Catalyst for preparing gasoline blending component through alcohol-naphtha coupling, preparation method and application thereof

A naphtha and catalyst technology, which is applied in the field of catalysts for preparing gasoline, can solve the problems of low added value, restricting the development of naphtha aromatization, low yield of modified gasoline and the like, and achieves the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

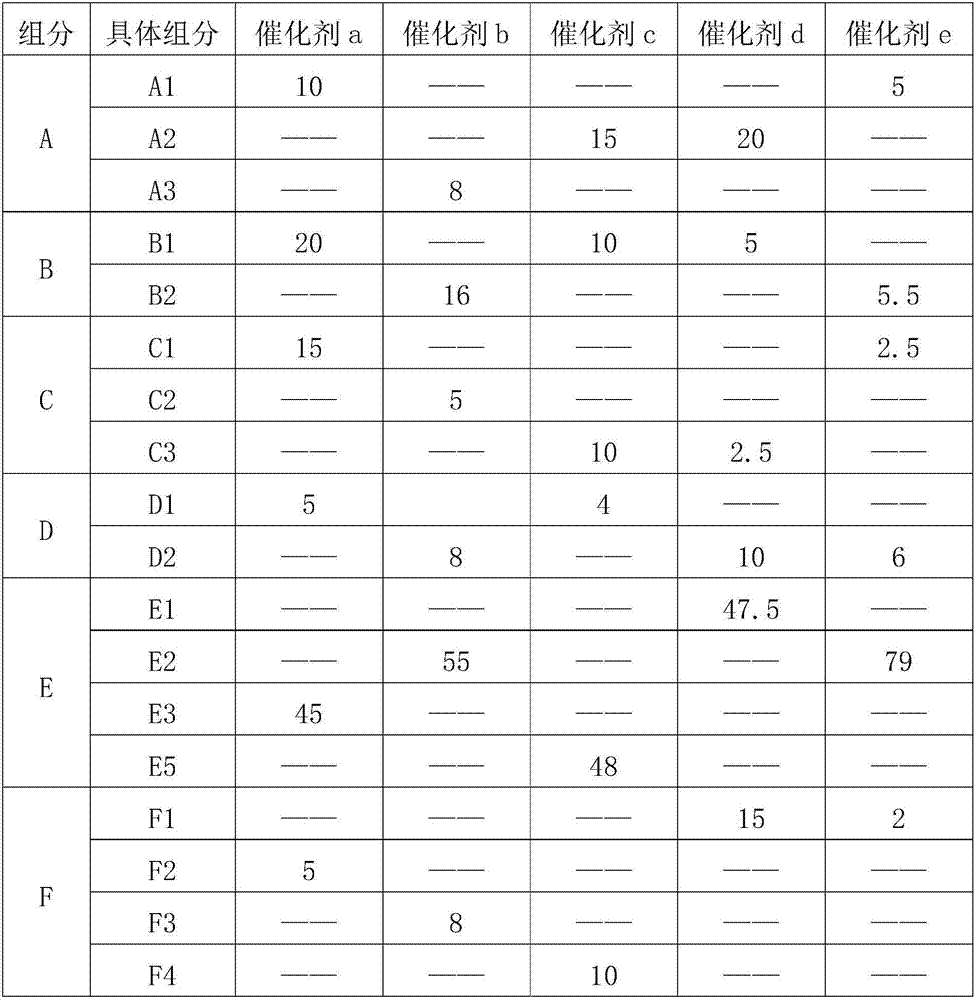

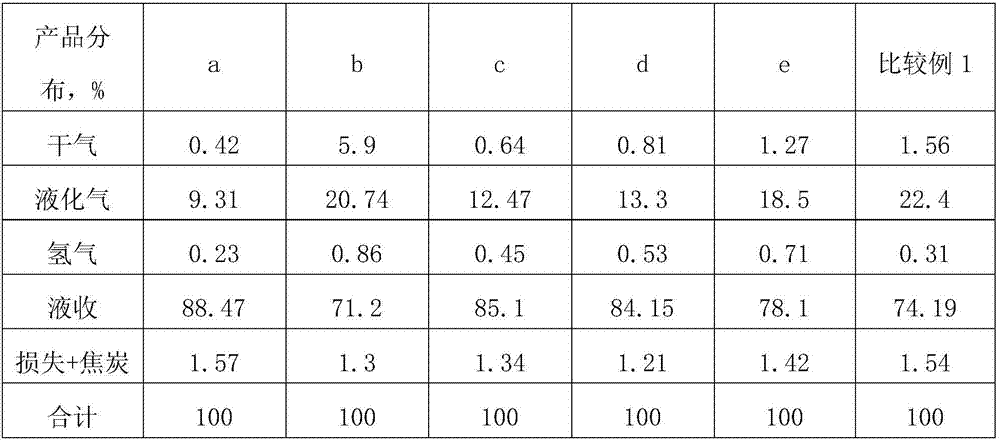

Examples

Embodiment 1

[0053] Component A1 of this example is SAPO-11 molecular sieve modified by tin and nickel, wherein the mass fractions of nickel and tin in component A are 5% and 2%, respectively.

[0054] The preparation method of described component A1 is as follows:

[0055] Weigh 24.8g of nickel nitrate hexahydrate and dissolve it in 120g of deionized water to obtain a nickel nitrate solution for subsequent use. Mix 100g of SAPO-11 molecular sieve powder with 2.53g of tin oxide, add to the prepared nickel nitrate solution, soak at 60-100°C for 4h, then dry at 110°C for 4h, then dry at 500°C Calcined under air atmosphere for 5h to obtain the active component A1 of the catalyst for use.

Embodiment 2

[0057] Component A2 of this example is SAPO-11 molecular sieve modified by tin and nickel, wherein the mass fractions of nickel and tin in component A are 7.5% and 3%, respectively.

[0058] The preparation method of described component A2 is as follows:

[0059] Weigh 35.4g of nickel nitrate hexahydrate and dissolve it in 130g of deionized water to obtain a nickel nitrate solution for subsequent use. Mix 100g of SAPO-11 molecular sieve powder with 3.8g of tin oxide, add it to the prepared nickel nitrate solution, soak it at 60-100°C for 4h, then dry it at 110°C for 4h, and then dry it at 500°C Calcined for 5 hours under an air atmosphere to obtain active component A2 of the catalyst for use.

Embodiment 3

[0061] Component A3 of this example is SAPO-11 molecular sieve and MgAPO-11 molecular sieve modified by tin and nickel, wherein the mass fractions of nickel and tin in component A are 10% and 4%, respectively.

[0062] The preparation method of described component A3 is as follows:

[0063] Weigh 49.5g of nickel nitrate hexahydrate and dissolve it in 130g of deionized water to obtain a nickel nitrate solution for subsequent use. Mix 50g of SAPO-11 molecular sieve powder and 50g of MgAPO-11 molecular sieve powder with 5.1g of tin oxide, add to the prepared nickel nitrate solution, soak at 60-100°C for 4h, and then bake at 110°C Dry for 4 hours, and then calcined at 500°C for 5 hours in an air atmosphere to obtain the active component A3 of the catalyst for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com