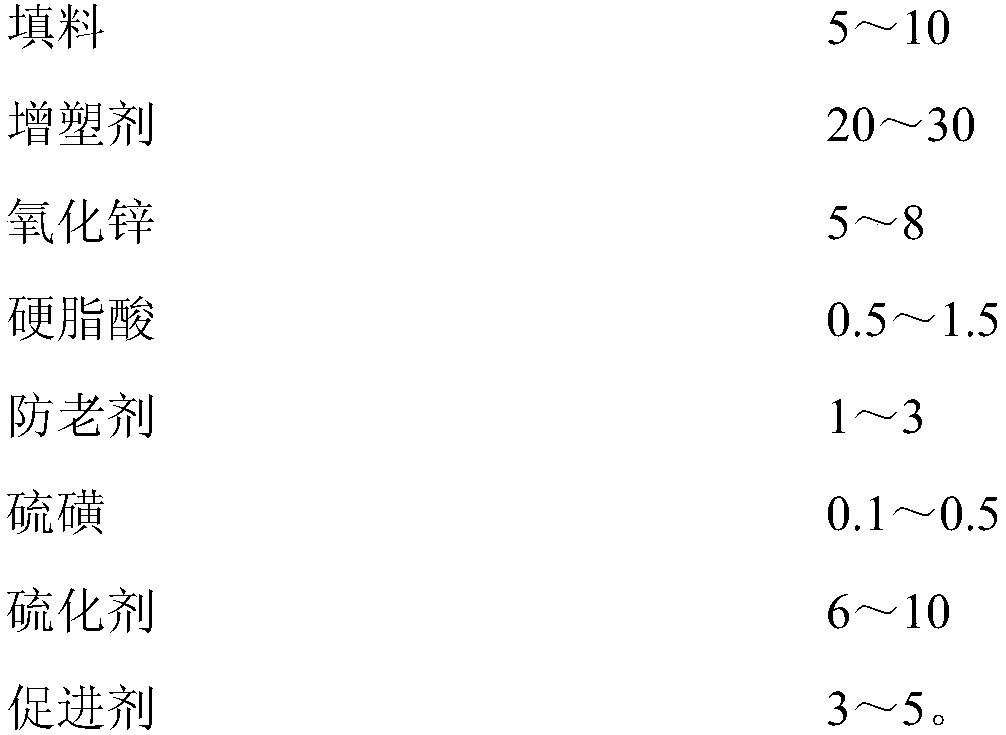

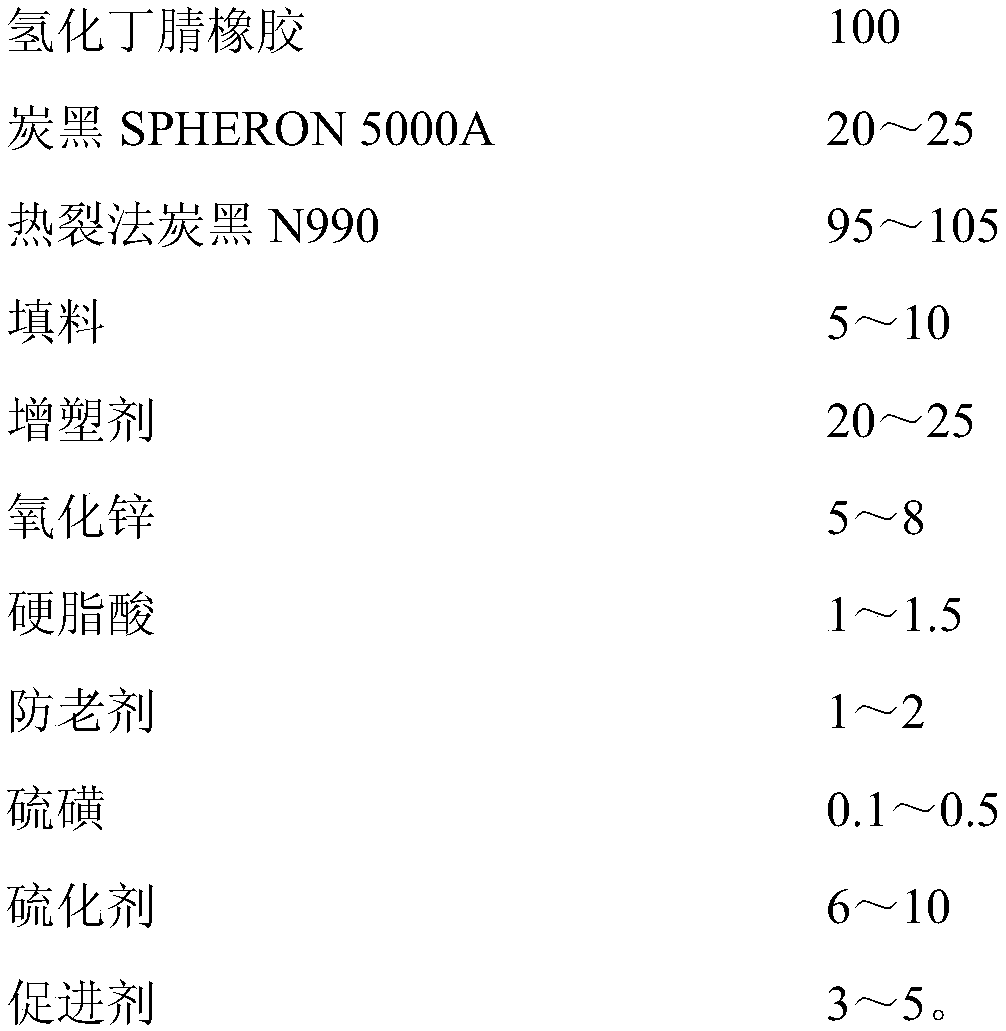

[0028] A kind of hydrogenated acrylonitrile-butadiene rubber composition with high tearing, biodiesel resistance for automobile hose, its component is as table 1, is made by following preparation method, and step is as follows:

[0029] Step (1), pressurizing the hydrogenated nitrile rubber, zinc oxide, stearic acid and anti-aging agent under pressure of 0.25-0.35Mpa for 1min;

[0030] Step (2), then add high-clean carbon black SPHERON 5000A, thermal black N990, filler, plasticizer, and banbury at a pressure of 0.2-0.25Mpa for 3min;

[0031] Step (3), control the pressure at 0.2-0.25Mpa, raise the temperature to 90°C, add sulfur, vulcanizing agent, and accelerator, raise the temperature to 100°C, lift the top bolt on the internal mixer, and after the mixing rubber is turned over, mix it The top bolt on the machine is lifted and lowered, and when the temperature is raised to 125°C, the top bolt on the internal mixer is lifted, the rubber is discharged, cooled, and the strip is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com