Ammonia nitrogen remover and preparation method thereof

A technology of remover and ammonia nitrogen, which is applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc., can solve the problems of limited use, few types of removers, narrow application range, etc., and avoid waste , increase sales, the effect of precise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

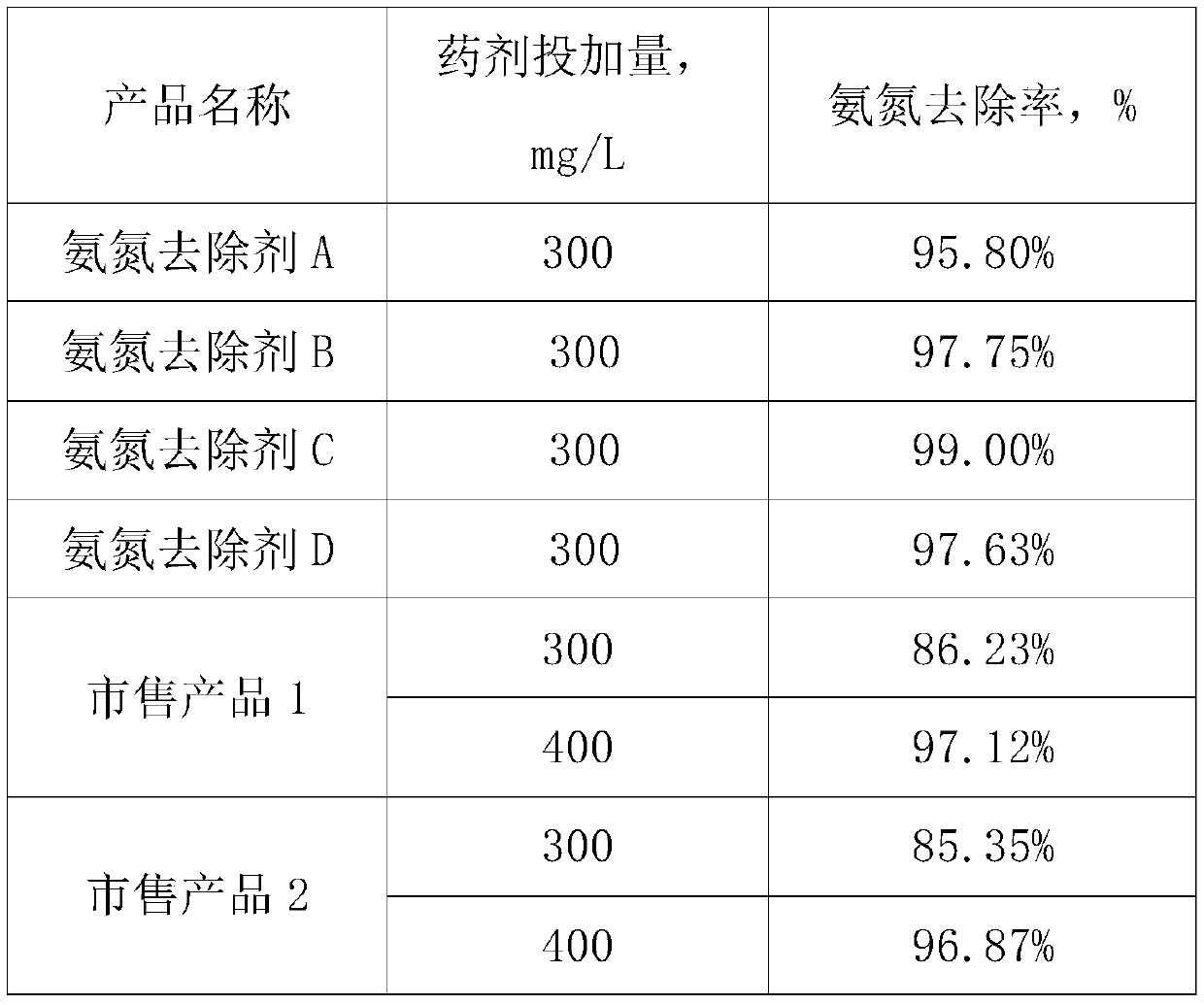

Examples

Embodiment 1

[0027] Step 1. Raw material pretreatment: Put enough purchased raw materials into a grinder for grinding, grind the agglomerates therein, then pass the raw materials through a 150-mesh sieve, and store the raw materials under the sieve for later use;

[0028] Step 2, mixing processing: Weigh 30 parts of calcium hypochlorite, 2 parts of potassium ferrate, 6 parts of sodium carboxymethylcellulose and 9 parts of calcium chloride powder, and pour them into a mixer together at a speed of 15 rpm , and mix uniformly in 10 minutes to obtain the ammonia nitrogen remover;

[0029] Step 3: Sampling inspection and packing into storage: Sampling and testing the finished products of the ammonia nitrogen remover, mixing unevenly mixed materials again until the materials are evenly distributed, and packing into storage after passing the test.

Embodiment 2

[0031] Step 1. Raw material pretreatment: Put enough purchased raw materials into a grinder for grinding, grind the agglomerates therein, then pass the raw materials through a 150-mesh sieve, and store the raw materials under the sieve for later use;

[0032] Step 2, mixing processing: Weigh 39 parts of calcium hypochlorite, 3 parts of potassium ferrate, 7 parts of sodium carboxymethylcellulose and 10 parts of calcium chloride powder, and pour them into a mixer together at a speed of 15 rpm , and mix uniformly in 10 minutes to obtain the ammonia nitrogen remover;

[0033] Step 3: Sampling inspection and packing into storage: Sampling and testing the finished products of the ammonia nitrogen remover, mixing unevenly mixed materials again until the materials are evenly distributed, and packing into storage after passing the test.

Embodiment 3

[0035] Step 1. Raw material pretreatment: Put enough purchased raw materials into a grinder for grinding, grind the agglomerates therein, then pass the raw materials through a 150-mesh sieve, and store the raw materials under the sieve for later use;

[0036] Step 2, mixing processing: Weigh 41 parts of calcium hypochlorite, 4 parts of potassium ferrate, 8 parts of sodium carboxymethylcellulose and 11 parts of calcium chloride powder, and pour them into a mixer together at a speed of 15 rpm , and mix uniformly in 10 minutes to obtain the ammonia nitrogen remover;

[0037] Step 3: Sampling inspection and packing into storage: Sampling and testing the finished products of the ammonia nitrogen remover, mixing unevenly mixed materials again until the materials are evenly distributed, and packing into storage after passing the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com