Biological contact oxidation pond and method for oxidizing Fe<2+> in dump leaching process

A technology of biological contact and heap leaching, applied in the field of biological contact oxidation ponds, can solve problems such as the difficulty in achieving a high redox potential of the system, the difficulty in achieving efficient oxidation of a large number of microorganisms, and the difficulty in controlling the growth environment, so as to improve the activity of microorganisms and mineral oxidation rate, process parameters are easy to control, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A large part of the refractory gold ores is pyrite-coated gold, but due to the insufficient biooxidation rate of pyrite, this part of gold is difficult to be effectively exposed, resulting in low heap leaching efficiency and long production cycle, so Improving the oxidation efficiency of pyrite is of great significance for improving production efficiency and reducing production costs.

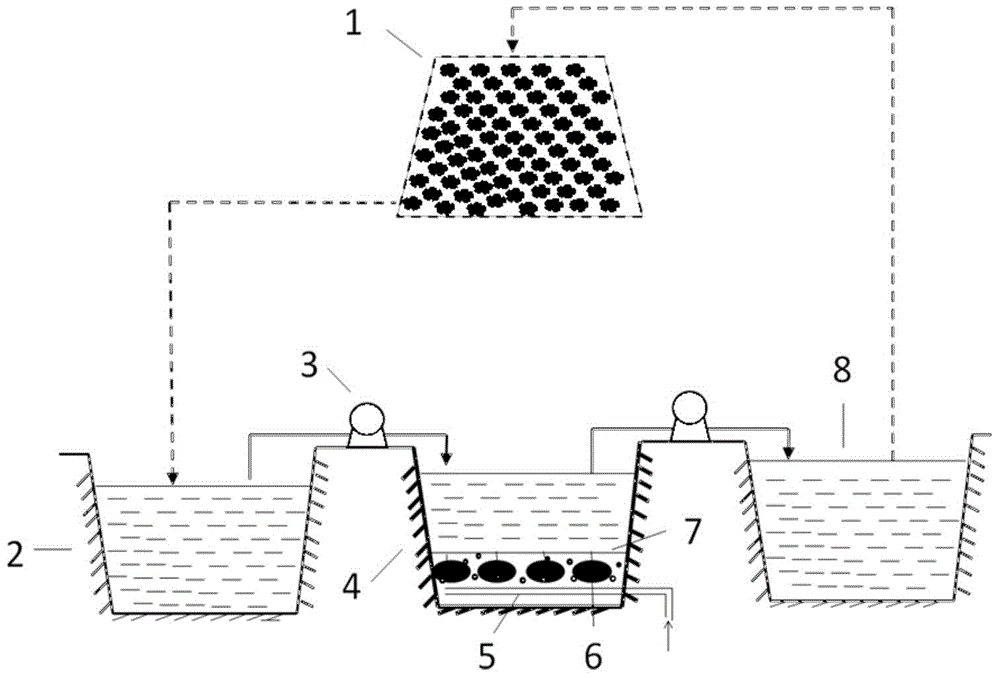

[0039] In the industrial test of bioheap leaching pre-oxidation of a low-grade refractory gold mine (the process flow is as follows Figure 4 ), the ore contains 5.3% sulfur, 0.2% arsenic, and 2.3g / t gold. The ore is crushed to a particle size of less than 20mm, and a gold-bearing pyrite leaching pile is constructed with a height of 10 meters. At the initial stage of heap leaching, acidophilic iron-oxidizing bacteria were enriched and cultivated from local acidic wastewater (medium composition: 9K, 10g / L FeSO 4 , pH1.8), mainly including Leptospira ferrooxidans and Thiobacillus ferroox...

Embodiment 2

[0043] In the bioheap leaching industrial test of a low-grade secondary copper ore (the process flow is as follows Image 6 ), the ore composition is Cu0.37%, Fe3.59%, S5.28%. The main copper minerals in the ore are chalcocite, copper blue and chalcocite, of which chalcocite accounts for more than 90% and pyrite content is 10%. The main gangue minerals are feldspar, quartz and sericite. After the secondary copper ore is crushed to a particle size of less than 40mm, a copper ore leaching heap is constructed. In the test production stage, local acidic wastewater was used to continuously spray the copper ore leaching heap. The pH of the acidic wastewater was 2.1, the total iron content was 3g / L, and the Eh was 690mV. However, due to the high acid consumption of the ore pile during the production process, the acidity of the spray liquid is not enough, and the production efficiency is low. In the test, a biological contact oxidation pond (volume of 1,000 cubic meters and depth of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com