Desulphurization, denitration and dust removal integrated treatment process of exhaust gas

A technology for treating process and exhaust gas, which is applied in new processes and devices for integrated desulfurization treatment, glass and cement exhaust gas dedusting, and denitrification. Large and other problems, to achieve the effect of saving manpower maintenance and operating costs, operating cost savings, and low device operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

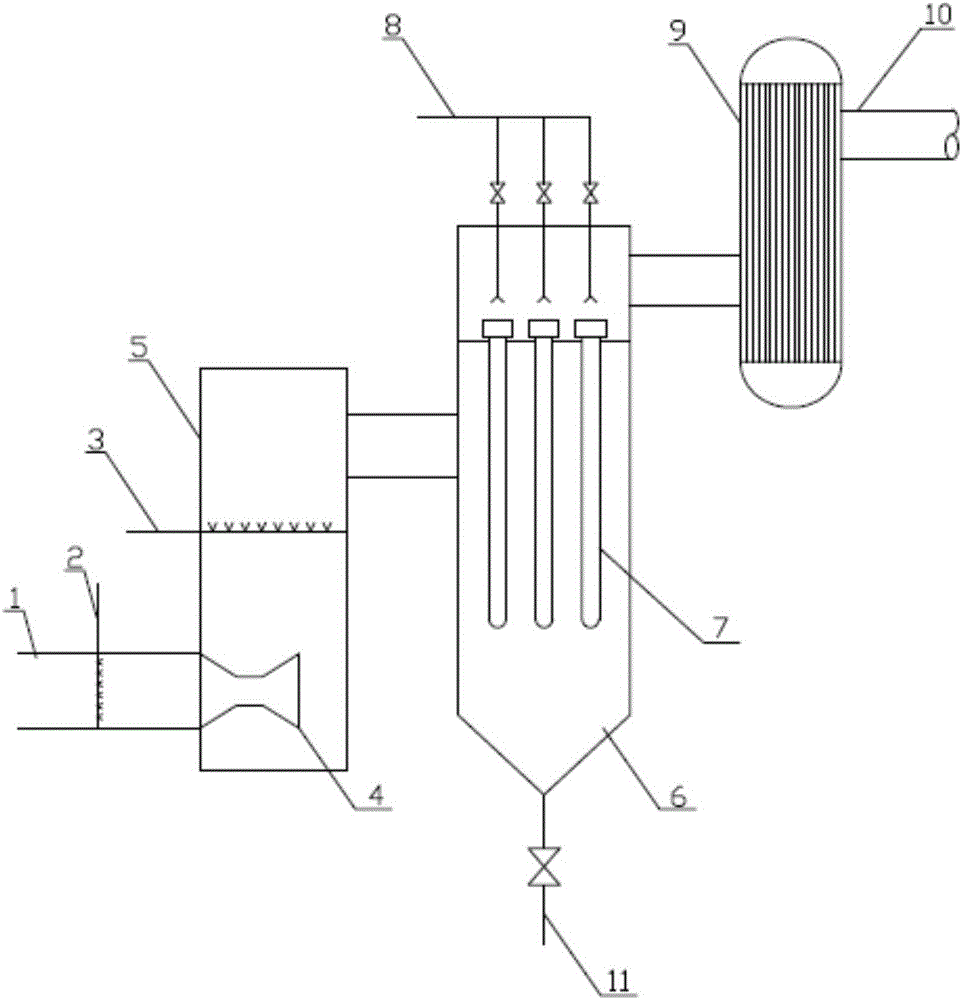

[0026] Taking flue gas denitrification in the cement industry as an example, figure 1 It is a schematic structural diagram of the new process device. As shown in the figure, the system mainly includes a desulfurizing agent injection device 2, a denitrification agent injection device 3, a flue gas mixing device 5, an integrated catalyst ceramic filter cartridge device 7, and an energy recovery device 9. The desulfurization agent injection device 2 is arranged on the inlet flue 1 of the device, and is injected into the flue gas mixing device 5 through the Venturi structure 4 for mixing and preliminary desulfurization reaction. In order to achieve higher desulfurization efficiency and reduce the consumption of desulfurization agent The flue gas mixing device 5 can be set as a circulating fluidized bed reaction tower, that is, part of the circulating ash is drawn from the dust collecting device 6 to the flue gas mixing device 5 to realize the recycling of incomplete reaction desulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com