Waste water denitrogenation and marsh gas desulfurization coupling technique

A biogas desulfurization and denitrification technology, applied in aerobic and anaerobic process treatment, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of explosion danger, difficult control of oxygen, energy consumption, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

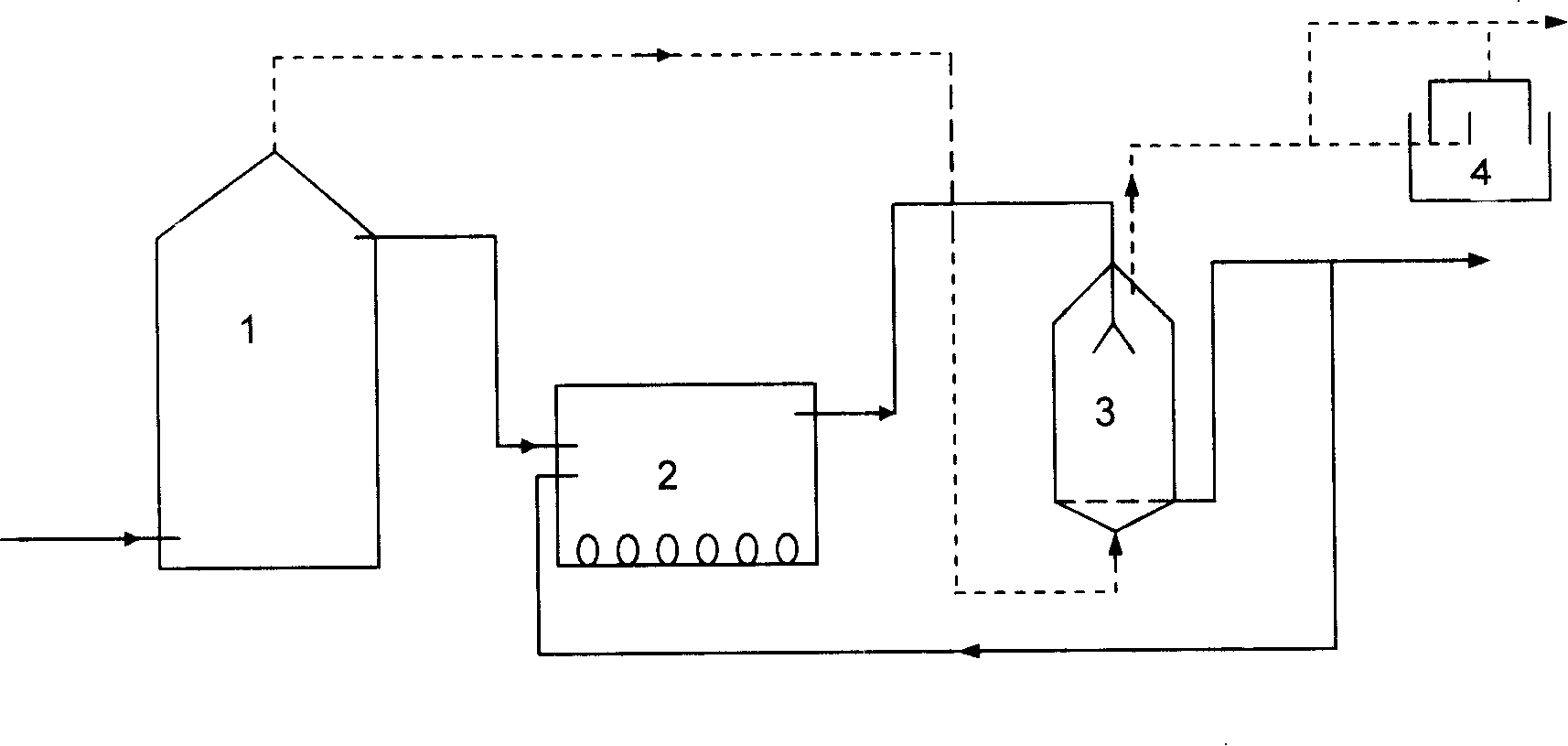

[0012] In the coupling process of wastewater denitrification and biogas desulfurization of the present invention, the main process units include an anaerobic digestion unit, a digestive liquid aerobic treatment unit, and a denitrification and desulfurization unit. According to the respective characteristics of different organic wastewaters, a pretreatment unit (regulation tank, solid-liquid separation, collection tank, etc.) and a sludge dewatering unit are added to the process according to the specific conditions. Anaerobic digestion unit includes anaerobic digestion reactor, biogas conveying system, etc. According to the characteristics of wastewater, anaerobic digestion reactor can adopt anaerobic contact reactor (AC), anaerobic filter (AF), upflow anaerobic sludge bed (UASB), etc. The aerobic post-treatment unit of digestion liquid can adopt active method, contact oxidation method, sequential batch activated sludge method, oxidation ditch, etc. The implementation steps of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com