A desulfurizer composition and its application in cement clinker production

A technology of cement clinker and desulfurizer, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems that powder-based desulfurization substances are difficult to disperse, desulfurization is not completely solved, and the oxygen content of flue gas is low. Solve the problem of sulfur cycle, highly efficient oxidation capacity, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

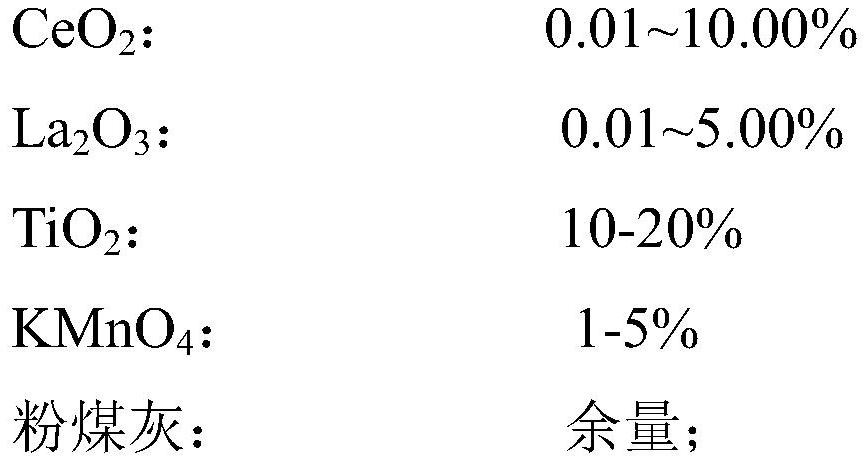

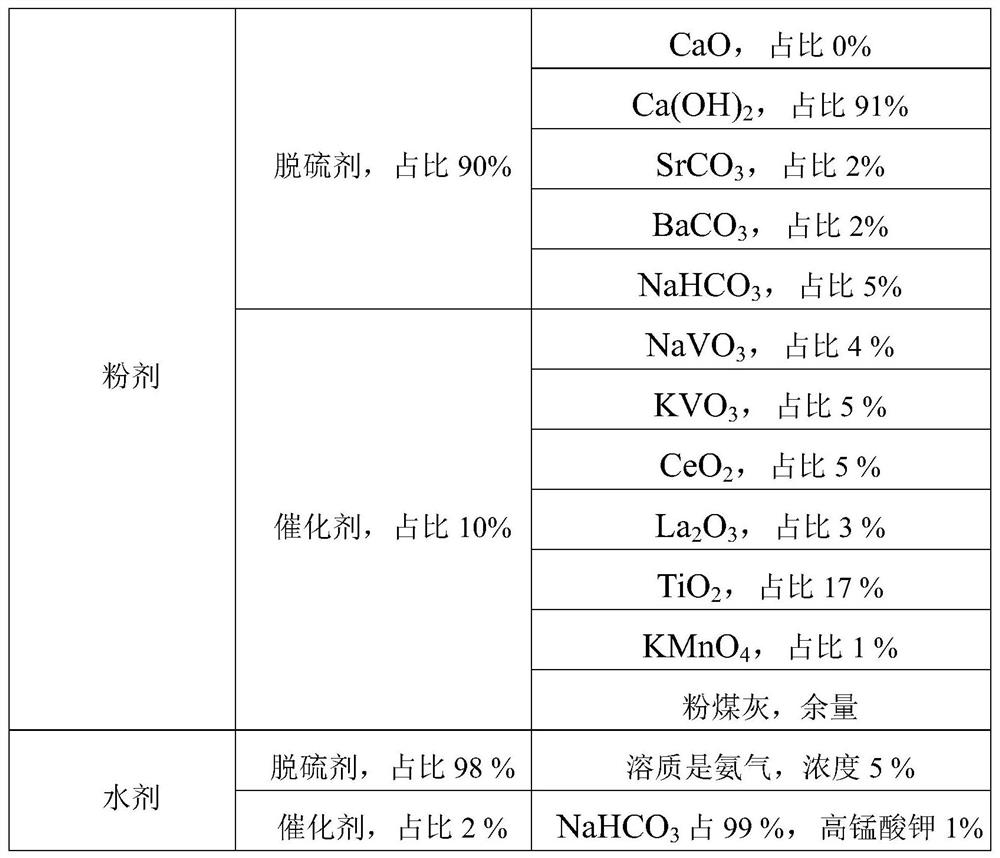

[0058] A desulfurizer composition, its composition is as shown in the following table:

[0059]

[0060] Note: The proportion stated in the second column is the mass percentage of the powder or liquid; the proportion stated in the third column is the mass percentage of the desulfurizer or catalyst; the same below;

Embodiment 2

[0062] A desulfurizer composition, its composition is as shown in the following table:

[0063]

Embodiment 3

[0065] A desulfurizer composition, its composition is as shown in the following table:

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com