Desulfurization application method of super-deep oxidative desulfurization catalyst

A desulfurization catalyst, deep oxidation technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of high sulfur content and olefin loss, and achieve desulfurization Low cost, high utilization rate, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 Catalyst [C 18 h 37 N + (CH 3 ) 3 ] 4 [H 2 Se IV 3 W 6 o 34 ] Preparation:

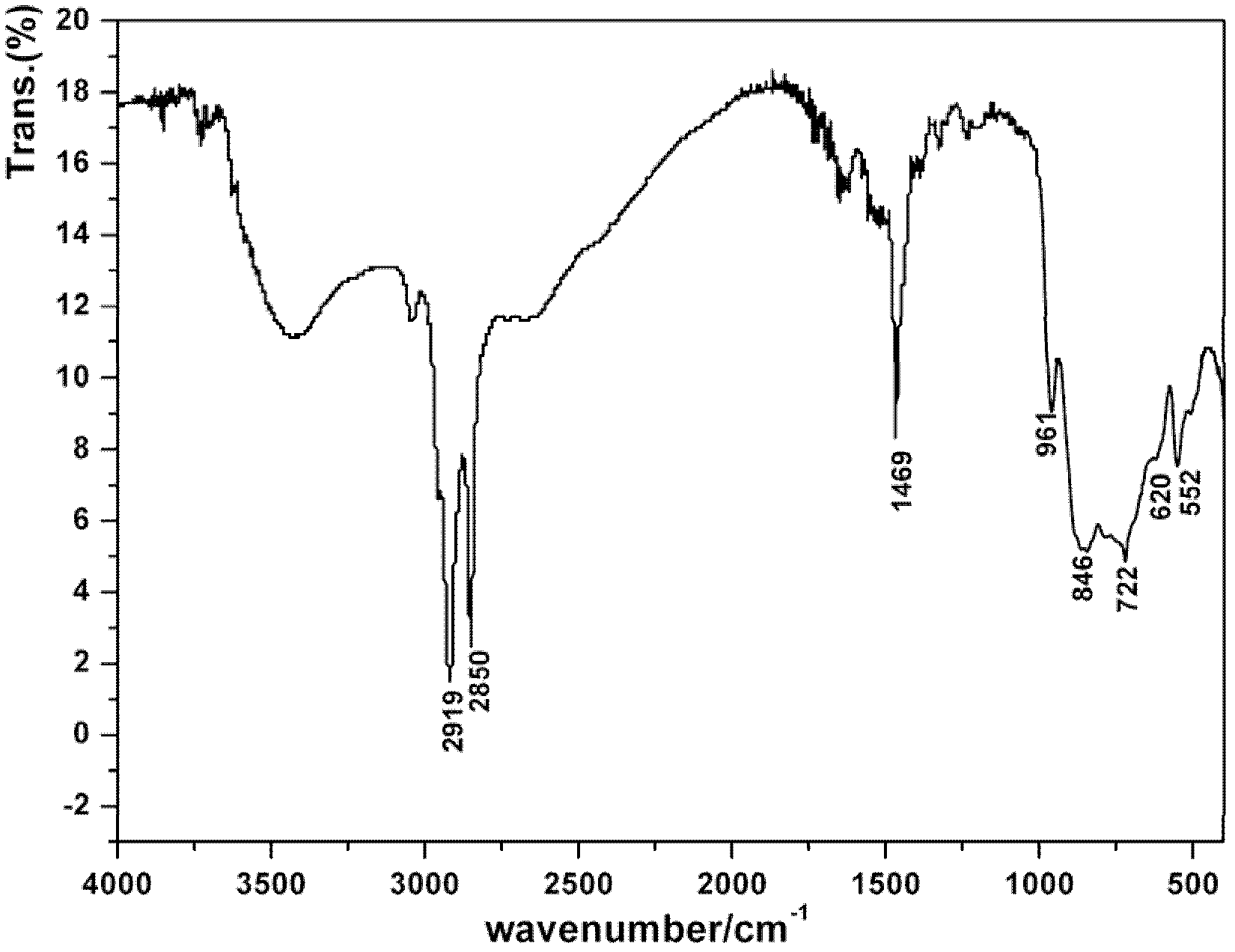

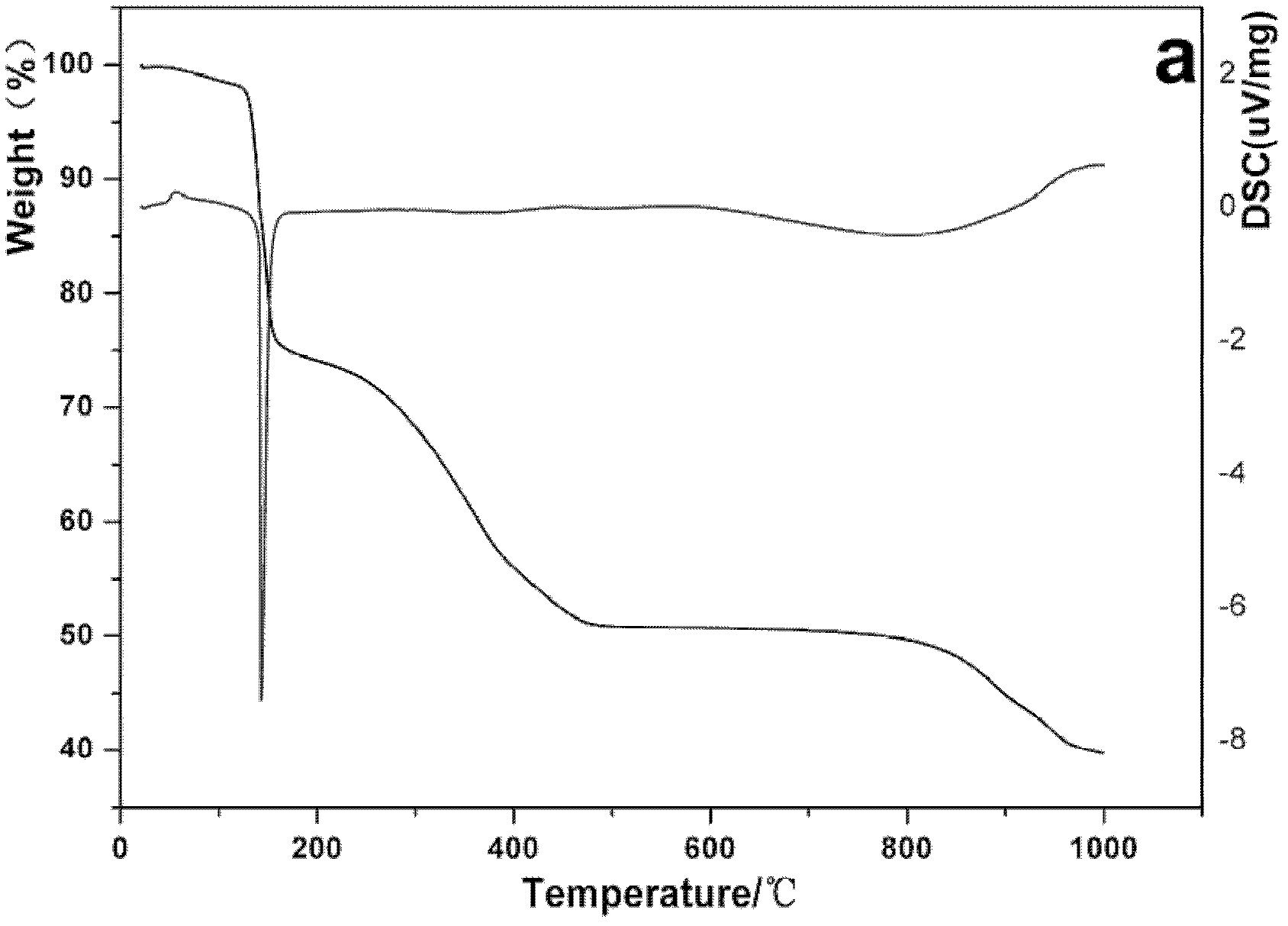

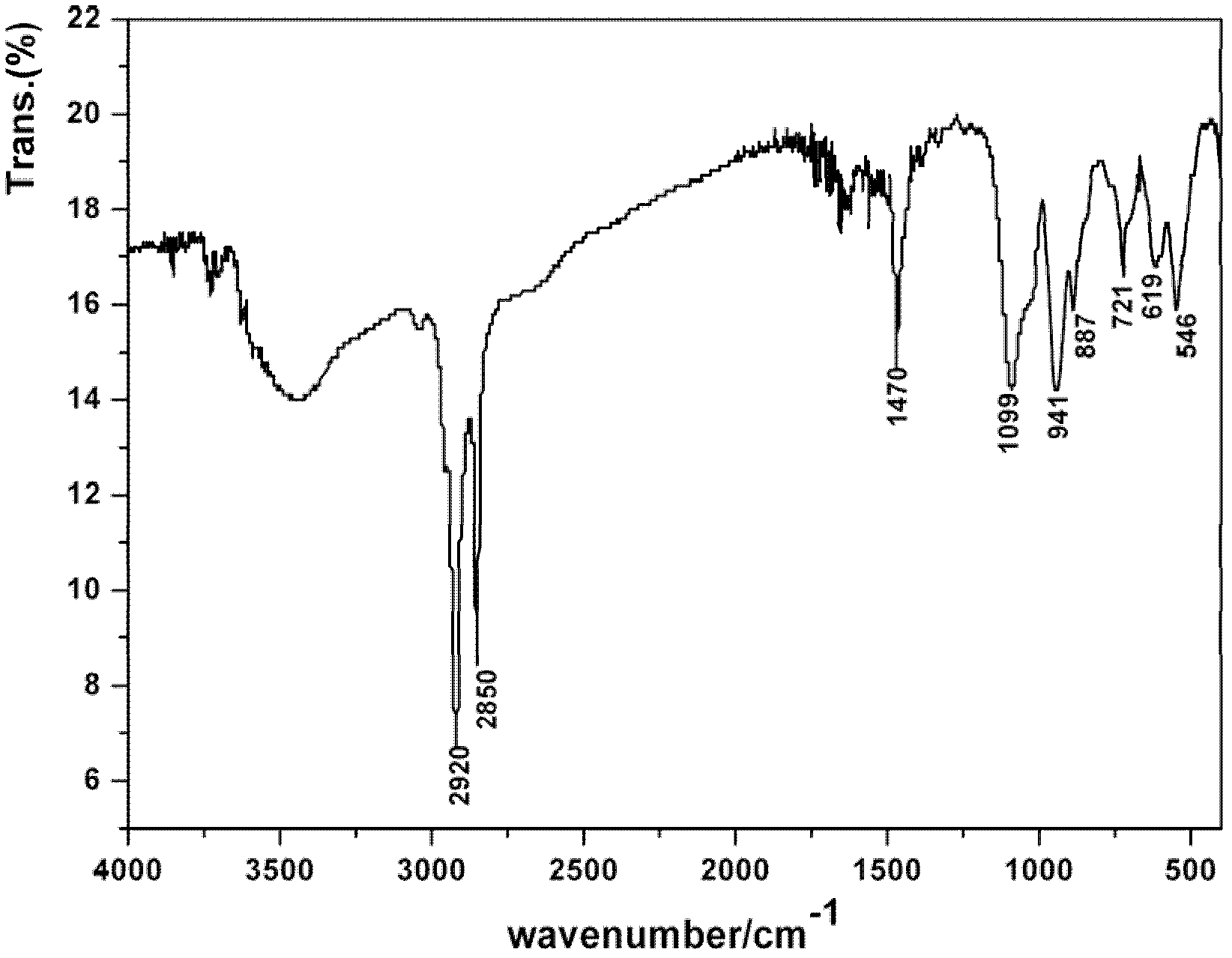

[0043] As a typical example, the catalyst [C 18 h 37 N + (CH 3 ) 3 ] 4 [H 2 Se IV 3 W 6 o 34 ] can be prepared as follows: 2.53g H 2 WO 4 Suspended in 8 mL of 30% H 2 o 2 , stirred in a water bath at 60°C for 40min to obtain a light yellow turbid liquid, and removed insoluble matter by centrifugation (2000rpm, 15min) and then added 2.23g of 60% H 2 SeO 3 aqueous solution, and stirred at room temperature for 60min to obtain a clear solution L, and another 3.52g [C 18 h 37 N + (CH 3 ) 3 ]Cl dissolved in 20mL CHCl 3 , after shaking well, slowly add it dropwise into solution L, stir vigorously while adding, and immediately obtain a white emulsion. 4 After drying, the organic solvent was evaporated to obtain a beige flaky solid. After washing with excess water and absolute ethanol, it was placed in a vacuum oven overnight to obtain catalyst A. The infrare...

Embodiment 2

[0045] With embodiment 1, just drop [C 18 h 37 N + (CH 3 ) 3 ]Cl CHCl 3 The solution was changed to direct addition (n-C 4 h 9 ) 4 N + Cl, to obtain catalyst B.

Embodiment 3

[0047] With embodiment 1, just [C 18 h 37 N + (CH 3 ) 3 ]Cl to [C 12 h 25 N + (CH 3 ) 3 ]Cl to obtain catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com