Patents

Literature

79results about How to "Excellent abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer binders for flexible and transparent conductive coatings containing carbon nanotubes

InactiveUS20050209392A1Decrease in optical transparencyDecrease in surface conductivityMaterial nanotechnologySpecial tyresThermoplasticCarbon nanotube

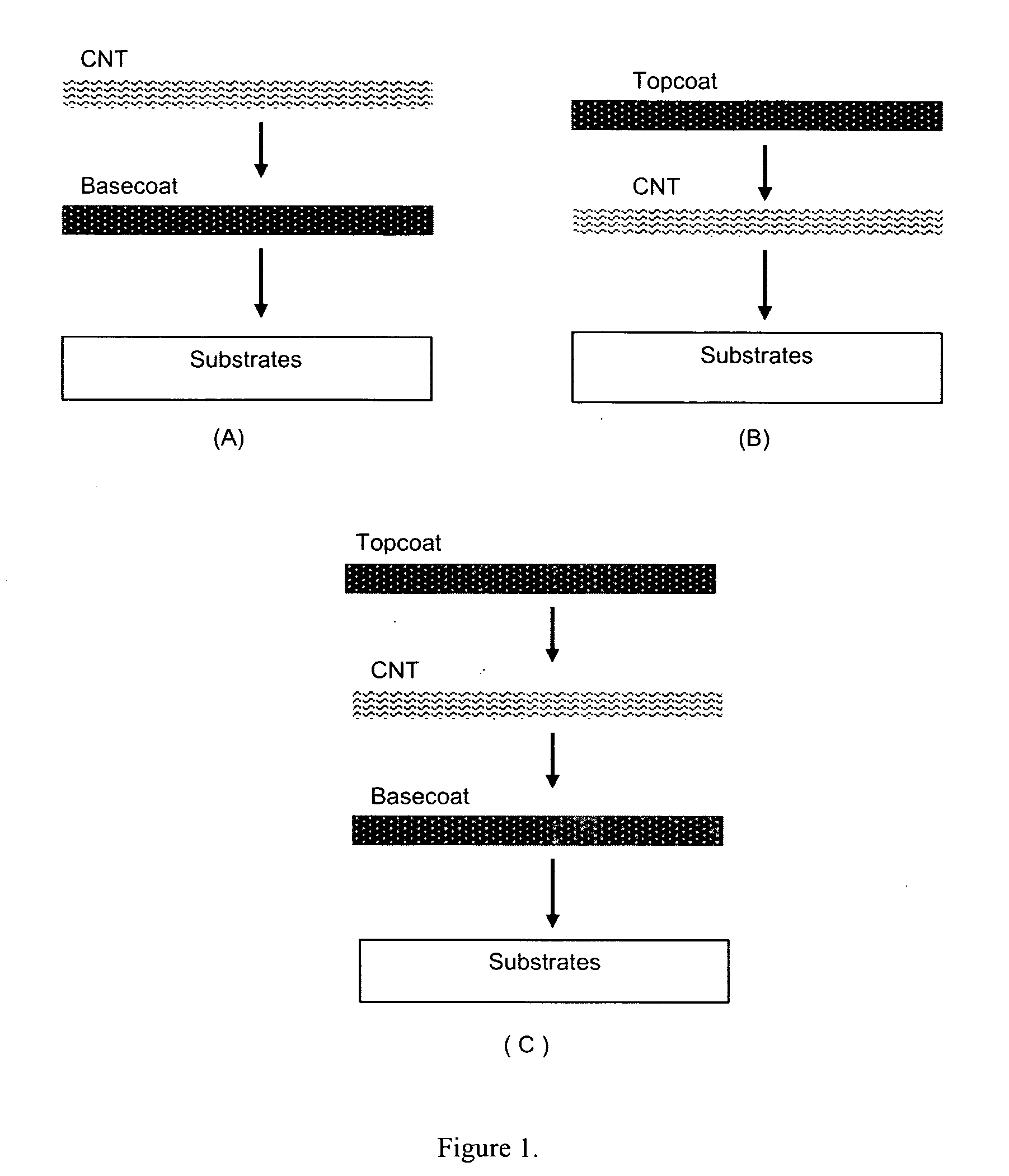

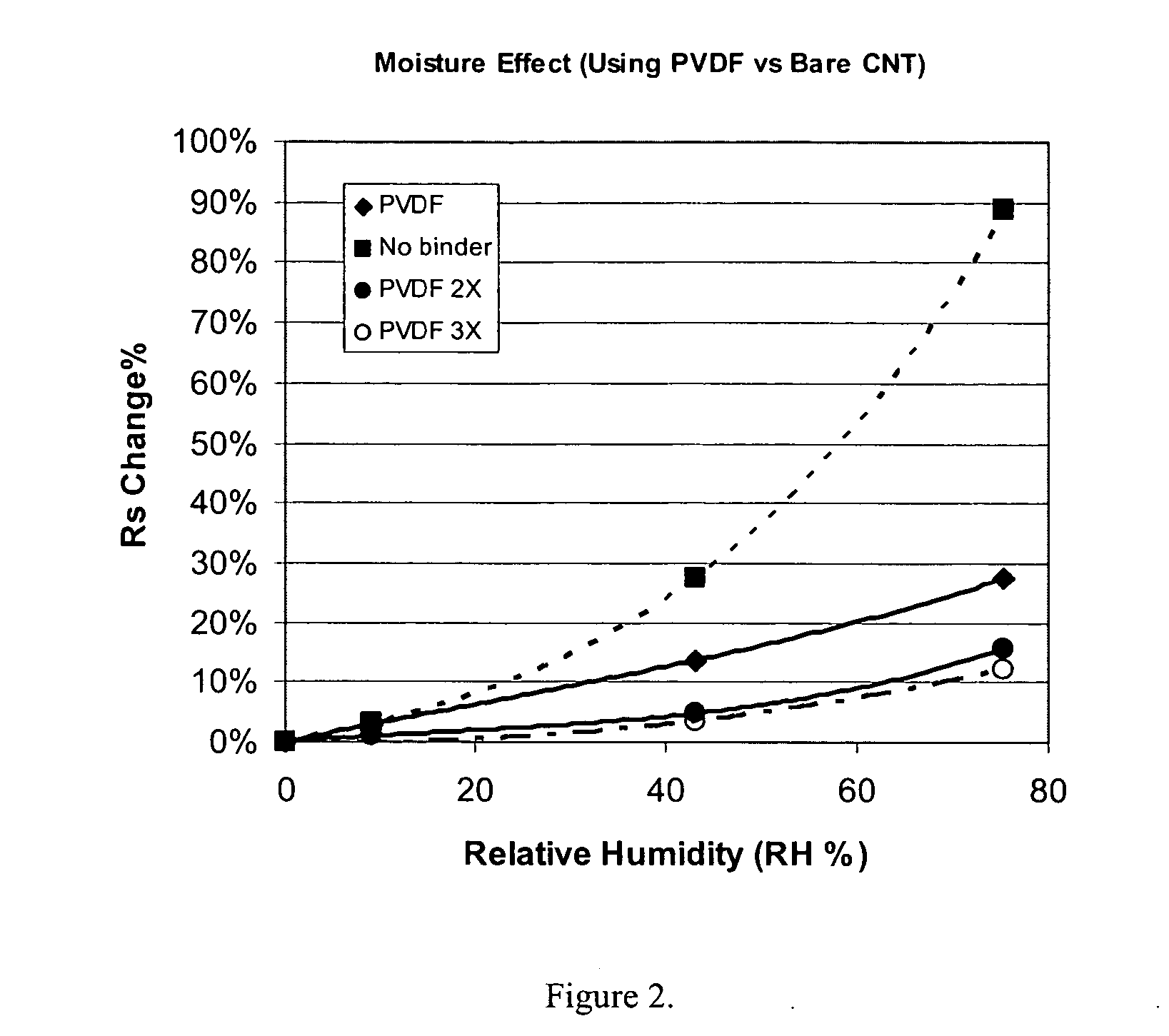

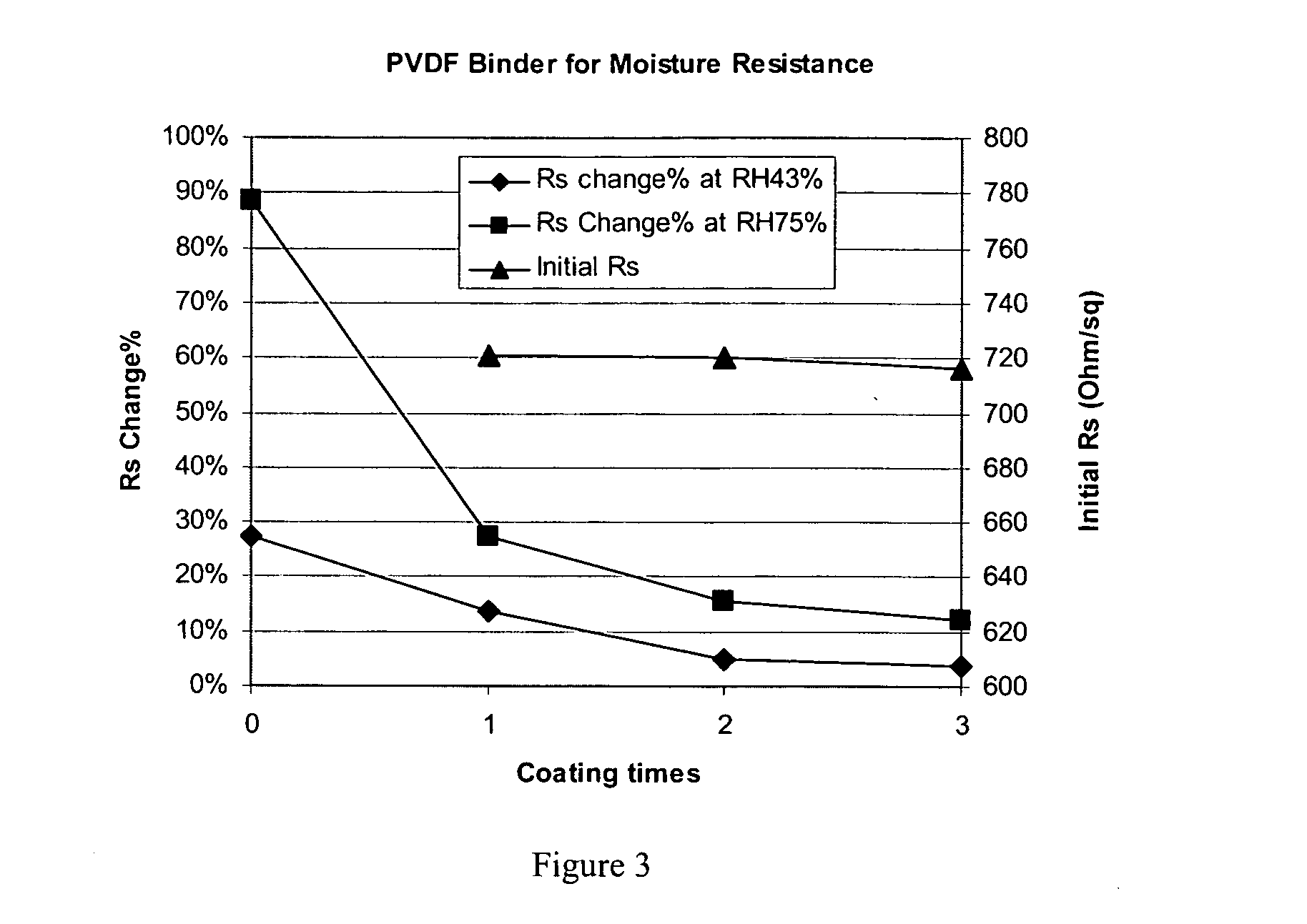

This invention relates to flexible, transparent and conductive coatings and films formed using single wall carbon nanotubes and polymer binders. Preferably, coatings and films are formed from carbon nanotubes (CNT) applied to transparent substrates forming one or multiple conductive layers at nanometer level of thickness. Polymer binders are applied to the CNT network coating having an open structure to provide protection through infiltration. This provides for the enhancement of properties such as moisture resistance, thermal resistance, abrasion resistance and interfacial adhesion. Polymers may be thermoplastics or thermosets, or any combination of both. Polymers may also be insulative or inherently electrical conductive, or any combination of both. Polymers may comprise single or multiple layers as a basecoat underneath a CNT coating, or a topcoat above a CNT coating, or combination of the basecoat and the topcoat forming a sandwich structure. Binder coating thickness can be adjusted by changing binder concentration, coating speed and / or other process conditions. Resulting films and articles can be used as transparent conductors for flat panel display, touch screen and other electronic devices.

Owner:EIKOS

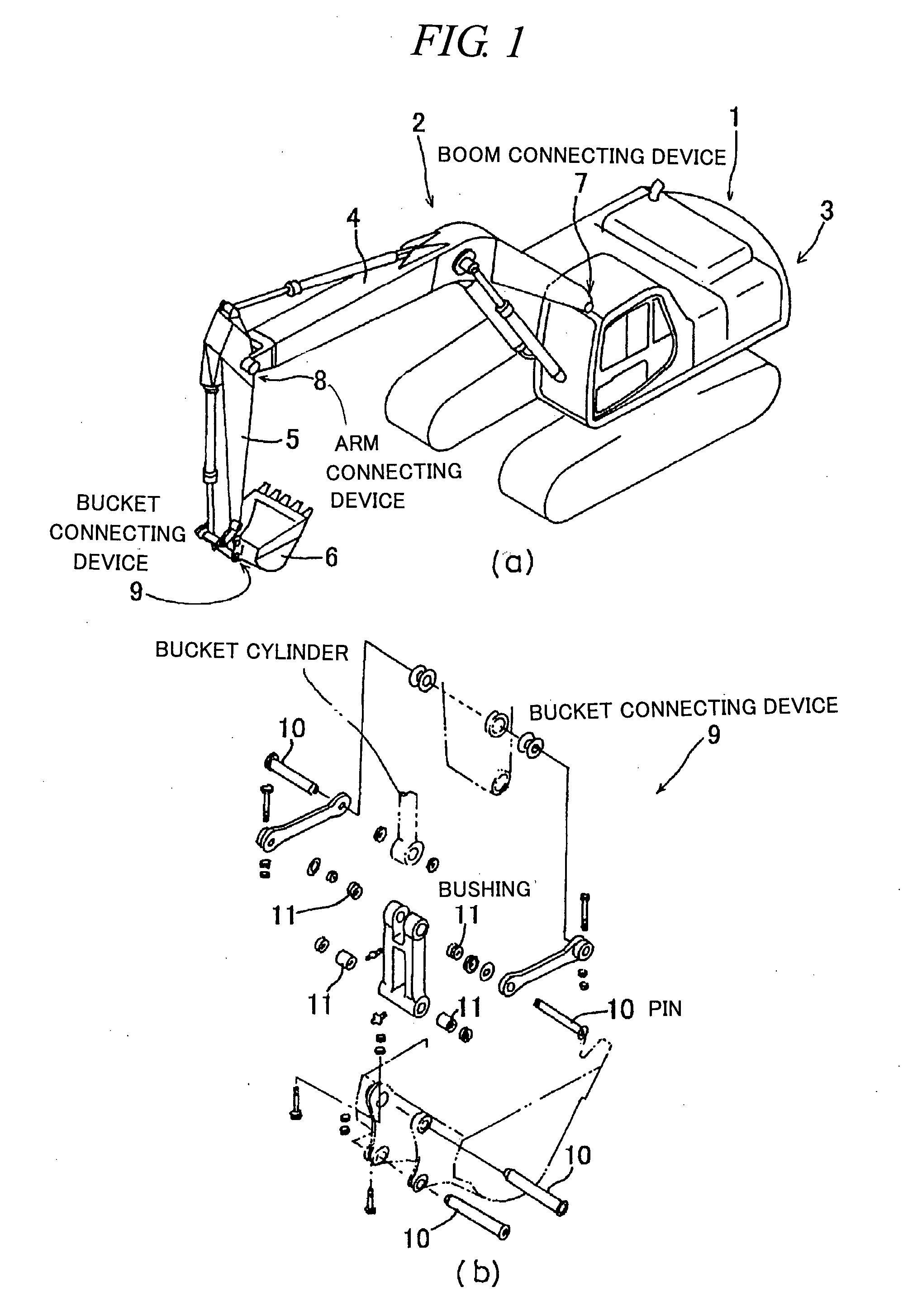

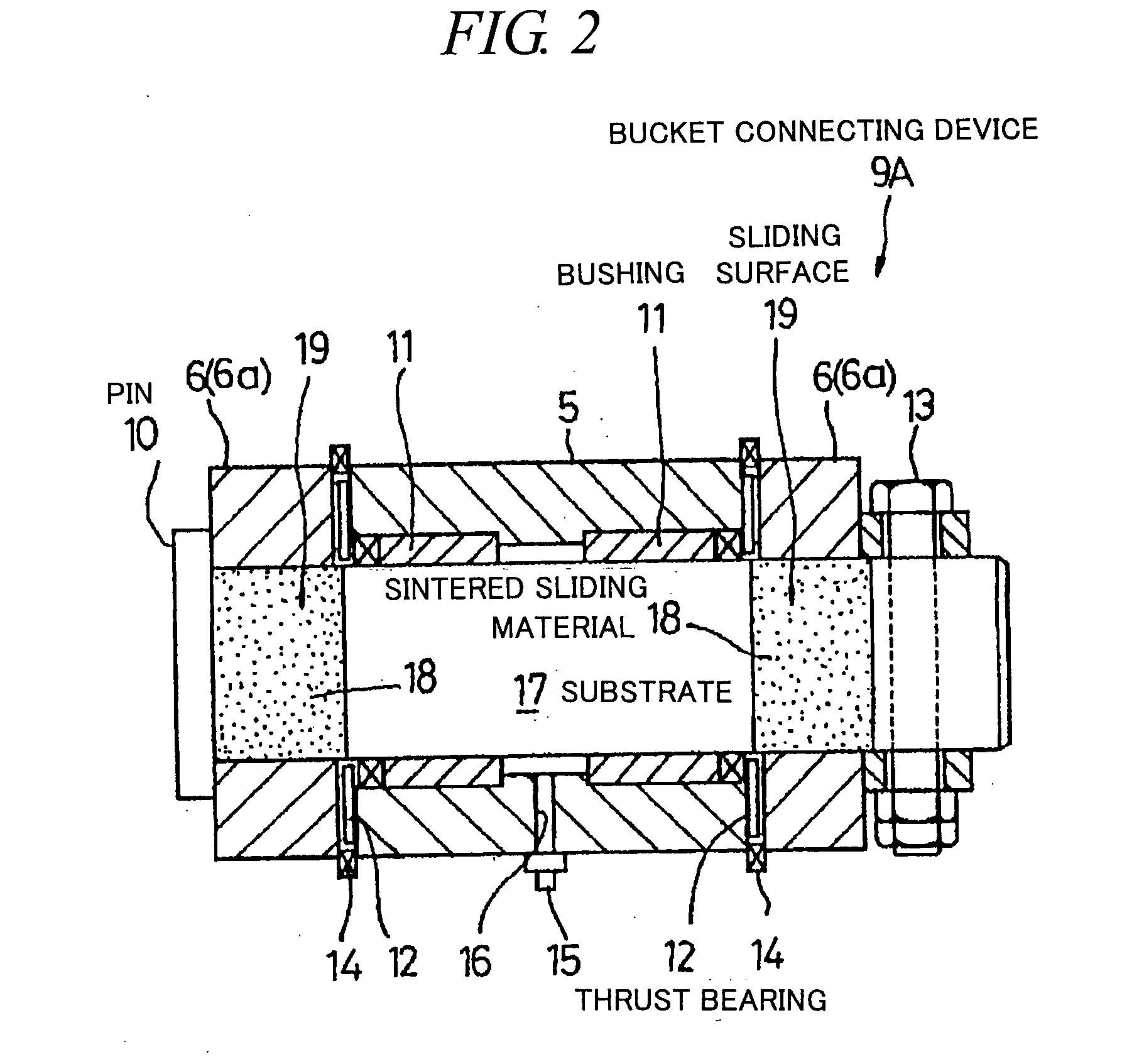

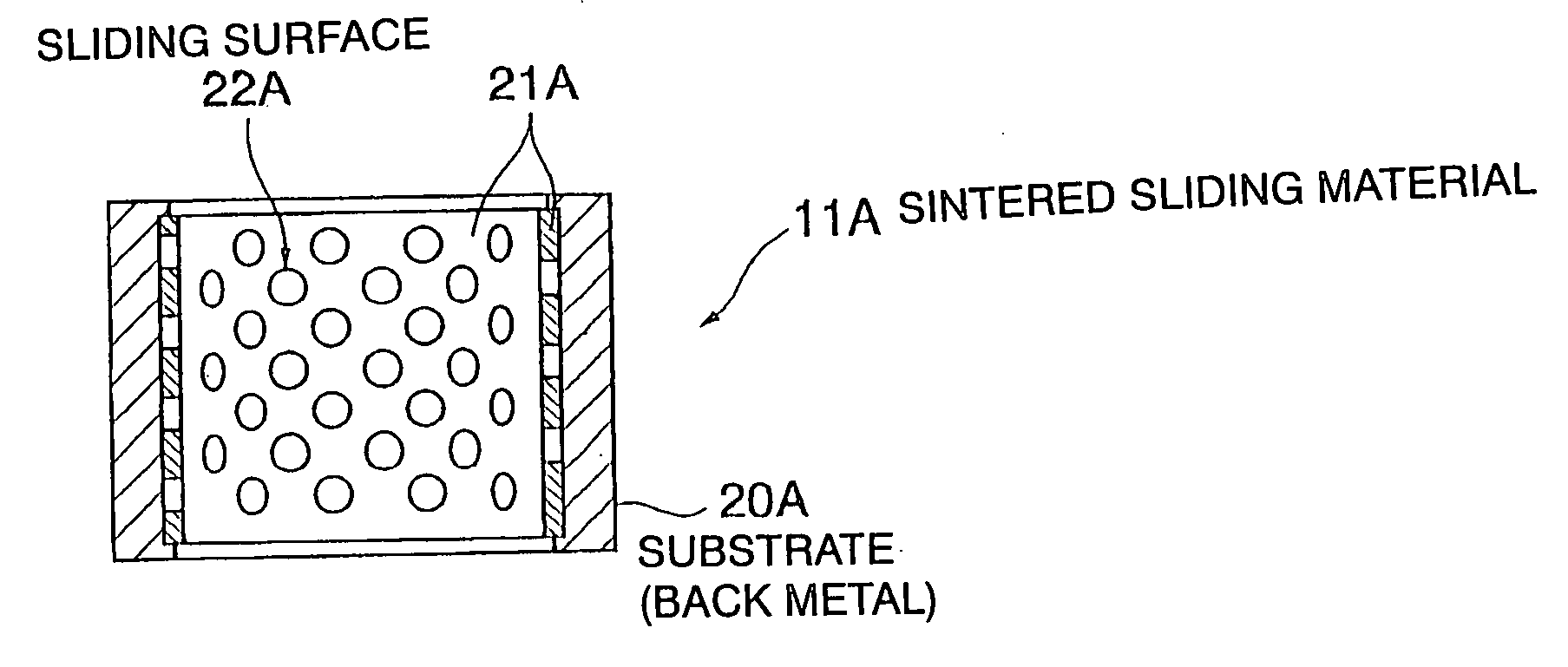

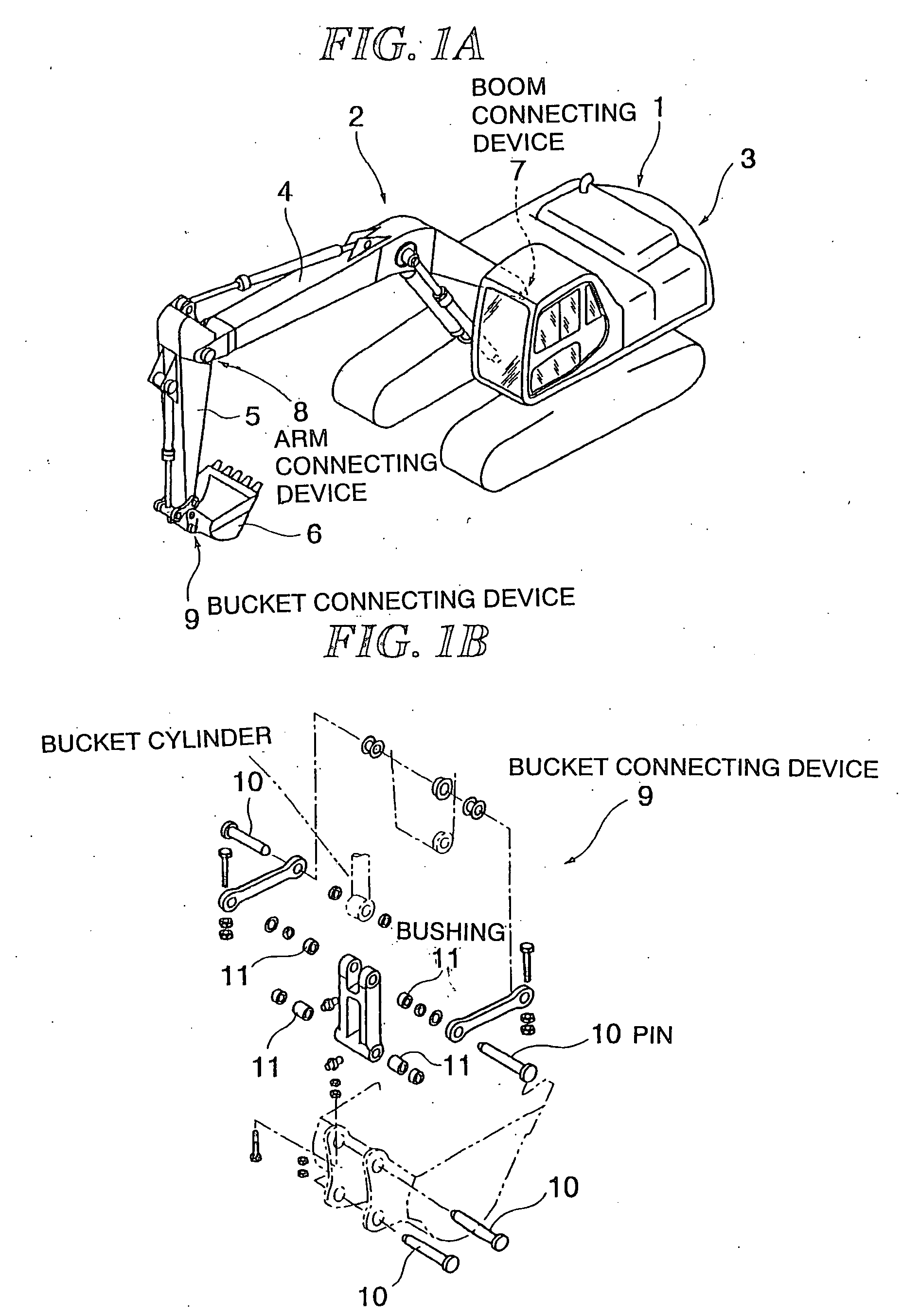

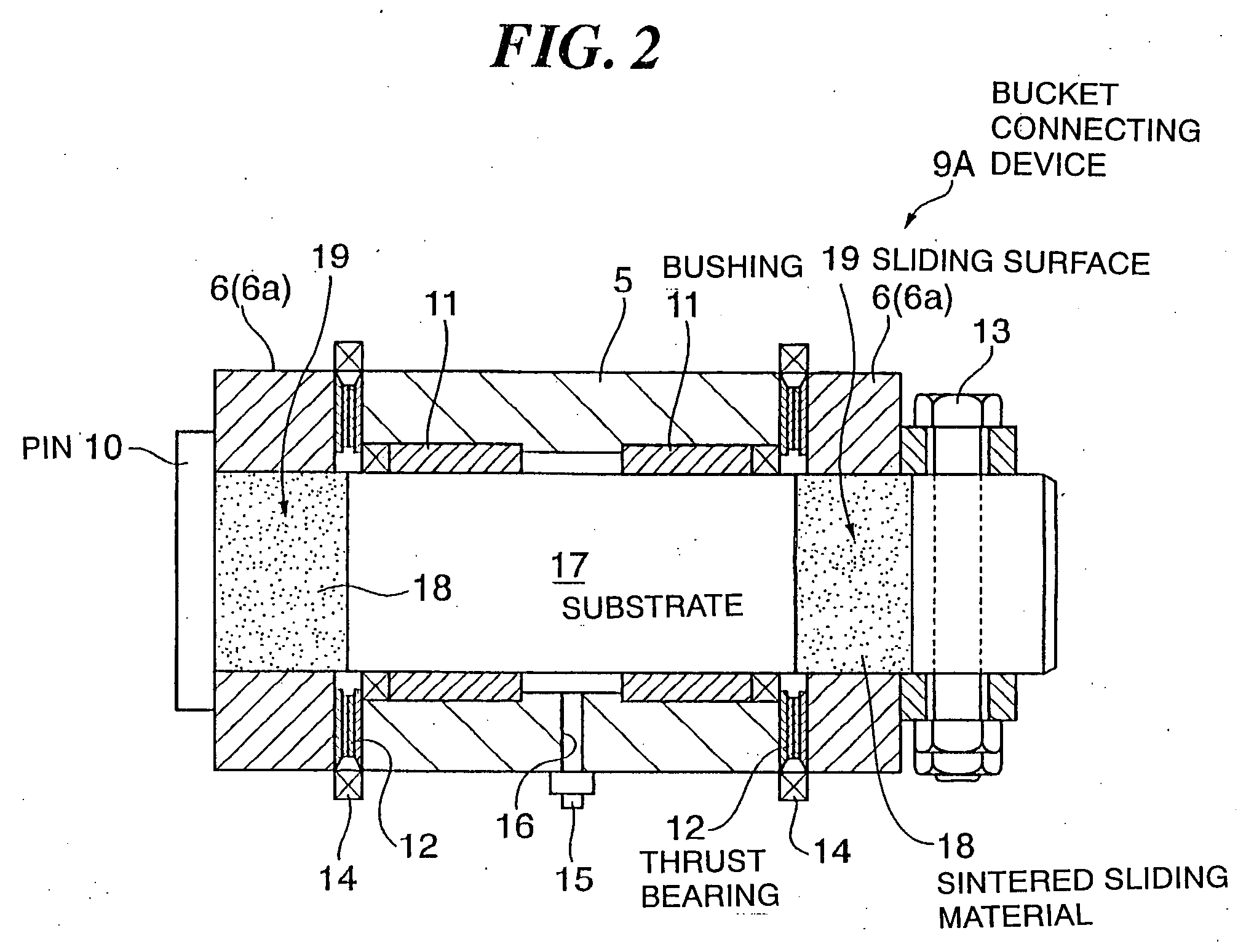

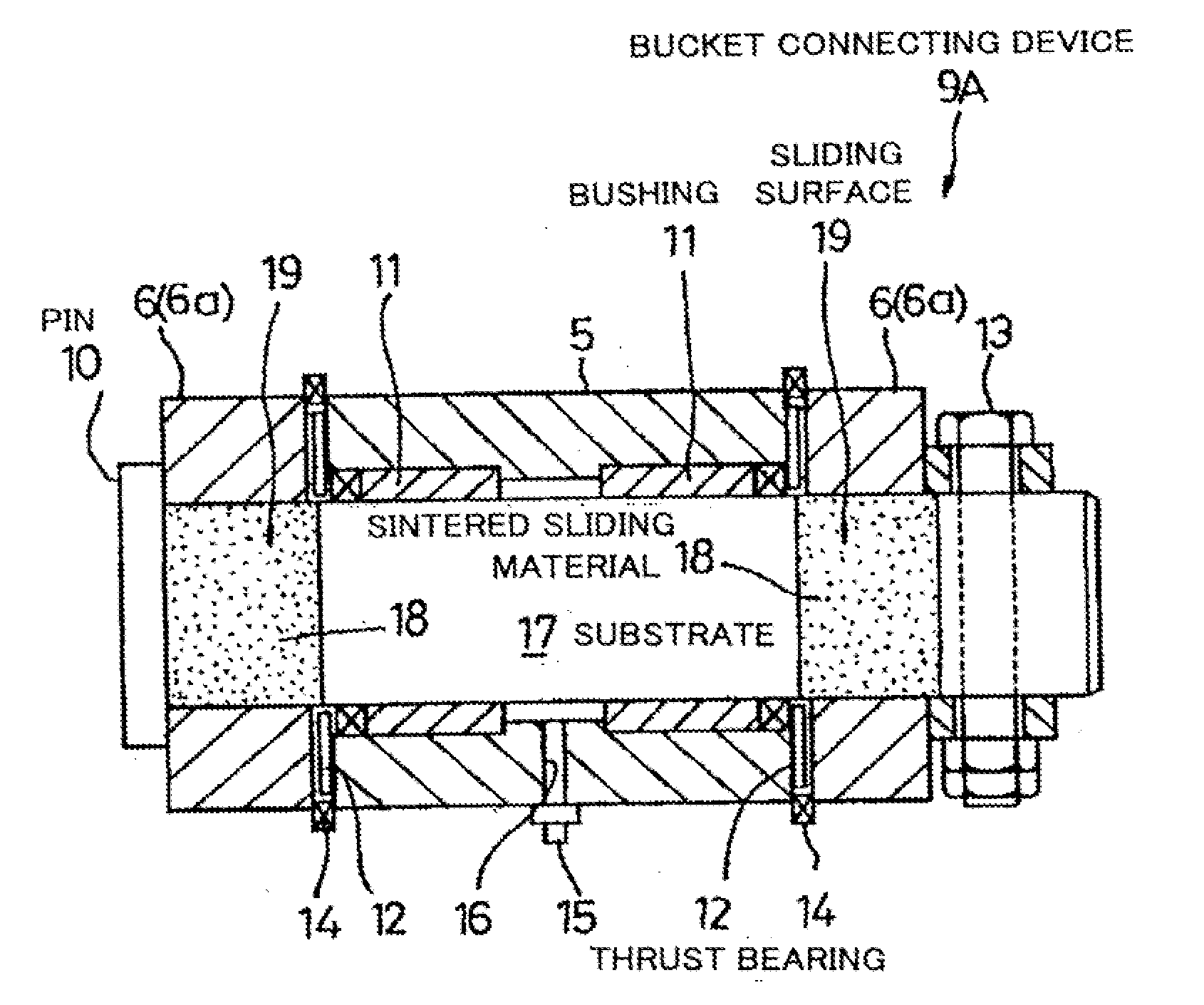

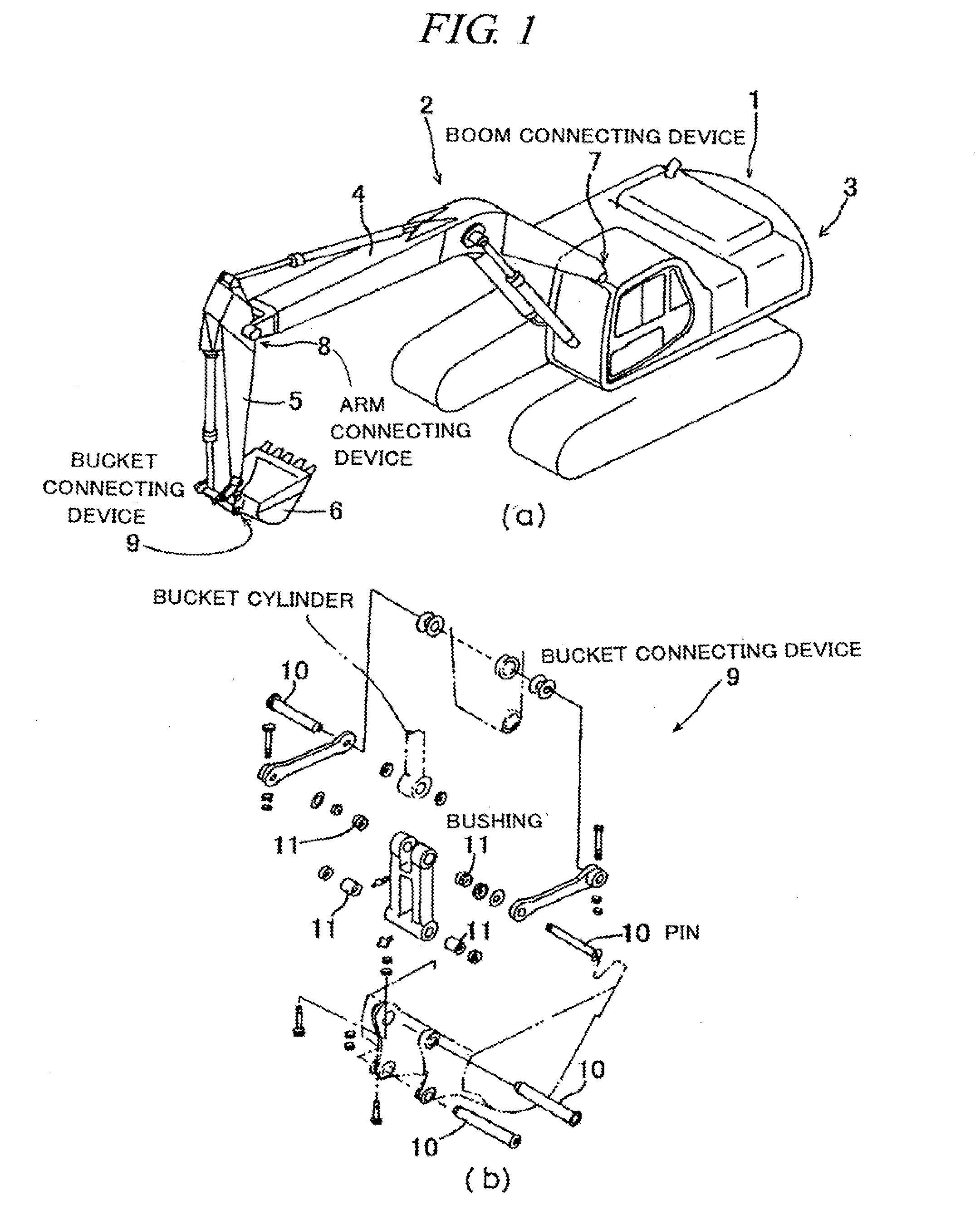

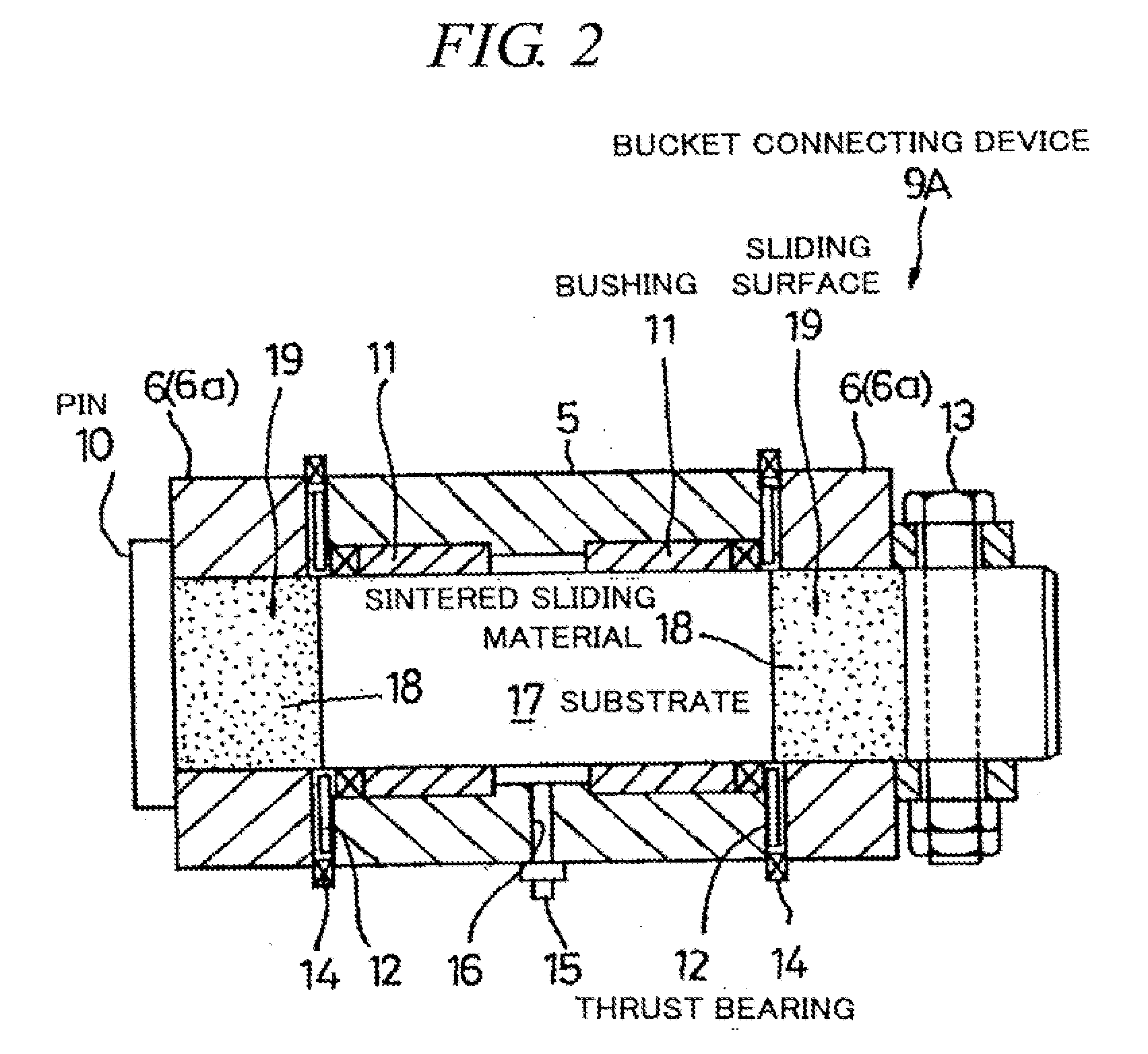

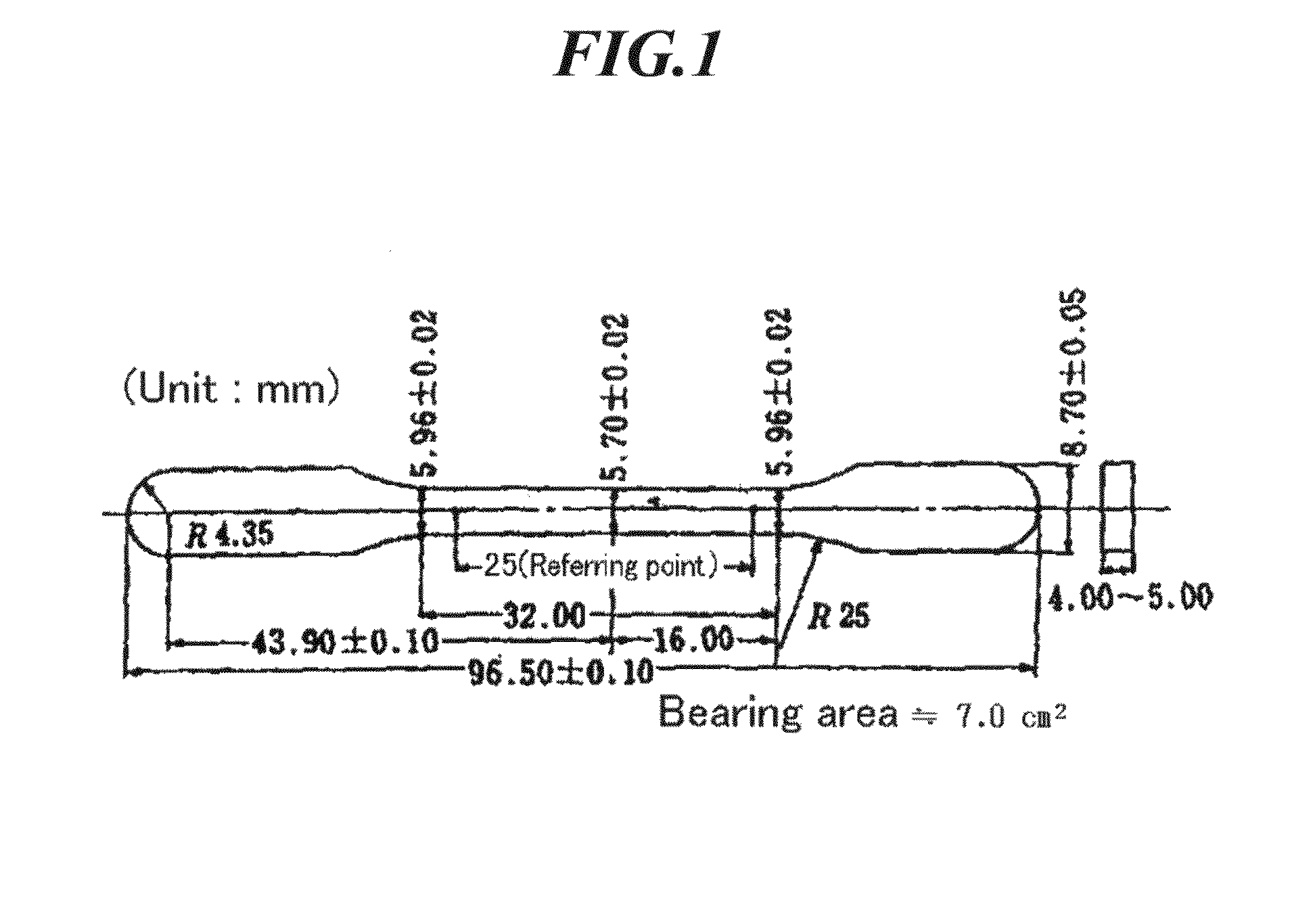

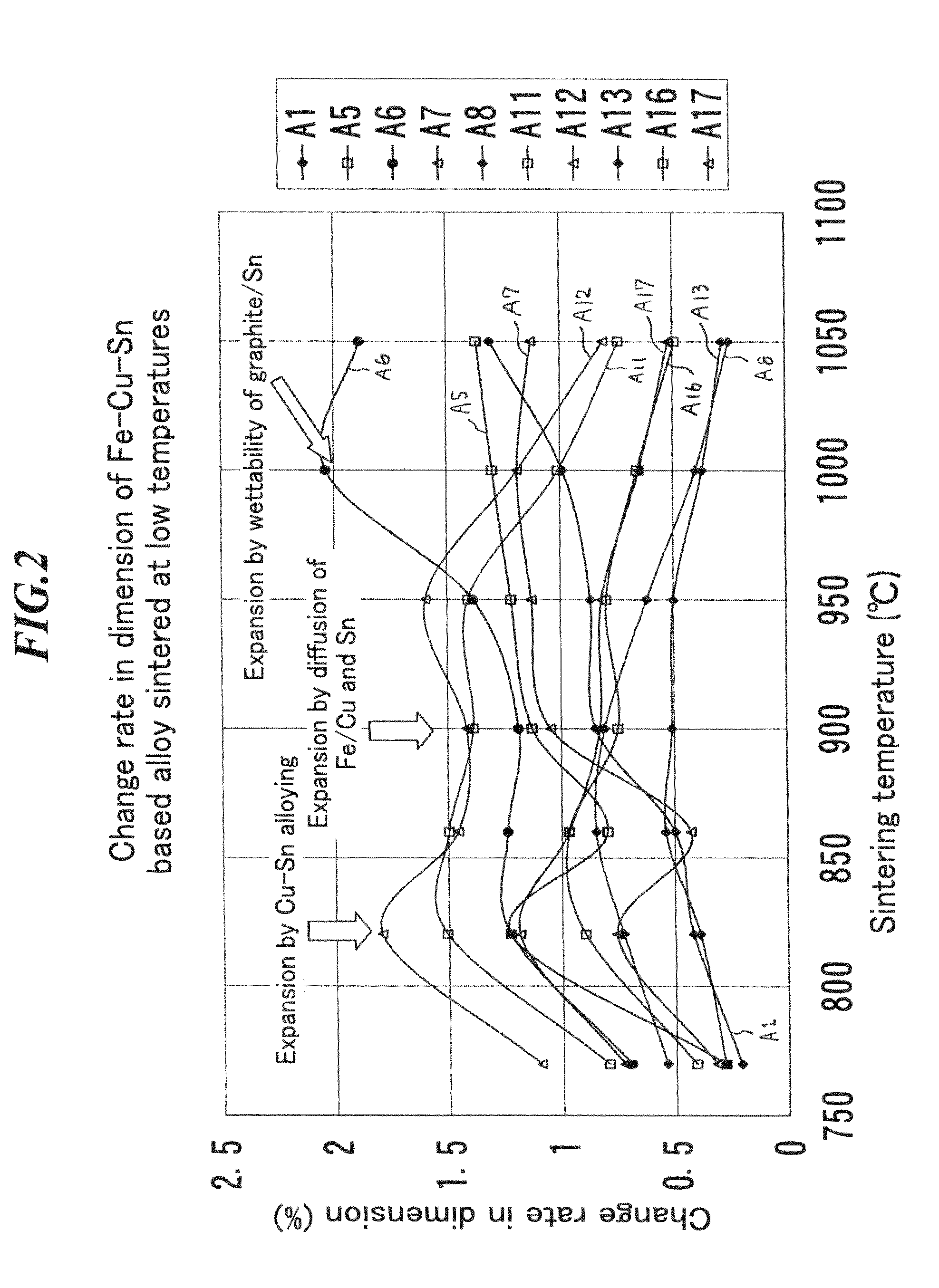

Sintered Material, Ferrous Sintered Sliding Material, Producing Method of the Same, Sliding Member, Producing Method of the Same and Coupling Device

InactiveUS20080146467A1Excellent abrasion resistanceReduce necessityBearing componentsPowder mixtureGraphite particle

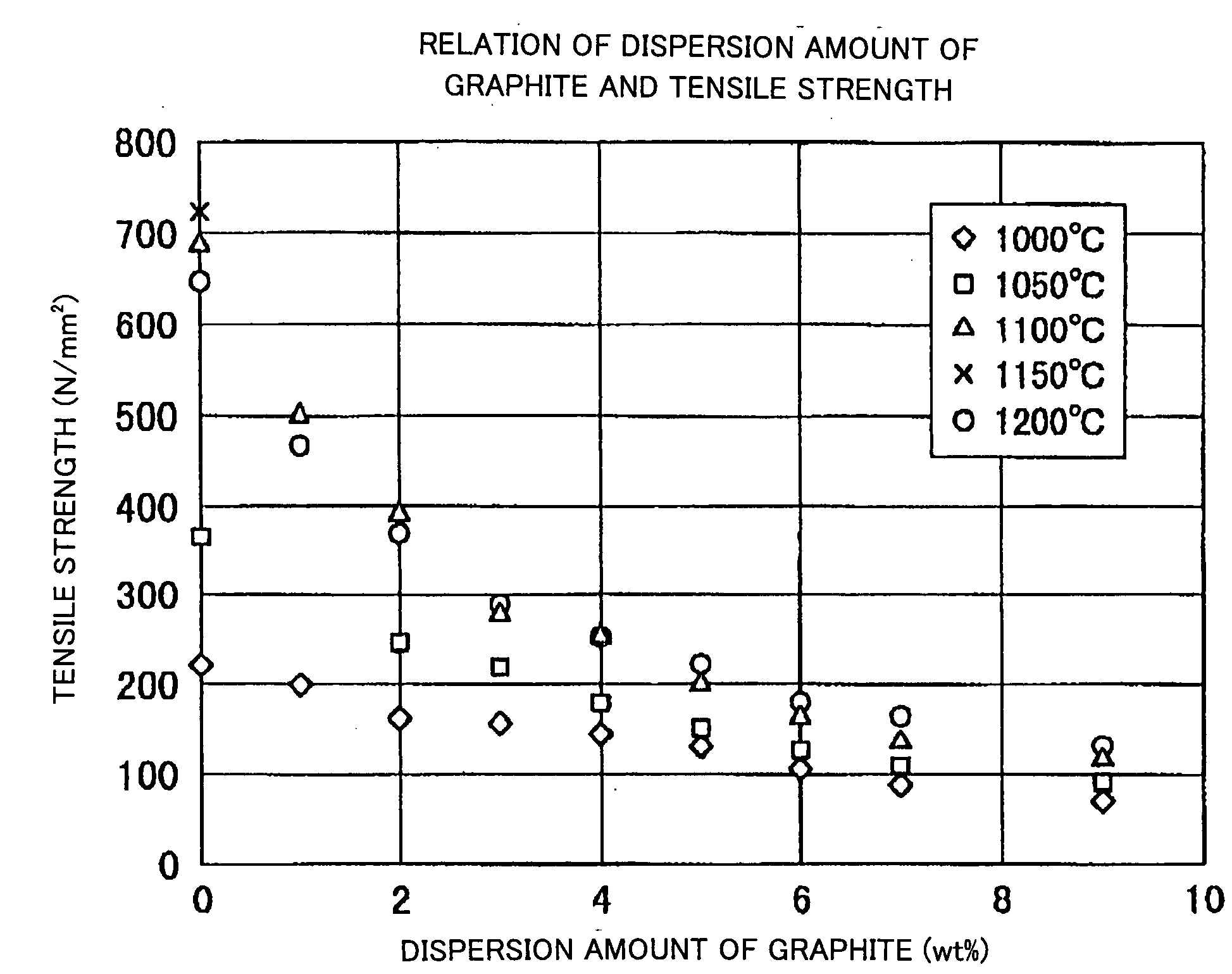

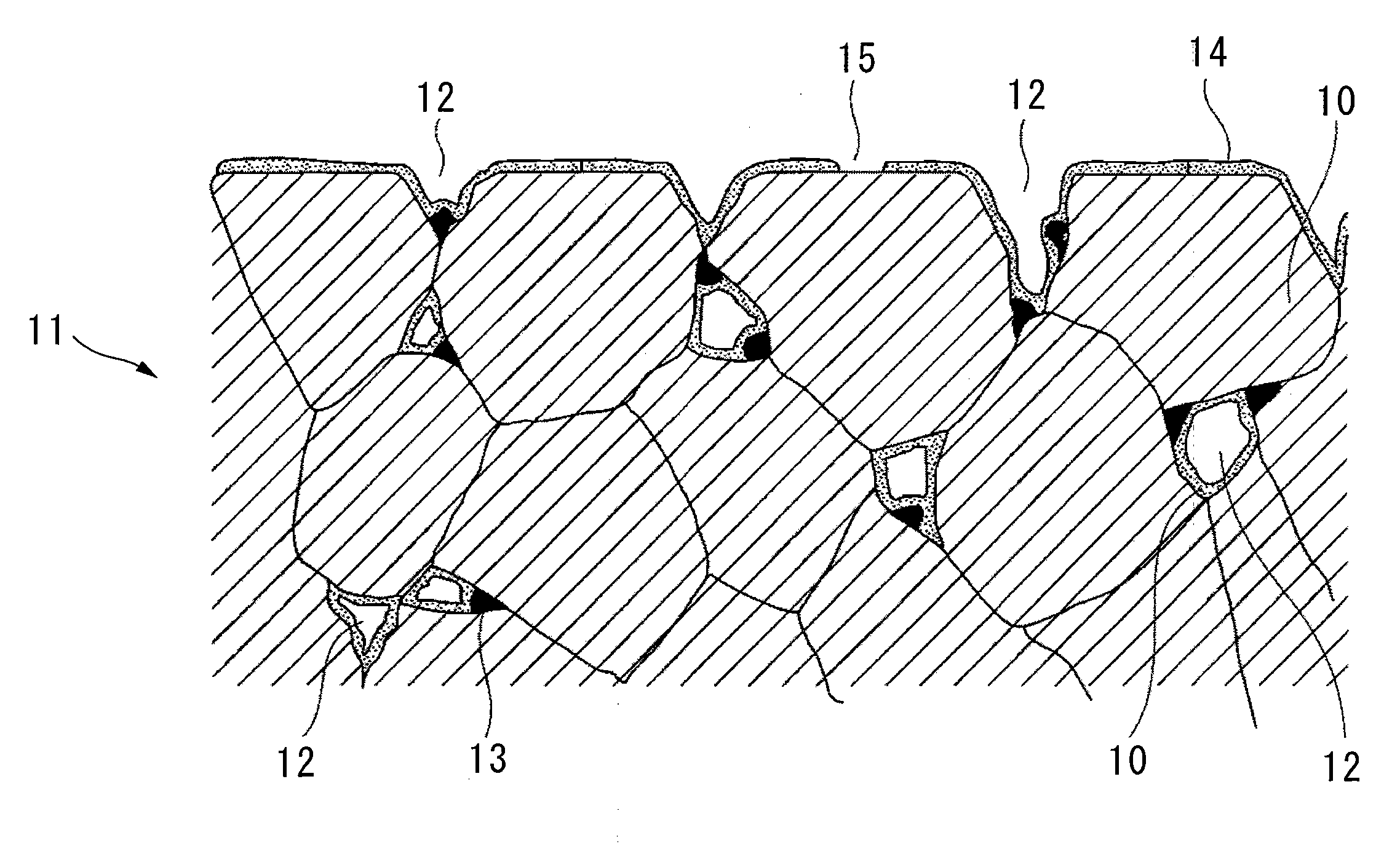

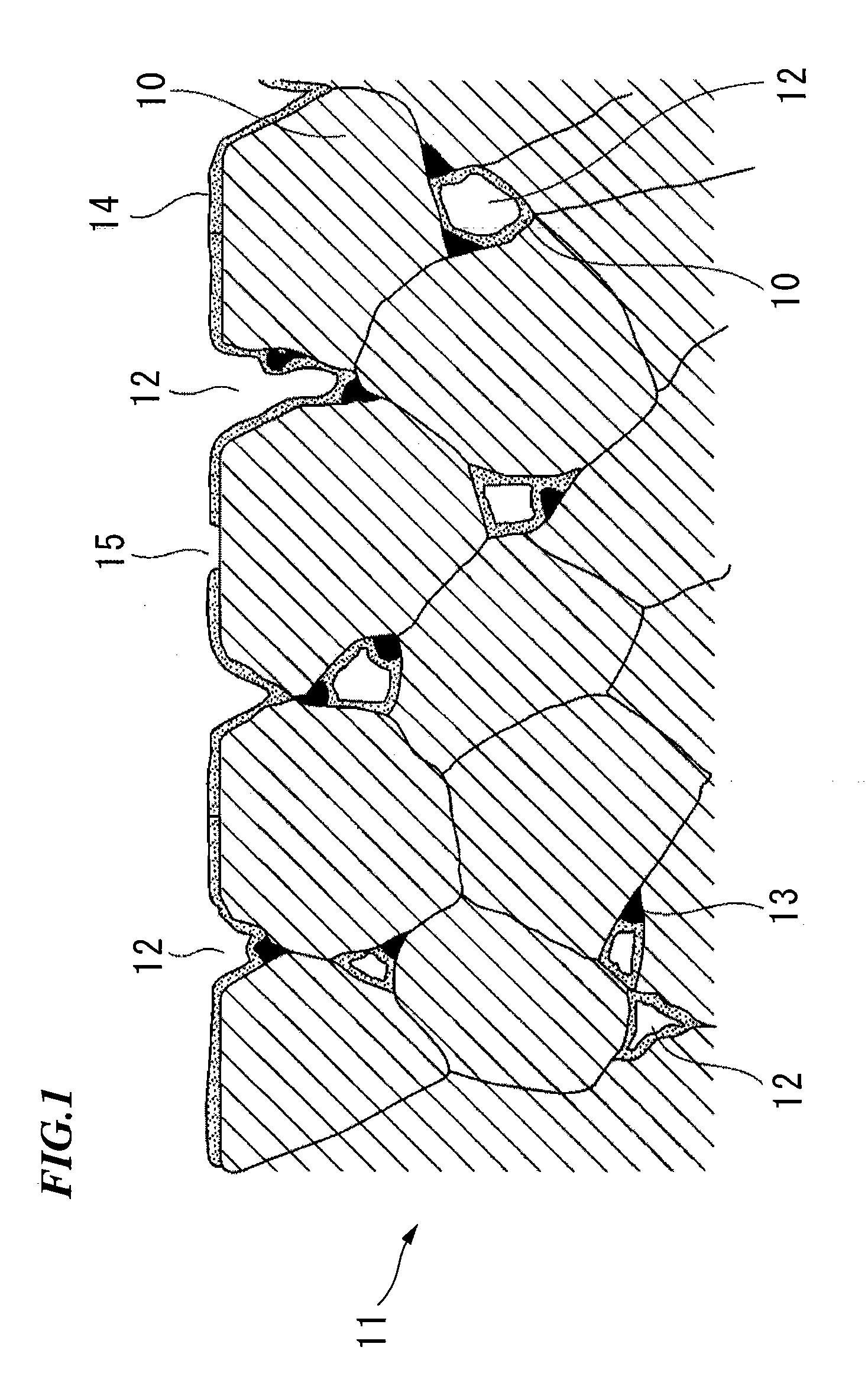

The iron-based sintered sliding material comprises: a sintered structure which contains 10-50 wt. % copper and 1-15 wt. % carbon and has been formed by sintering a powder mixture obtained by mixing at least one of an Fe—Cu alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and an Fe—Cu—C alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and containing carbon in an amount of 0-5 wt. %, excluding 0 wt. %, with a graphite powder and at least one of a copper powder and a copper alloy powder; and graphite particles dispersed in the sintered sliding material in an amount of 1-14 wt. % or 3-50 vol. %.

Owner:KOMATSU LTD

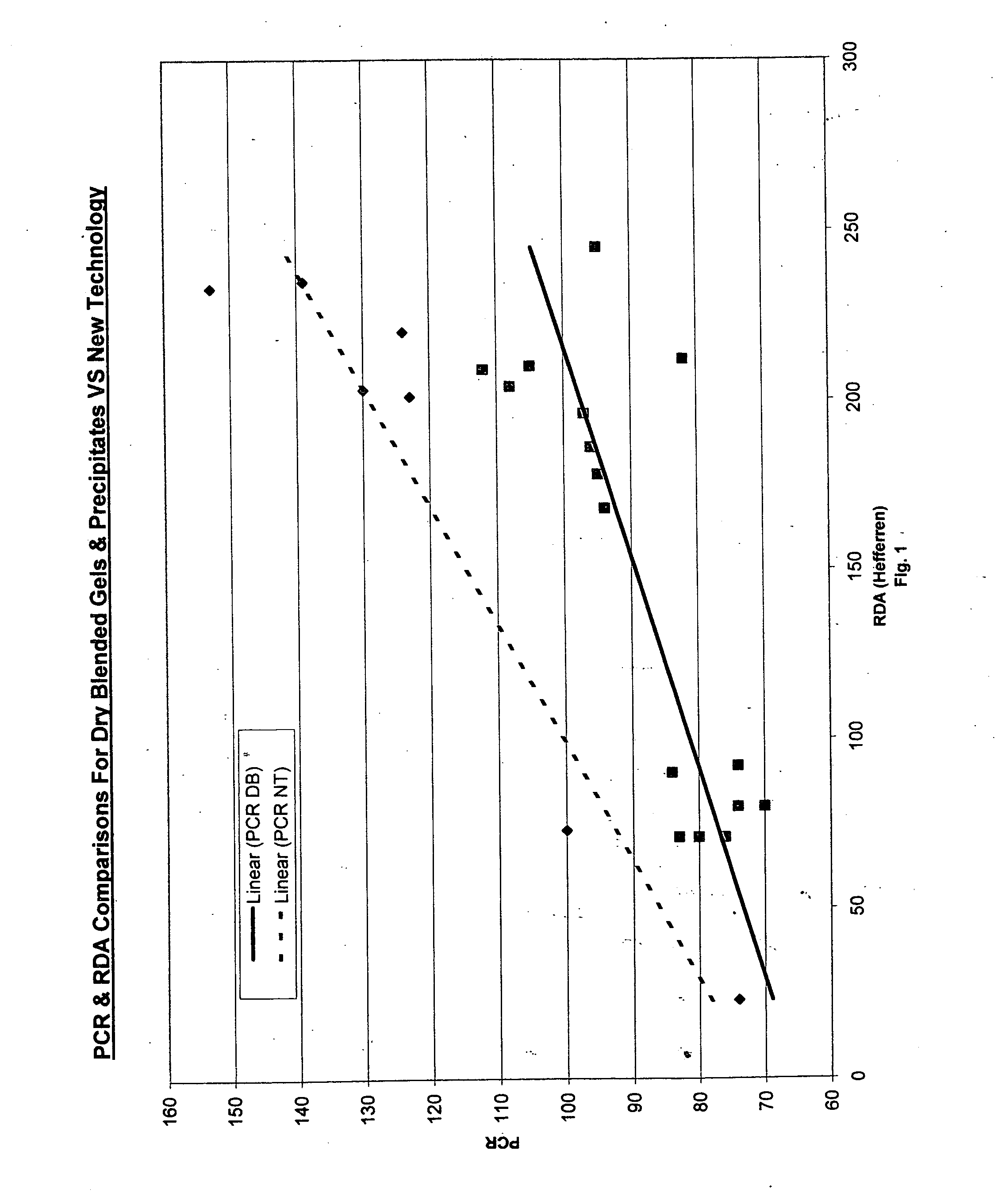

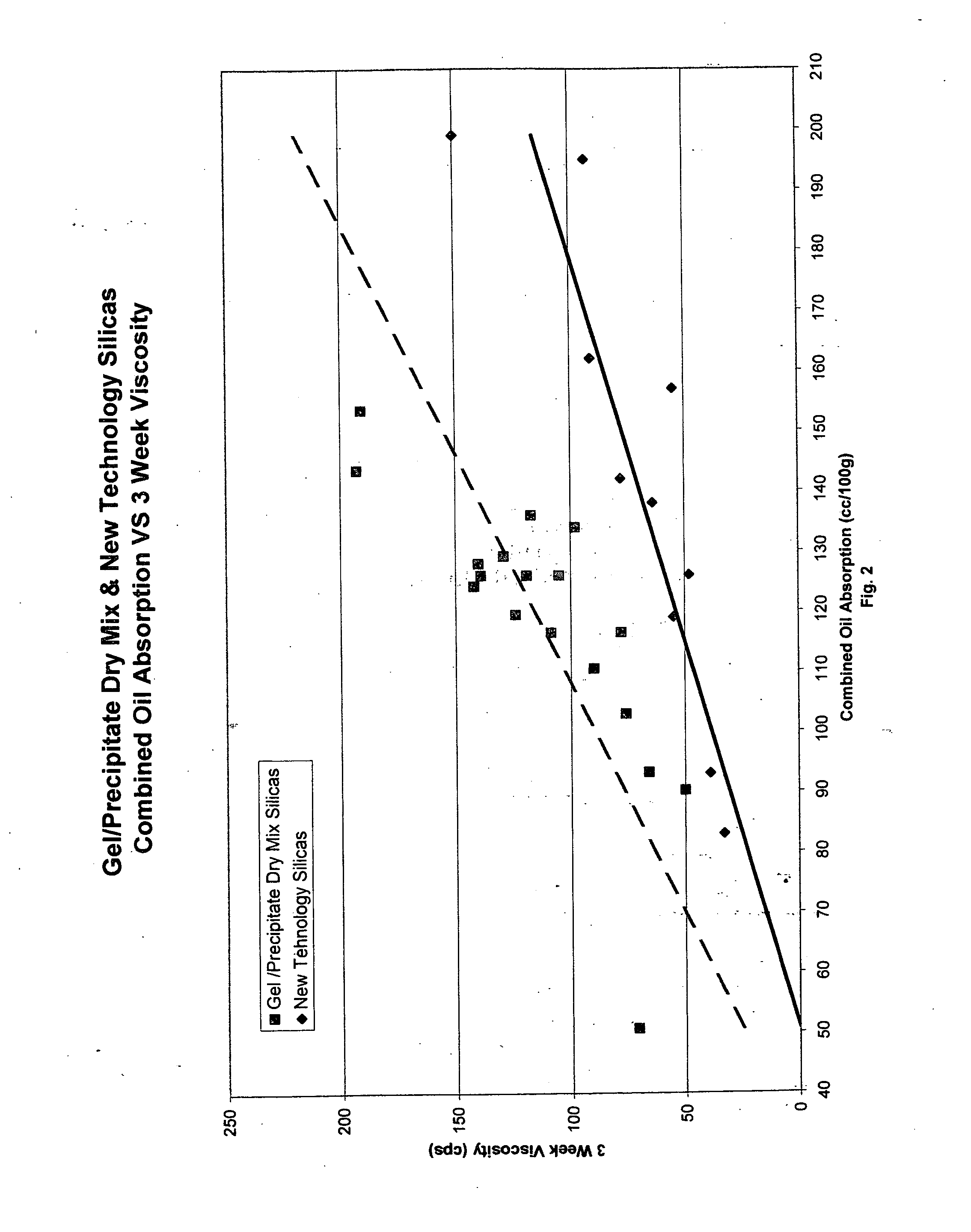

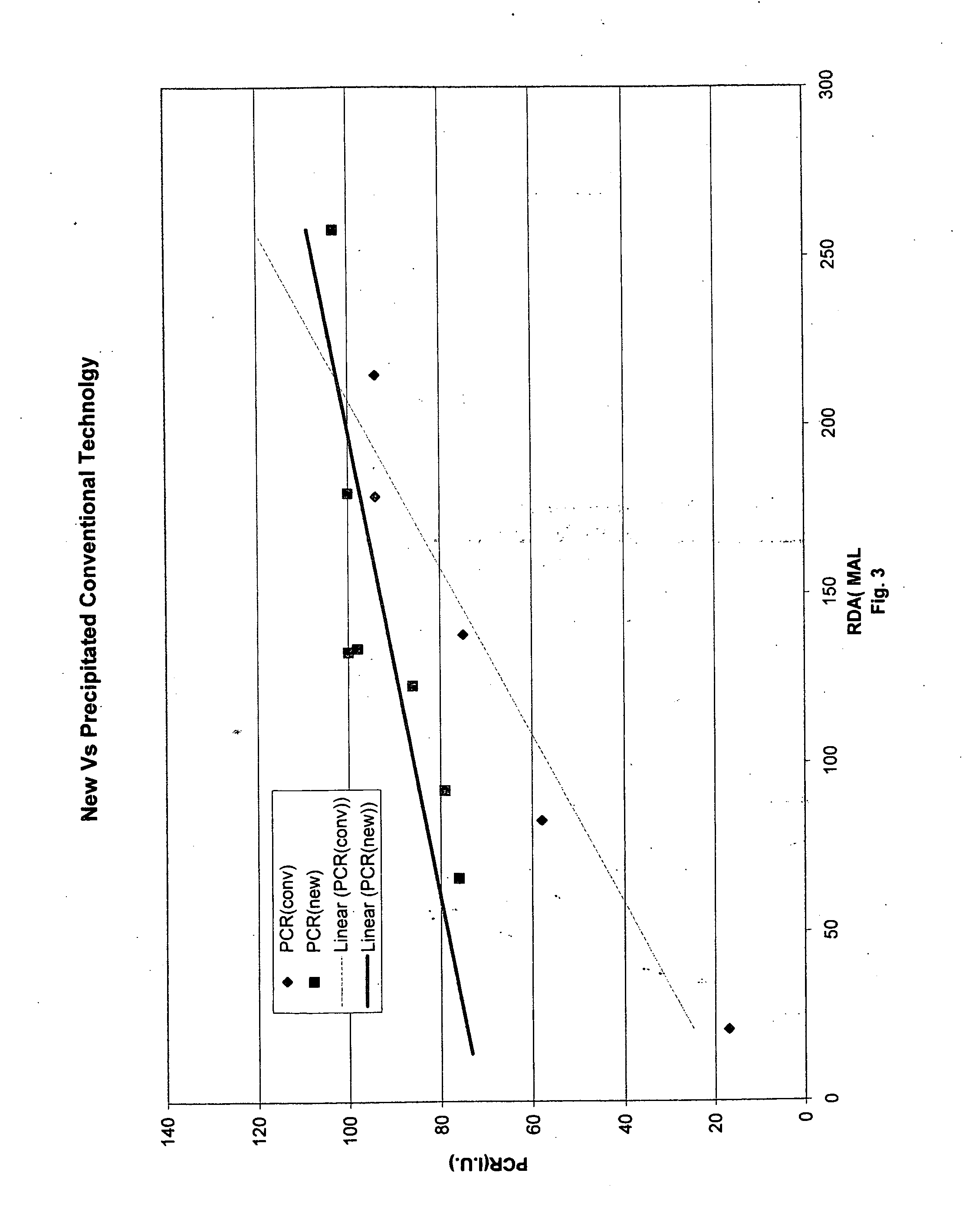

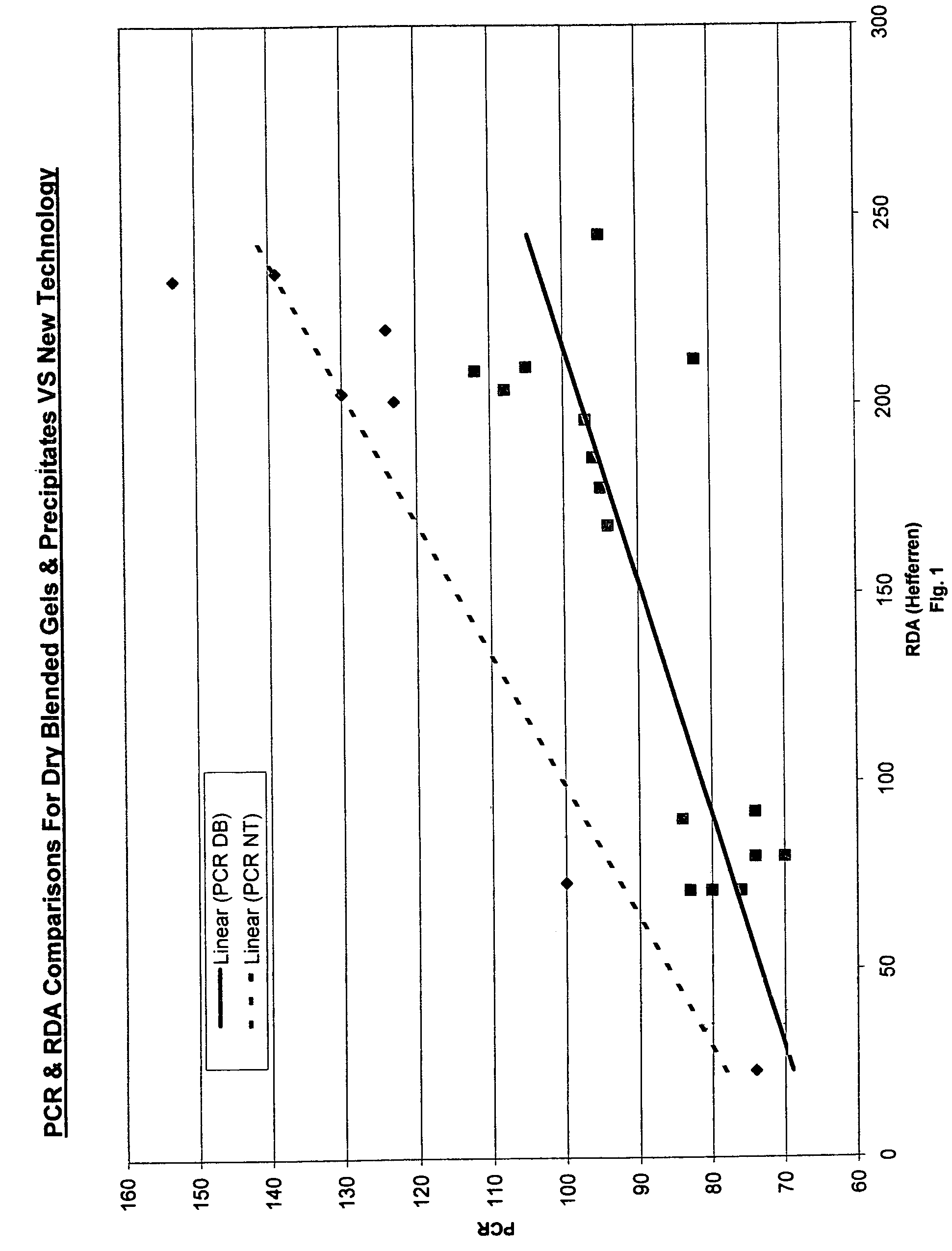

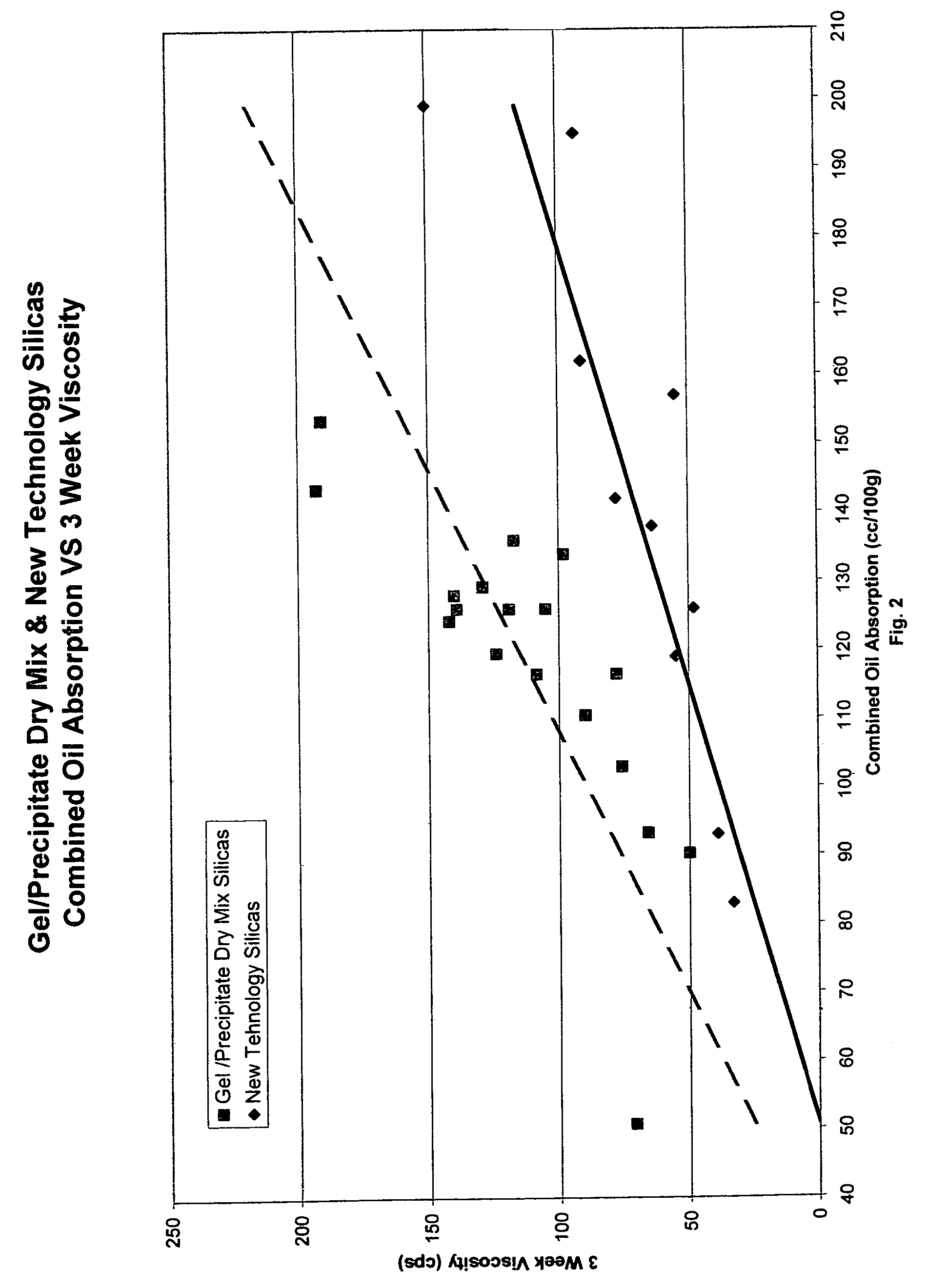

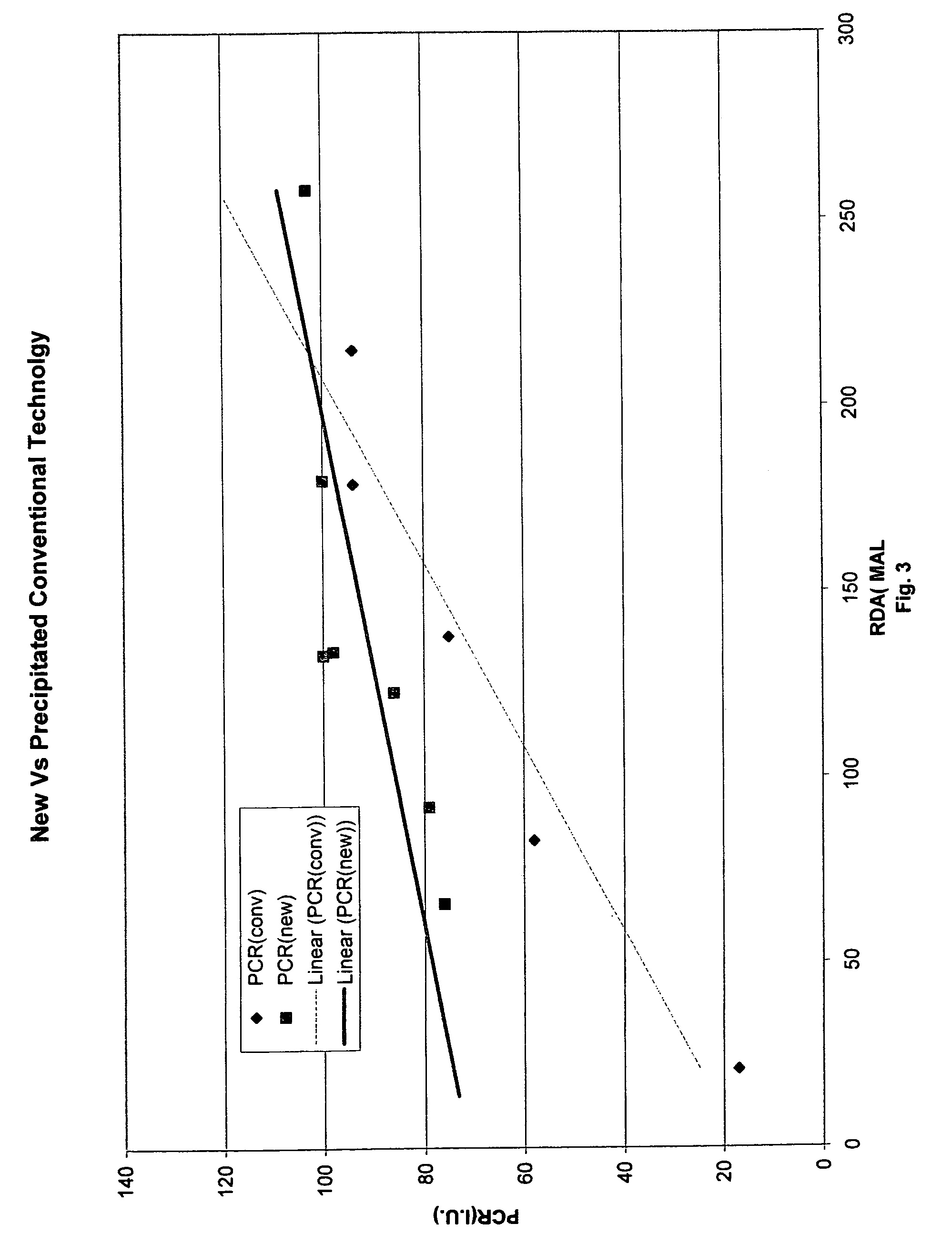

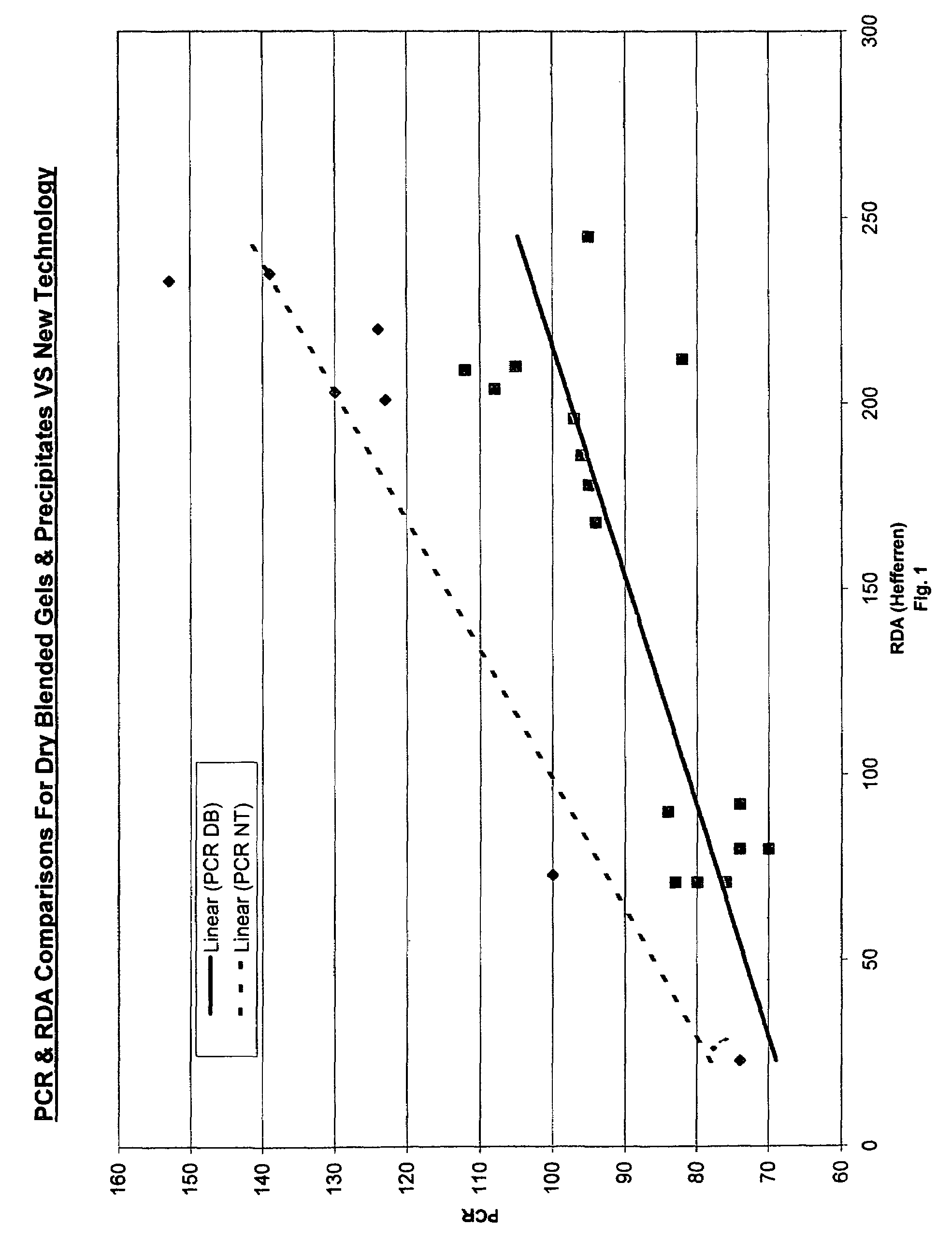

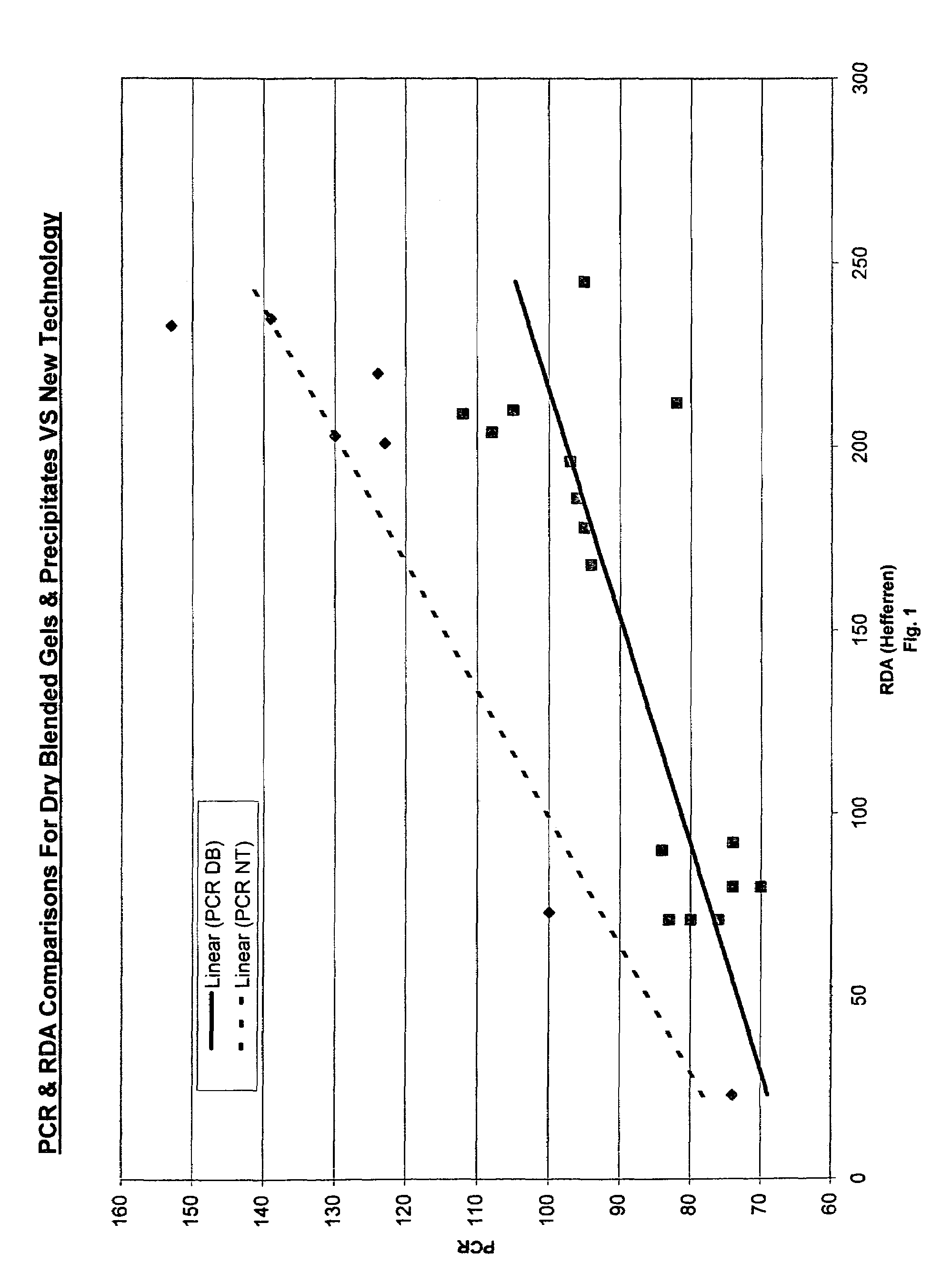

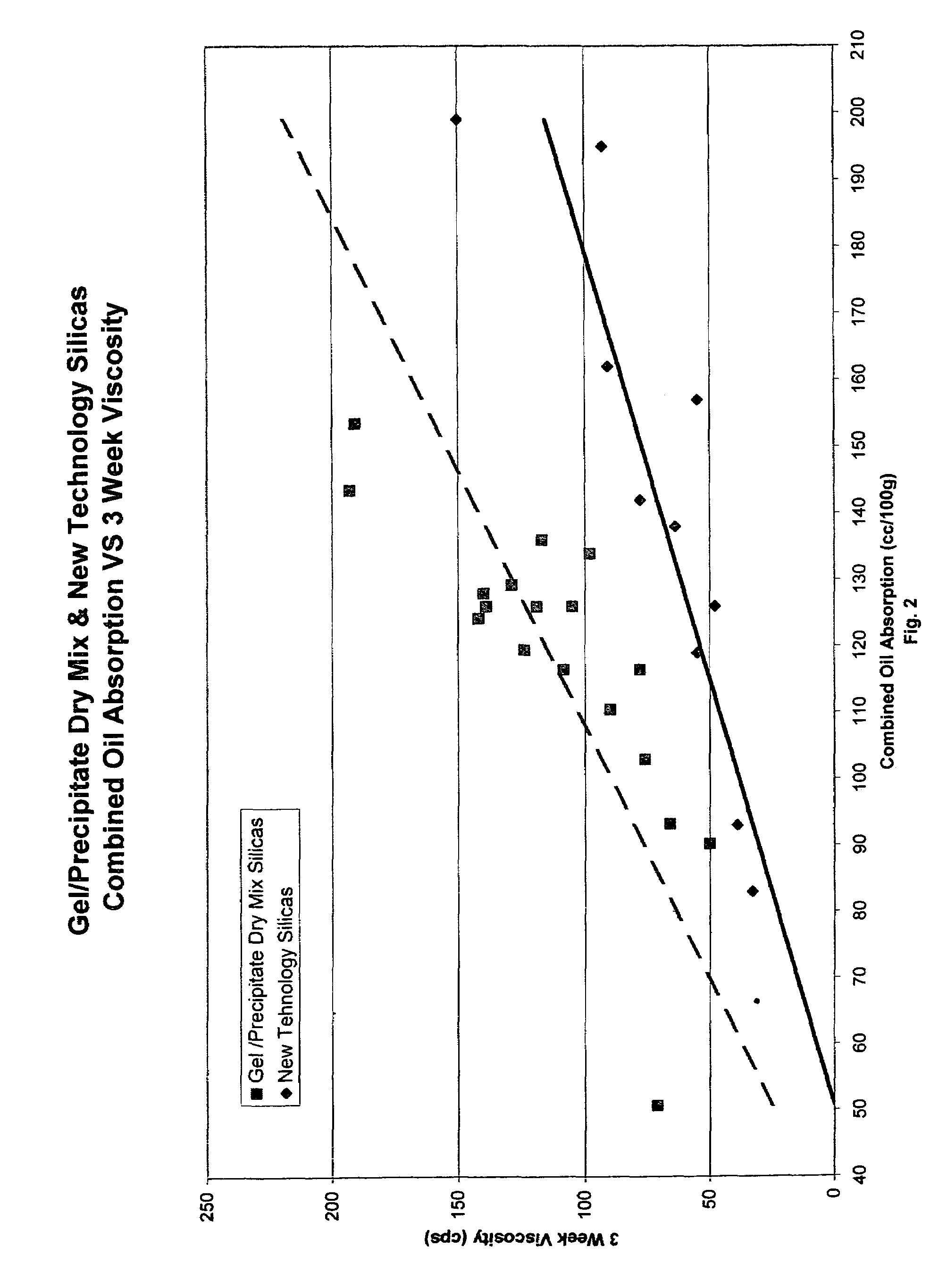

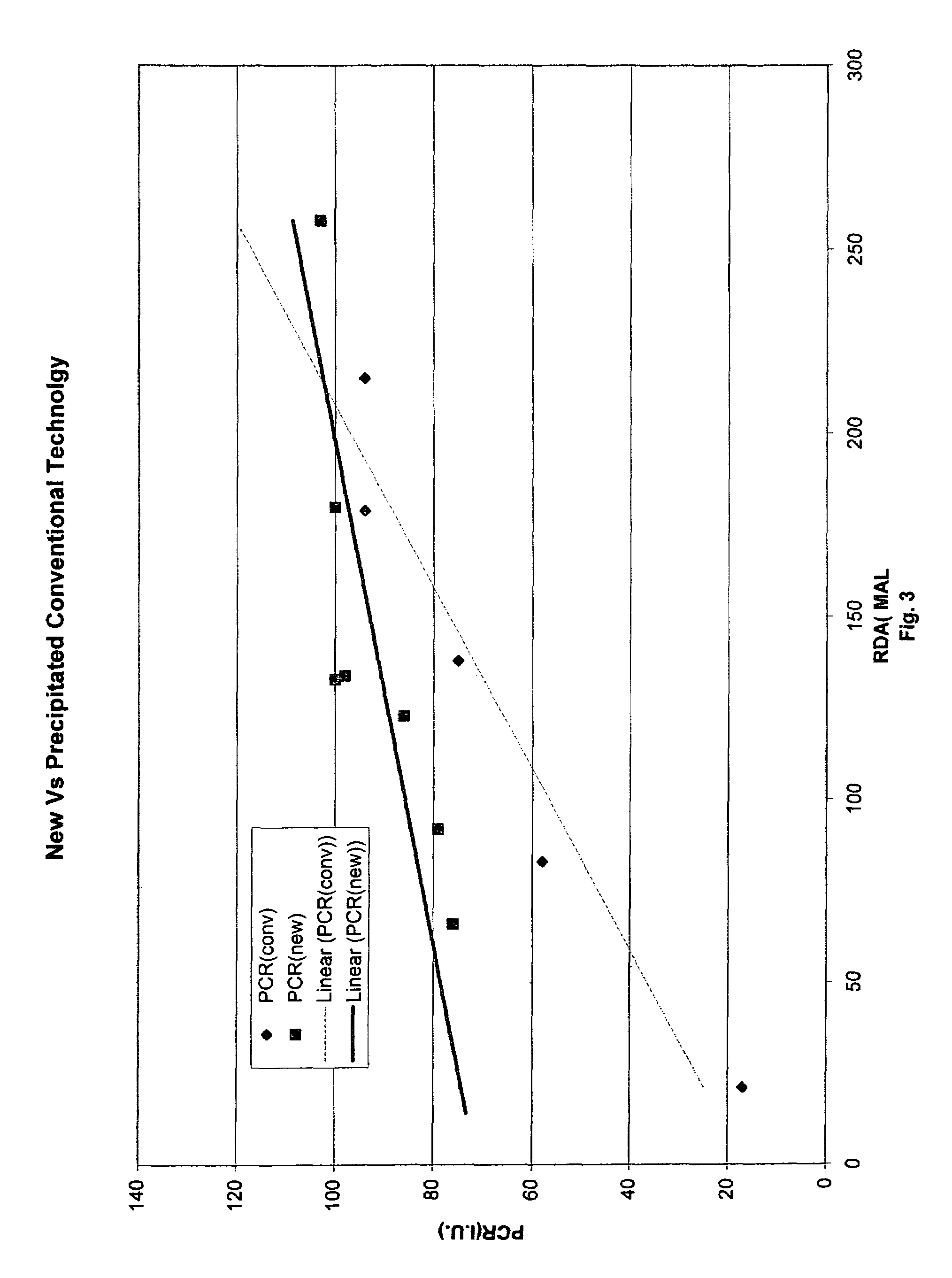

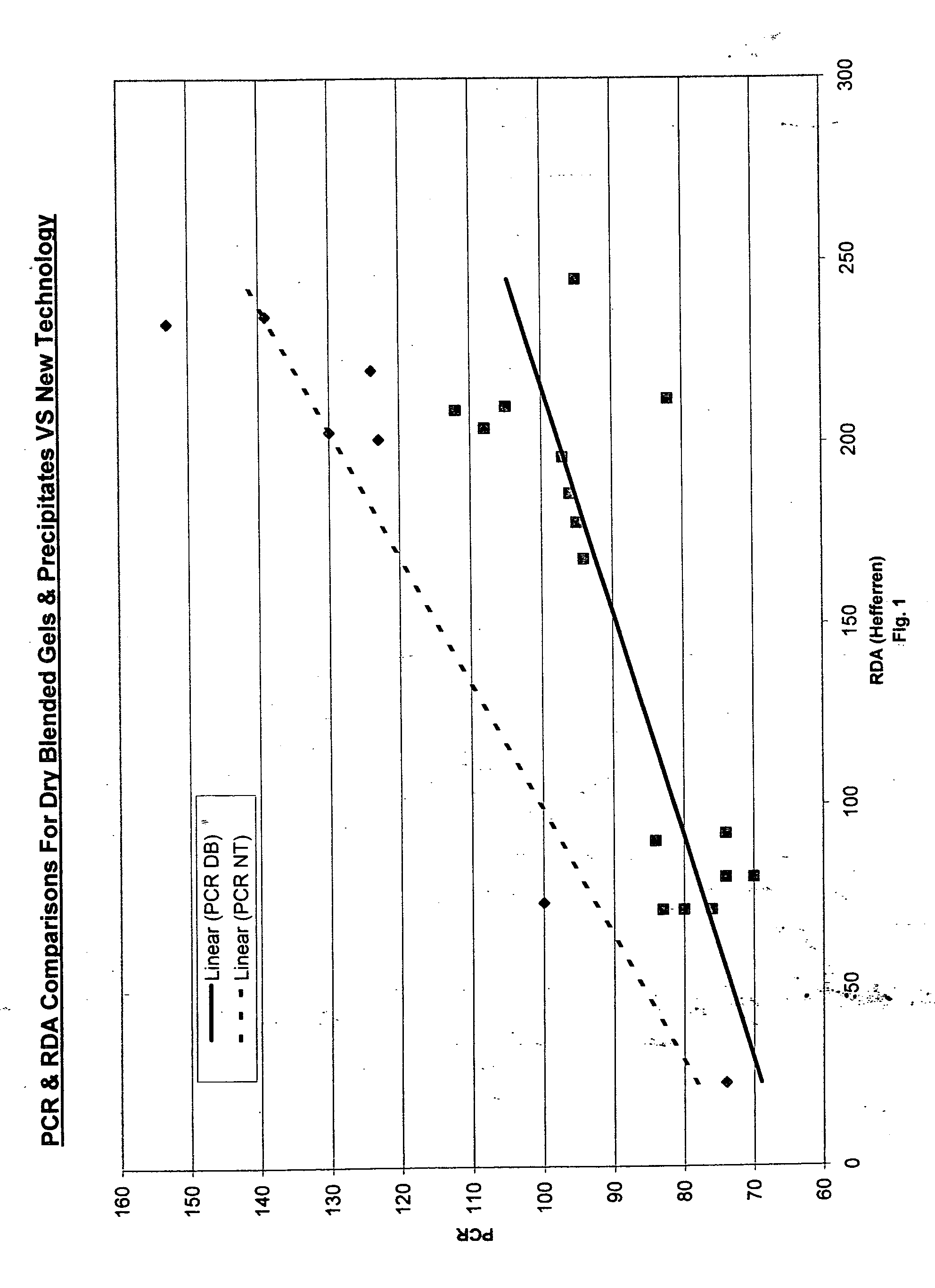

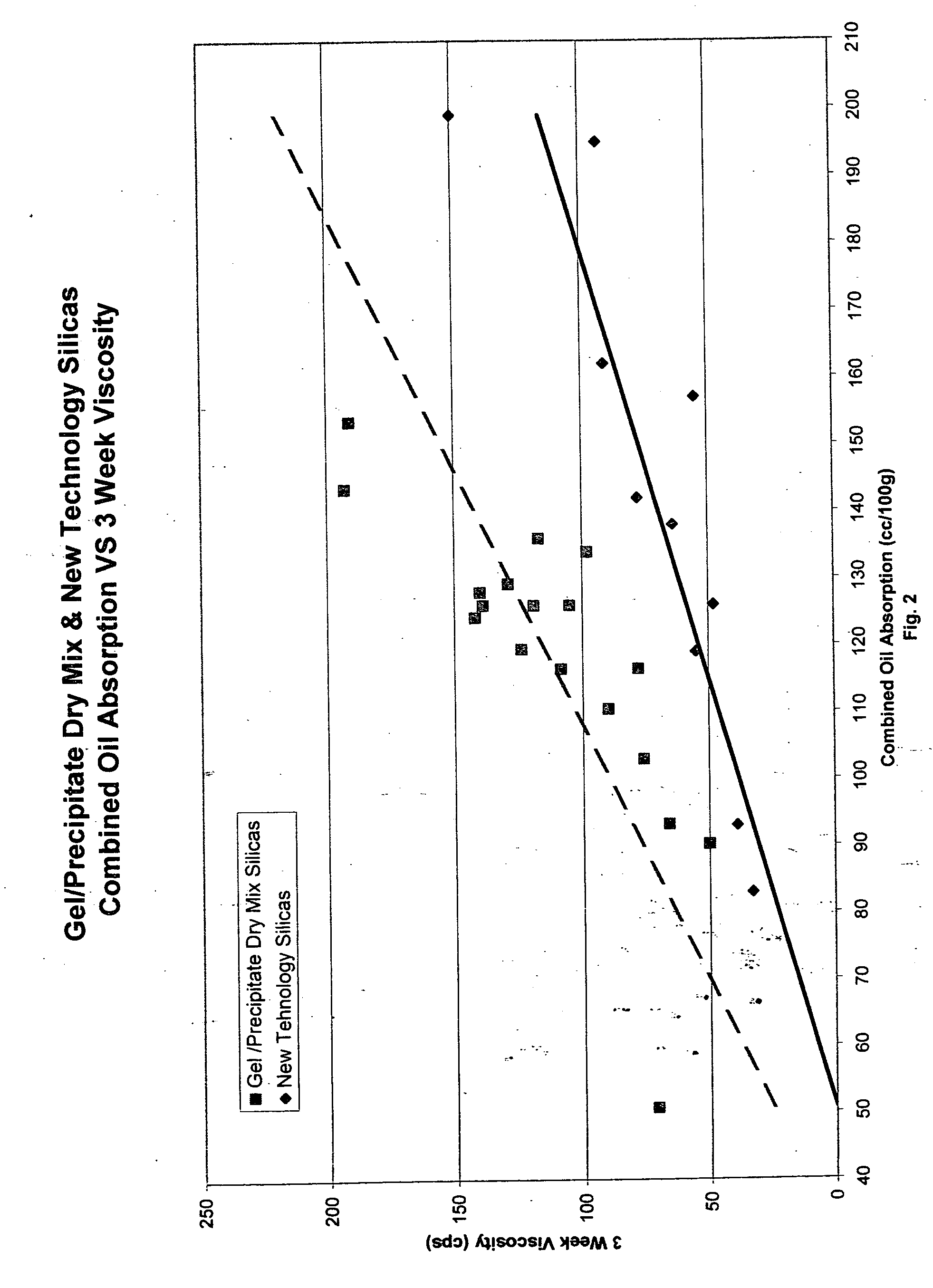

High-cleaning silica materials made via product morphology control and dentifrice containing such

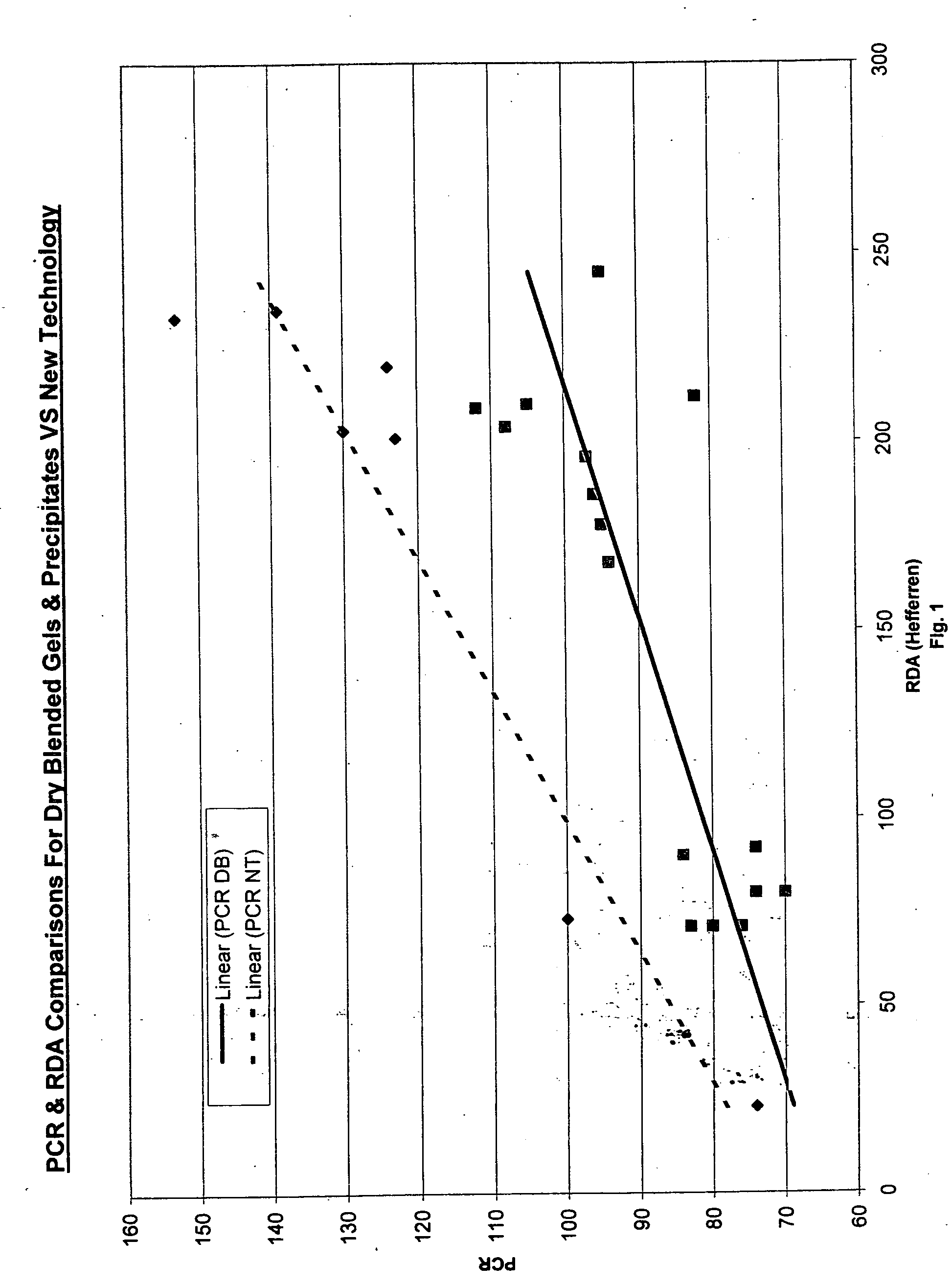

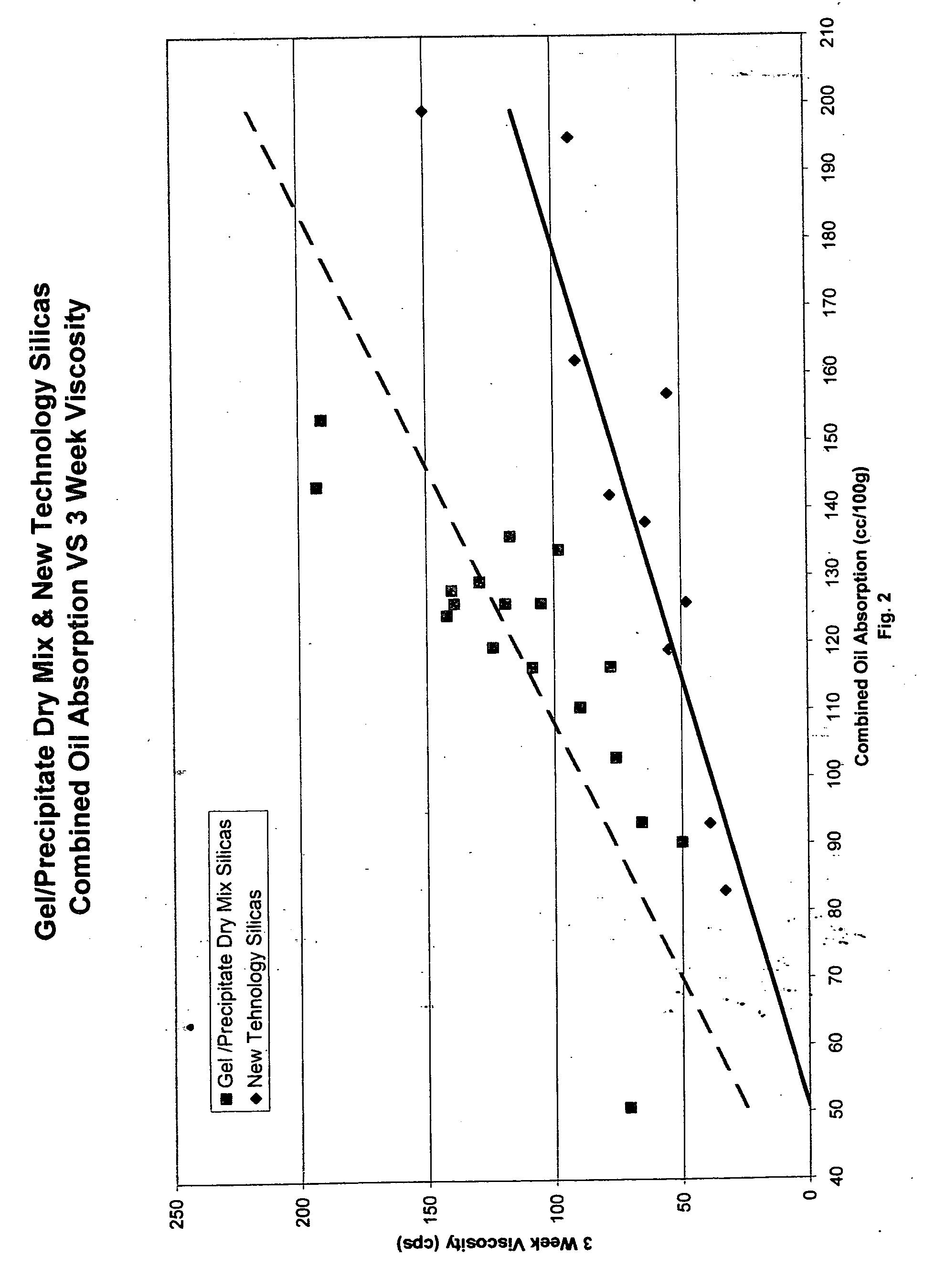

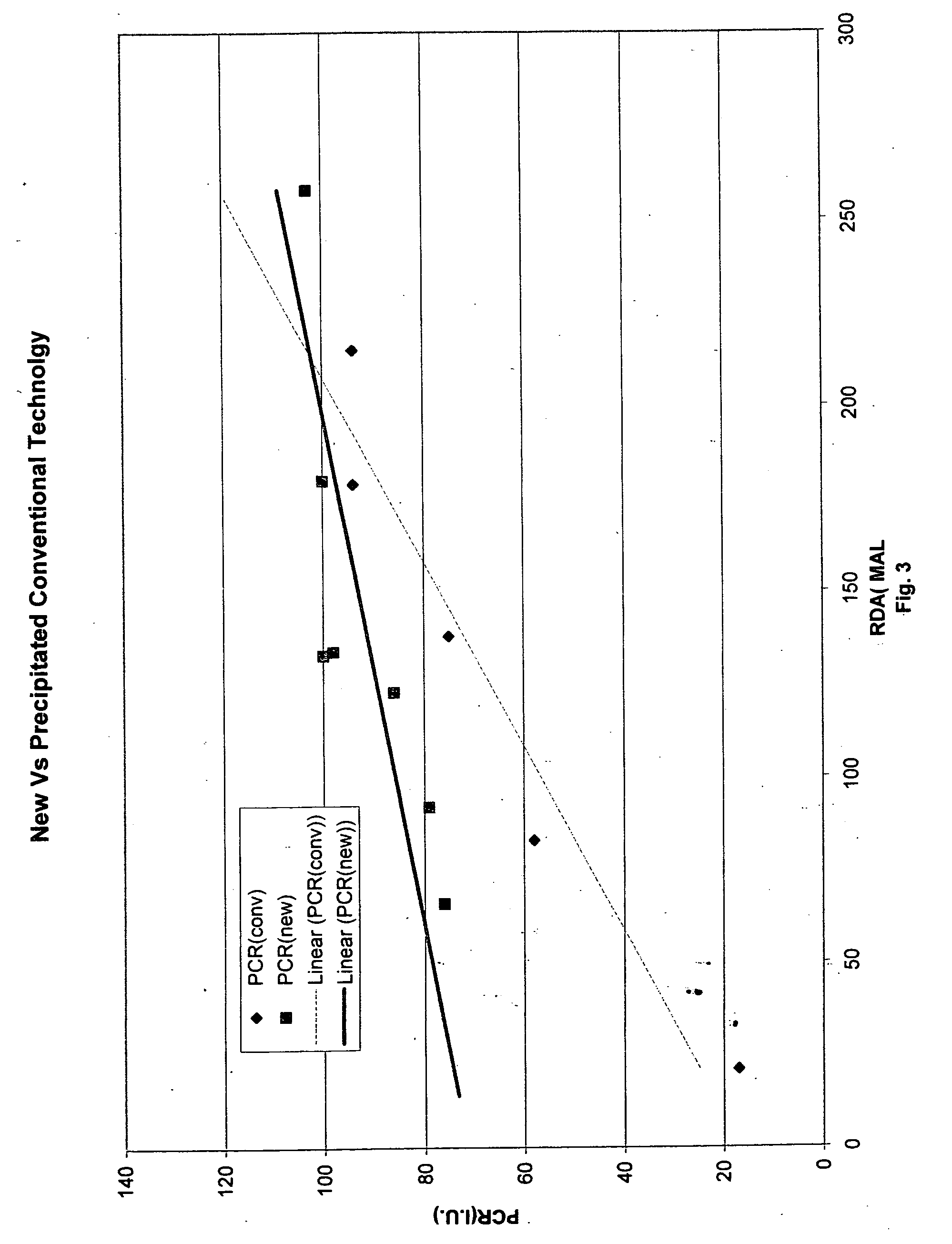

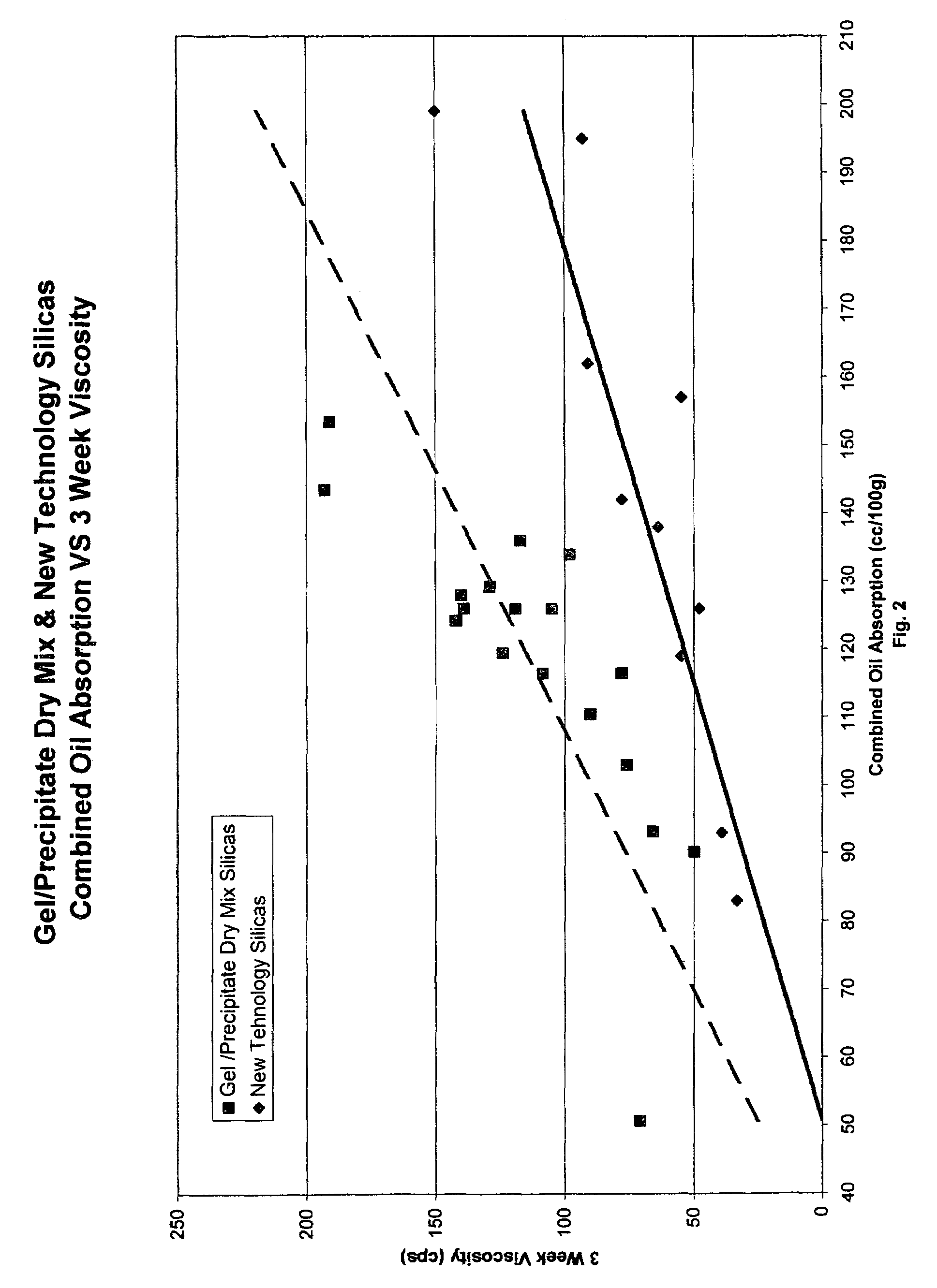

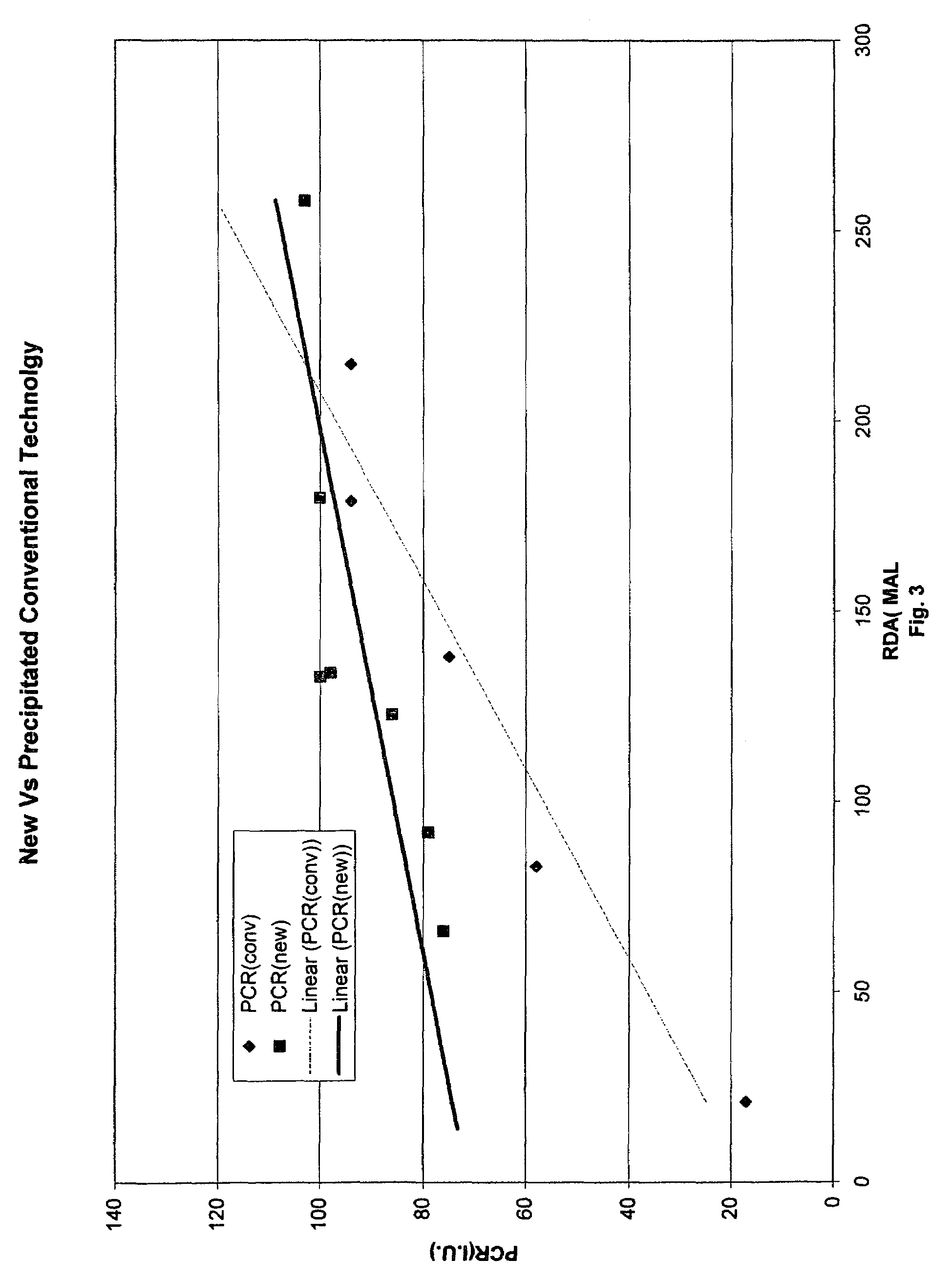

InactiveUS20060110307A1Excellent thickening propertyDesirable abrasivePigmenting treatmentCosmetic preparationsClean teethViscosity

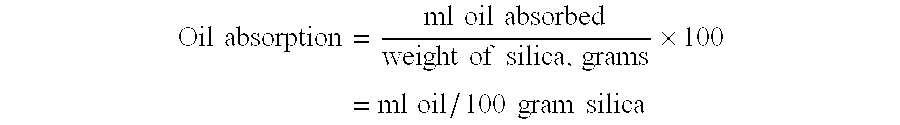

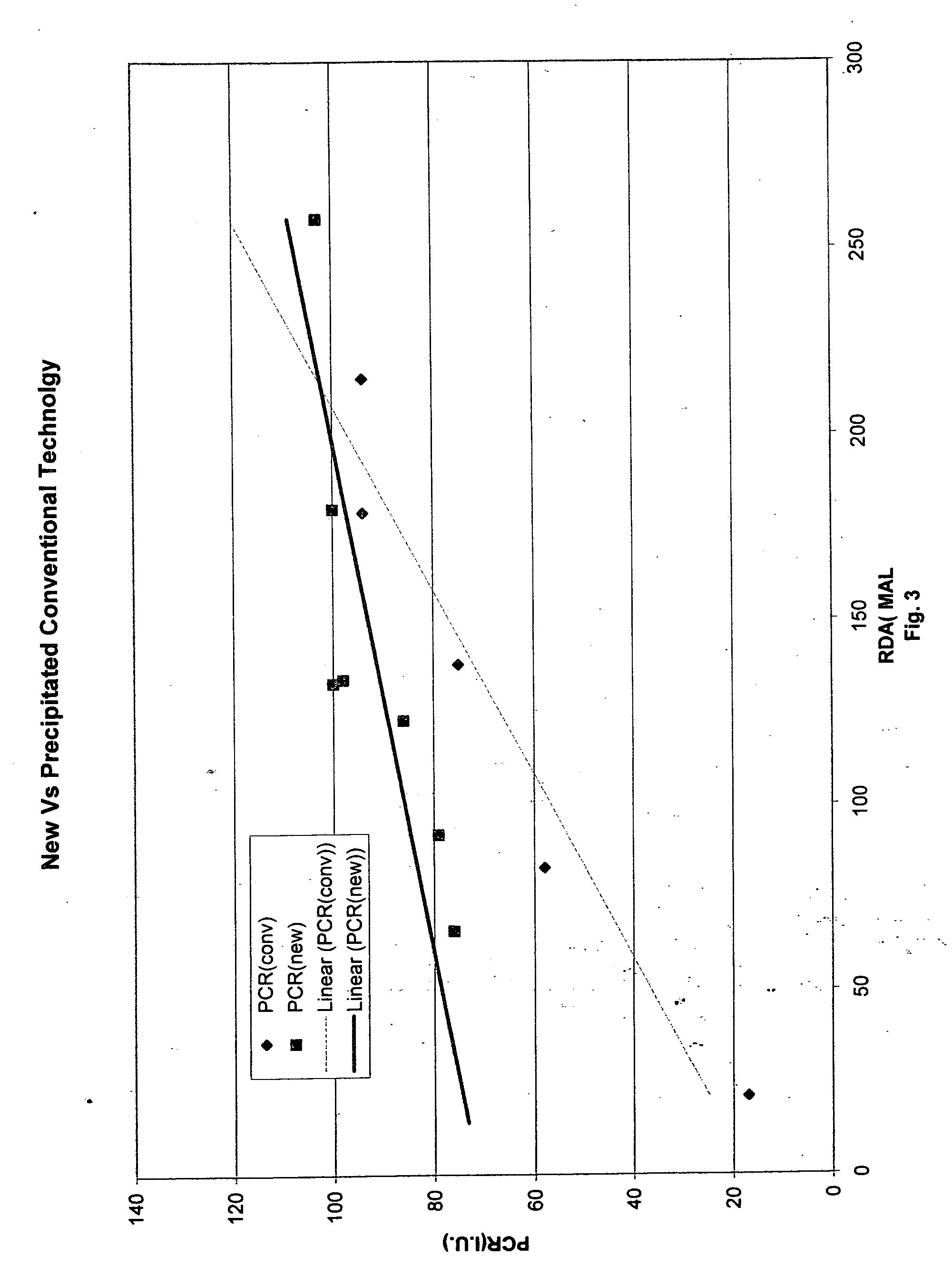

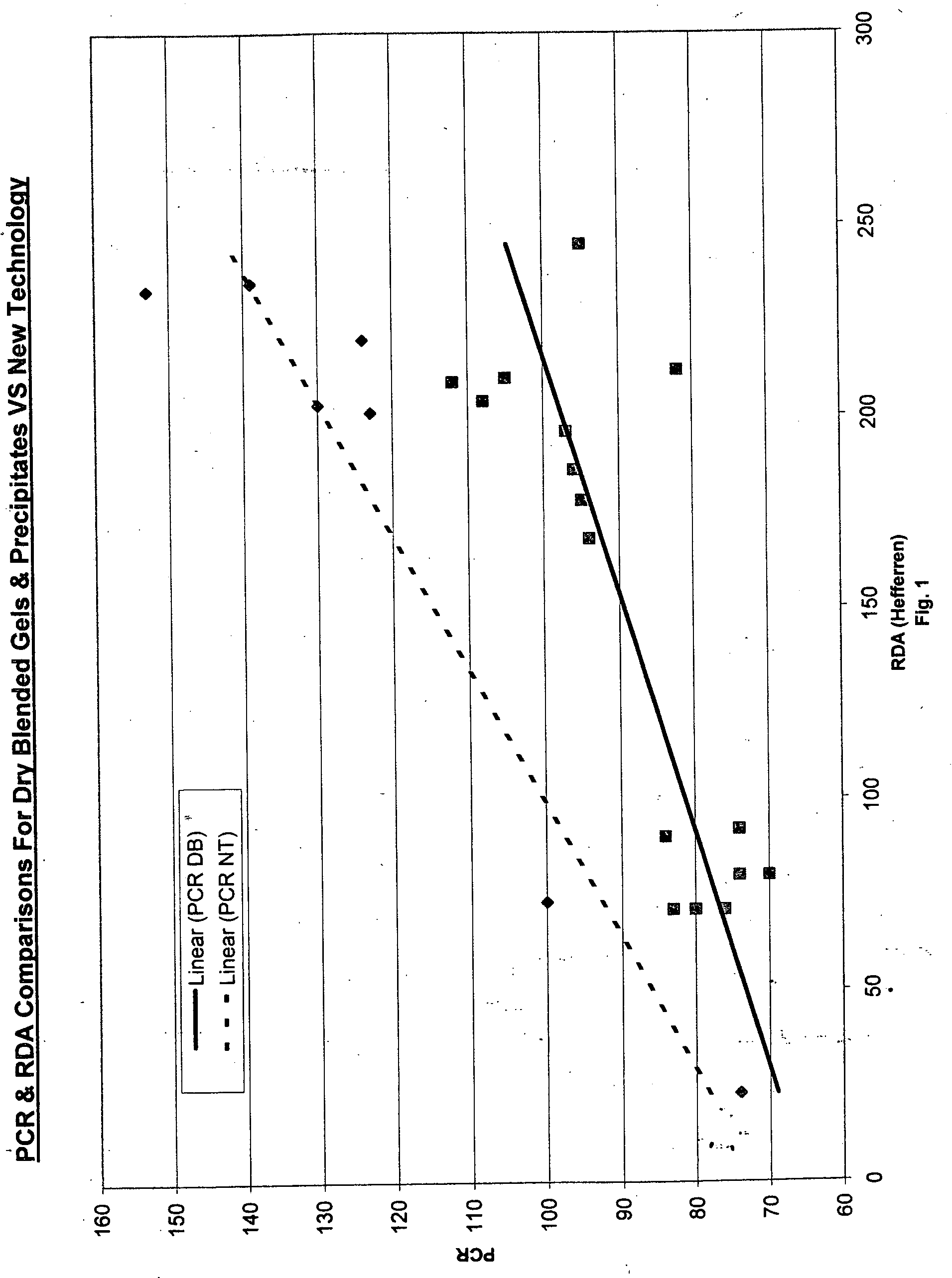

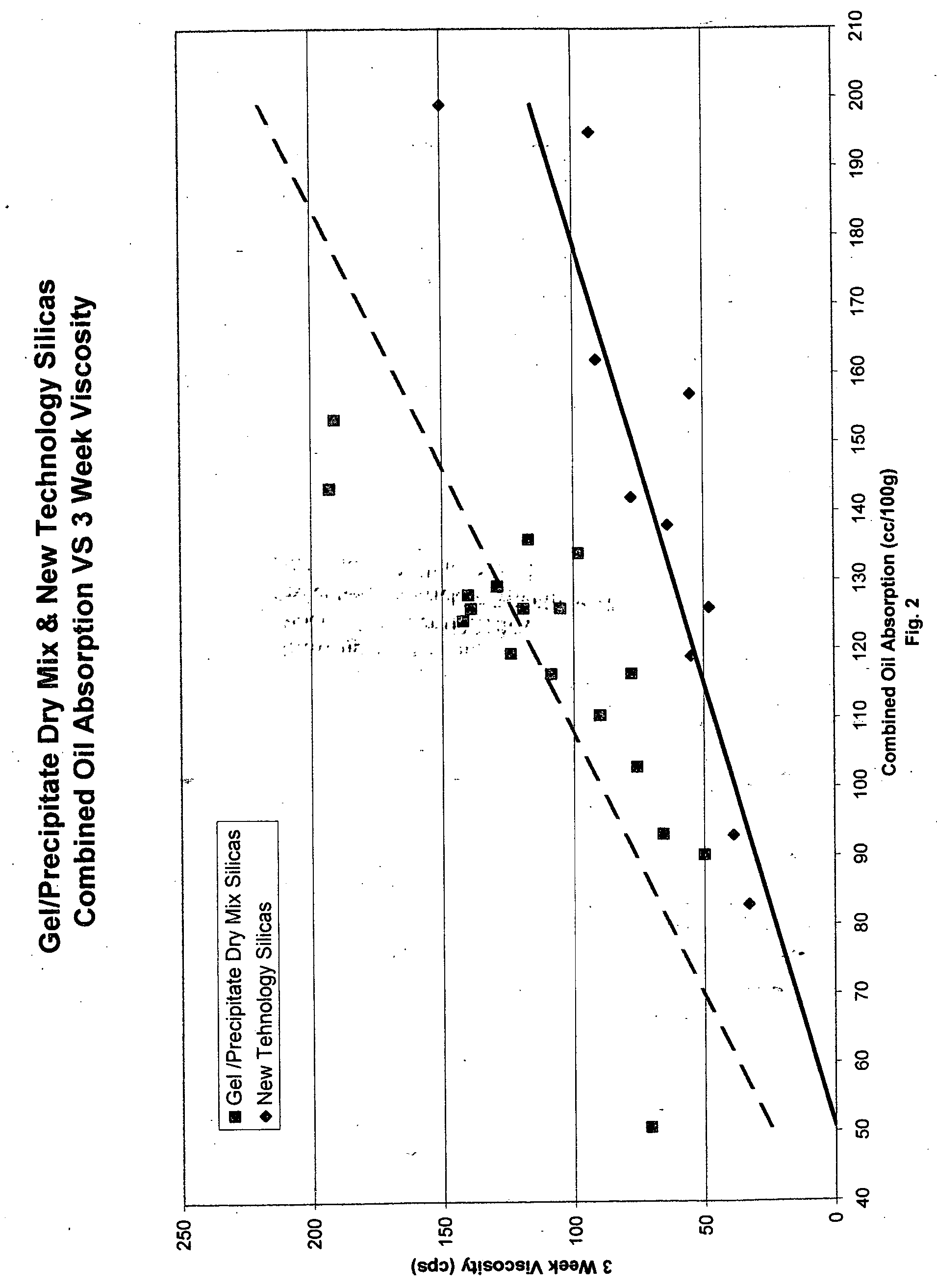

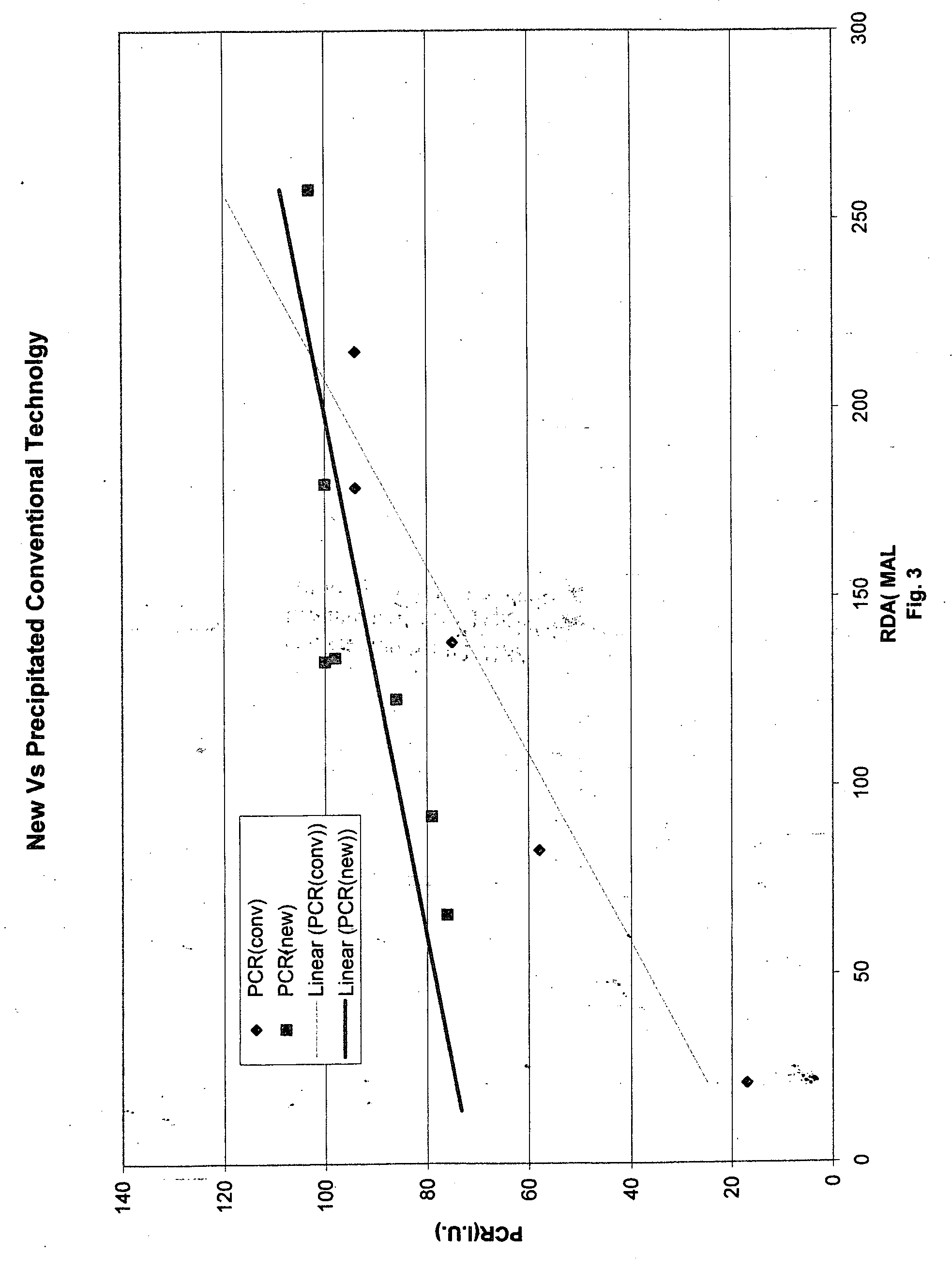

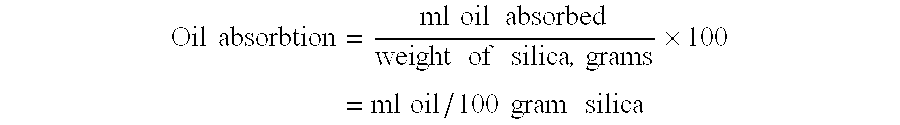

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Alumina/zirconia ceramics and method of producing the same

InactiveUS7148167B2Excellent abrasionHigh hardnessCeramic shaping apparatusClaywaresHigh fractureHardness

Owner:KYOCERA CORP

Sintered sliding material, sliding member, connection device and device provided with sliding member

InactiveUS20070009757A1Excellent seizing resistanceExcellent abrasion resistanceThermometers using material expansion/contactionShaftsVolumetric Mass DensityRelative density

A sintered sliding material, a sliding member and a connecting device capable of demonstrating excellent seizing resistance and abrasion resistance under very bad lubricating conditions such as a high-bearing stress and slow-speed sliding condition and an oscillating condition can be provided. The sintered sliding material is composed of a sintered compact containing Cu or Cu alloy in an amount of 10 to 95 wt % and a residue made of Mo principally, in which the sintered compact has a relative density of 80% or more.

Owner:KOMATSU LTD

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS20060110338A1Desirable abrasiveGood thickening effectPigmenting treatmentCosmetic preparationsSilica gelSilicon dioxide

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Sintered material, ferrous sintered sliding material, producing method of the same, sliding member, producing method of the same and coupling device

InactiveUS20120177528A1Excellent abrasion resistanceImprove the lubrication effectShaftsSoil-shifting machines/dredgersPowder mixtureGraphite particle

An iron-based sintered sliding material includes: a sintered structure which contains 10-50 wt. % copper and 1-15 wt. % carbon and has been formed by sintering a powder mixture obtained by mixing at least one of an Fe—Cu alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and an Fe—Cu—C alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and containing carbon in an amount of 0-5 wt. %, excluding 0 wt. %, with a graphite powder and at least one of a copper powder and a copper alloy powder; and graphite particles dispersed in the sintered sliding material in an amount of 1-14 wt. % or 3-50 vol. %.

Owner:KOMATSU LTD

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS7267814B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsPigmenting treatmentCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

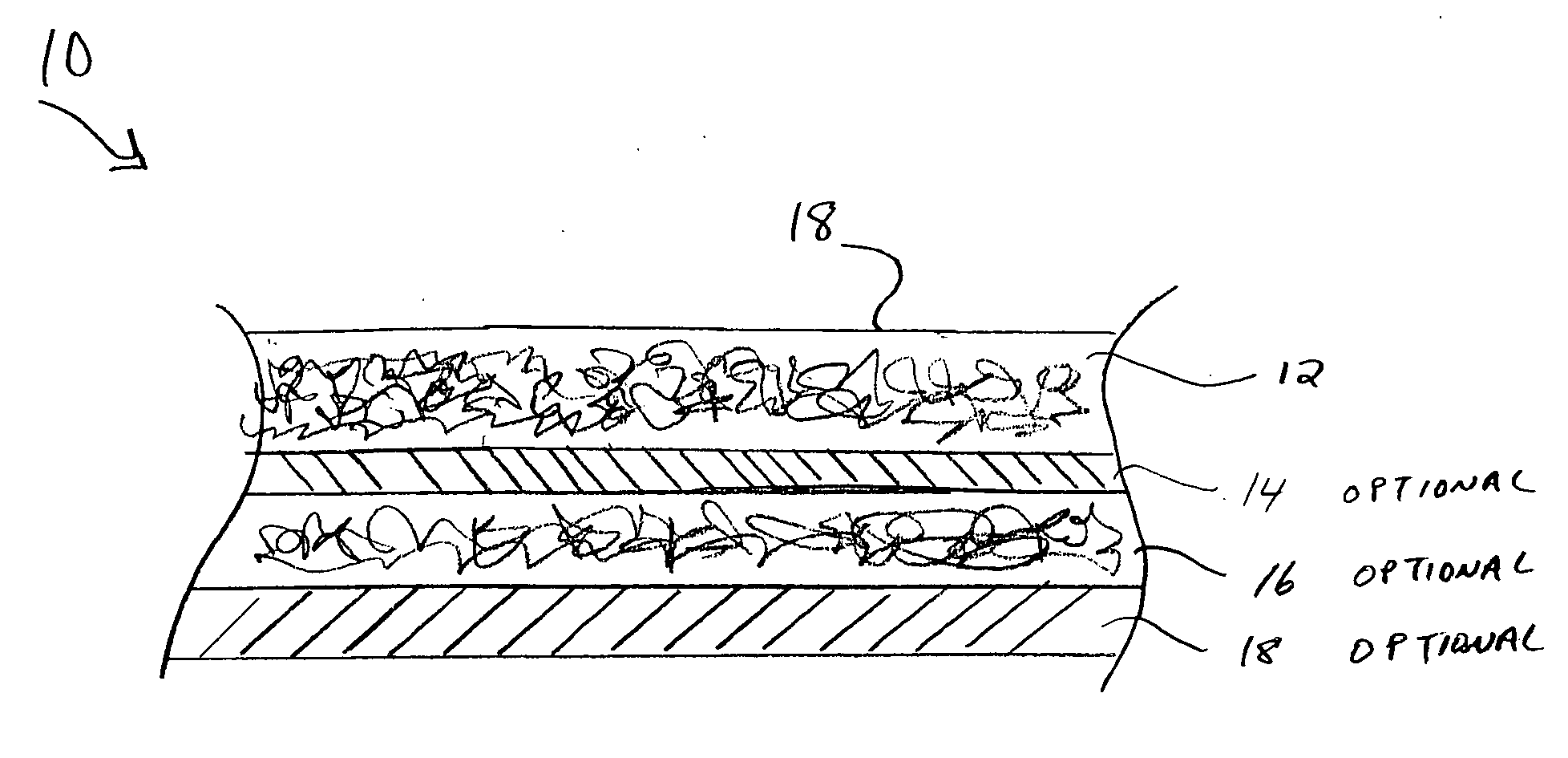

Fire-retardant, lightweight aircraft carpet

InactiveUS20060240217A1Increased durabilityImprove acousticsLayered product treatmentFloor coveringsFiberEngineering

The present invention is a lightweight carpet for use in aircrafts that meets rigorous fire standards testing, is impervious to fluids, and is capable of being printed for decorative effect. In one embodiment, the carpet composed of a layer of fire retardant treated PET fibers adhered to a fire retardant treated PE film. This carpet is durable to normal foot traffic, resistant to most stains, non-fraying, and can be recycled.

Owner:FOSS MFG CO LLC

High-cleaning/moderate abrasive silica materials and dentifrice containing such materials

InactiveUS7306788B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsSilicaLinseed oilSilica gel

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

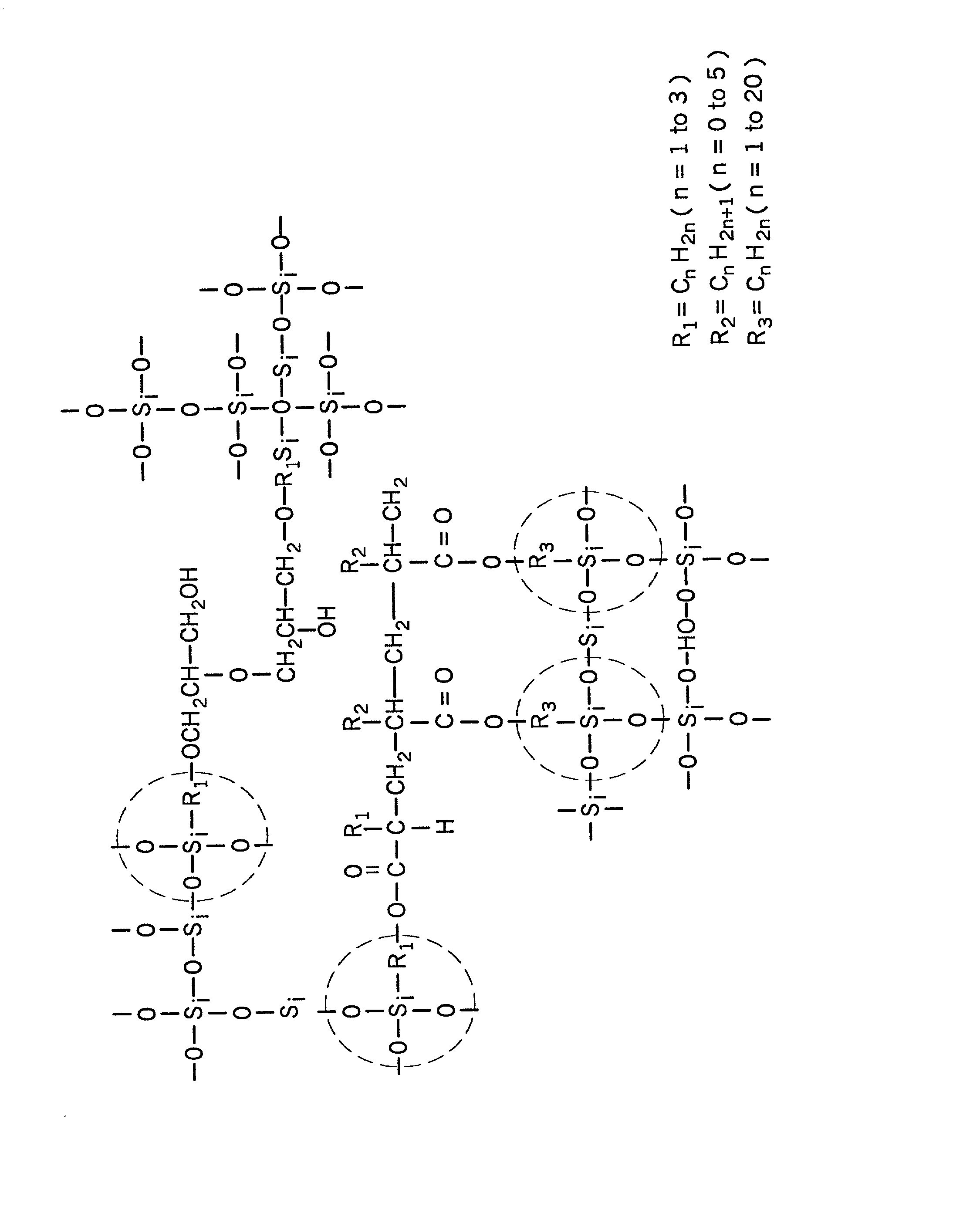

Organic-inorganic hybrid polymer and method of making same

InactiveUS20020127330A1High densityExcellent abrasionSynthetic resin layered productsPretreated surfacesSilanesMolecular level

An optically clear protective thin film having covalent chemical bonds on a molecular level between organic polymer and in situ generated silica molecules is formed from a hydrolyzed coating solution of tetraalkyl orthosilicate, epoxyalkylalkoxy silanes, (math)acryloxyalkylalkoxy silanes and solvent.

Owner:JIN DAN L +1

Insulated wire

ActiveUS20110226508A1Excellent solvent resistance and abrasion resistanceHigh voltagePlastic/resin/waxes insulatorsInsulated cablesResilient modulusMelt viscosity

An inverter surge-resistant insulated wire, having an enamel baked layer, an adhesive layer, and an extrusion-coated resin layer, around the outer periphery of a conductor, wherein the sum of the thickness of the enamel baked layer, the extrusion-coated resin layer, and the adhesive layer is 60 μm or more, wherein the thickness of the enamel baked layer is 50μm or less, and wherein the extrusion-coated resin layer is formed from a polyphenylene sulfide resin composition, which contains a polyphenylene sulfide polymer having a melt viscosity at 300° C. of 100 Pa·s or more, 2 to 8 mass % of a thermoplastic elastomer, and an antioxidant, and which has a tensile modulus of elasticity at 25° C. of 2,500 MPa or more, and a tensile modulus of elasticity at 250° C. of 10 MPa or more.

Owner:ESSEX FURUKAWA MAGNET WIRE JAPAN CO LTD +2

High-cleaning silica materials made via product morphology control under high shear conditions

InactiveUS20070224133A1Desirable abrasiveIncrease brightnessCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Alumina/zirconia ceramics and method of producing the same

InactiveUS20050049137A1Excellent abrasionHigh hardnessCeramic shaping apparatusClaywaresCeramicHardness

Alumina / zirconia ceramics containing Al2O3 in an amount of not less than 65 mass % and ZrO2 in an amount of 4 to 34 mass %, and further containing TiO2, MgO and SiO2. The ceramics effectively suppresses the growth of shape isotropic particles of alumina, suppresses the growth of zirconia particles, and has a high strength and a high hardness. Besides, the ceramics containing SrO features a high fracture toughness.

Owner:KYOCERA CORP

Bearing for motorized fuel pump

ActiveUS20090011268A1Excellent abrasion resistanceImprove corrosion resistanceBearing componentsThin material handlingPorosityGraphite

Owner:AISAN IND CO LTD +1

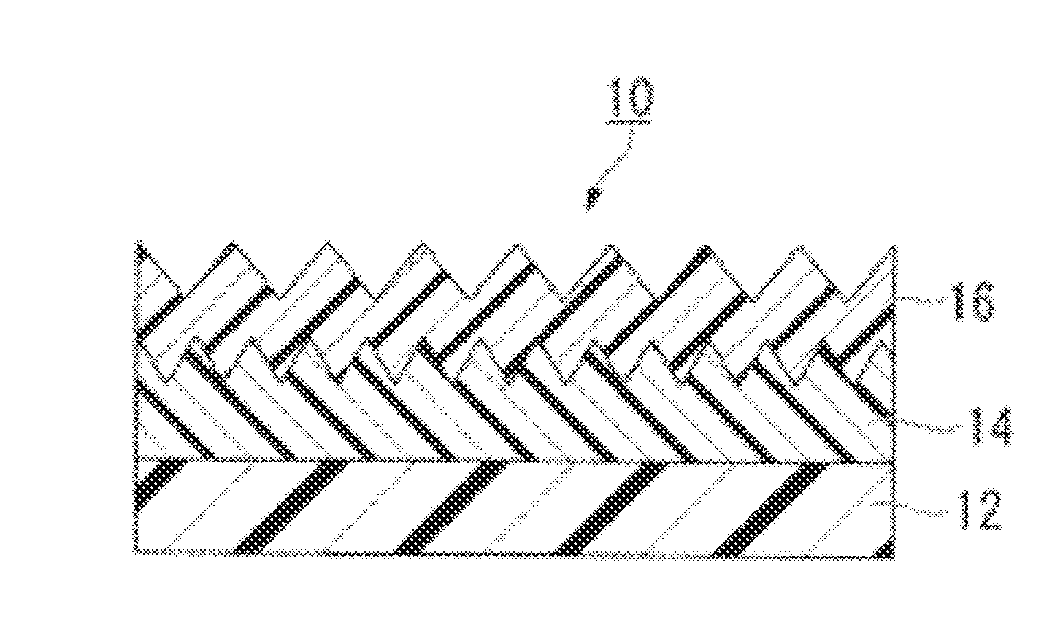

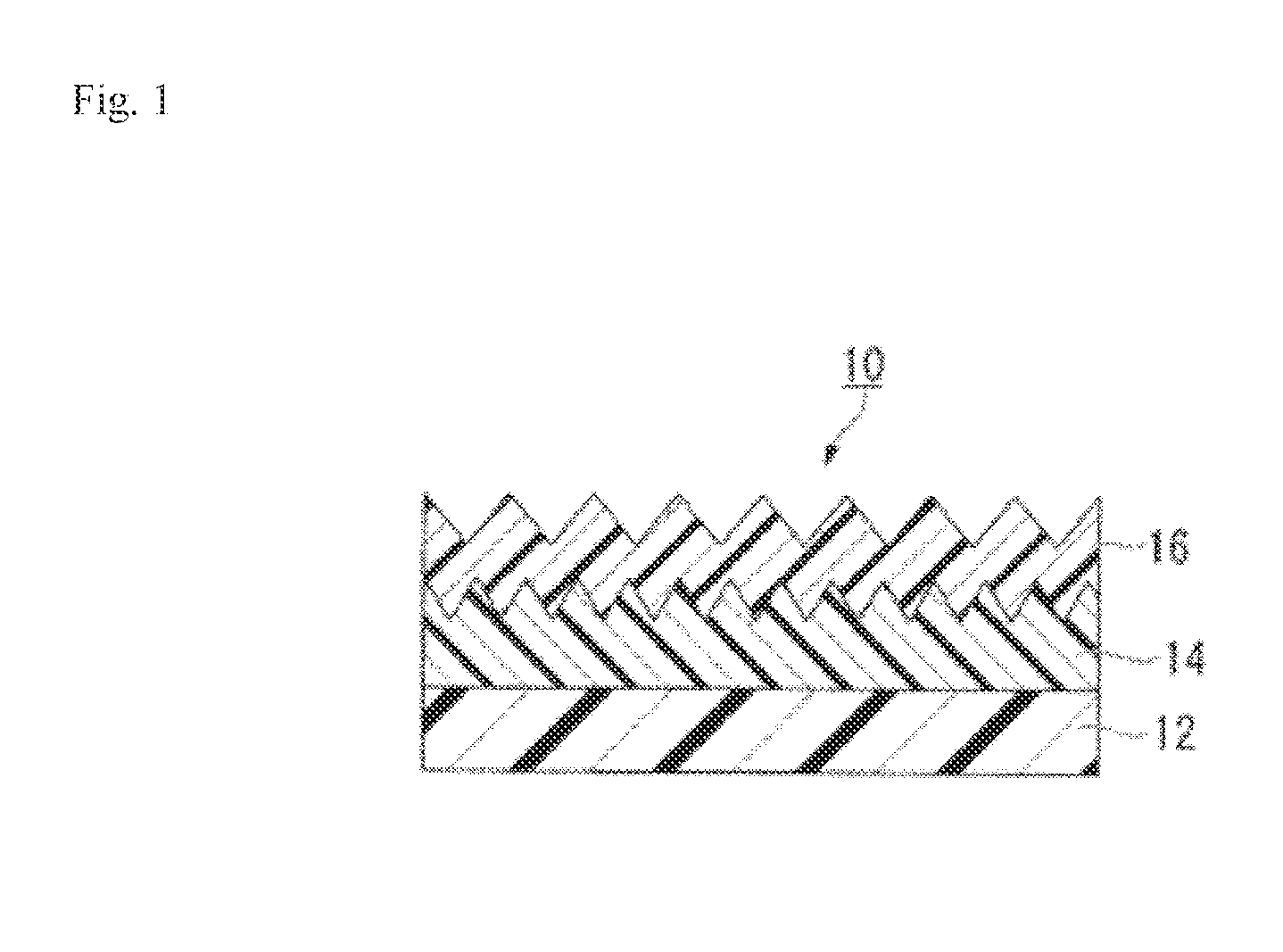

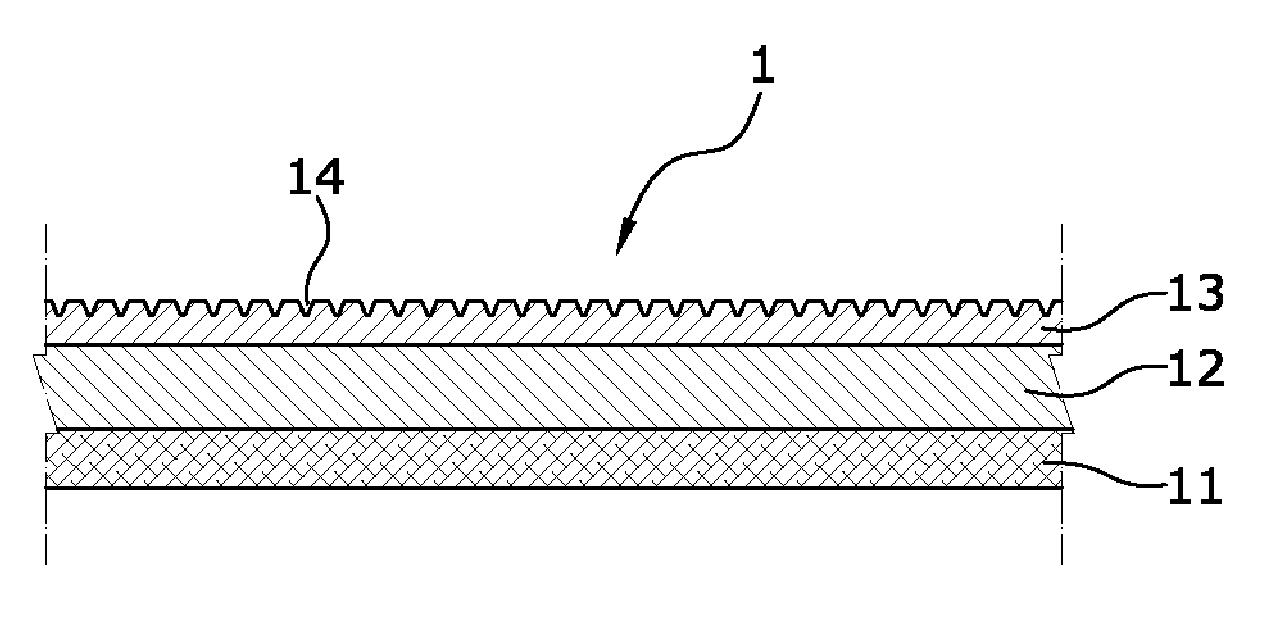

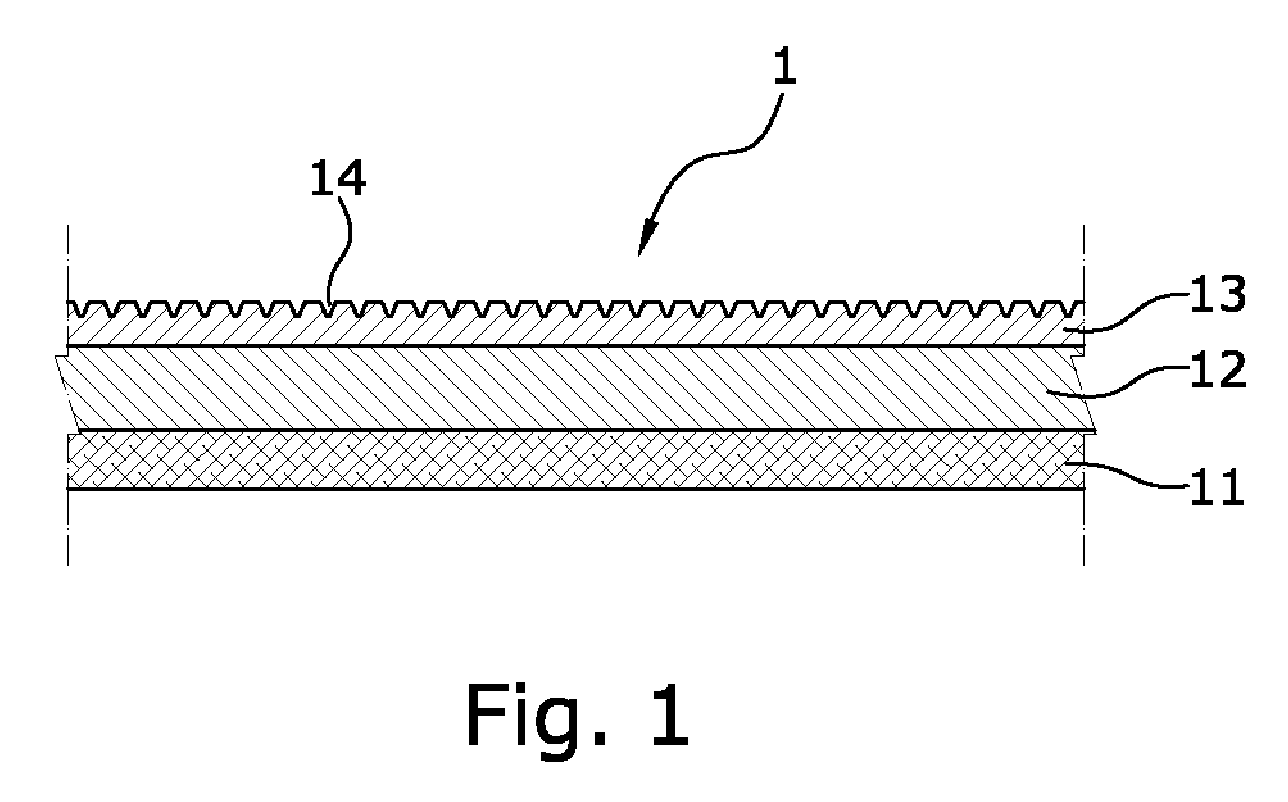

Multilayer structure, method for producing same, and article

InactiveUS20160082688A1Improve performanceIncrease resistanceSynthetic resin layered productsRecord information storageHardnessLength wave

A base, an intermediate layer and an outermost layer are sequentially laminated. The intermediate layer has a Martens hardness of 120 N / mm2 or more; outermost layer has an- elastic modulus recovery ratio of 70% or more; and surface of outermost layer is provided with microrelief structure that has pitch not more than the wavelength of visible light. A method for producing the multilayer structure, comprises an active energy ray curable resin composition having a polymerizable functional group arranged on a light-transmitting base, and active energy ray irradiation carried out, forming an intermediate layer with rate of reaction of the polymerizable functional group in the surface is 35-85% by moleStep; an active energy ray curable resin composition (Y) arranged between the intermediate layer and a mold for microrelief structure transfer Step; and second active energy ray irradiation is carried out from the base side, to form an outermost layer.

Owner:MITSUBISHI CHEM CORP

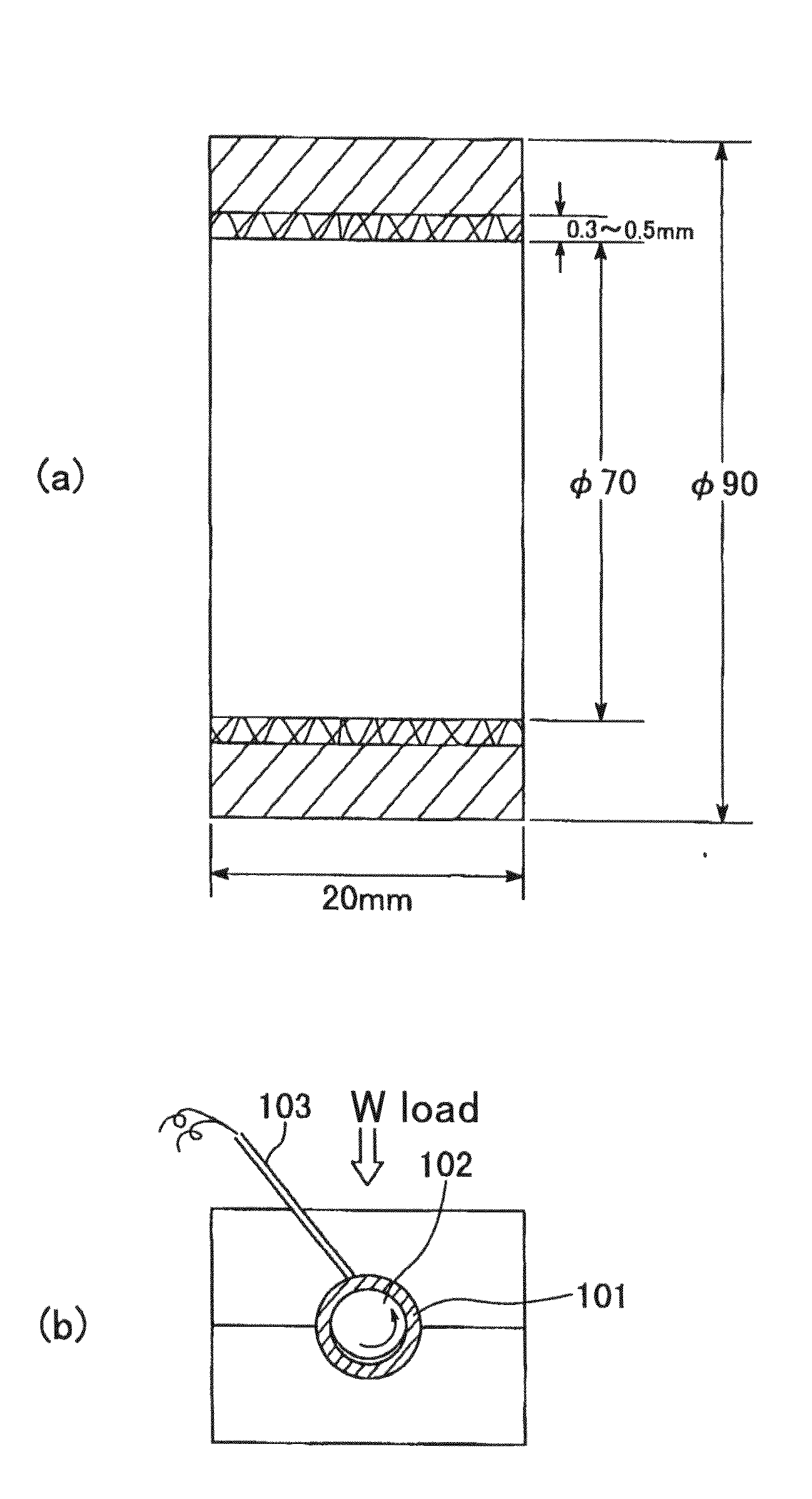

Ferrous Sintered Multilayer Roll-Formed Bushing, Producing Method of the Same and Connecting Device

InactiveUS20100227188A1Low coefficient of frictionExcellent seize resistance and abrasion resistanceBearing assemblyMetal-working apparatusLubricationDiffusion layer

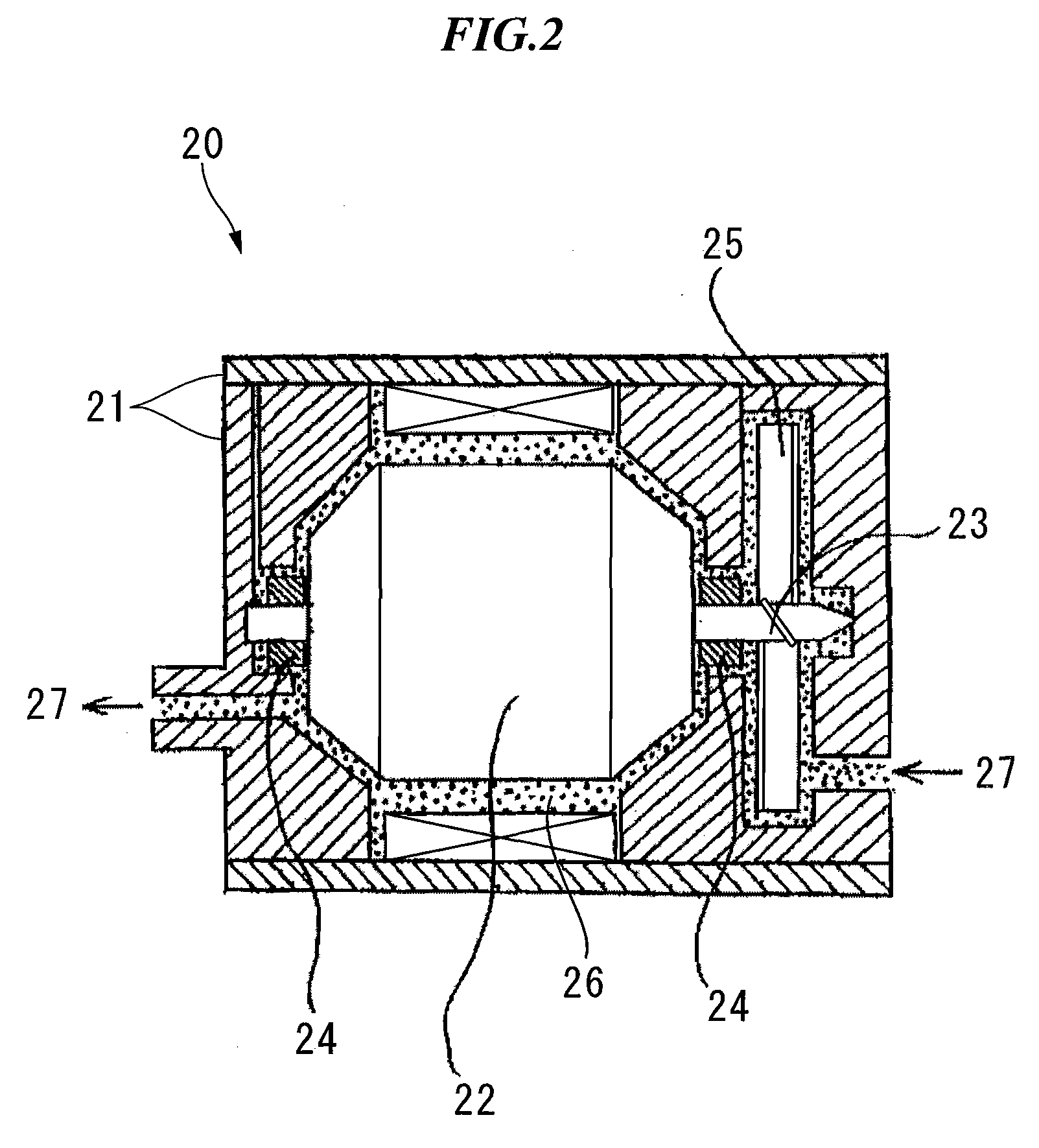

An economic ferrous sintered multilayer roll-formed bushing, a producing method of the same and a connecting device are provided, in which a ferrous sintered sliding material layer is tightly sintered-bonded to a back metal steel, the ferrous sintered sliding material layer being intended to have low coefficient of friction, having excellent seizing resistance and abrasion resistance and providing self-lubricating property so as to prolong a lubrication interval or eliminate the necessity of lubricating.The ferrous sintered multilayer roll-formed bushing according to the present invention comprises: a back metal steel; a ferrous sintered sliding material layer sinter-bonded to the back metal steel; a diffusion layer of ferrous alloy particle formed at the vicinity of the bonding boundary between the ferrous sintered sliding material layer and the back metal steel; and a Cu alloy phase formed at the vicinity of the bonding boundary and extending in the direction of the bonding boundary.

Owner:KOMATSU LTD

Viscosity-modifying silica materials that exhibit low cleaning and abrasive levels and dentifrices thereof

InactiveUS7303742B2Excellent abrasionImprove rendering capabilitiesCosmetic preparationsSilicaCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

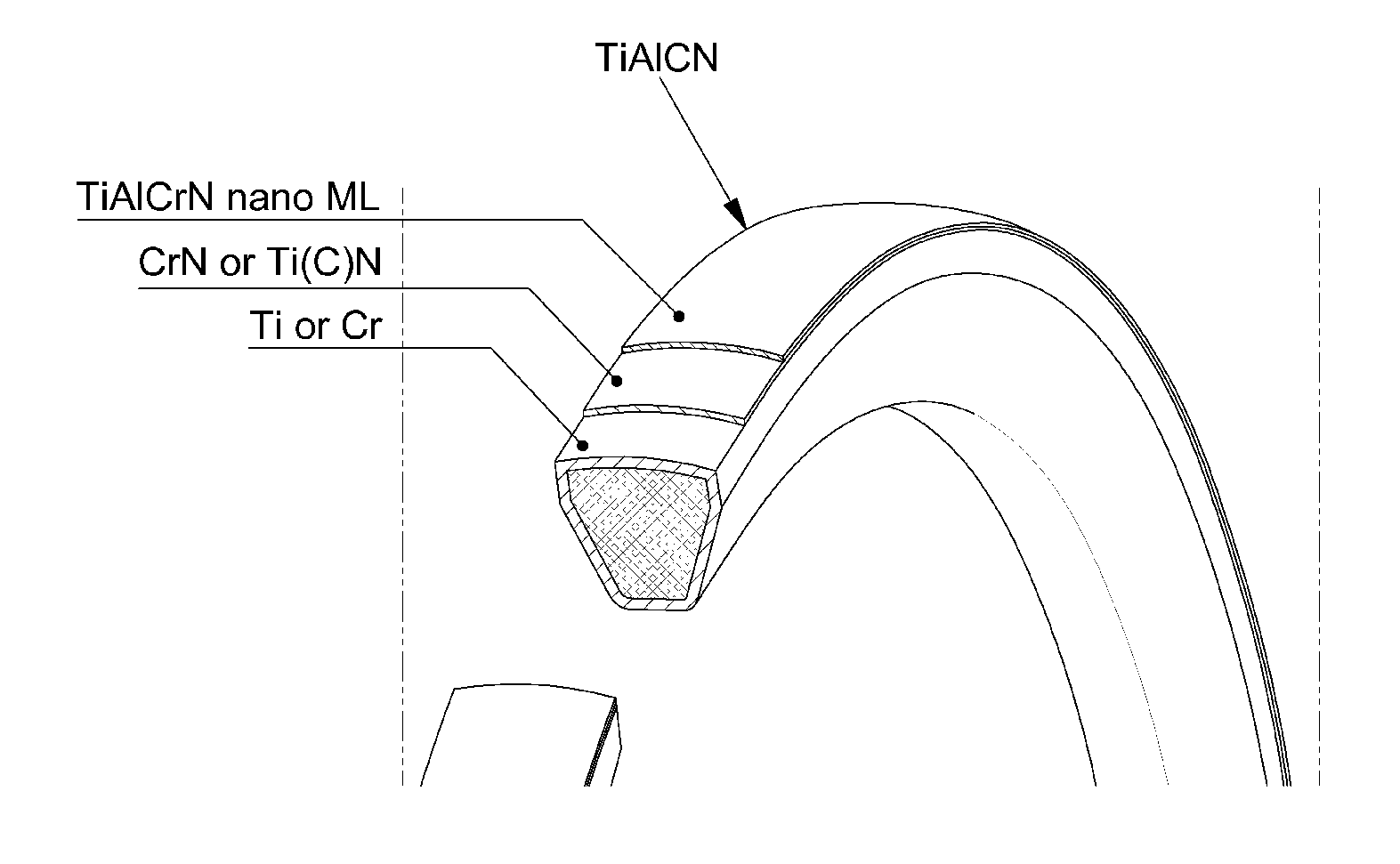

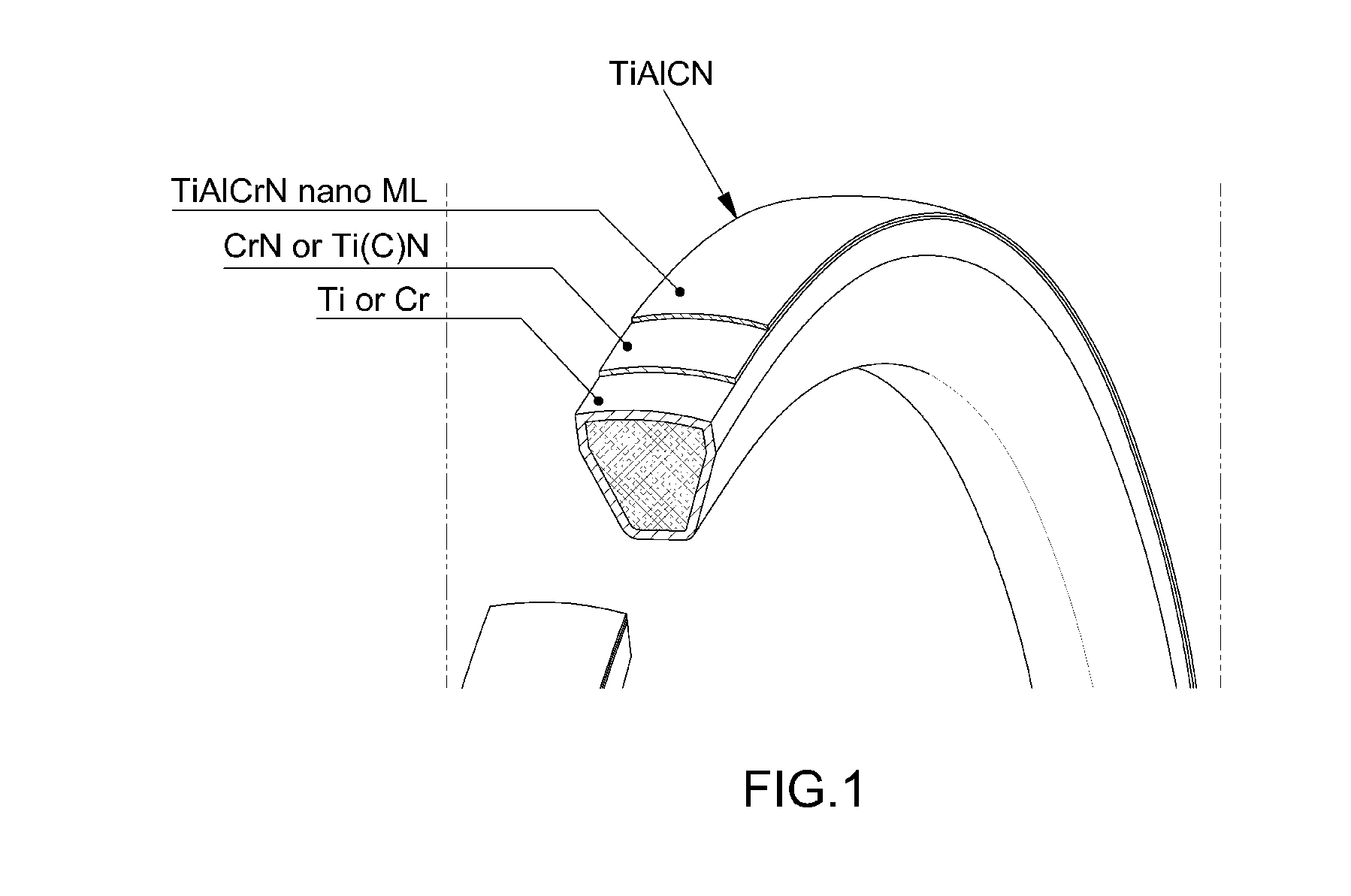

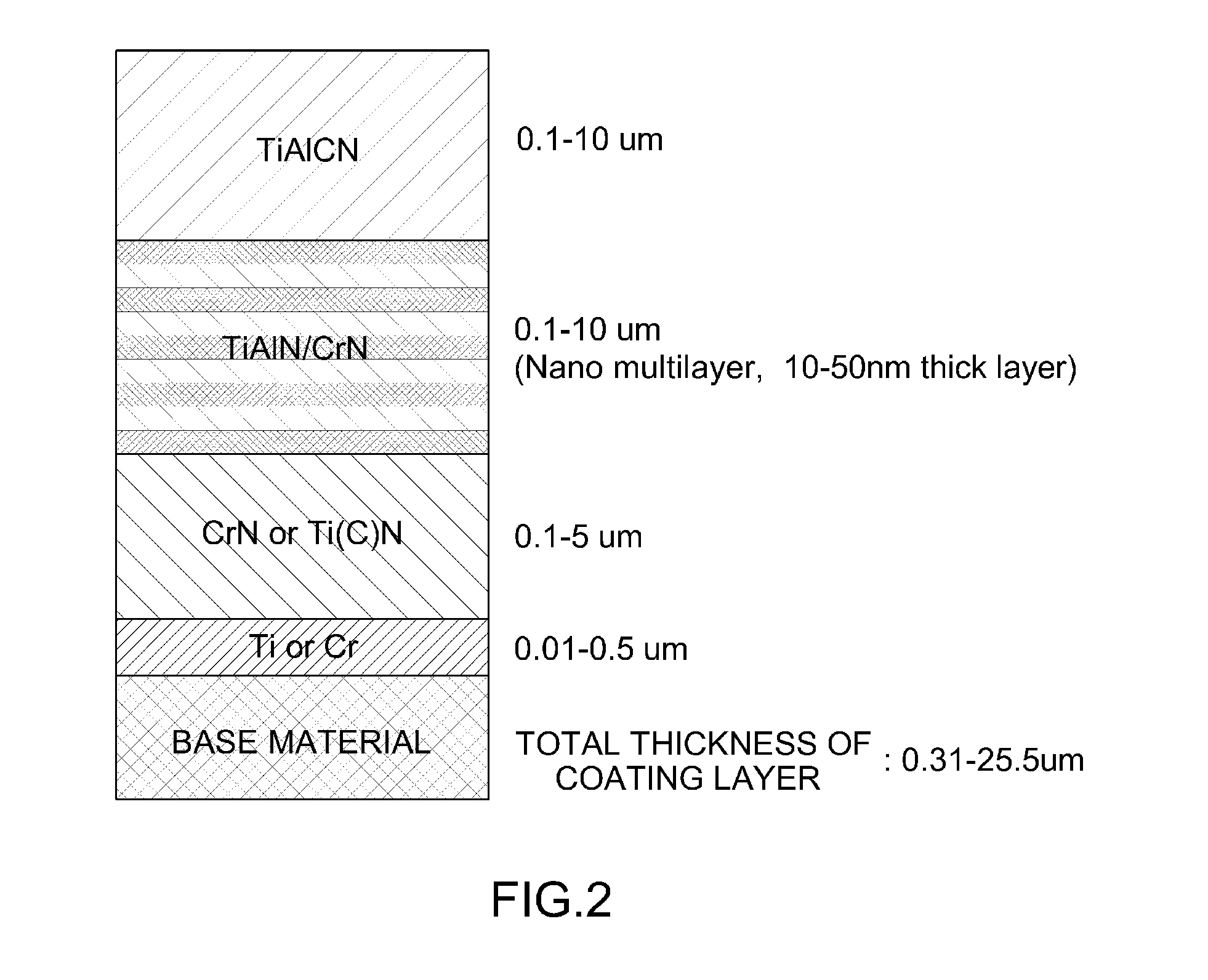

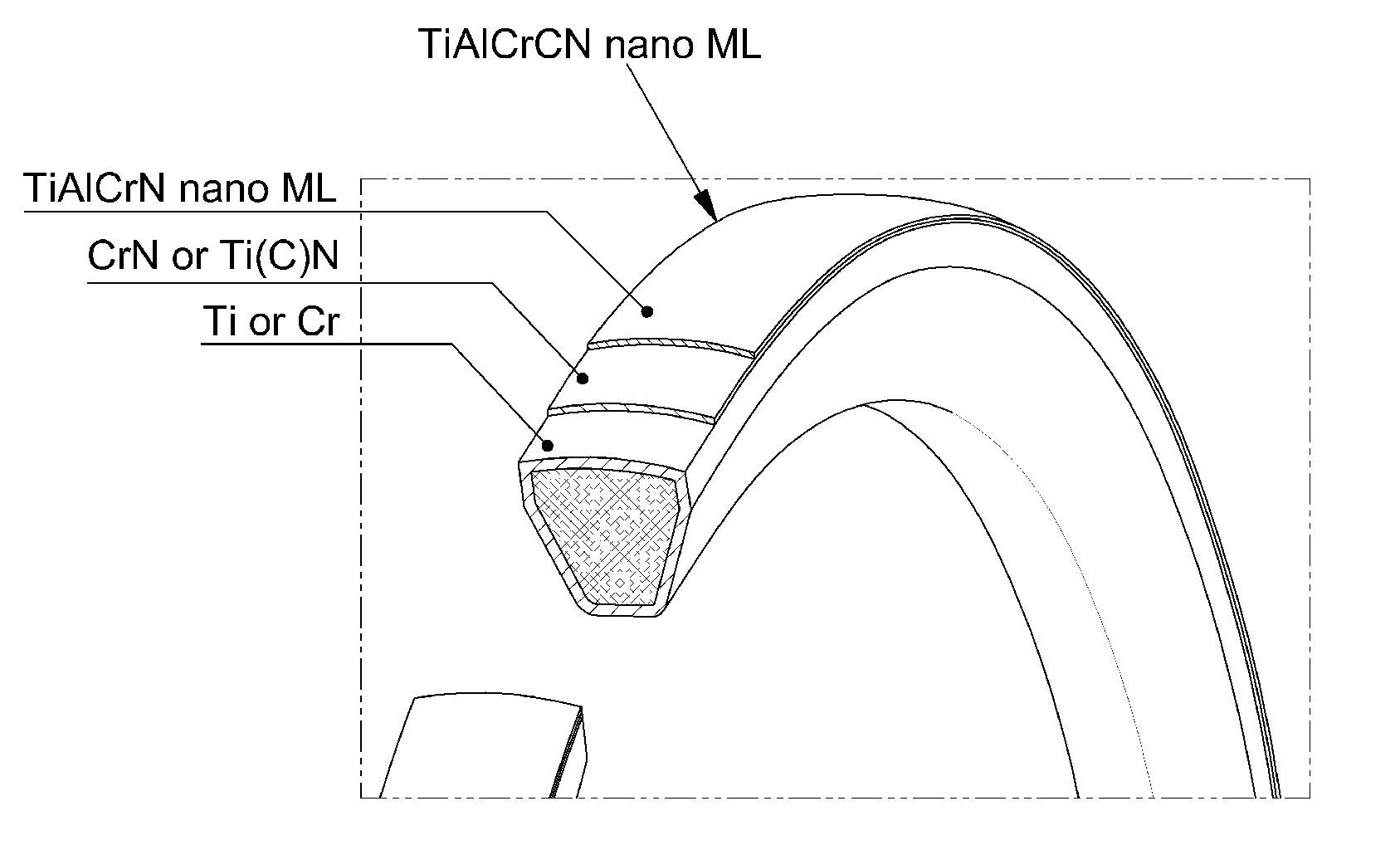

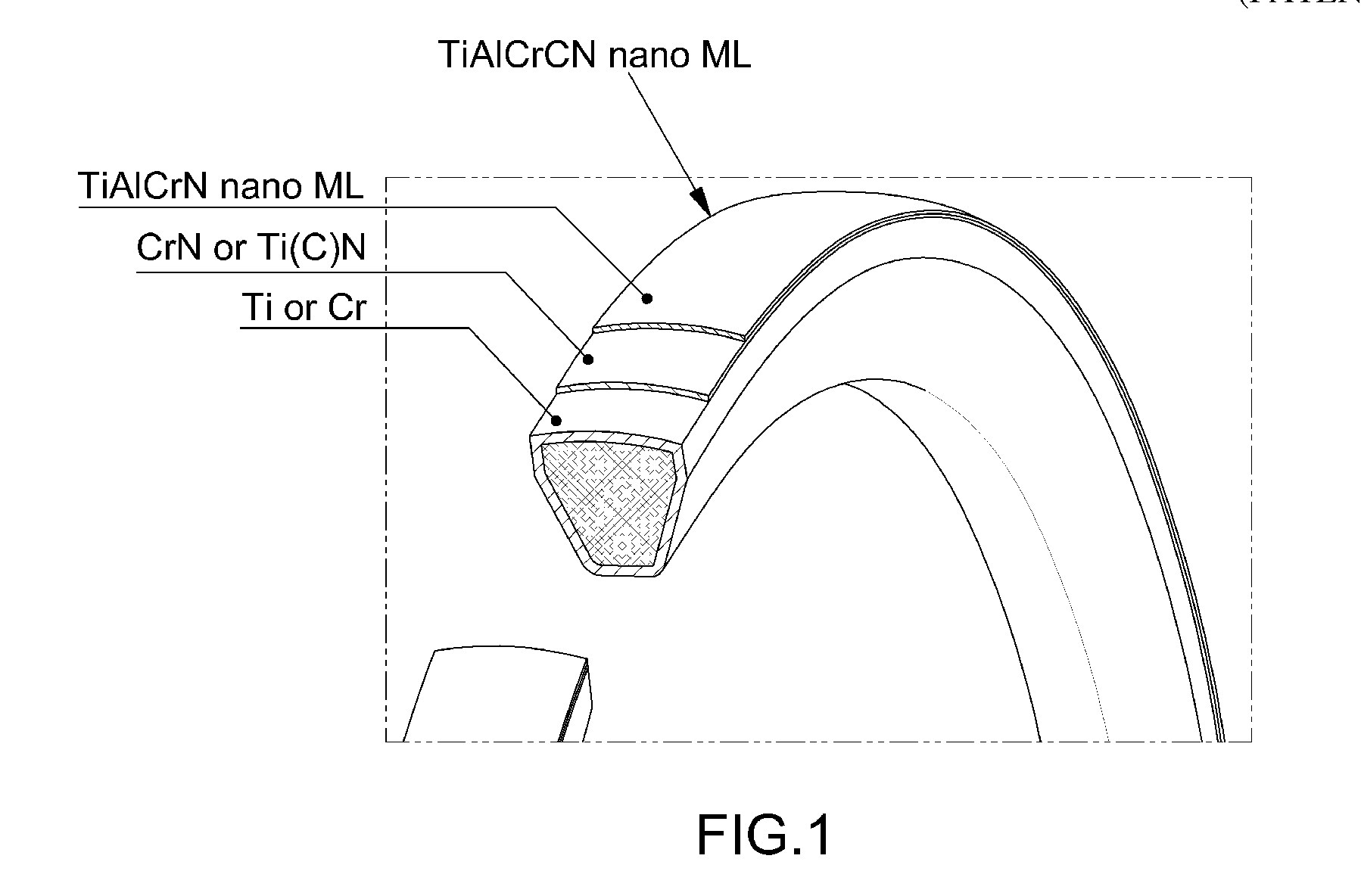

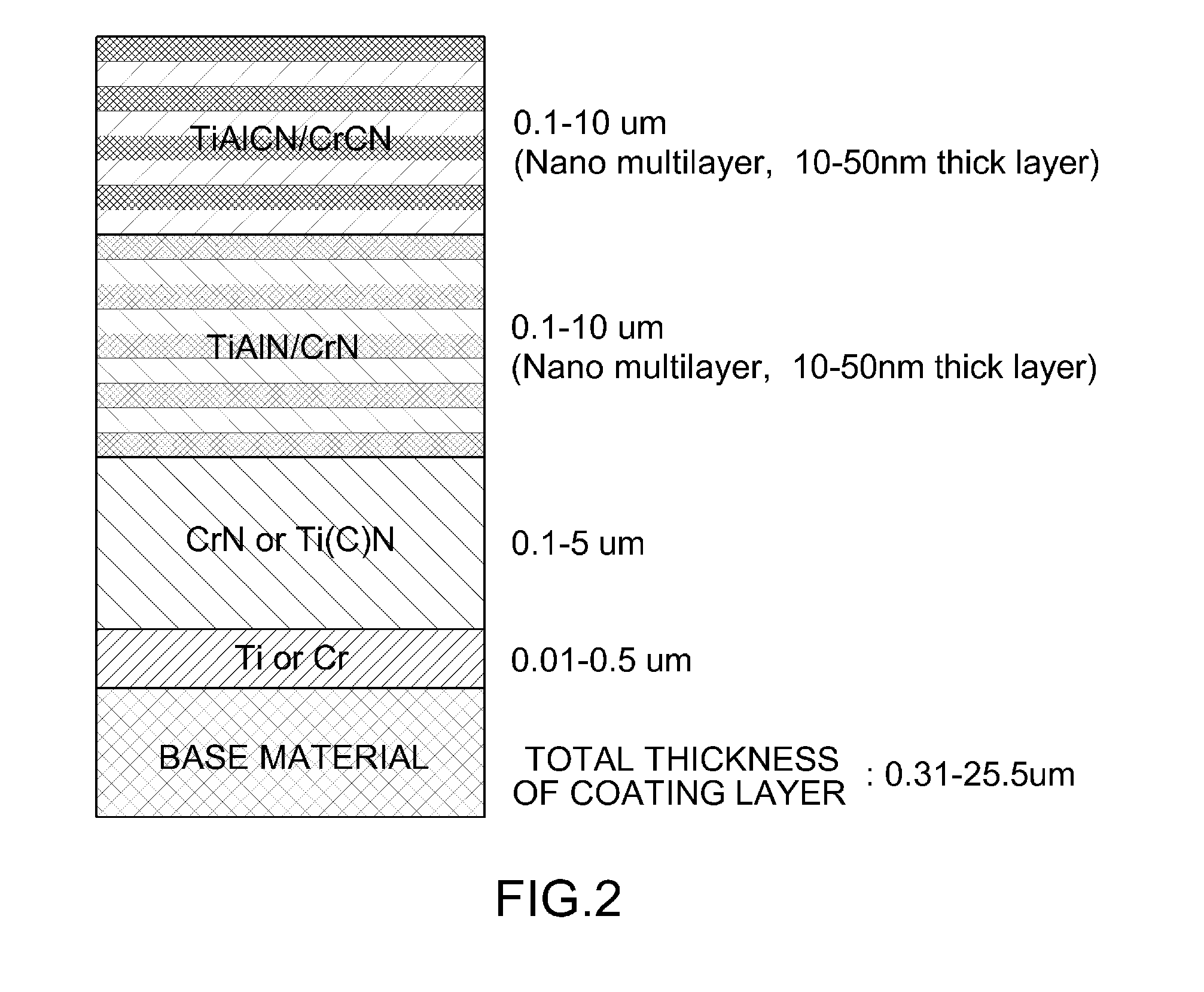

Vehicle piston ring having multi-layer coating

InactiveUS20130214493A1Secure heat resistanceExcellent abrasion resistancePiston ringsBraking action transmissionSurface layerInter layer

Disclosed is a piston ring having a multi-layer coating. The piston ring includes a buffer layer, a intermediate layer, a TiAlN / CrN nano multilayer, and a TiAlCN layer. The buffer layer is coated over a base material of a piston ring. The intermediate layer is coated over the buffer layer. The TiAlN / CrN nano multilayer is coated over the intermediate layer. The TiAlCN layer is coated over the TiAlN / CrN nano multilayer as an outermost surface layer.

Owner:HYUNDAI MOTOR CO LTD +1

Coating Liquid for Forming Transparent Coating Film and Base with Transparent Coating Film

InactiveUS20080268253A1High refractive indexExcellent abrasion resistanceMaterial nanotechnologyPigmenting treatmentNitrogenCarboxylic acid

A hard coat or a transparent film having excellent adhesion to a polycarbonate substrate is provided. The transparent film-forming coating liquid of the present invention comprises the following components (A) to (D): (A) an organosilicon compound and / or a hydrolyzate of the organosilicon compound, (B) metal oxide fine particles each of which comprises a metal oxide core particle and a coating layer composed of antimony oxide, (C) one or more curing agents (curing agent (A)) selected from the group consisting of a polythiol compound, an organic polycarboxylic acid and an acetylacetone metal complex, and (D) a curing agent (curing agent B) comprising a compound containing basic nitrogen. The metal oxide particles (B) have been surface-modified with an organosilicon compound or an amine compound.

Owner:JGC CATALYSTS & CHEM LTD

Vehicle piston ring having a NANO multi-layer coating

InactiveUS20130200572A1Low friction characteristicLow friction propertiesPiston ringsBraking action transmissionOptoelectronicsSurface layer

Owner:HYUNDAI MOTOR CO LTD +1

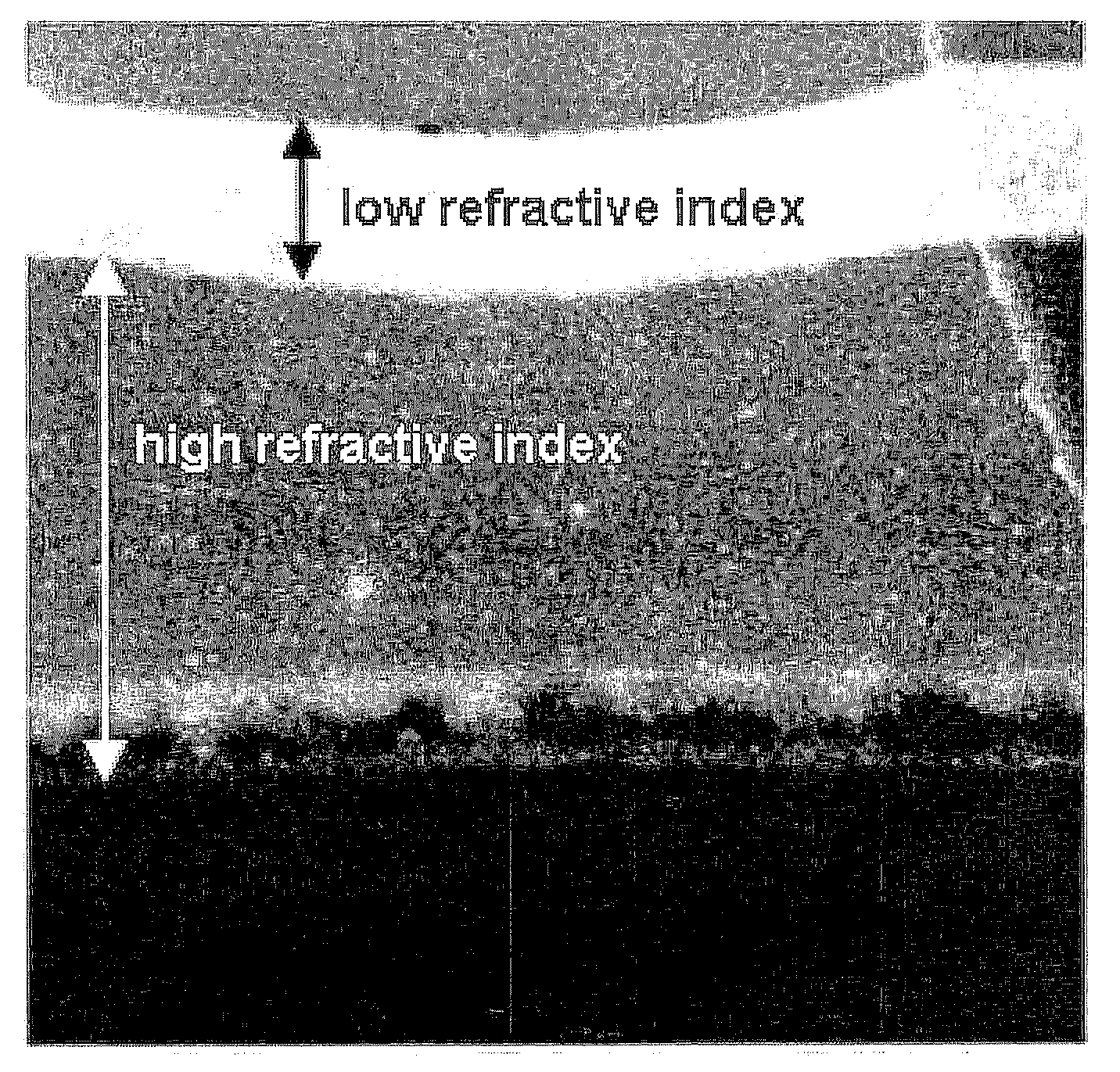

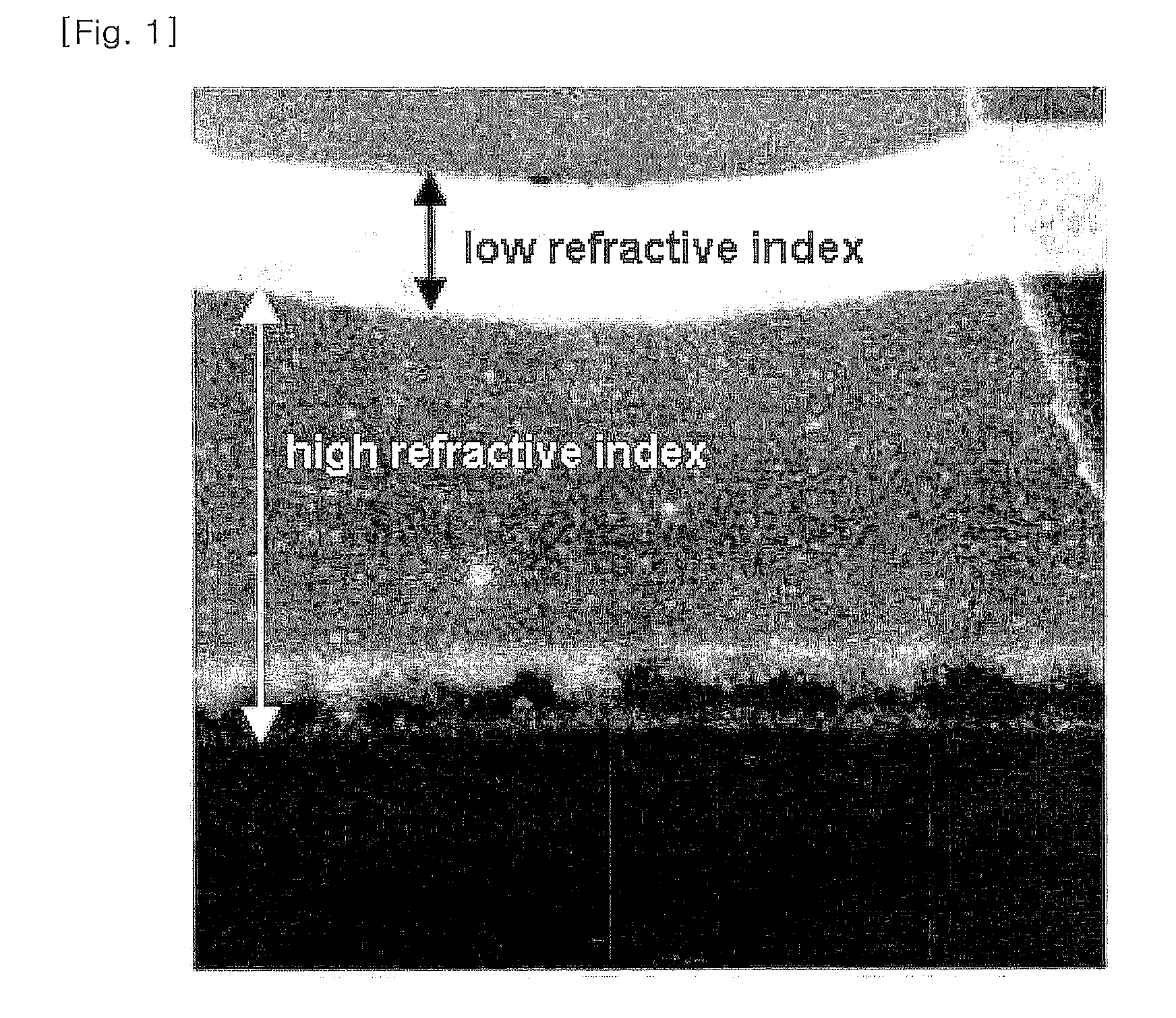

Coating composition for antireflection, antireflection film and method for preparing the same

InactiveUS20100265580A1Excellent abrasionExcellent characteristicsSynthetic resin layered productsPolarising elementsManufacturing cost reductionPolymer science

The present invention provides a coating composition for antireflection that includes a low refractive material having a refractive index of 1.2 to 1.45 and a high refractive resin having a refractive index of 1.46 to 2, in which the difference in the surface energy between two materials is 5 mN / m or more; an antireflection film manufactured using the coating composition for antireflection; and a method of manufacturing the antireflection film. According to the present invention, the antireflection film having excellent abrasion resistance and antireflection characteristic can be manufactured using a single composition by one coating process, thereby reducing manufacturing cost.

Owner:LG CHEM LTD

Viscosity-modifying silica materials that exhibit low cleaning and abrasive levels and dentifrices thereof

InactiveUS20060110339A1Desirable abrasiveGood thickening effectCosmetic preparationsSilicaSilica gelSilicon dioxide

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

High-cleaning silica materials and dentifrice containing such

InactiveUS20060110336A1Excellent abrasionImprove rendering capabilitiesCosmetic preparationsToilet preparationsCleaned teethLinseed oil

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

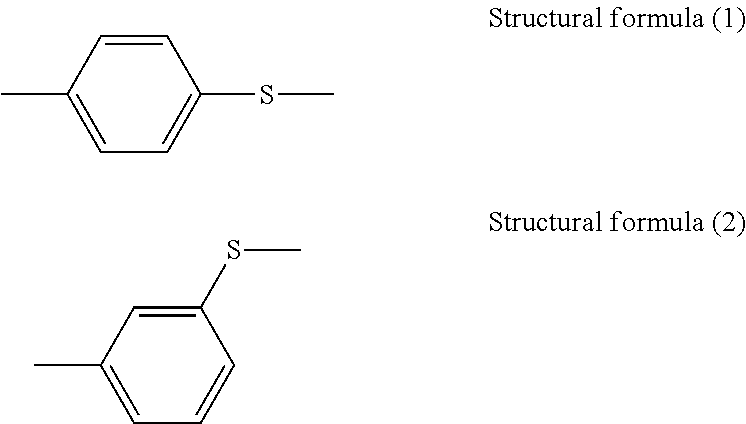

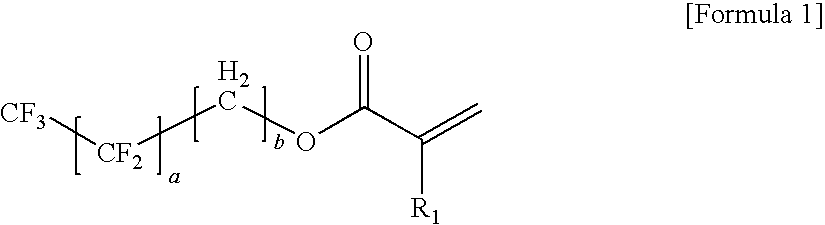

Rubber composition for tire and pneumatic tire

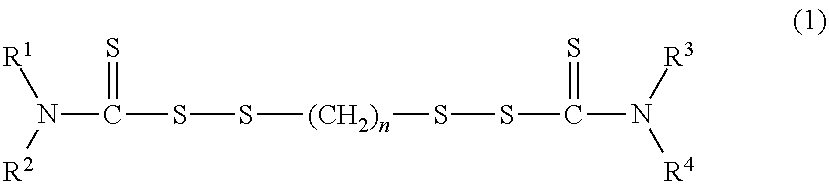

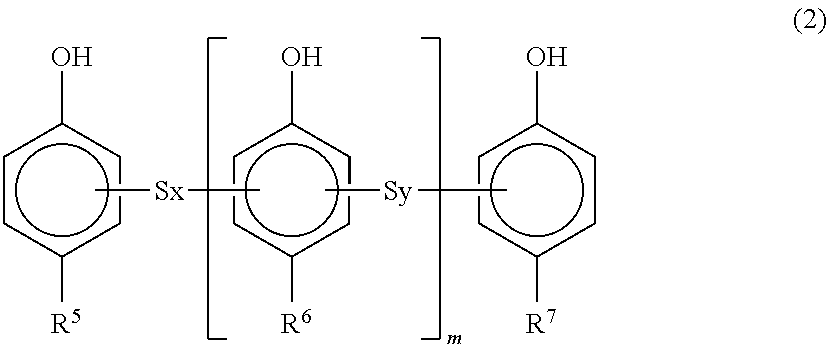

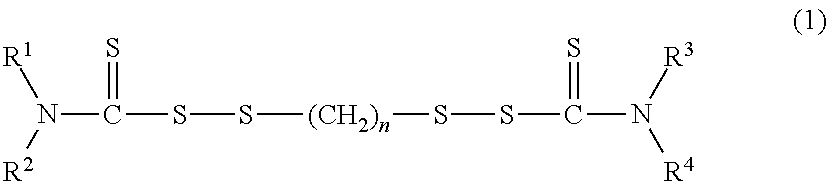

InactiveUS20110071253A1Favorable productivityIncrease production capacitySpecial tyresPneumatic tyre reinforcementsAging resistanceAryl

The present invention provides: a rubber composition for a tire having favorable productivity, excellent heat aging resistance and abrasion resistance, and excellent fuel economy; and a pneumatic tire using the rubber composition. The rubber composition contains neither soluble sulfur nor insoluble sulfur, and contains diene rubber, 1-15 parts by mass of compound 1 represented by formula (1) and 0.1-5 parts by mass of compound 2 represented by formula (2), per 100 parts by mass of the diene rubber, and the amount ratio of compound 1 to compound 2 (compound 1 / compound 2) is 1-8.wherein R1-R4 are the same or different, and represent C1-20 alkyl, C6-20 aryl, or C7-20 aralkyl, and n represents an integer of 1-12;wherein R5-R7 are the same or different, and represent C5-12 alkyl, x and y are the same or different, and represent an integer of 2-4, and m represents an integer of 0-10.

Owner:SUMITOMO RUBBER IND LTD

High-cleaning, low abrasion, high brightness silica materials for dentrifices

InactiveUS7270803B1Excellent abrasionImprove rendering capabilitiesCosmetic preparationsPigmenting treatmentCleaned teethSilica gel

Unique abrasive materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial, particularly simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels. Such a result thus accords the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Furthermore, the produced abrasive materials also exhibit very high and desirable brightness properties that permit easy incorporation and utilization within dentifrices for aesthetic purposes. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, particularly under high shear conditions, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

Facer and construction materials made therewith

ActiveUS8268737B1Reduce energy costsGood chemical resistanceSynthetic resin layered productsAbsorbent padsOligomerUltraviolet lights

Electron beam curable resins or ultraviolet light curable resins can be used in combination with filler and other additives to make coated facers that can be used on insulation boards. Also disclosed are facers made of such composition, the process for making said facers and their use in insulation, building and construction boards. More specifically a flexible facer can be made by a process that comprises (1) applying a monomeric composition to a fiber mat, wherein the fiber mat is a non-asphaltic, non-cellulosic fiber mat, and wherein the monomeric composition is comprised of at least one monomer and / or at least one oligomer, and a filler, (2) initiating polymerization of the monomer within the monomeric composition by exposing the monomeric composition to ultraviolet light or an electron beam, and (3) allowing the monomer to polymerized to produce the flexible facer.

Owner:BMIC LLC

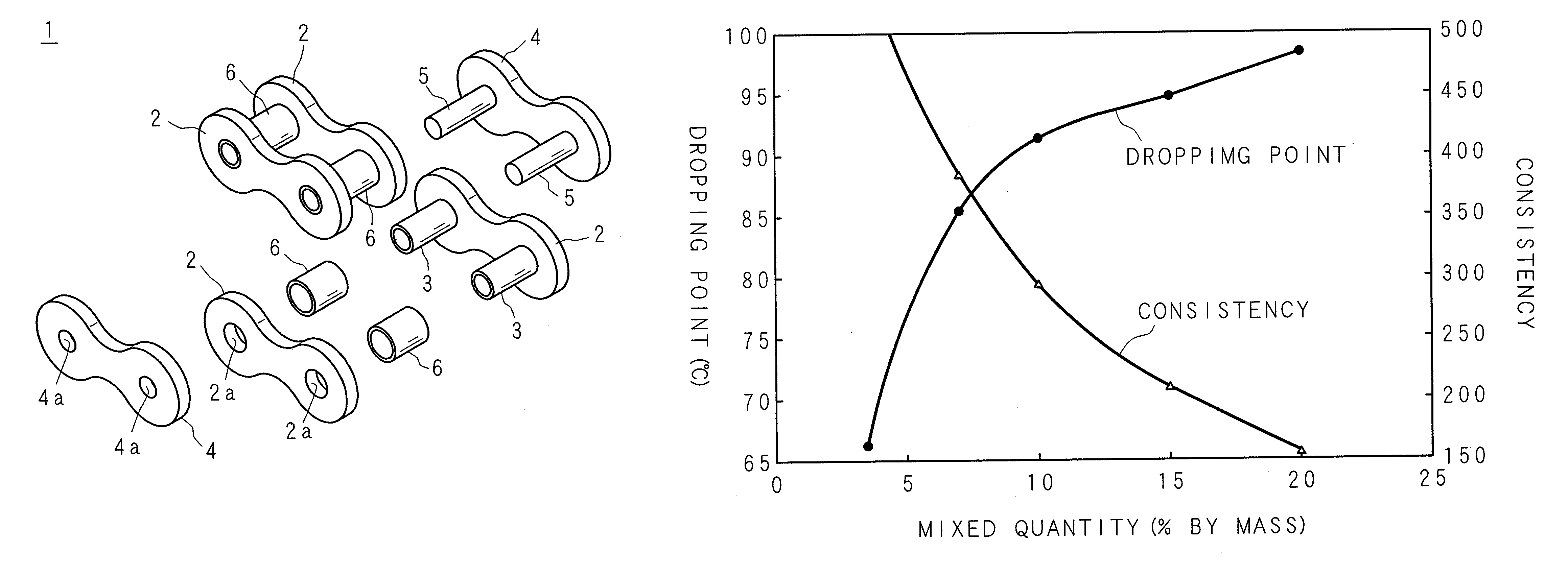

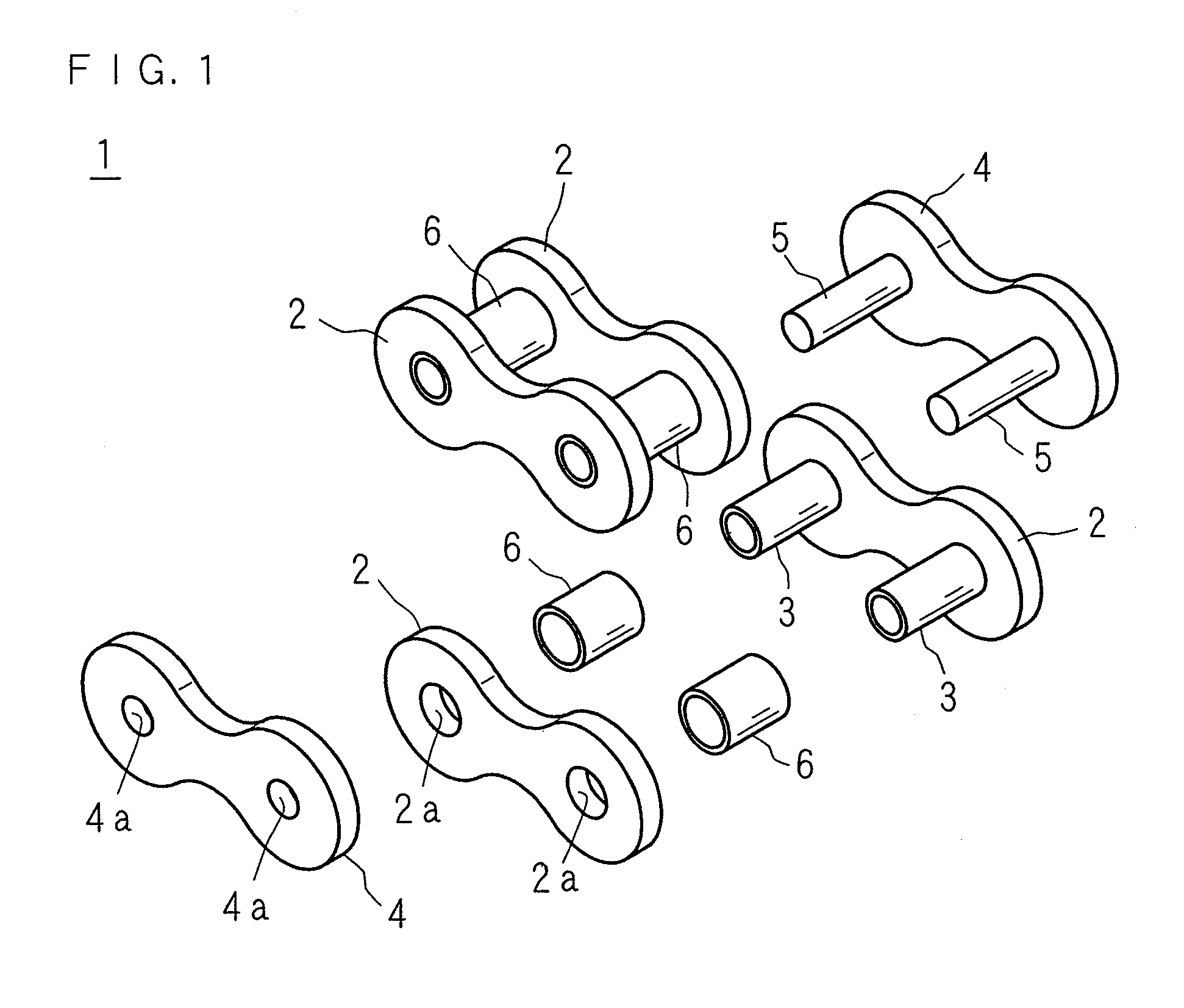

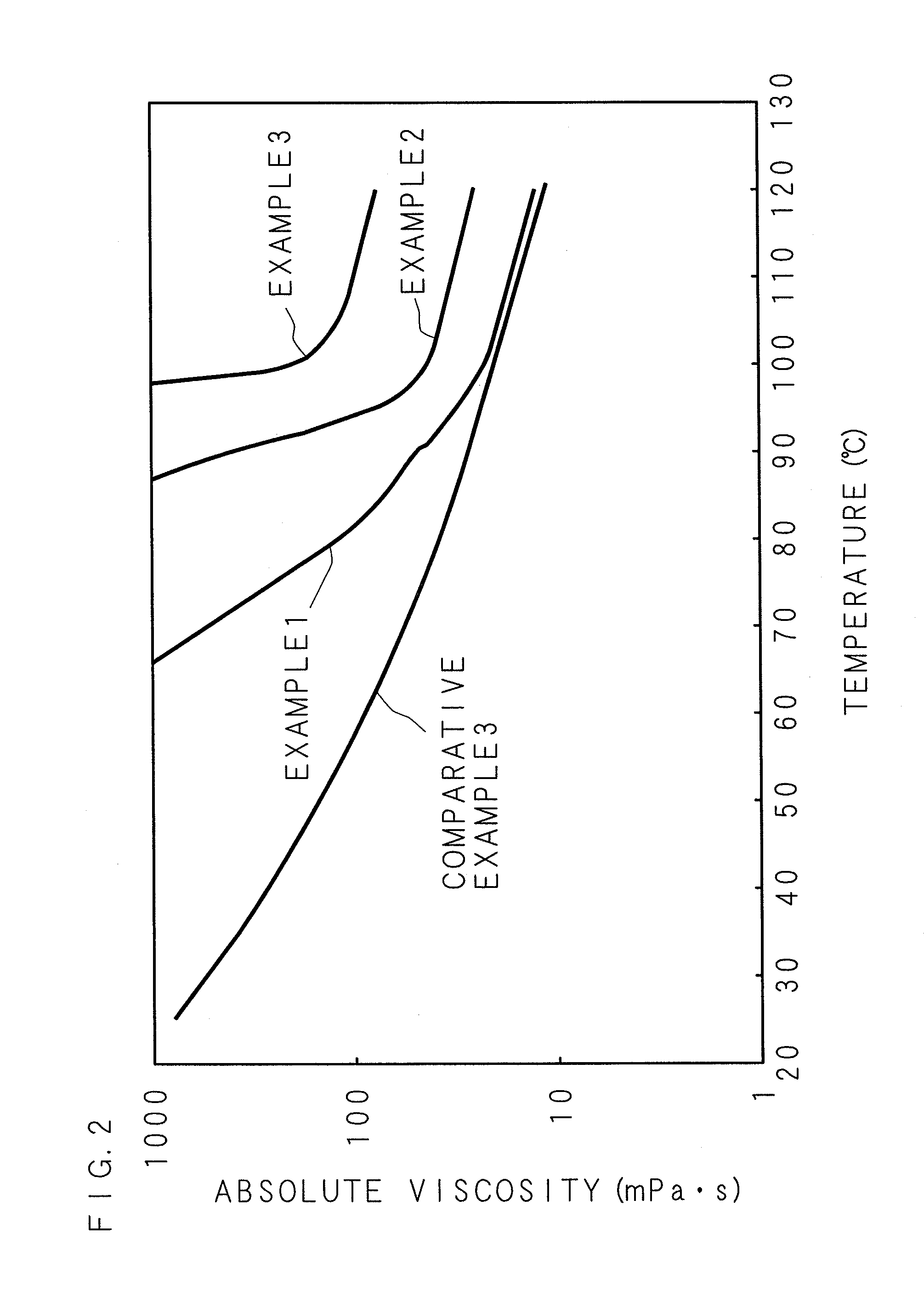

Lubricant composition for chains, and chain

InactiveUS8771119B2Excellent abrasionImprove the lubrication effectSolid fuelsLiquid carbonaceous fuelsWaxRoom temperature

Owner:TSUBAKIMOTO CHAIN CO

Cooking UItensils with Metallic Non-Stick Coating and Methods for Making the Same

InactiveUS20080073357A1Limited temperature toleranceImprove impact performanceCooking-vessel materialsMolten spray coatingChromium carbideHeat resistance

Disclosed is a cooking utensil coated with a metallic non-stick coating made of a nickel-aluminum-molybdenum (NiAlMo) alloy mainly composed of nickel aluminum (NiAl), and / or a nickel-chrome-chromic carbide (NiCr—Cr3C2) alloy mainly composed of chromic carbide (Cr3C2). A method for coating a cooking utensil with a metallic non-stick coating is also provided. The metallic non-stick coating of the invention possesses high impact, heat and abrasion resistances.

Owner:QIN RAYMOND +1

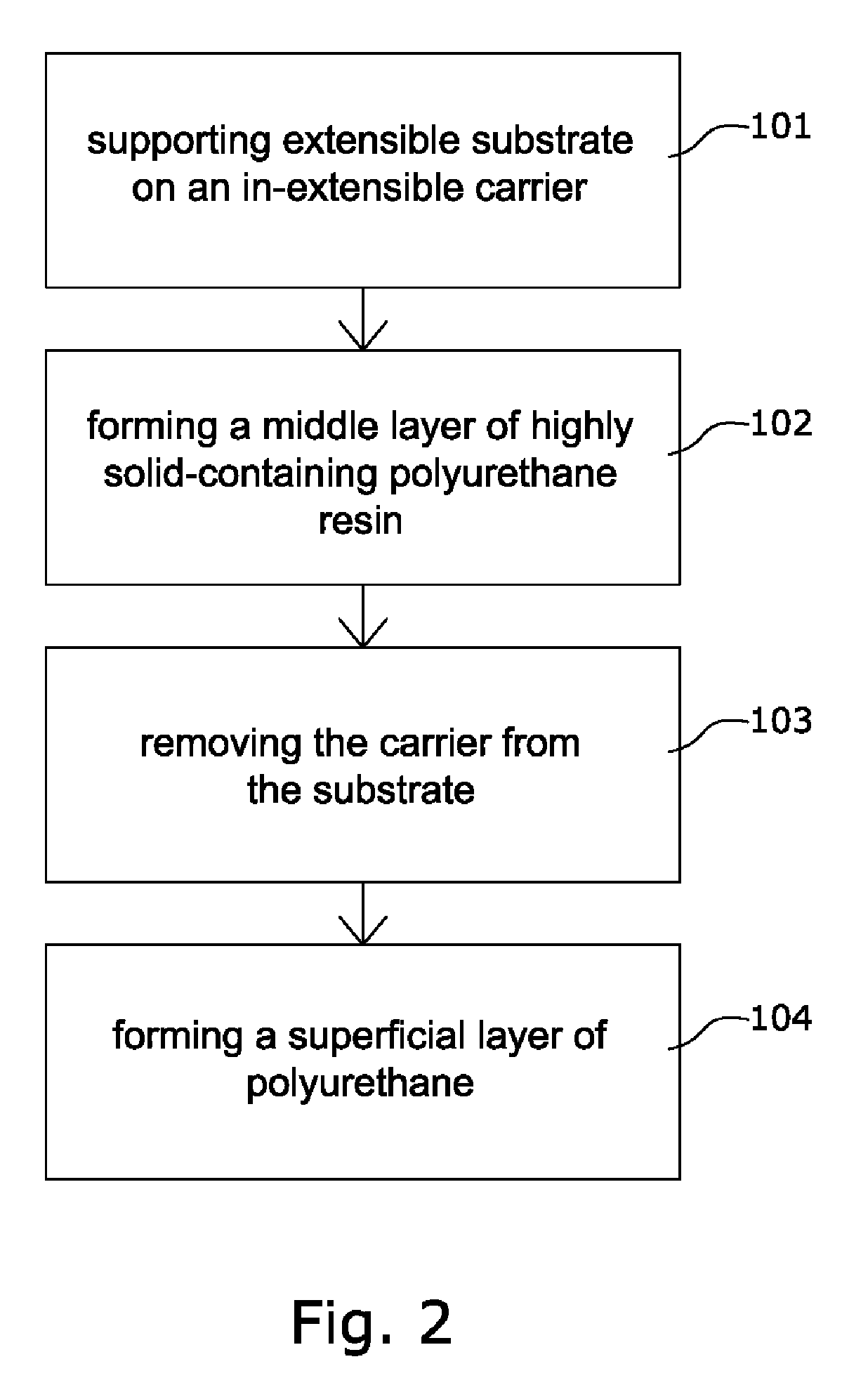

Extensible artificial leather and method for making the same

InactiveUS20080145613A1Excellent strength against peeling and abrasion and dissolutionShort processSynthetic resin layered productsPretreated surfacesEngineeringTextile

A method is provided for making extensible artificial leather. In the method, a substrate is supported on in-extensible woven cloth and locating the substrate firmly on a coating machine. Foamy highly solid-containing water-based polyurethane resin is coated on the substrate for forming a middle layer with tiny open cells. The middle layer is dried and the woven cloth is removed from the substrate. A superficial layer of polyurethane is attached to the middle layer in a dry process so that the extensible artificial leather is made with excellent strength against peeling, abrasion and dissolution.

Owner:SAN FANG CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com