Trimeric quaternary ammonium salt type oil field sterilizing desulfurizer and preparation method thereof

A polyquaternary ammonium salt and oil field sterilization technology, which is applied in botany equipment and methods, biocides, chemical instruments and methods, etc., can solve the incompatibility of fungicides and desulfurizers, the difficulty of chemical management, and the high cost of treatment, etc. problems, to achieve the effect of convenient chemical agent management and filling, improved sterilization effect, and high sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

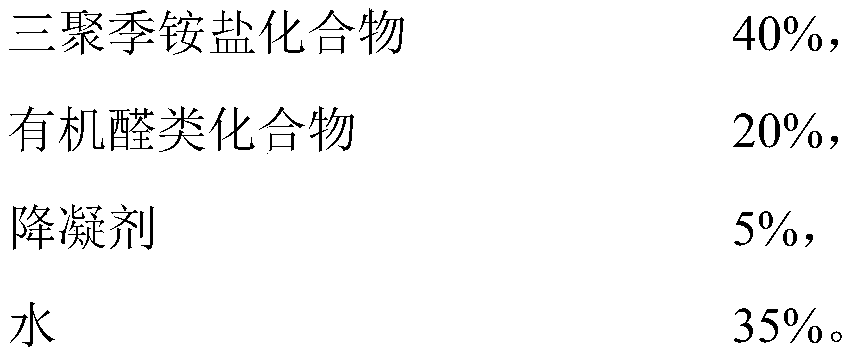

[0065] The trimer quaternary ammonium salt type oil field bactericidal desulfurizer described in this embodiment, the constituent components and weight percentages of the raw materials used are as follows:

[0066]

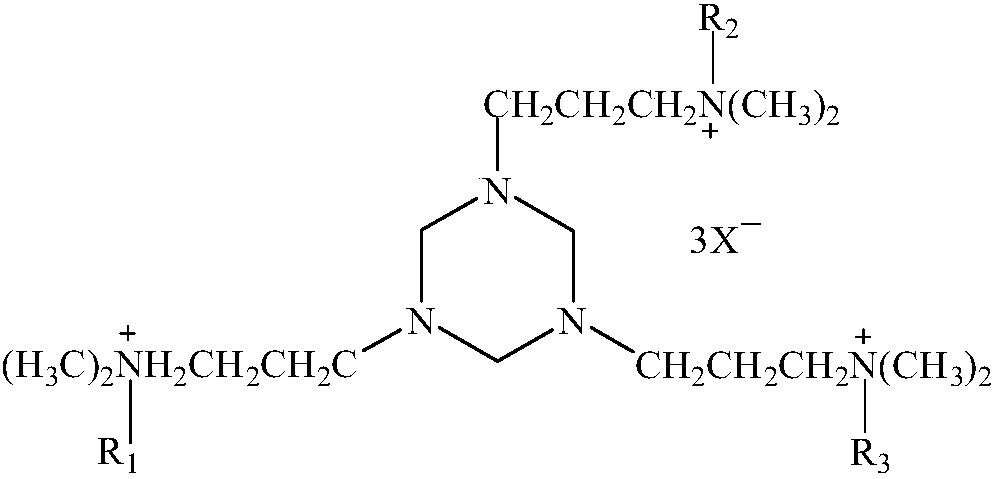

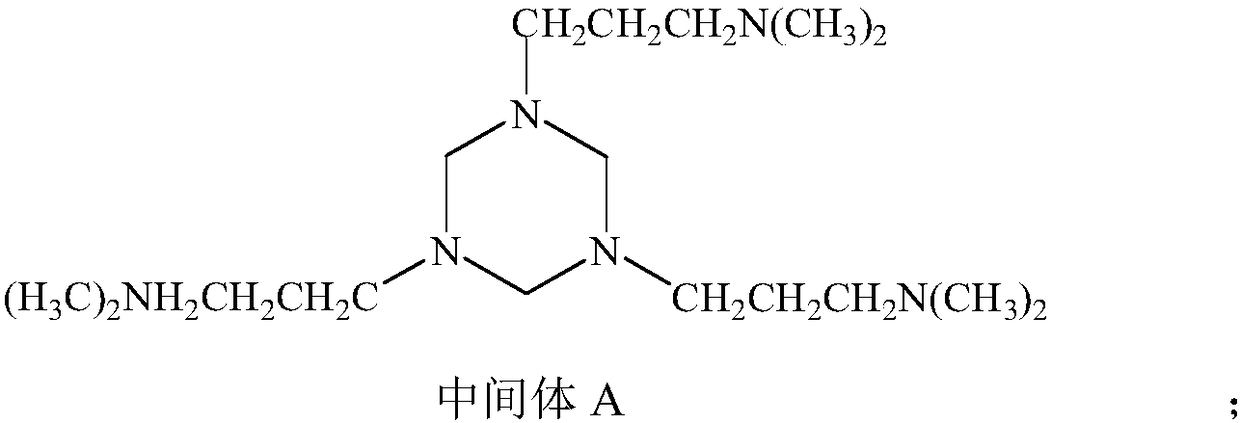

[0067] The structural formula of the trimerized quaternary ammonium compound is as follows:

[0068]

[0069] The preparation method of the above-mentioned trimerized quaternary ammonium salt type oil field bactericidal desulfurizer, its concrete operation steps are as follows:

[0070] Step (1), the preparation of trimerized quaternary ammonium compound

[0071] 1.1 Add 300g of N,N-dimethylpropylenediamine into the container, and add 100g of paraformaldehyde in 4 batches to the N,N-dimethylpropylenediamine under stirring conditions to carry out the aldehyde-amine condensation reaction, and the stirring speed It is always controlled at 100rpm / min. Since paraformaldehyde is added to N,N-dimethylpropylenediamine, aldolamine condensation reaction will occur, w...

Embodiment 2

[0079] The trimer quaternary ammonium salt type oil field bactericidal desulfurizer described in this embodiment, the constituent components and weight percentages of the raw materials used are as follows:

[0080]

[0081] The structural formula of the trimerized quaternary ammonium compound is as follows:

[0082]

[0083] The preparation method of the above-mentioned trimerized quaternary ammonium salt type oil field bactericidal desulfurizer, its concrete operation steps are as follows:

[0084] Step (1), the preparation of trimerized quaternary ammonium compound

[0085] 1.1 Add 300g of N,N-dimethylpropylenediamine into the container, and add 200g of paraformaldehyde in 6 batches to the N,N-dimethylpropylenediamine under stirring conditions to carry out aldehyde-amine condensation reaction. It is always controlled at 50rpm / min. Since paraformaldehyde is added to N,N-dimethylpropylenediamine, aldehyde-amine condensation reaction will occur, which is an exothermic re...

Embodiment 3

[0093] The trimer quaternary ammonium salt type oil field bactericidal desulfurizer described in this embodiment, the constituent components and weight percentages of the raw materials used are as follows:

[0094]

[0095] The structural formula of the trimerized quaternary ammonium compound is as follows:

[0096]

[0097] The preparation method of the above-mentioned trimerized quaternary ammonium salt type oil field bactericidal desulfurizer, its concrete operation steps are as follows:

[0098] Step (1), the preparation of trimerized quaternary ammonium compound

[0099] 1.1 Add 300g of N,N-dimethylpropylenediamine into the container, add 50g of formaldehyde in 2 batches to N,N-dimethylpropylenediamine under stirring condition, add 100g of paraformaldehyde in 3 batches For the aldolamine condensation reaction, the stirring speed is always controlled at 70rpm / min. Since paraformaldehyde is added to N,N-dimethylpropylenediamine, the aldolamine condensation reaction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com