Novel brushless motor fuel pump

A technology of brushless motors and fuel pumps, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems affecting the service life of fuel pumps, corrosion of position sensors, and electrical conductivity, etc. Shedding, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

[0022] The invention adopts the brushless motor fuel pump of the new counter electromotive force commutation technology.

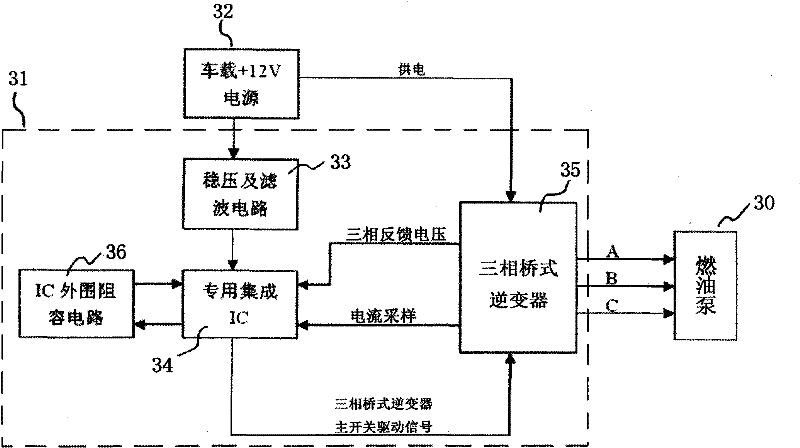

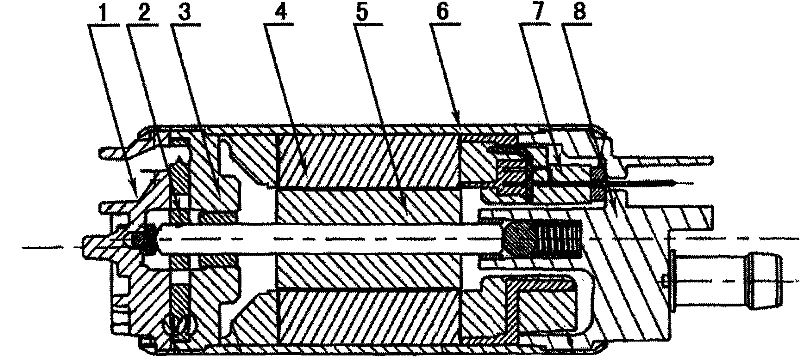

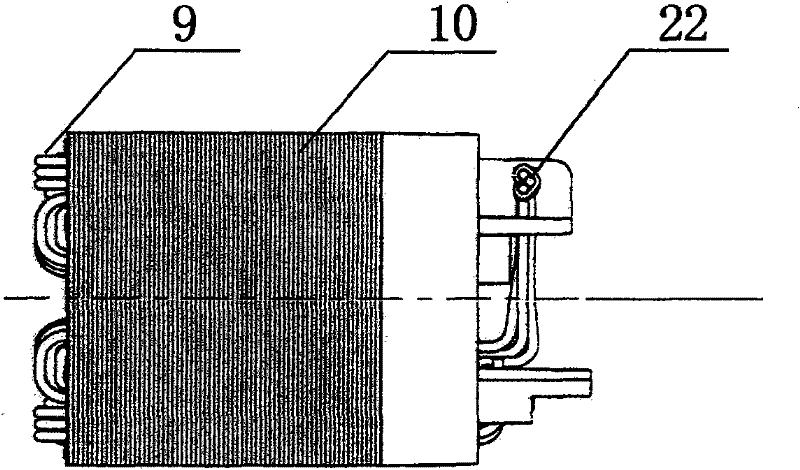

[0023] Such as figure 1 , as shown in Figure 12:

[0024] Brushless motor controller 31 ( figure 1 One end shown in the dotted line box) is connected to the fuel pump 30 by using the brushless motor three-phase winding wiring ABC, and the other end is connected to the vehicle power supply 32; in the brushless motor controller 31, one end of the voltage stabilizing and filtering circuit 33 is externally connected Vehicle-mounted power supply 32, the other end is connected with integrated circuit 34, and integrated circuit 34 is respectively connected with peripheral RC circuit 36, three-phase bridge inverter 35, and three-phase bridge inverter 35 is externally connected with fuel pump (pump body) 30; Wherein The integrated circuit 34 is decomposed into a starting circuit 37, a three-phase feedback voltage respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com