Patents

Literature

60 results about "Active Method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique in which the person voluntarily performs an osteopathic practitioner directed motion.

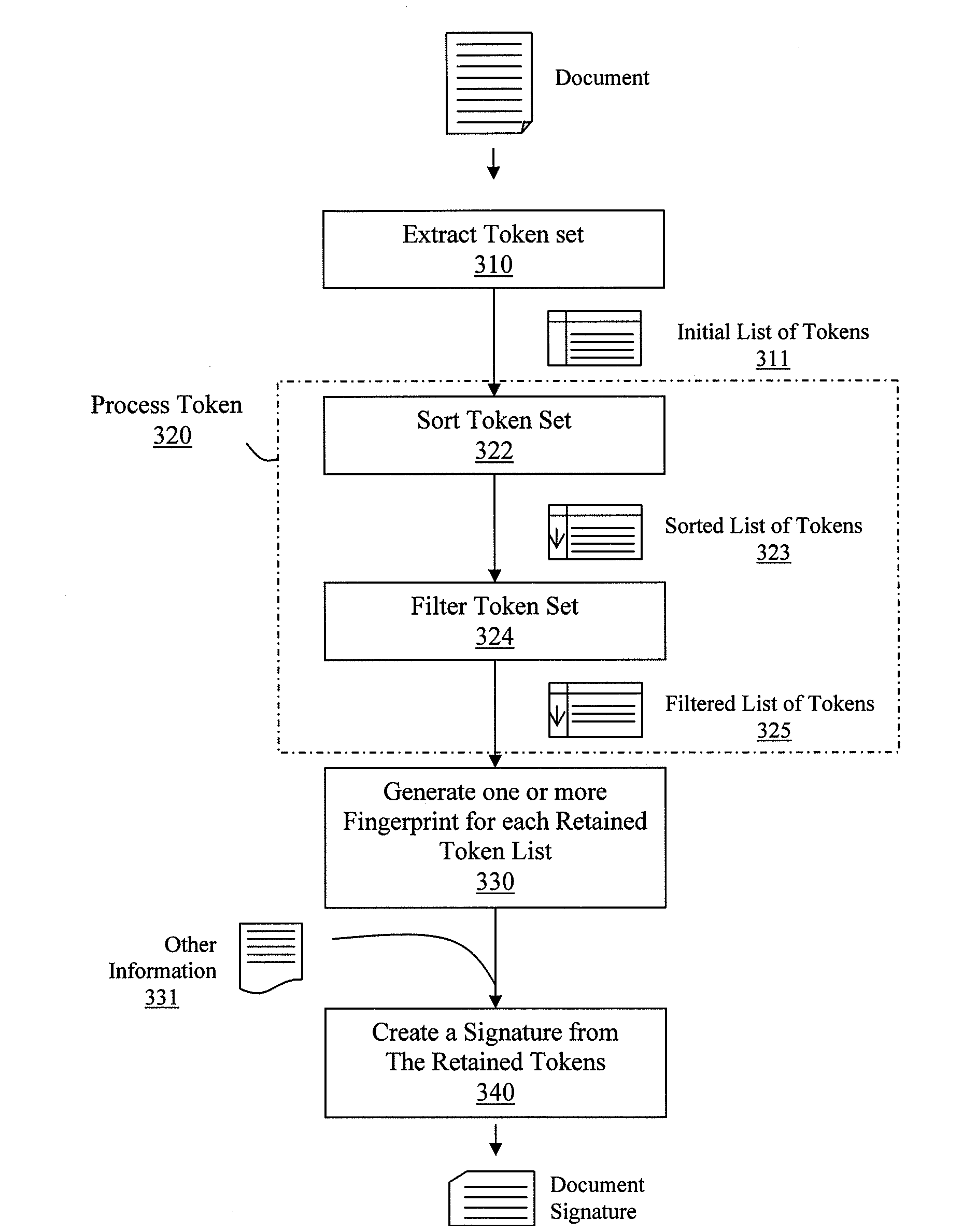

Automated forensic document signatures

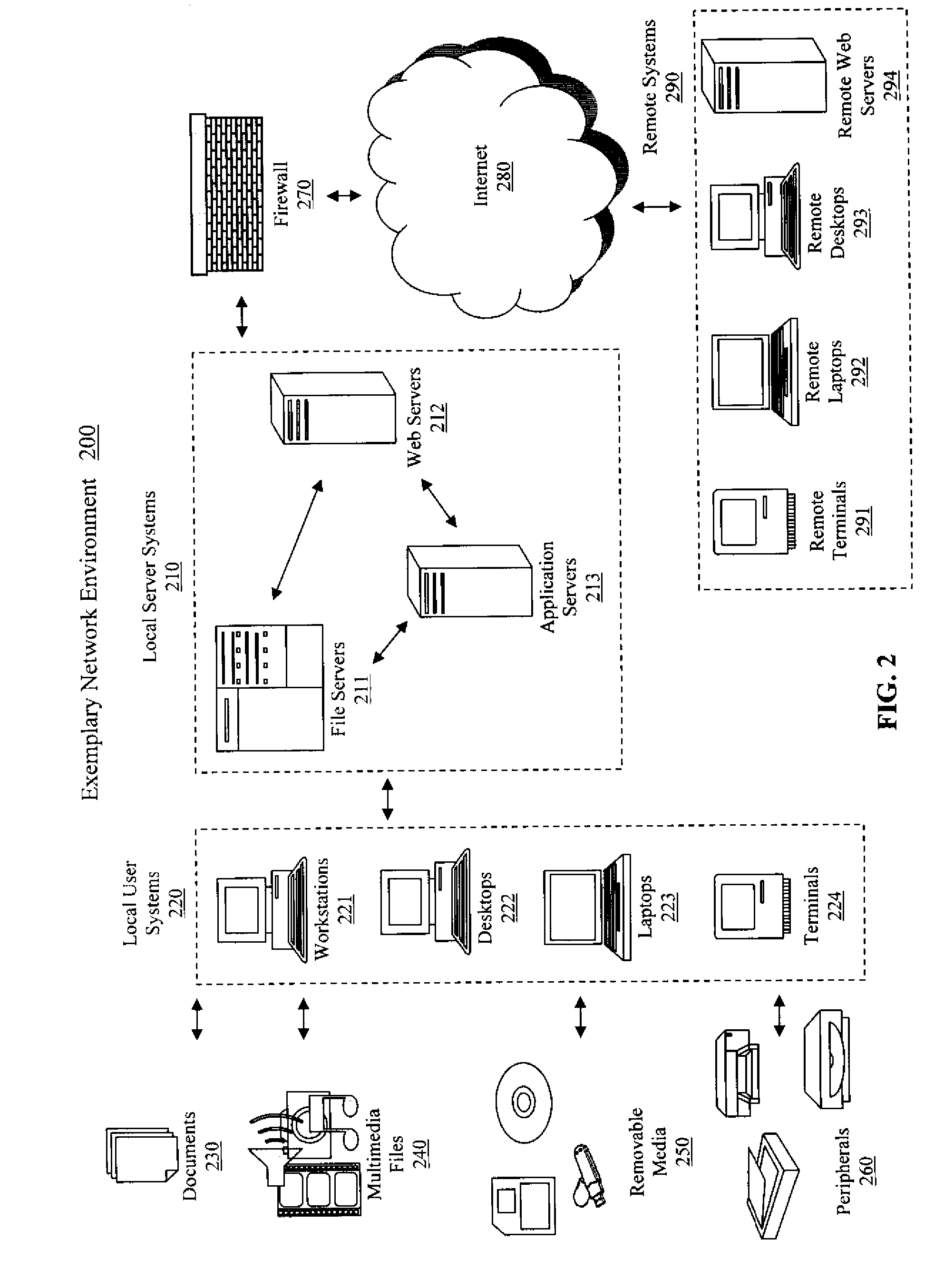

ActiveUS20100287196A1Facilitate methodDigital data processing detailsPlatform integrity maintainanceDocument preparationDigital fingerprint

Owner:GEORGETOWN UNIV

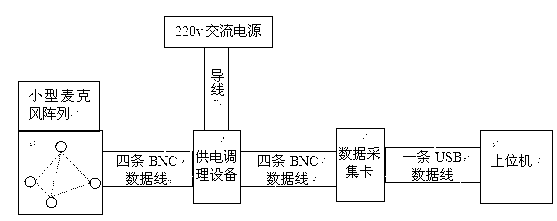

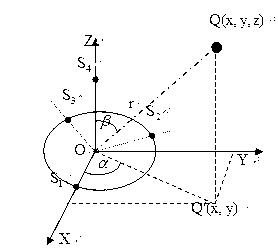

Sound source localization method of three-dimensional space

ActiveCN103064061APrecise positioningSmall amount of calculationPosition fixationSound sourcesThree-dimensional space

A sound source localization method of a three-dimensional space adopts a movable small microphone array and a sound source localization technology based on time delay estimation. The small microphone array is used for collecting a period of target sound source signals, a mutual correlation algorithm is used for calculating time differences between the microphones of the small microphone array, the time differences are substituted into computational formulas of azimuth and elevation to get the azimuth and the elevation of the target sound source, and then the small microphone array is moved for some distance along a certain azimuth, and the operations are repeated to get the azimuth and the elevation of the target sound source at the moment. Through measuring the azimuth and the elevation of the target sound source twice, the distance of the target sound source is calculated. The method of measuring target sound source is a passive method. The small microphone array is moved during the measuring process, and the defects that accuracy of the sound source target distance measuring of the prior art is low, and cost is high and safety is not ensured due to the fact that an active method is adopted to measure the sound source target distance are overcome.

Owner:HEBEI UNIV OF TECH

Automated forensic document signatures

ActiveUS20090164517A1Facilitate methodDigital data processing detailsUser identity/authority verificationDigital signatureMisuse detection

Methods and systems are provided for a proactive approach for computer forensic investigations. The invention allows organizations anticipating the need for forensic analysis to prepare in advance. Digital signatures are generated proactively for a specified target. The digital signature represents a digest of the content of the target, and can be readily stored. Searching and comparing digital signatures allows quick and accurate identification of targets having identical or similar content. Computational and storage costs are expended in advance, which allow more efficient computer forensic investigations. The present invention can be applied to numerous applications, such as computer forensic evidence gathering, misuse detection, network intrusion detection, and unauthorized network traffic detection and prevention.

Owner:GEORGETOWN UNIV

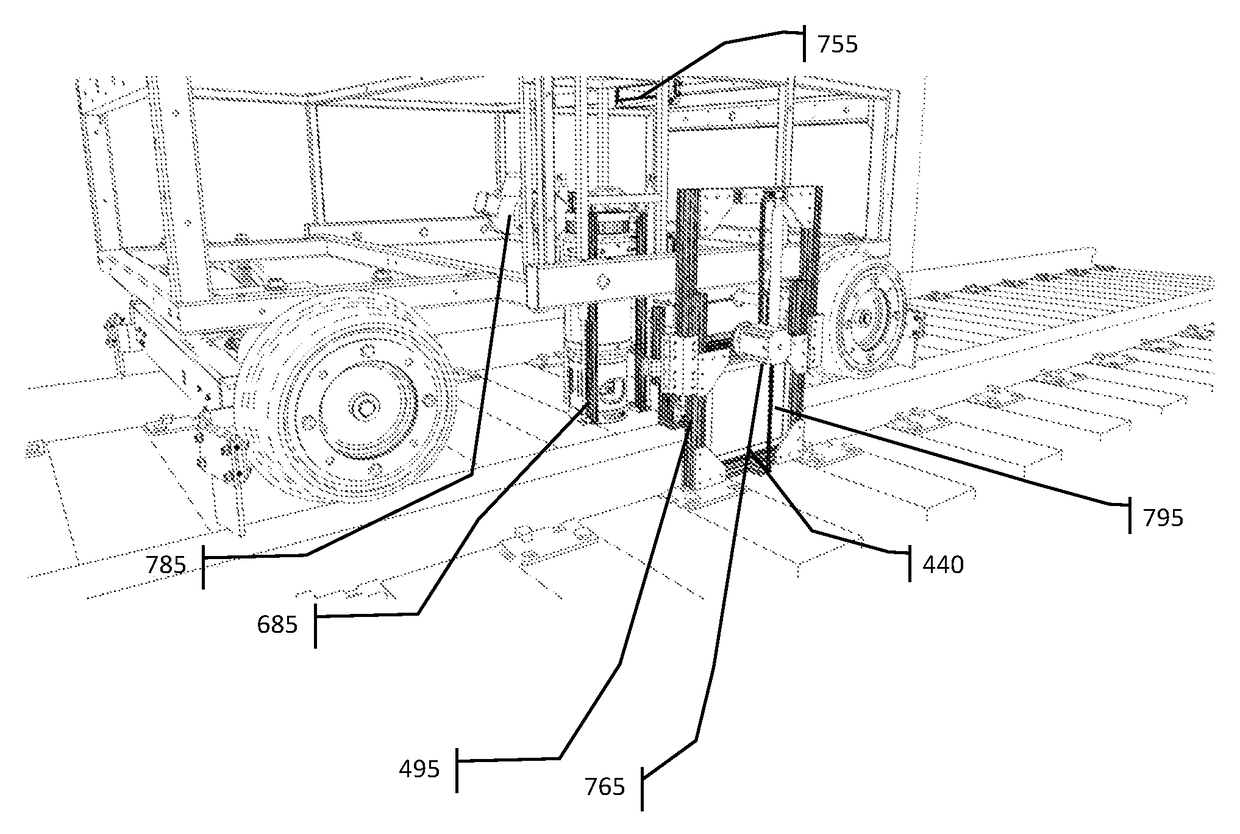

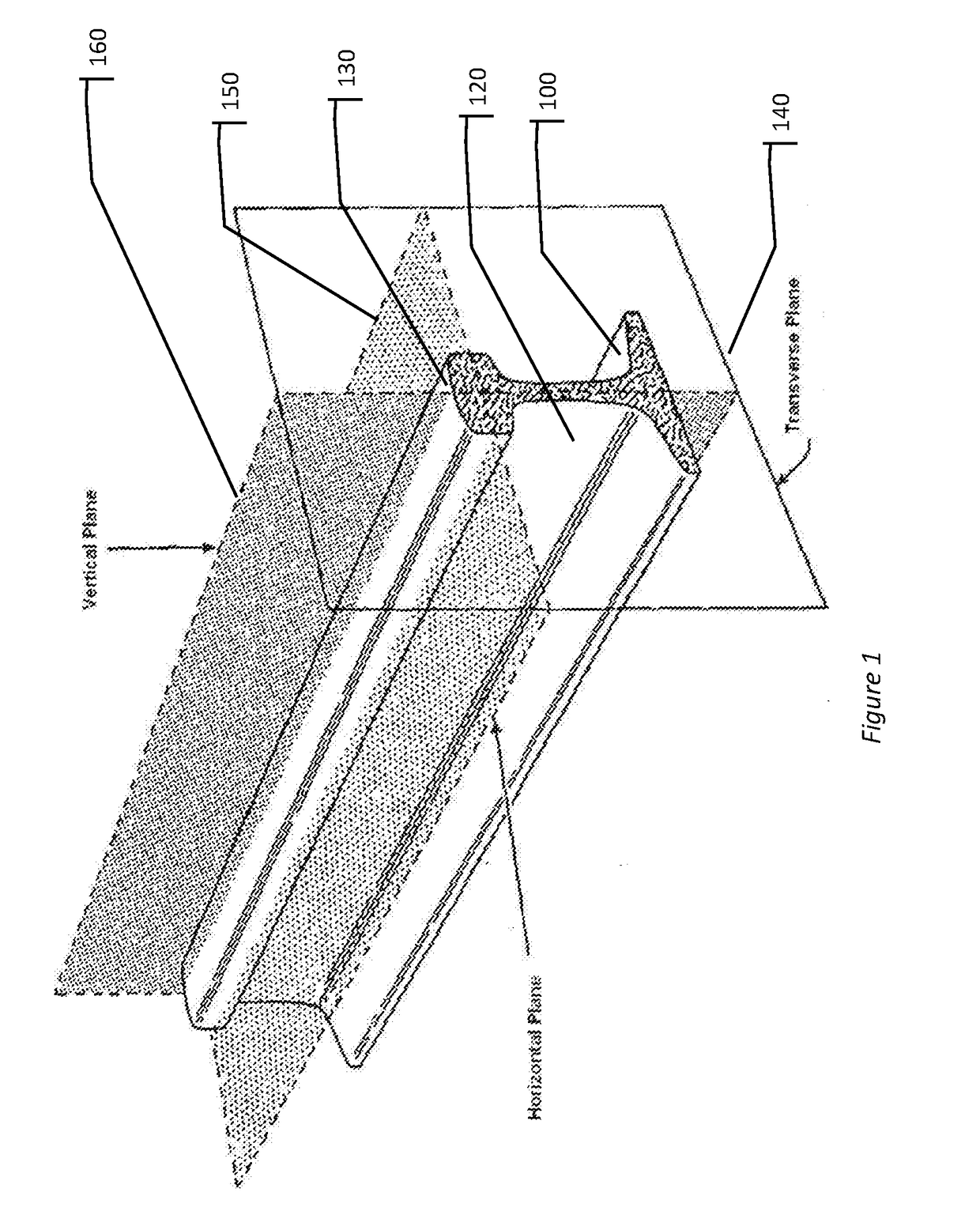

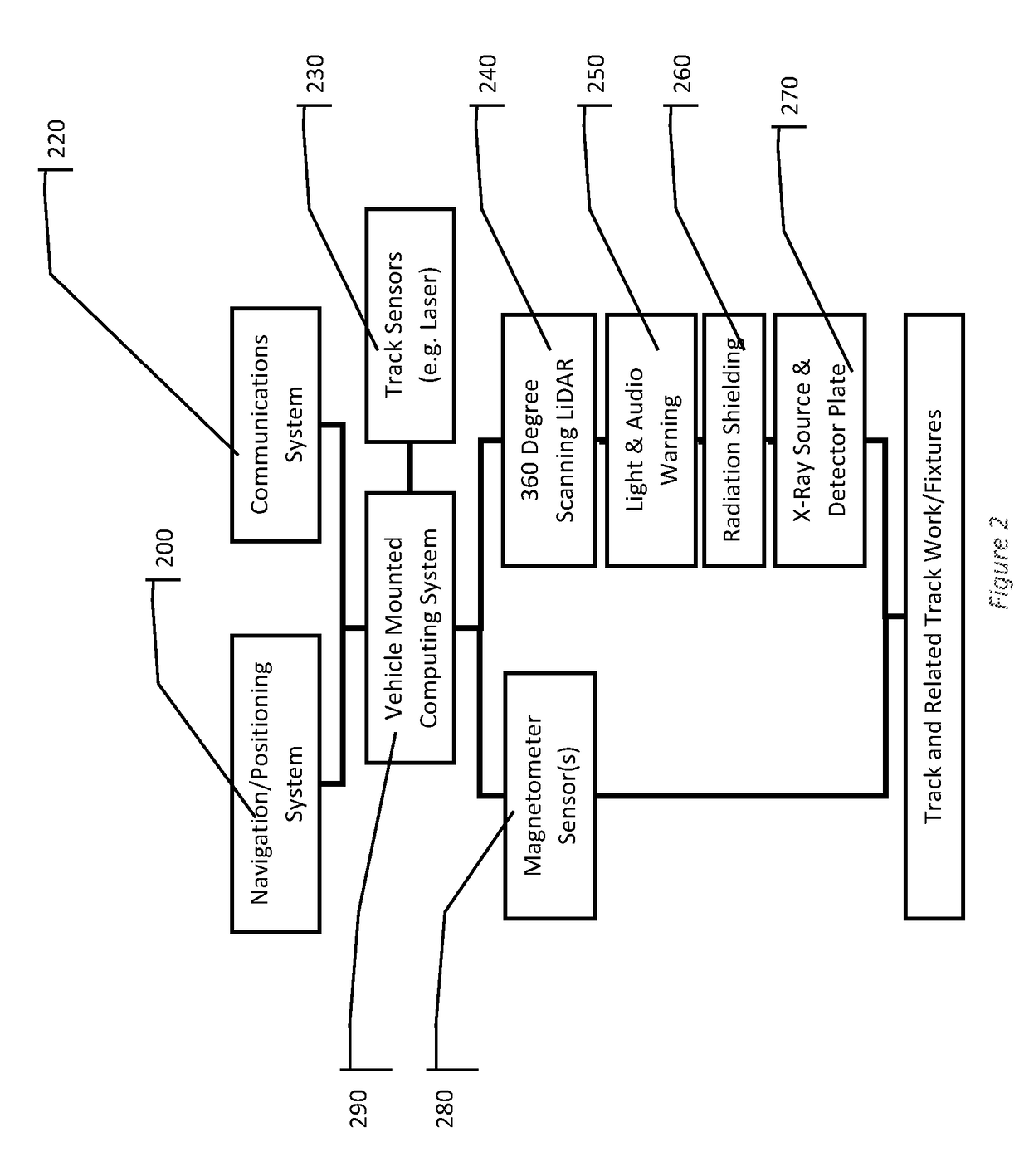

Combined Passive and Active Method and Systems to Detect and Measure Internal Flaws within Metal Rails

ActiveUS20170267264A1Quantifying growthImprove abilitiesRoute devices for controlling vehiclesElectromagnetic wave reradiationMagnetic tension forceX-ray

This invention utilizes two sensing technologies in combination with or in isolation of an automated inspection vehicle to conduct inspections of internal rail flaws in steel railroad track. A vehicle equipped with X-radiation sensing is used as a secondary method to assess the deviations in magnetic fields that are sensed by a primary sensor consisting of a single or multiple magnetometers. The magnetometers sense changes in magnetic field that are correlated to the flaws inside the steel rail. The combination of technologies improves the probability to detect railroad flaws and offers the ability to accurately track and monitor flaws.

Owner:RAILPOD

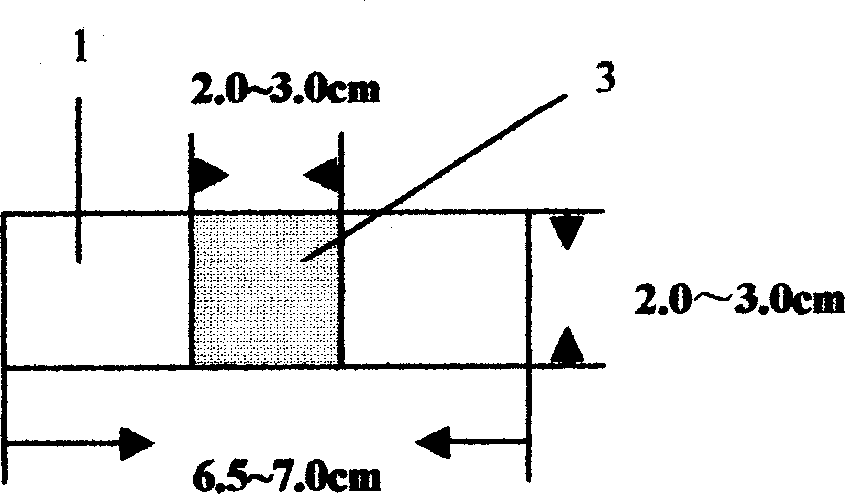

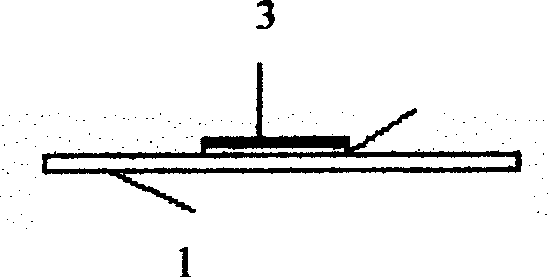

High-energy impact absorbing polycarbonate mounting method

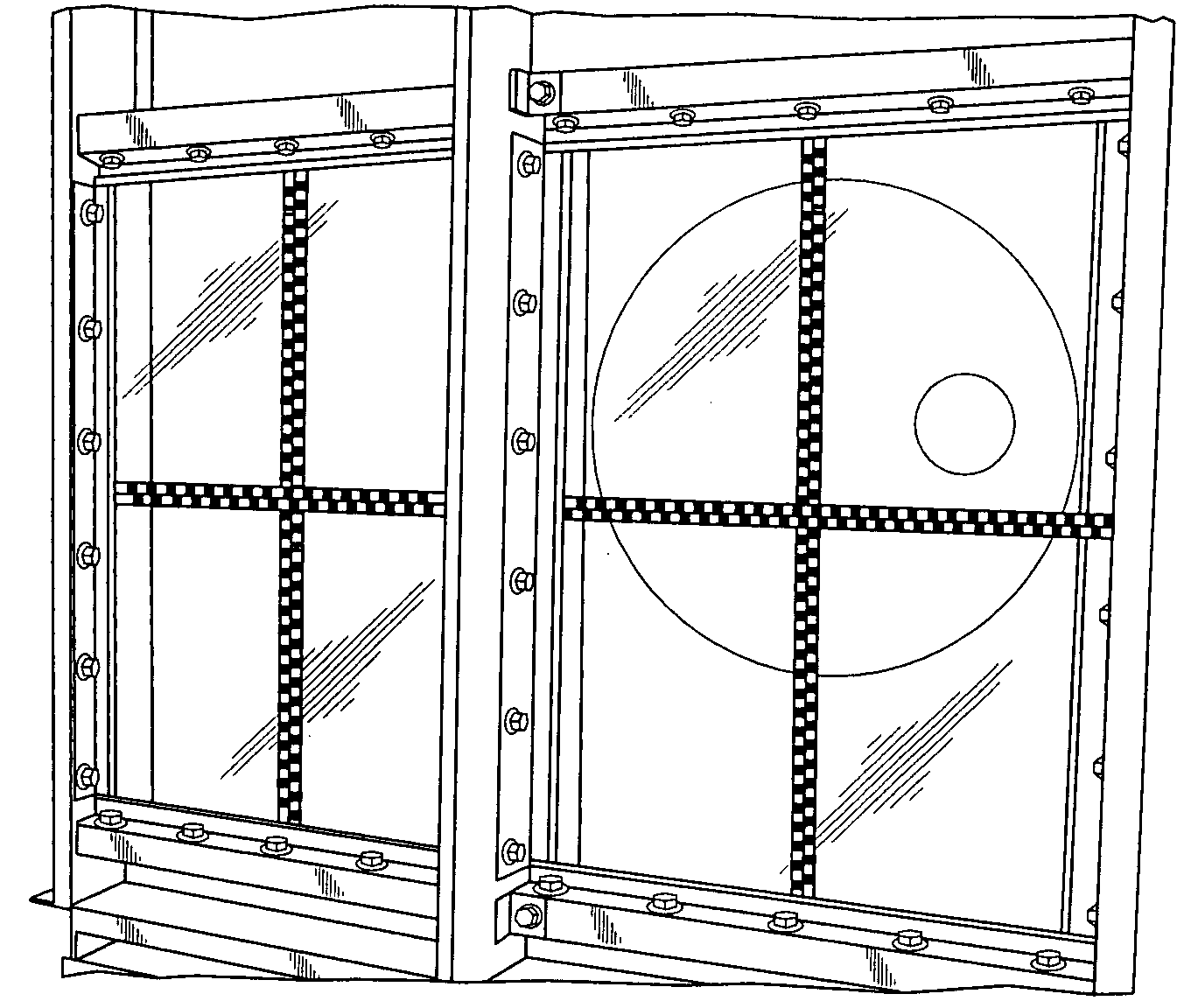

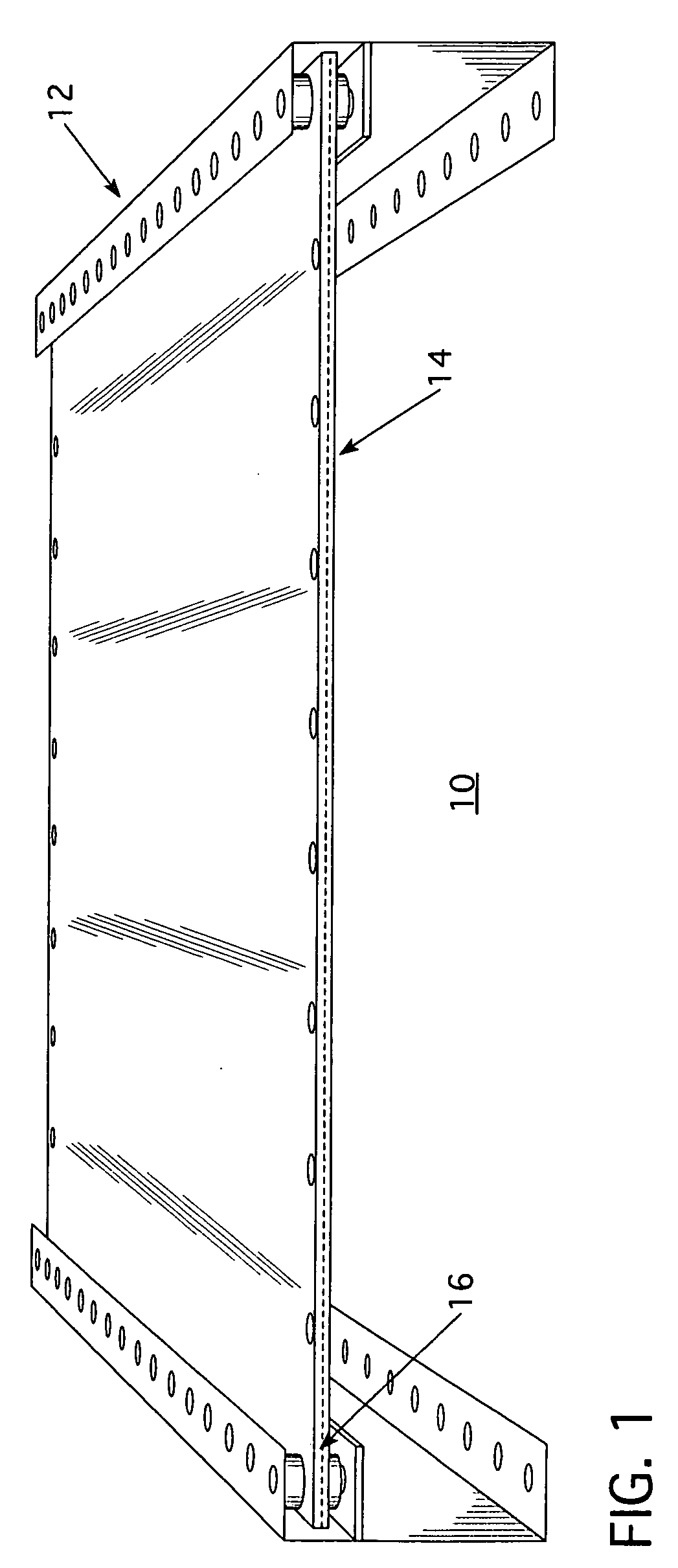

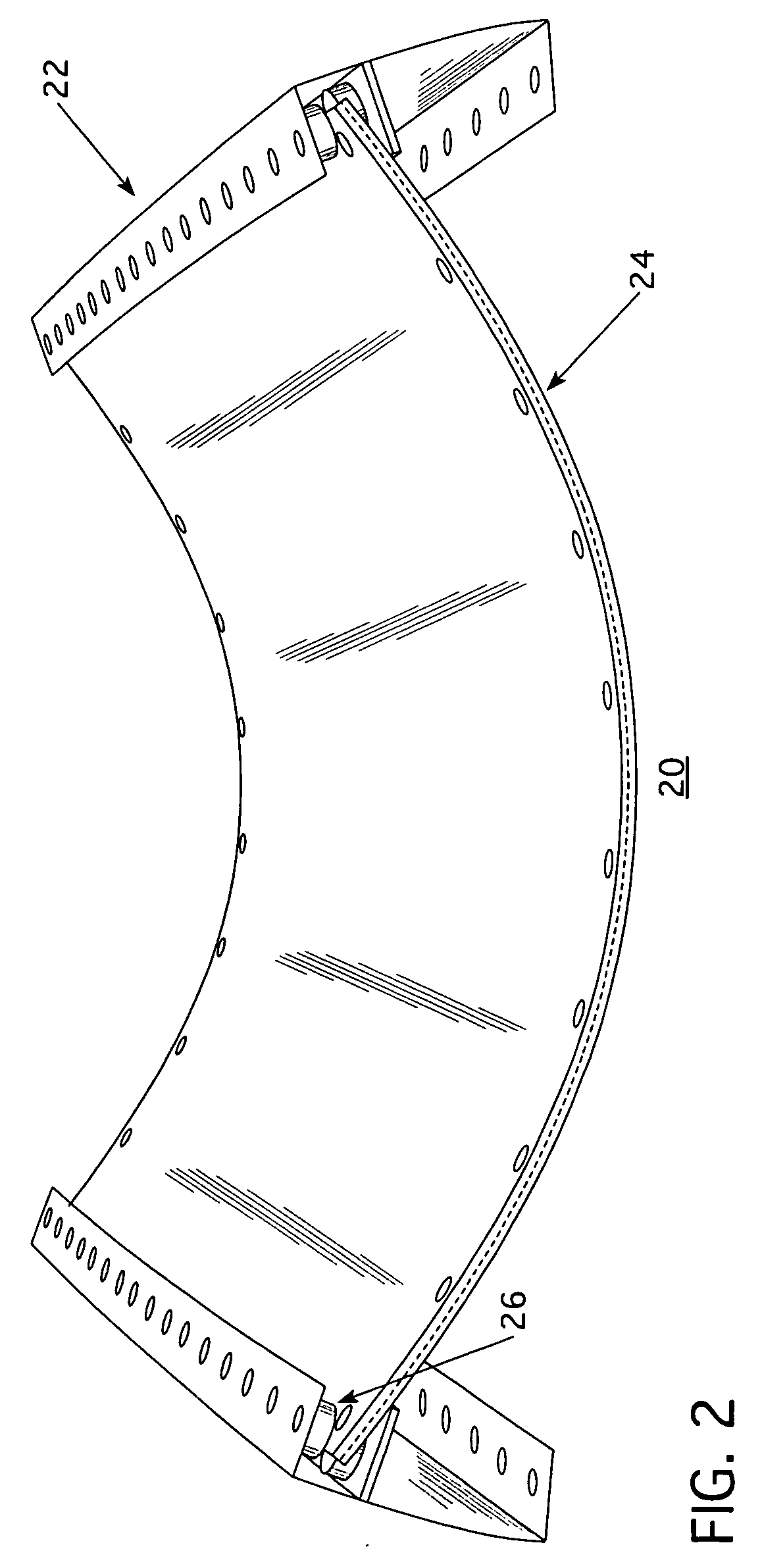

The present invention provides a bi-active method of mounting a monolithic polycarbonate sheet or a laminate in a semi-rigid metallic framing system along two parallel sides of a rectangular shaped sheet or laminate with the two shorter parallel sides being unconstrained. In the case of a square shaped sheet, two parallel sides are supported in the semi-rigid frame, and the other two parallel sides are unconstrained. The semi-rigid frame utilizes cylindrically shaped hardware (i.e., bolts, rivets, studs, etc.) to hold the sheet or laminate. The semi-rigid frame is designed, via section and material properties, to flex and hinge about fixed mounting points along the length of the frame.

Owner:PLASKOLITE MASSACHUSETTS LLC +1

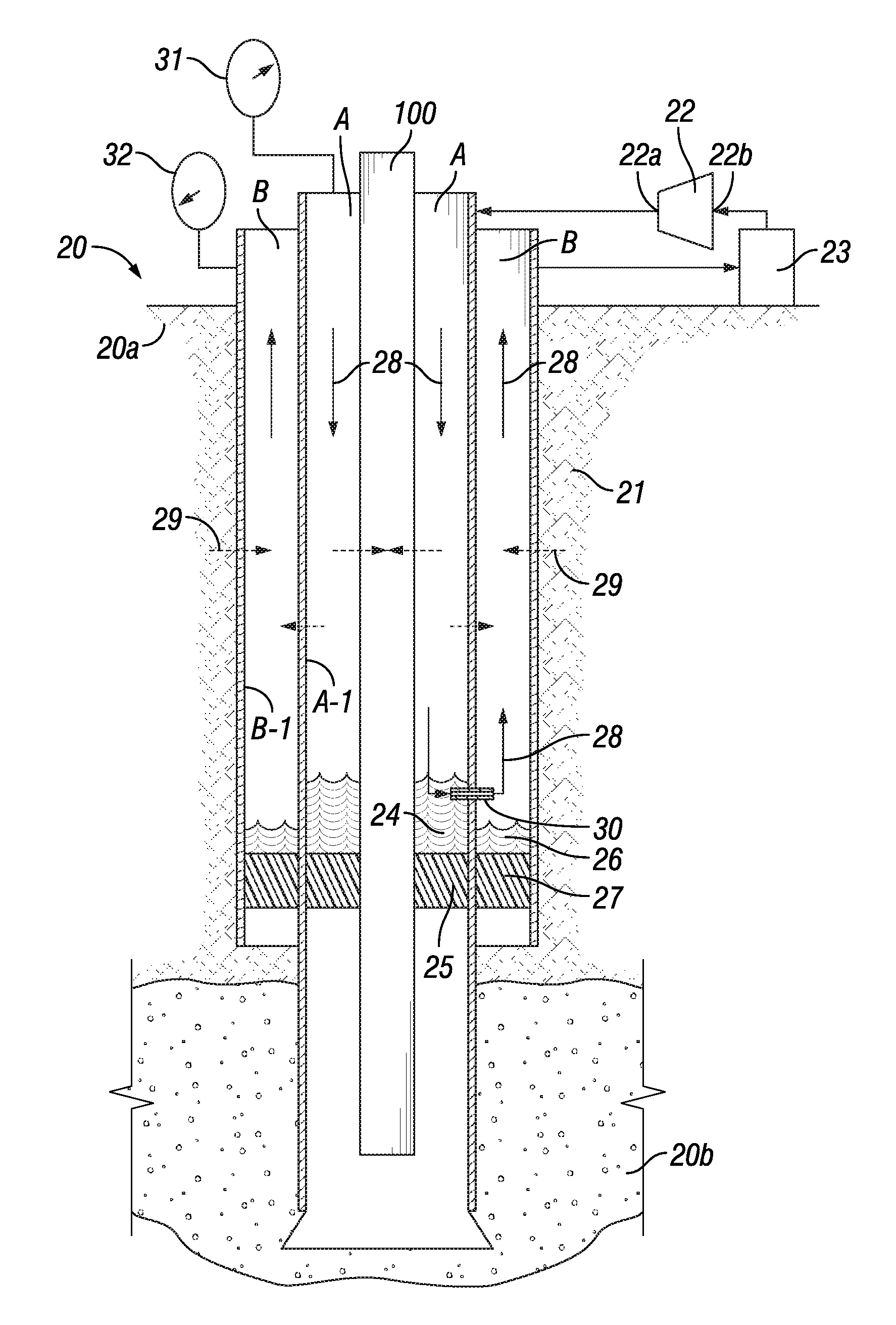

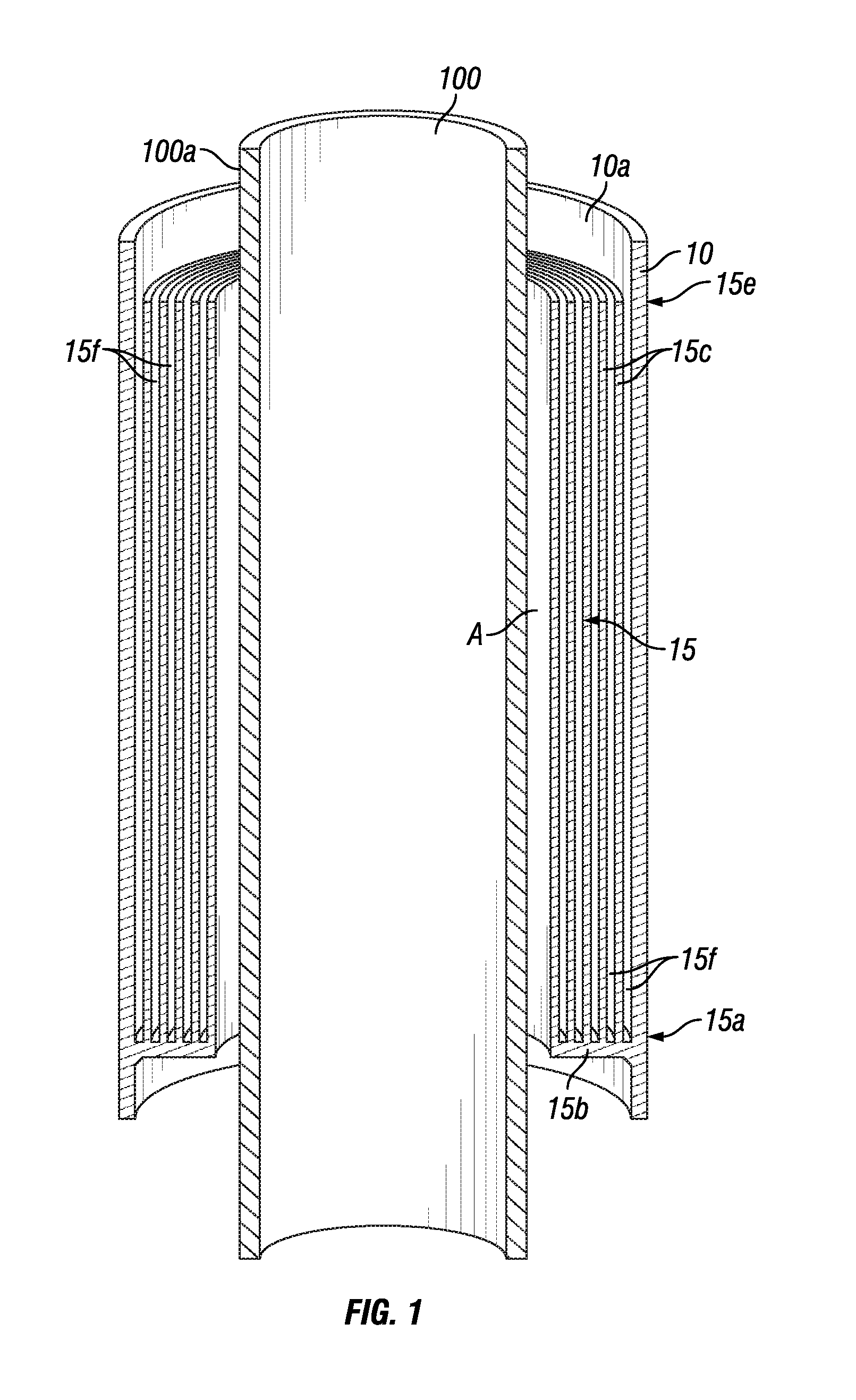

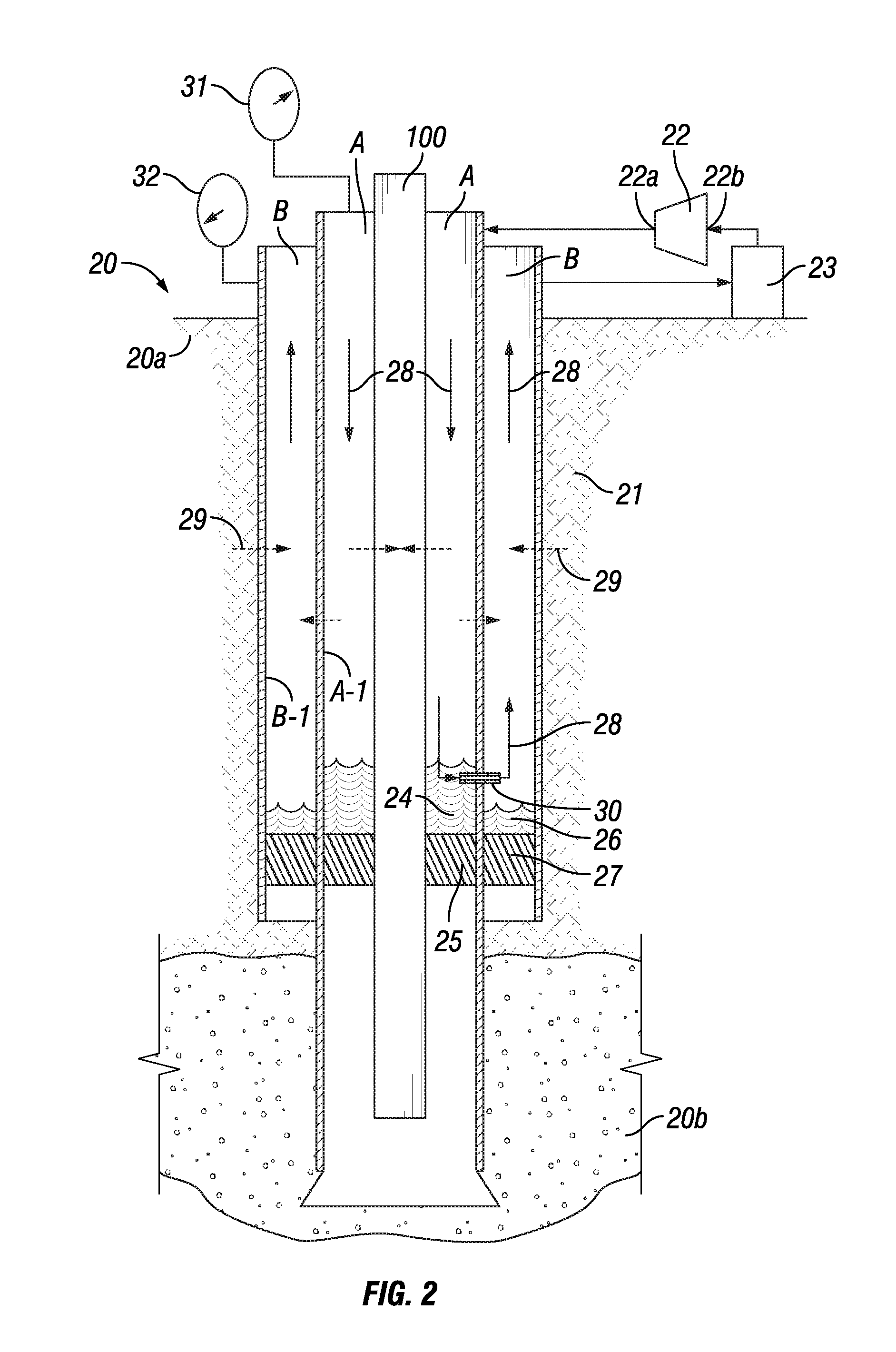

Methods for controlling temperatures in the environments of gas and oil wells

InactiveUS20100200237A1Reduce meltingHigh melting pointInsulationFluid removalPermafrostRefrigerated temperature

Methods and apparatus are provided for controlling temperatures in the environments of oil, gas condensate, or gas wells. Methods are provided for reducing the melting of glaciers and ice dams through the deployment of hydrate-forming substances. Active methods involve employing a vapor-compression refrigerator / heat pump cycle in an annulus lying between the relatively hot production string and the relatively cold outer pipe. Passive methods include: deploying cold hydrate-forming fluids into the external ice-laden environment of an oil, gas condensate, or gas well in a permafrost area and allowing those hydrate forming fluids to mix with any melt-water that may be present or that may subsequently form due to the loss of heat from the oil, gas condensate, or gas well. Mixtures of the hydrate forming fluids and the melt-water will set up into a solid having a much higher melting point and a much lower thermal conductivity than those of ice.

Owner:COLGATE SAM O +1

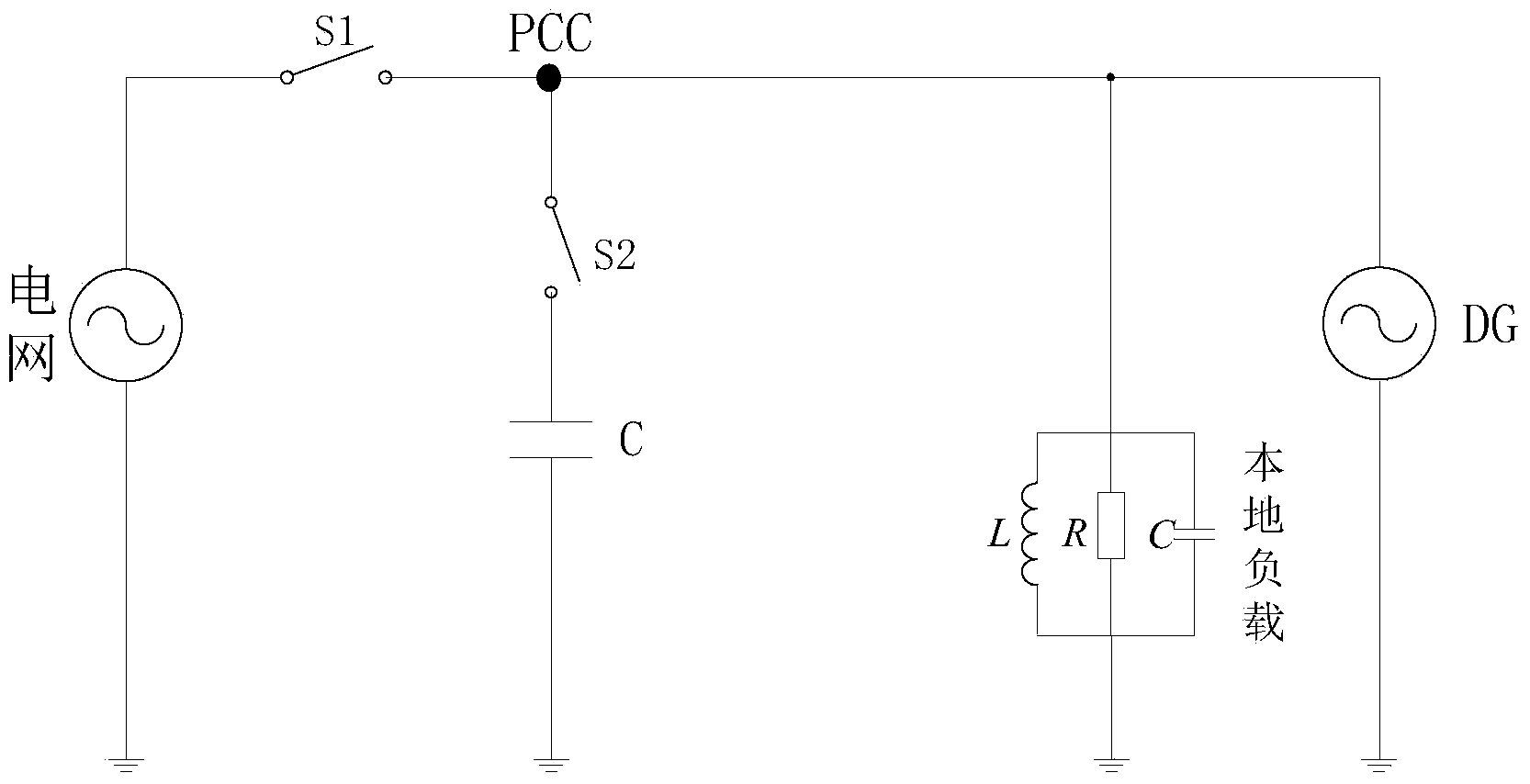

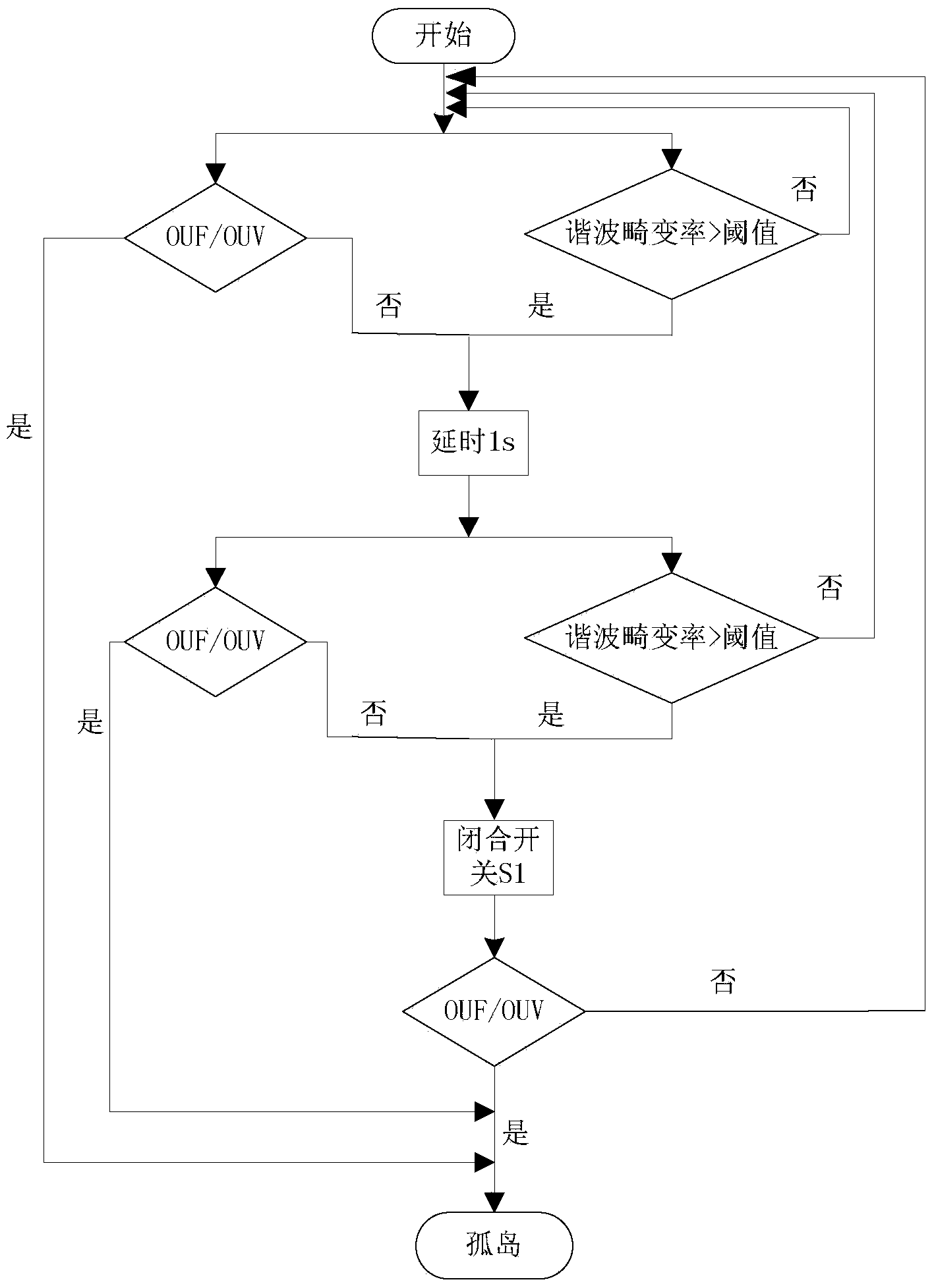

Island detection method

InactiveCN104062529AFast and effective detection functionPower quality does not affectFault locationOvervoltagePower quality

Provided is an island detection method. A passive method and an active method are matched, an island can be detected out fast according to an overfrequency / underfrequency and an overvoltage / undervoltage method, and the quality of electric energy is not affected; when islanding occurs and power matching is formed in an island system, power matching of the system can be destroyed according to a capacitor switching method with harmonic detection as a criterion, voltage and frequency in the system are made to change, and consequently the island is detected out.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for reactivating palledium/carbon catalyst

The invention relates to a Pd carbon catalyst anew active method. The method did justice of inactivation catalyst to obtain anew active Pd / carbon catalyst supplied for the TA hydrorefining reaction. The method includes: use out threshold CO2 extract washing inactivation Pd / carbon catalyst; put the inactivation Pd / carbon catalyst into nitric acid solution to boil up; after drying park in the hartshorn; in addition add to PdCl2; after filtration get the catalyst prosome; catalyst prosome through NaOH and formaldehyde revert,drying get the anew active Pd / carbon catalyst.

Owner:SINOPEC YANGZI PETROCHEM

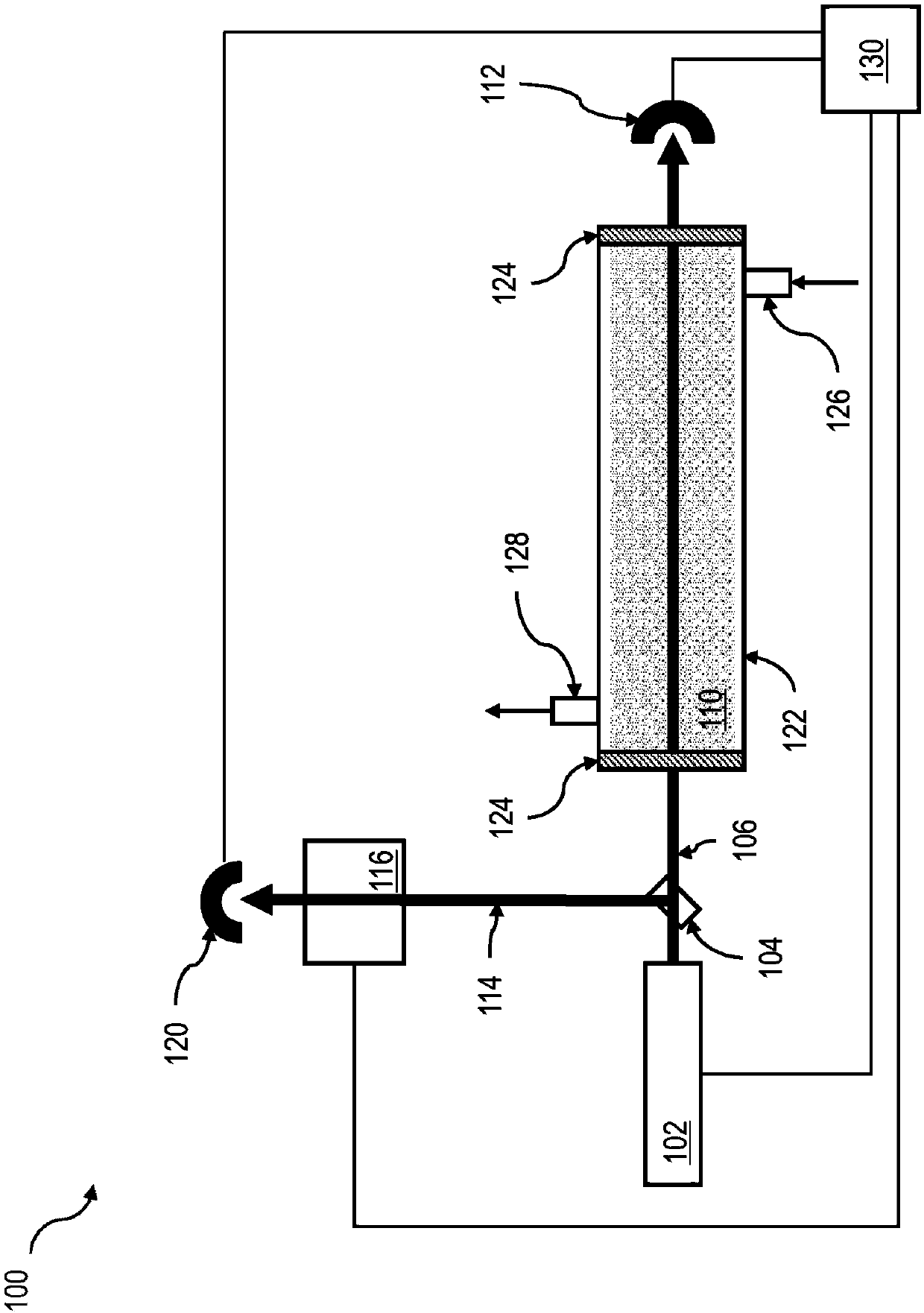

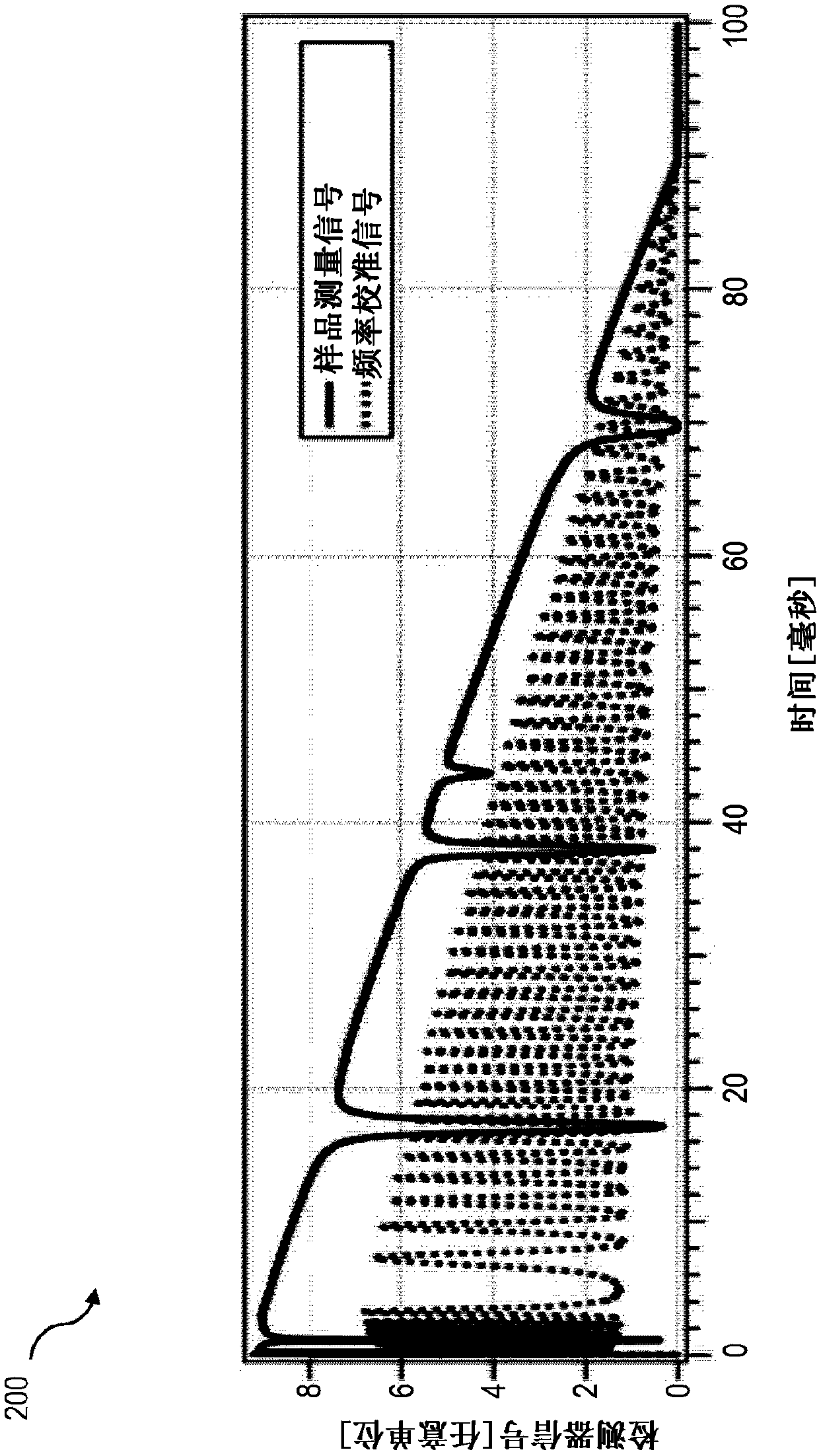

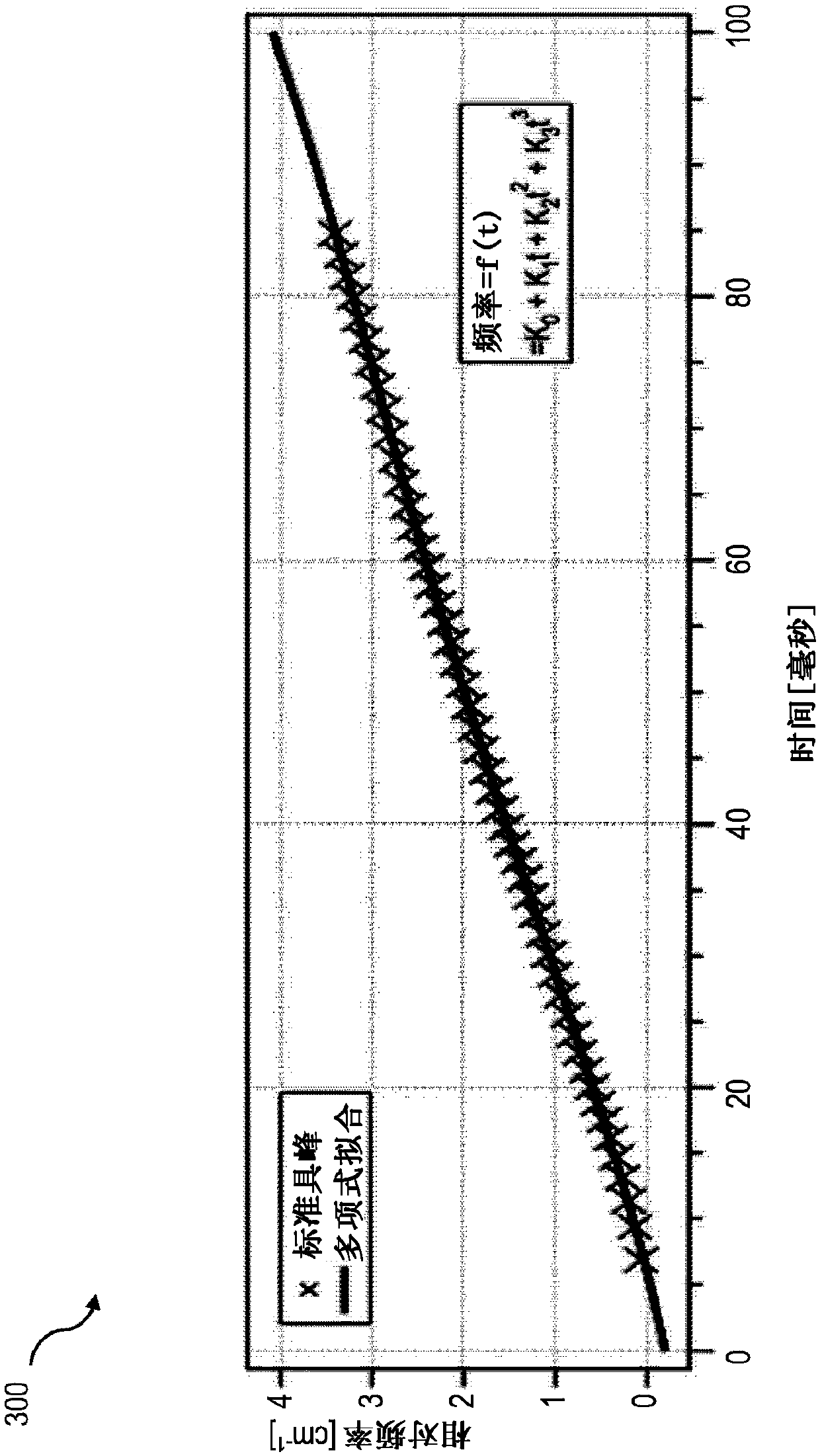

Reconstruction of frequency registration deviations for quantitative spectroscopy

ActiveCN107923794ARadiation pyrometryAbsorption/flicker/reflection spectroscopySpectroscopyAcoustics

Frequency registration deviations occurring during a scan of a frequency or wavelength range by a spectroscopic analysis system can be corrected using passive and / or active approaches. A passive approach can include determining and applying mathematical conversions to a recorded field spectrum. An active approach can include modifying one or more operating parameters of the spectroscopic analysissystem to reduce frequency registration deviation.

Owner:ENDRESS + HAUSER OPTICAL ANALYSIS INC

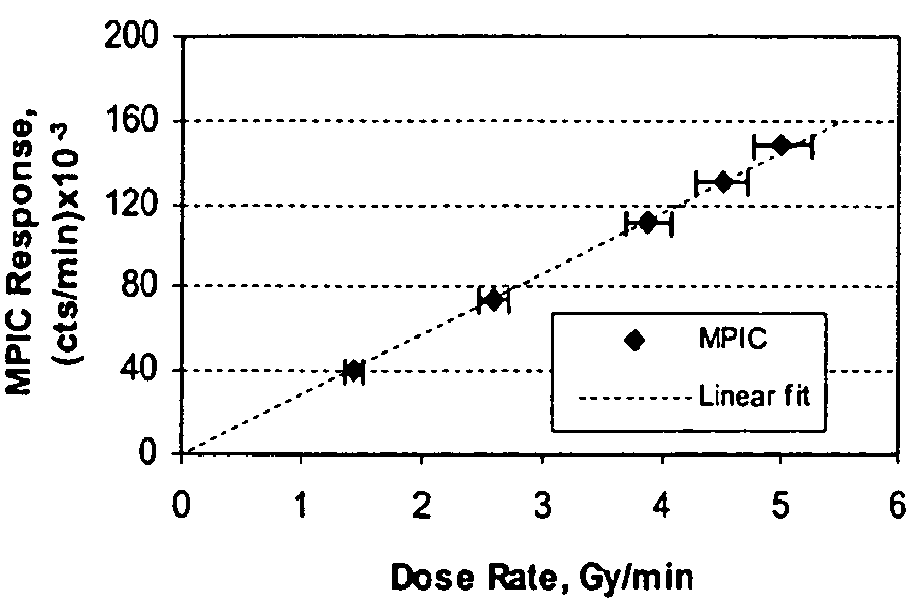

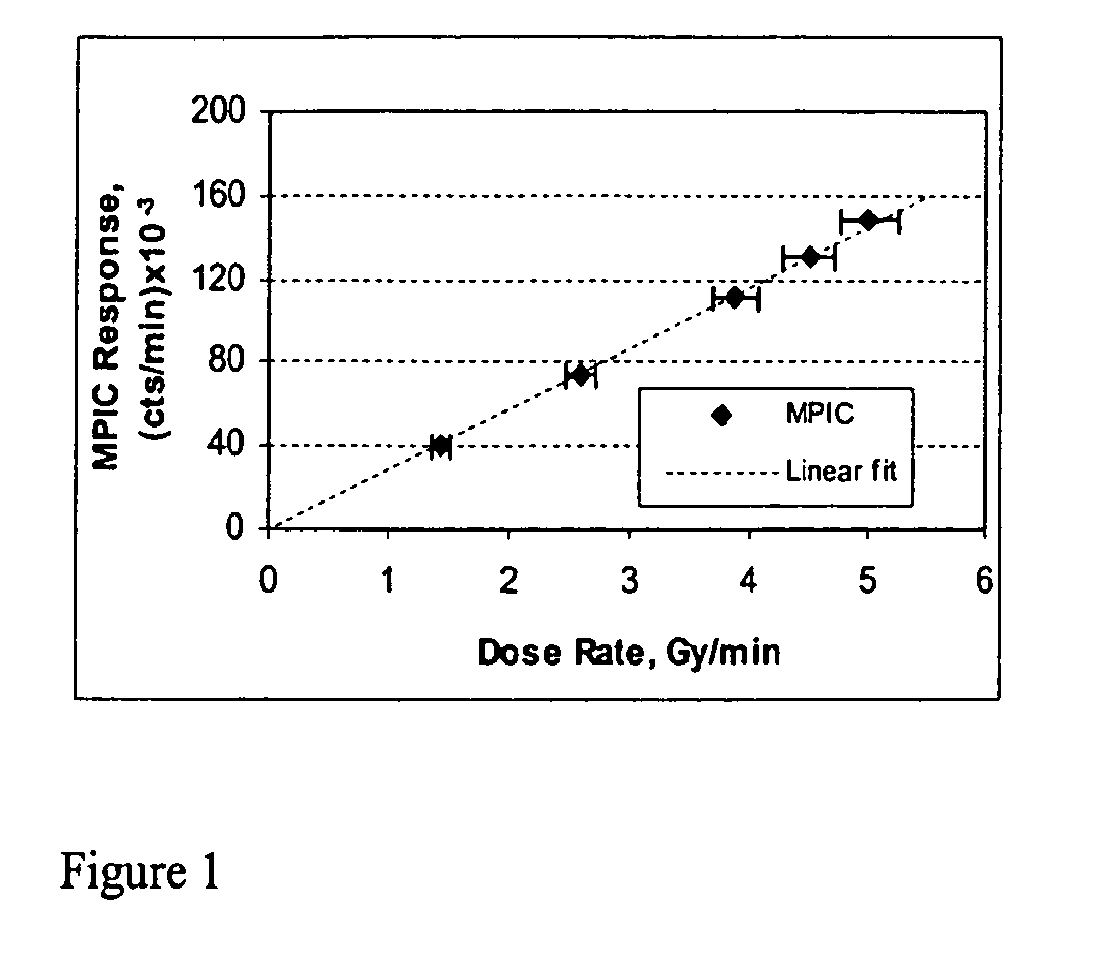

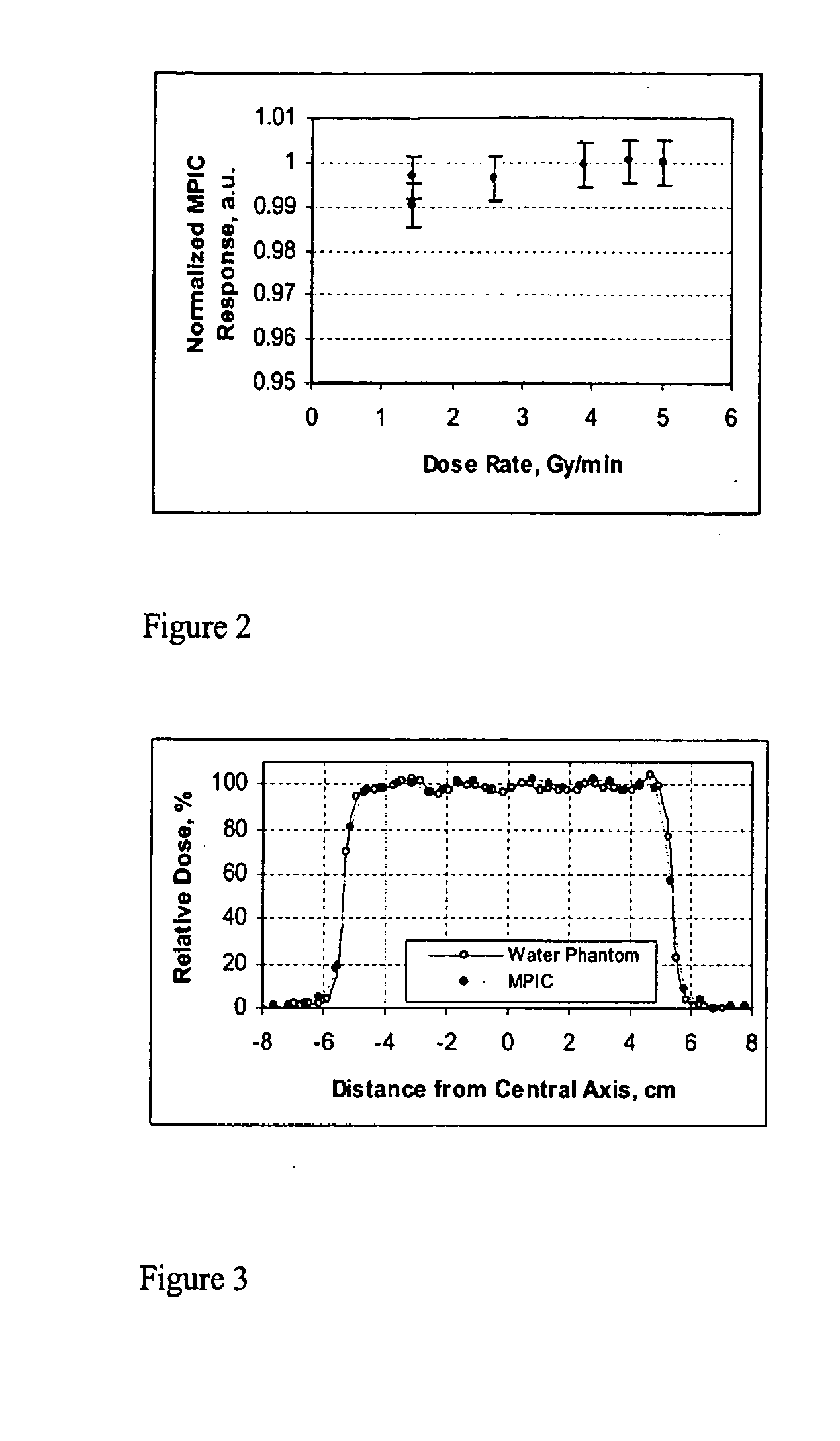

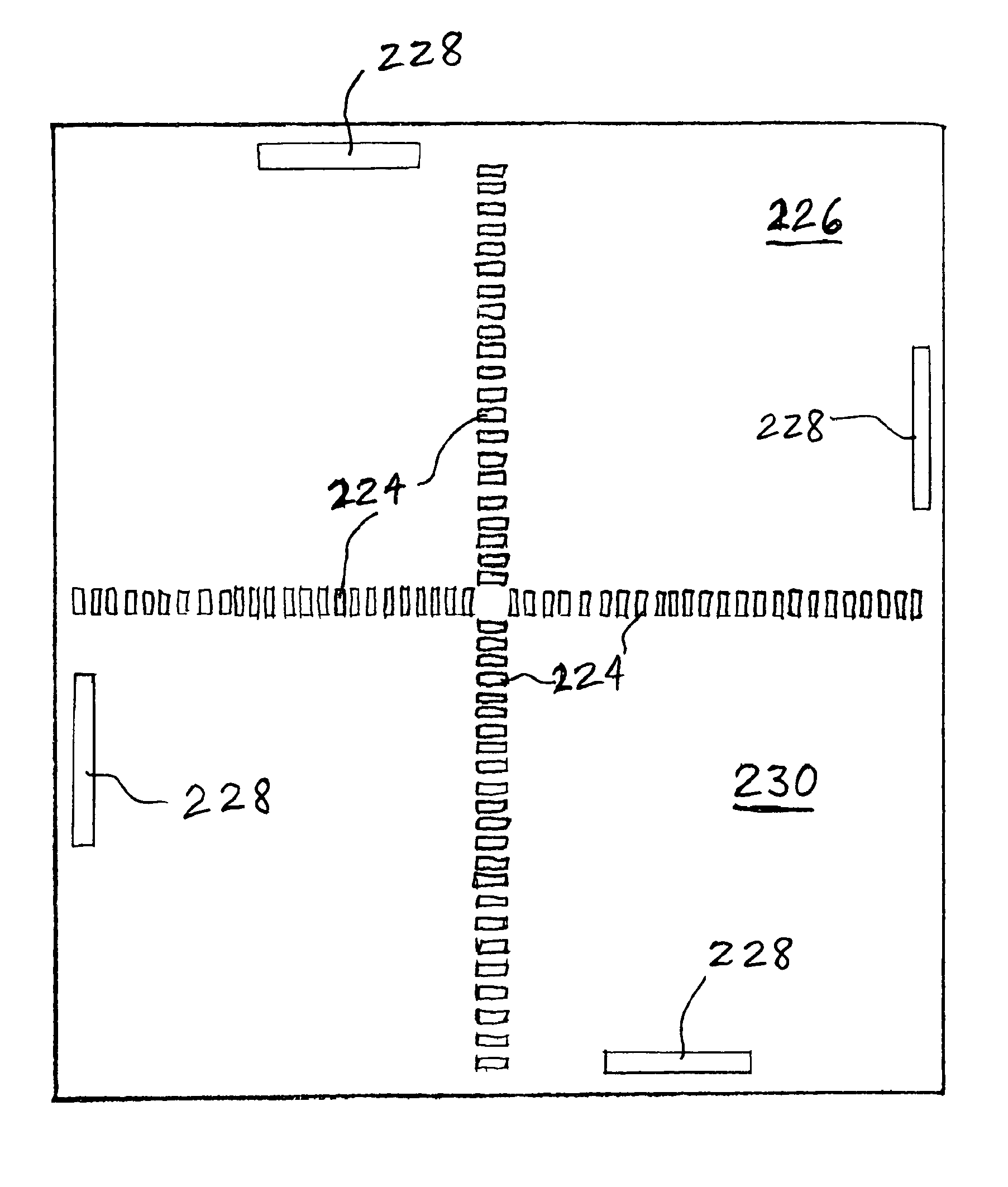

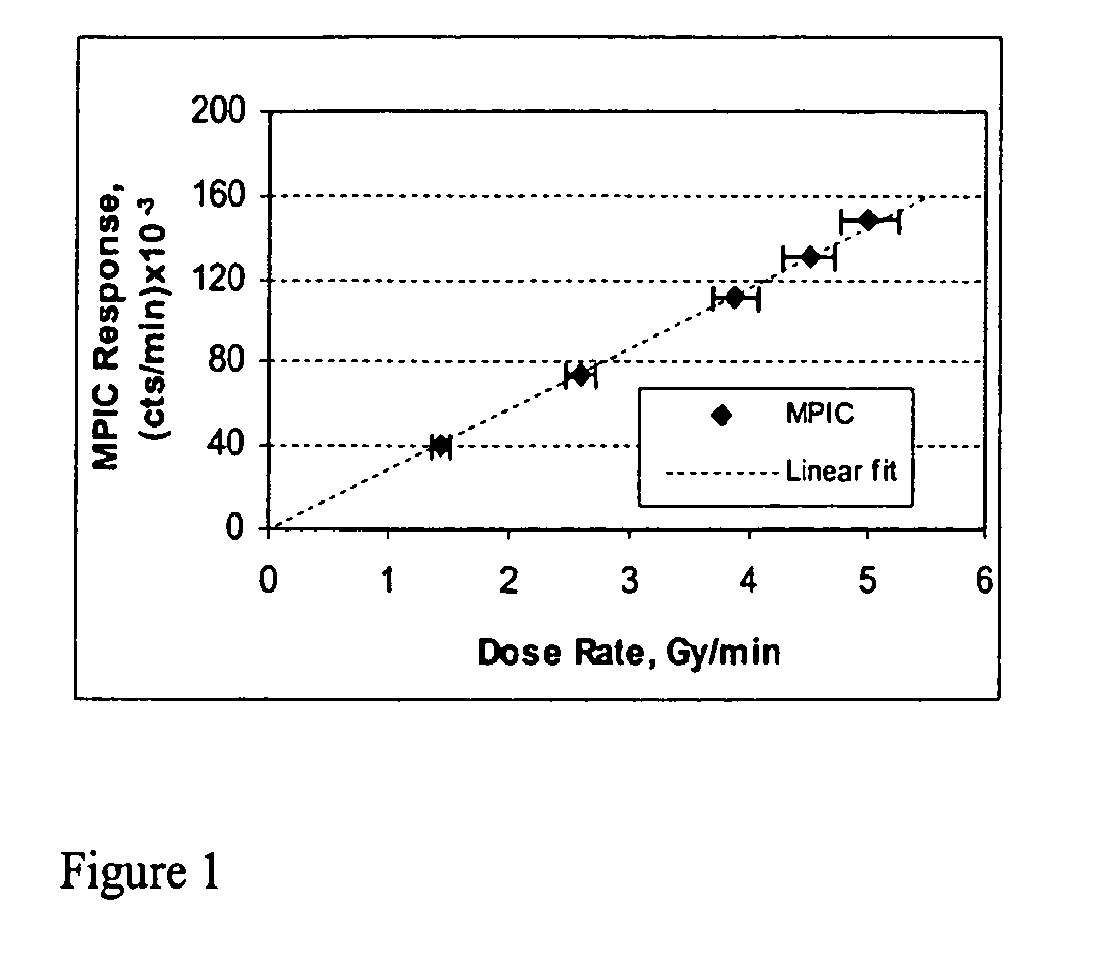

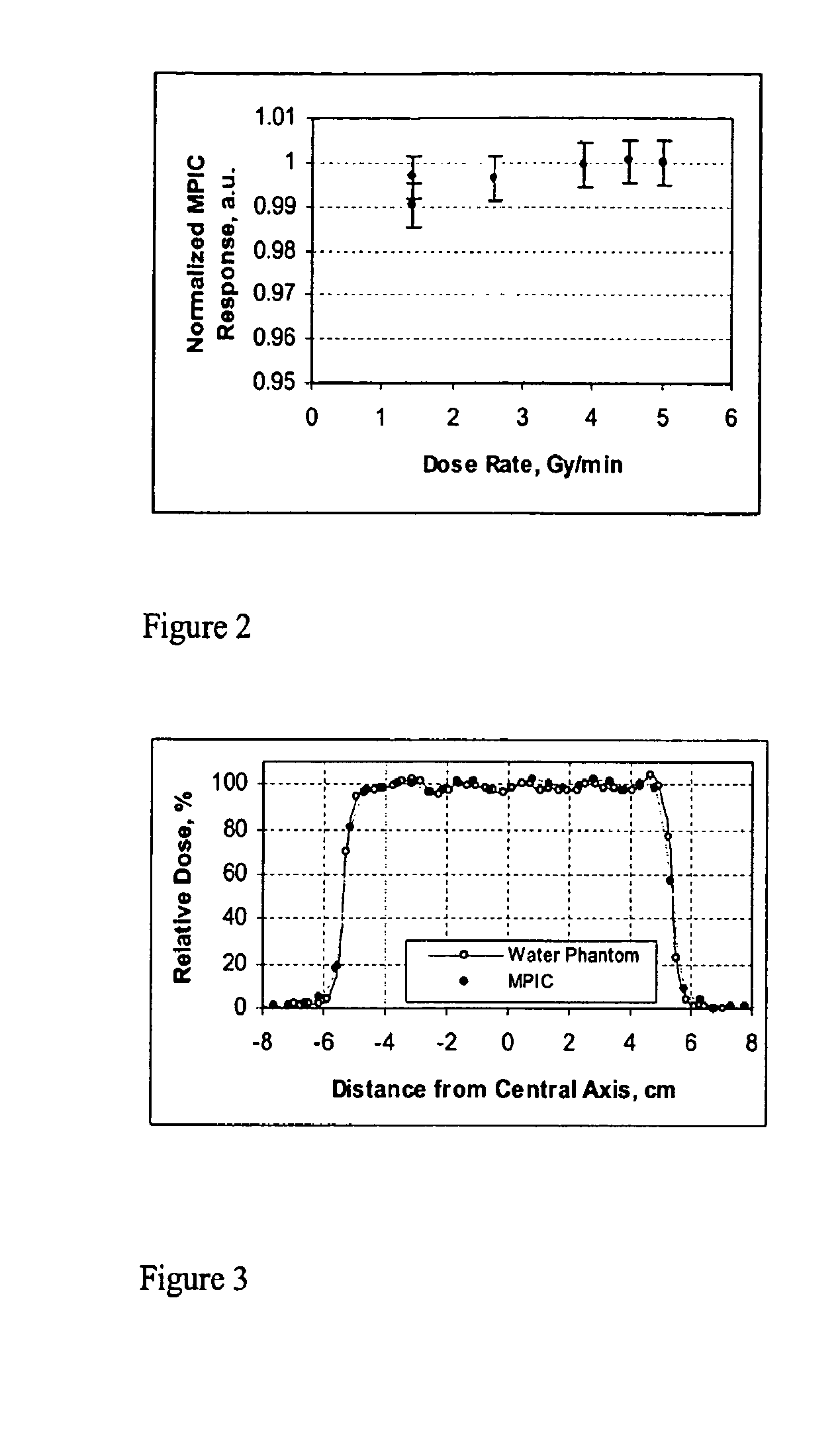

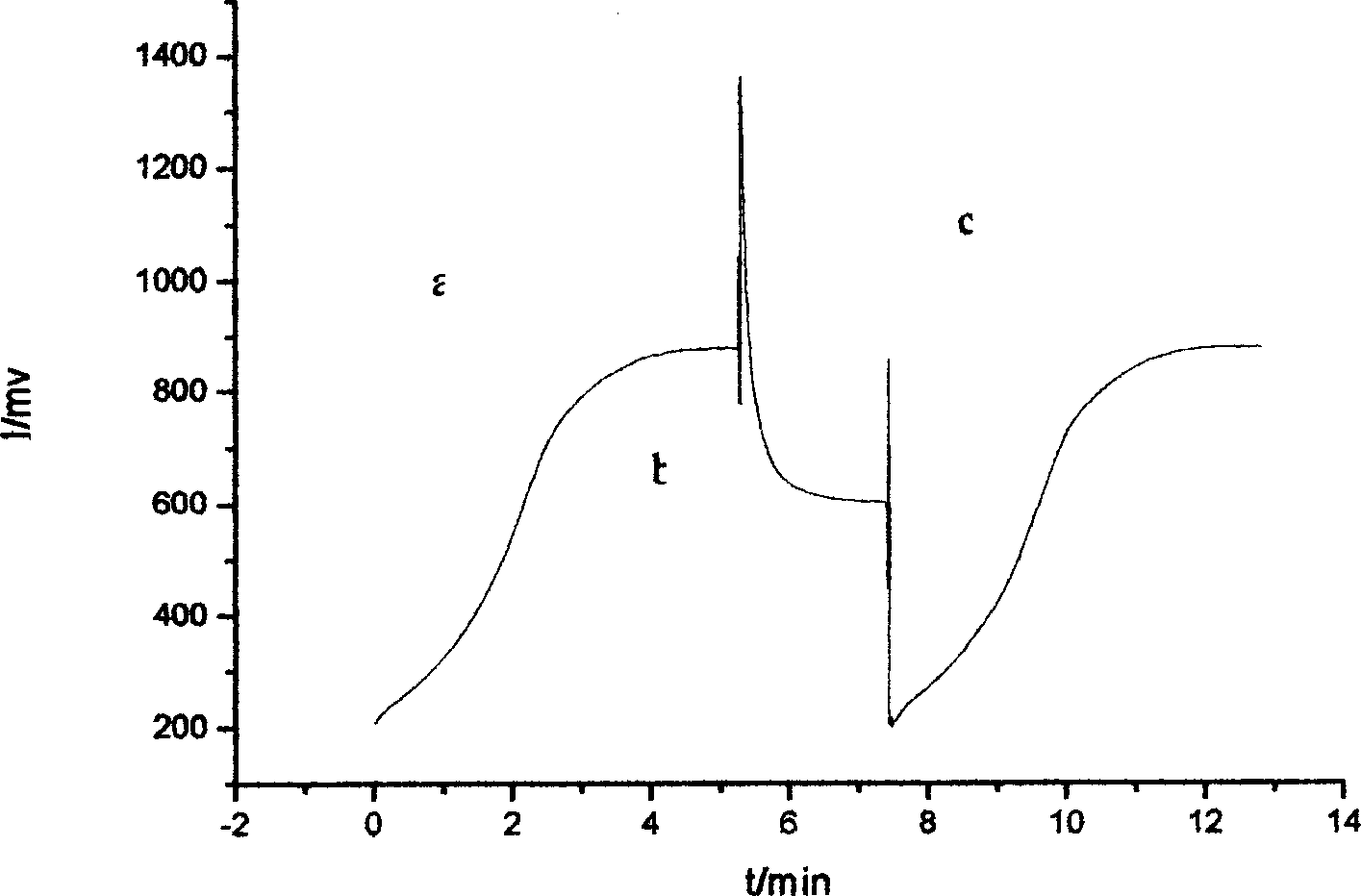

Dose profile measurement system for clinical proton fields

InactiveUS20100171504A1Sufficient precisionMinimize the numberMaterial analysis by electric/magnetic meansX/gamma/cosmic radiation measurmentDose profileData acquisition

A beam profile measurement detector is a tool to efficiently verify dose distributions created with active methods of a clinical proton beam delivery. A Multi-Pad Ionization Chamber (MPIC) has 128 ionization chambers arranged in one plane and measure lateral profiles in fields up to 38 cm in diameter. The MPIC pads have a 5 mm pitch for fields up to 20 cm in diameter and a 7 mm pitch for larger fields, providing an accuracy of field size determination of about 0.5 mm. The Multi-Layer Ionization Chamber (MLIC) detector contains 122 small-volume ionization chambers stacked at a 1.82 mm step (water-equivalent) for depth-dose profile measurements. The MLIC detector can measure profiles up to 20 cm in depth, and determine the 80% distal dose fall-off with about 0.1 mm precision. Both detectors can be connected to the same set of electronics modules, which form the detectors' data acquisition system. The detectors operate in proton fields produced with active methods of beam delivery such as uniform scanning and energy stacking. The MPIC and MLIC detectors can be used for dosimetric characterization of clinical proton fields.

Owner:INDIANA UNIV RES & TECH CORP

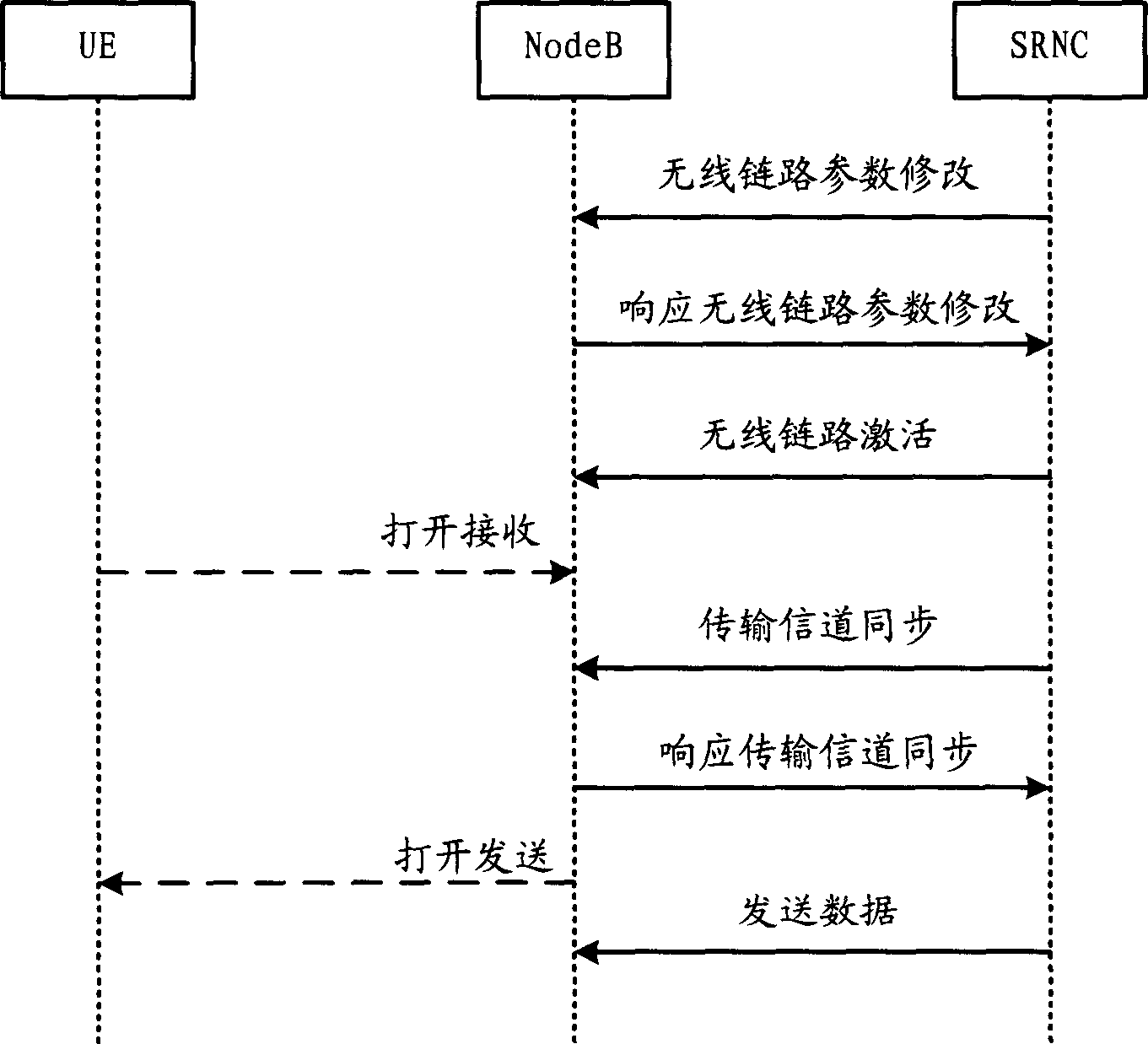

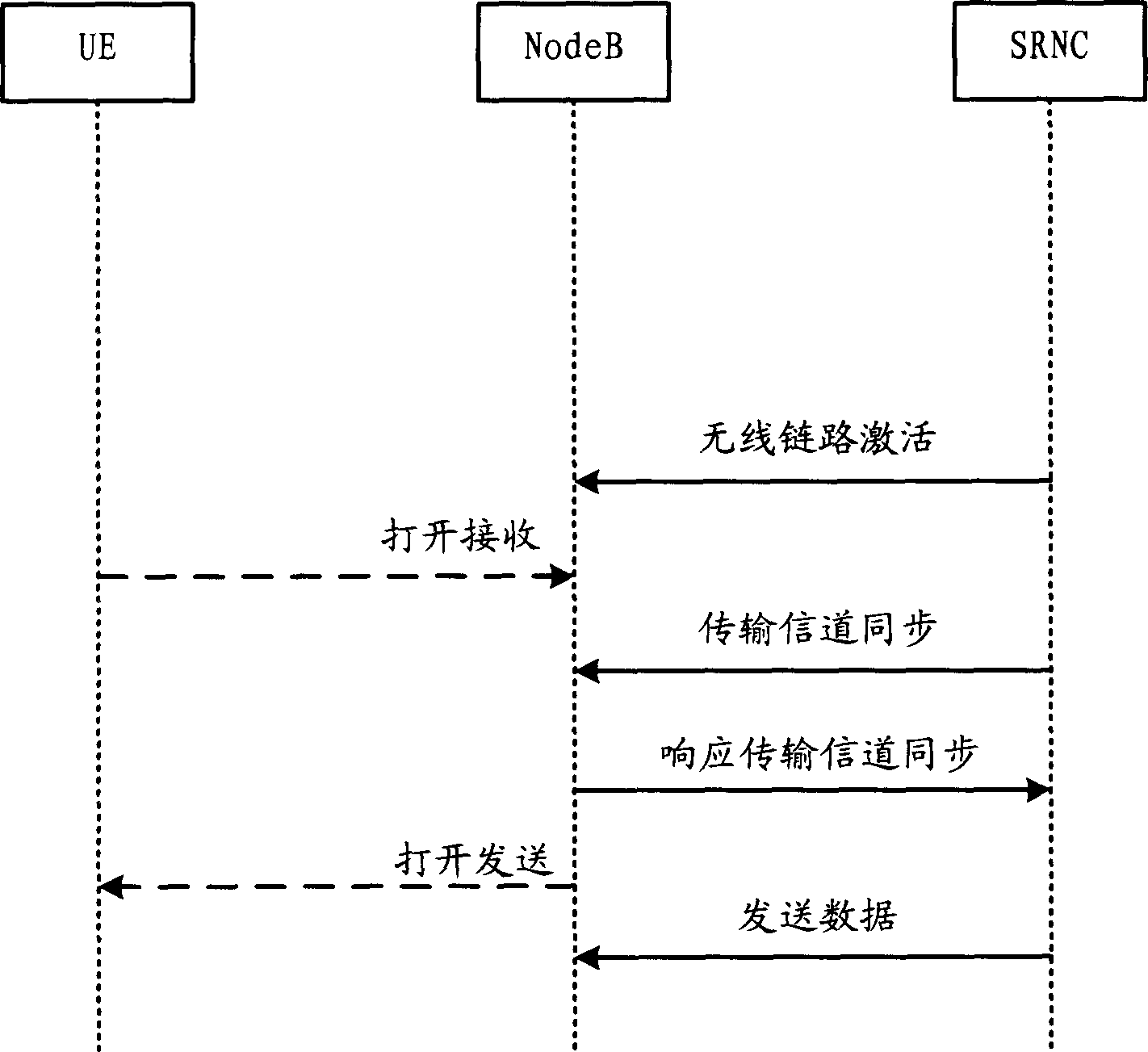

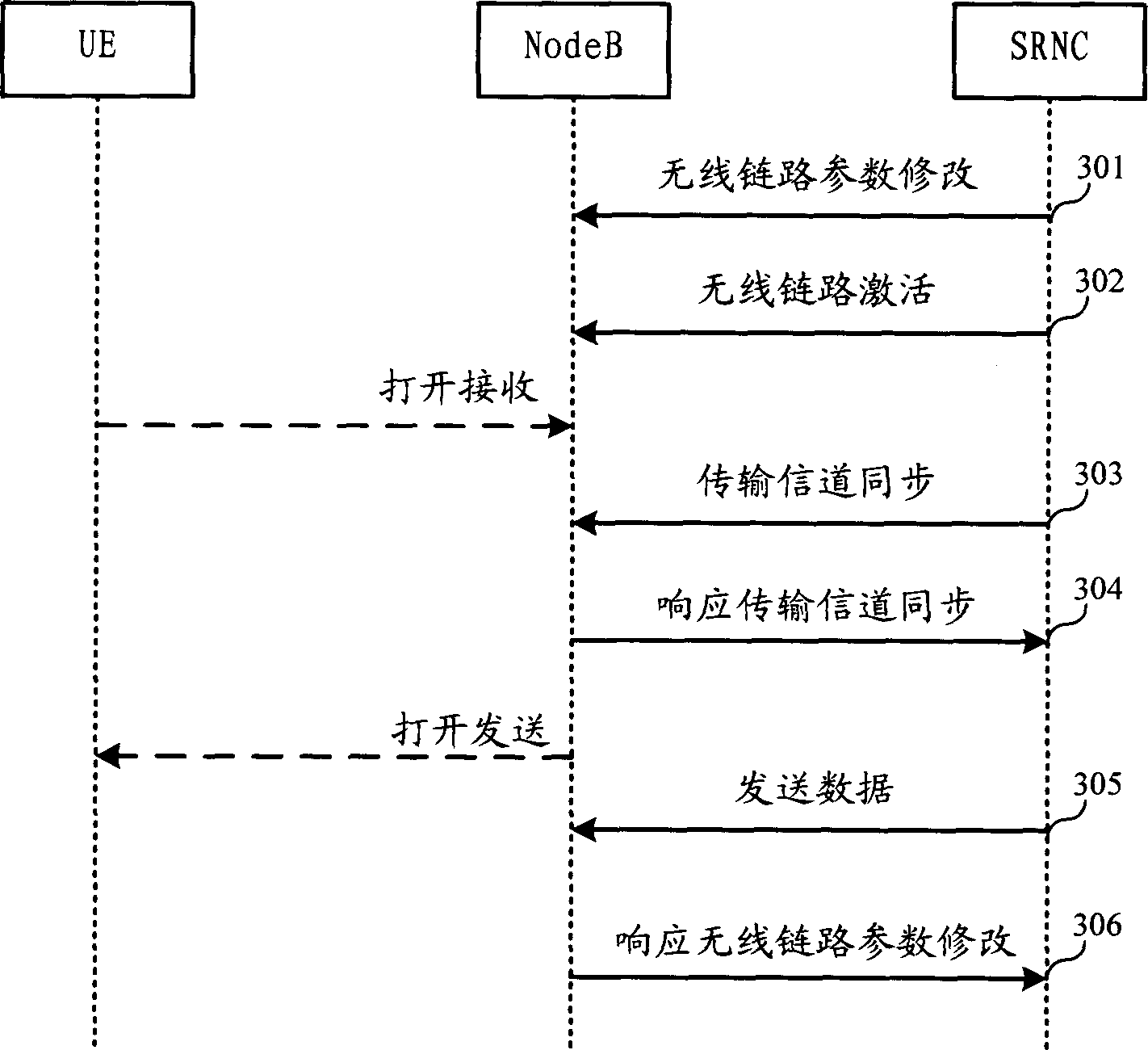

Preset resource active method in mobile communication system

InactiveCN1832614AEnsure reliabilityShorten the effective timeNetwork traffic/resource managementRadio/inductive link selection arrangementsCommunications systemSynchronous control

This invention relates to a process method for preserved resources in the mobile communication system, which applies different technologies to judge if the preserved resource activated parameters of SRNC to NodeB are effective to guarantee prompt and reliable communication, for example, the synchronous poll of the SRNC to the preserved resource periodic transmission channels is changed to that the NodeB responds the synchronous control frame of the transmiossion channels only after the activation and the parameter are valid to provide the criterion in the activation process.

Owner:SHANGHAI HUAWEI TECH CO LTD

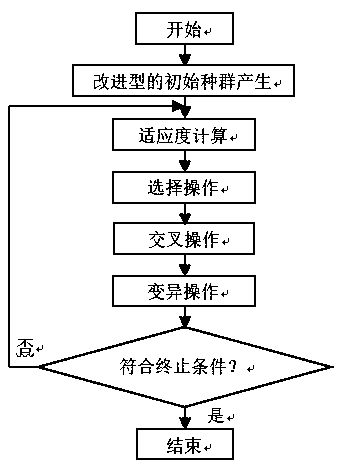

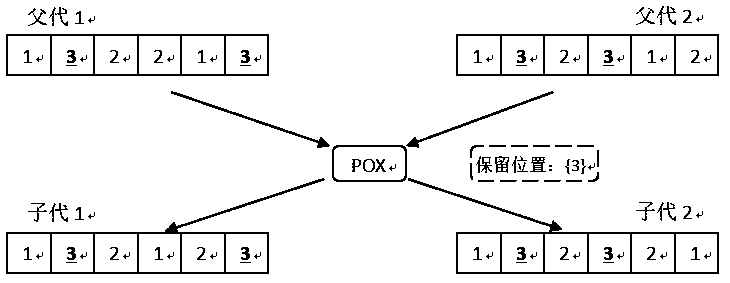

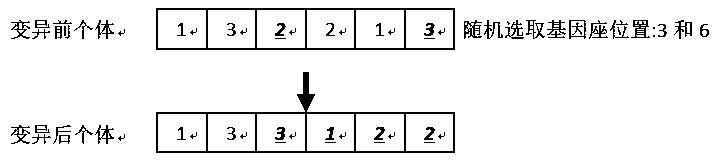

Job-shop scheduling method based on an improved genetic algorithm

InactiveCN108805403ADiversity guaranteedQuality improvementArtificial lifeResourcesCompletion timeAlgorithm

The invention discloses a job-shop scheduling method based on an improved genetic algorithm. The method comprises the operation steps of (1) determining operation parameters, including a population scale, a crossover probability, a variation probability and the number of iterations; (2) generating an improved initial population, and combining individuals generated by adopting an active method withindividuals generated randomly in a certain proportion to form an initial population; (3) performing fitness calculation, and taking a reciprocal of the total completion time of a scheduling scheme corresponding to the individuals as a fitness value; (4) performing selection operation by adopting a roulette selection operator; (5) performing crossover operation by selecting and using a POX crossover operator; (6) selecting and using an inverse variation operator as a variation operator; and (7) performing stop judgment, judging whether a stop condition is met or not, and if yes, stopping theprocess and outputting an optimal scheduling scheme, otherwise, going to the step (3). According to the method, the convergence speed of solving can be increased; the solving performance is good; andfor the production scheduling problem of job-shop, the method has high application values.

Owner:SHANGHAI UNIV

Dose profile measurement system for clinical proton fields

InactiveUS8552731B2Sufficient precisionMinimize the numberMaterial analysis by electric/magnetic meansX/gamma/cosmic radiation measurmentDose profileData acquisition

Owner:INDIANA UNIV RES & TECH CORP

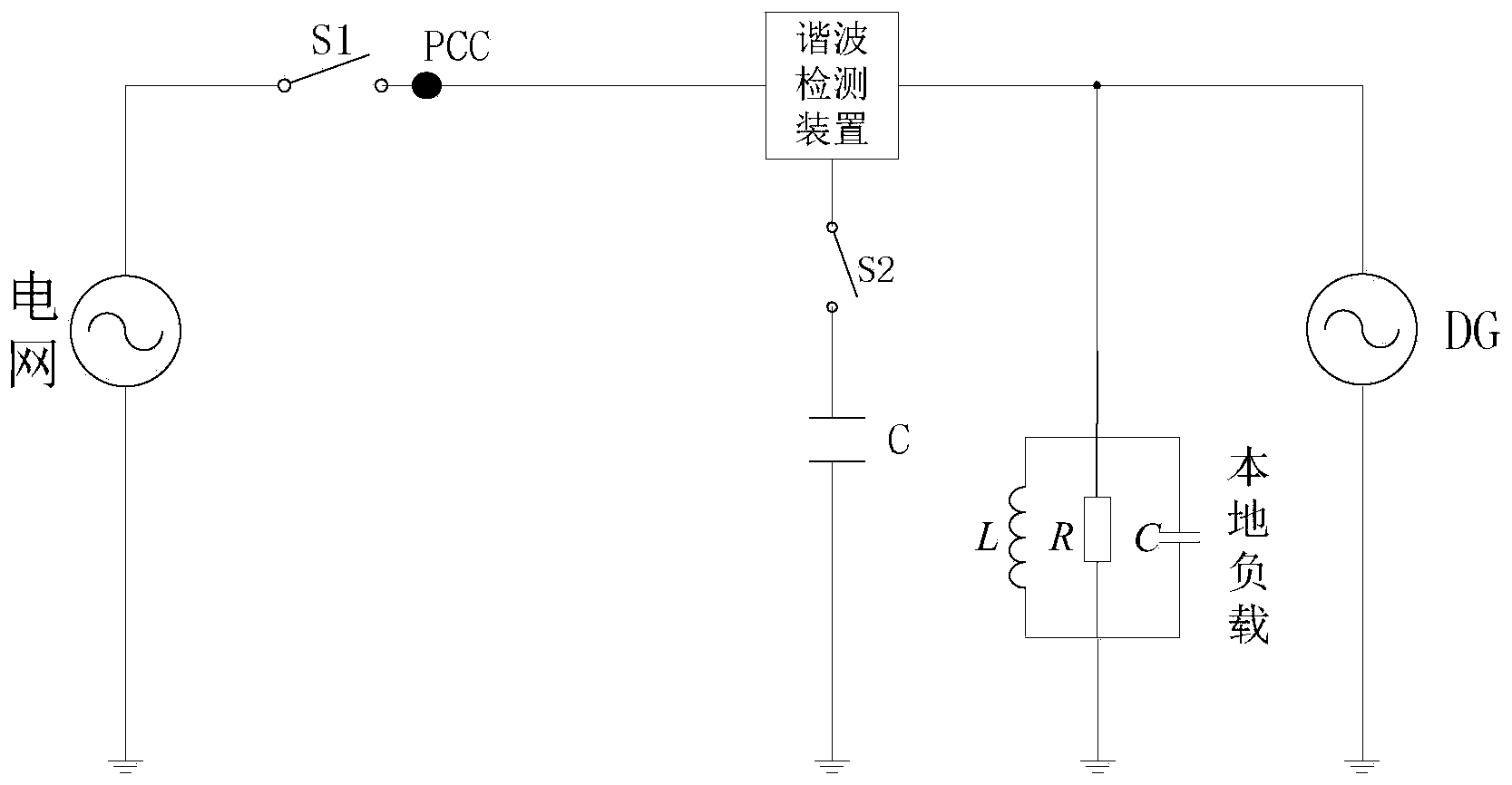

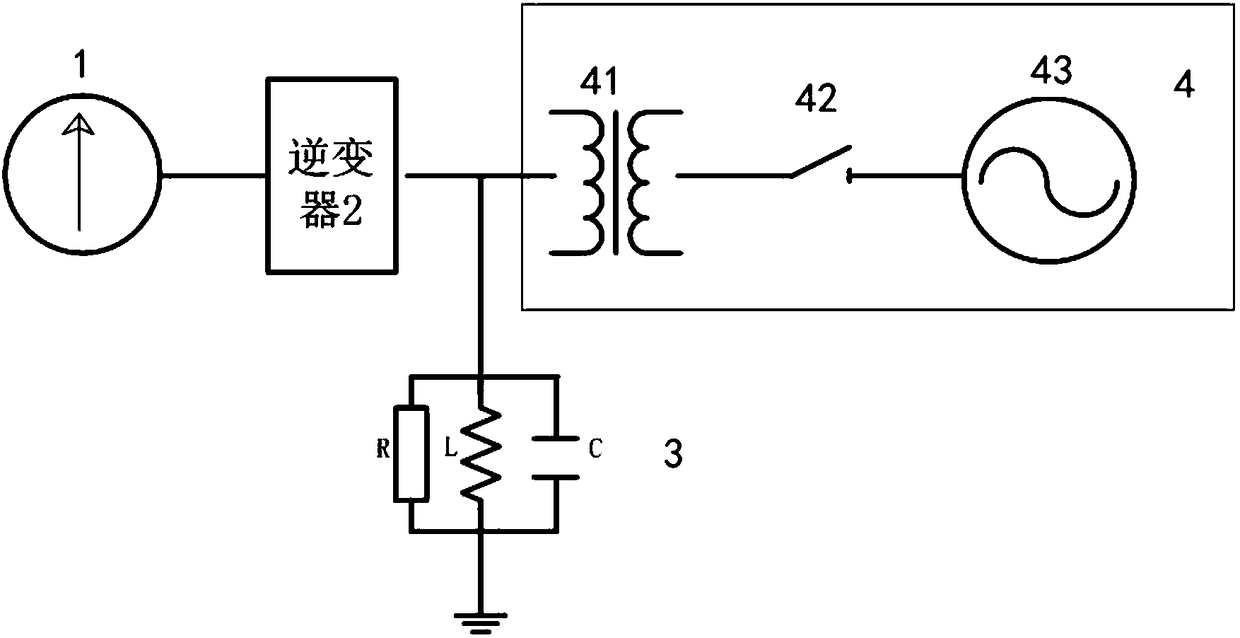

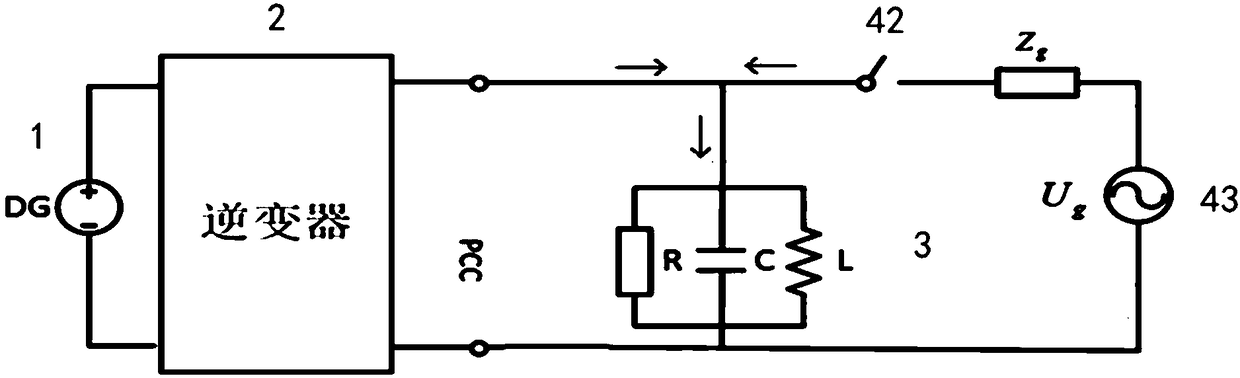

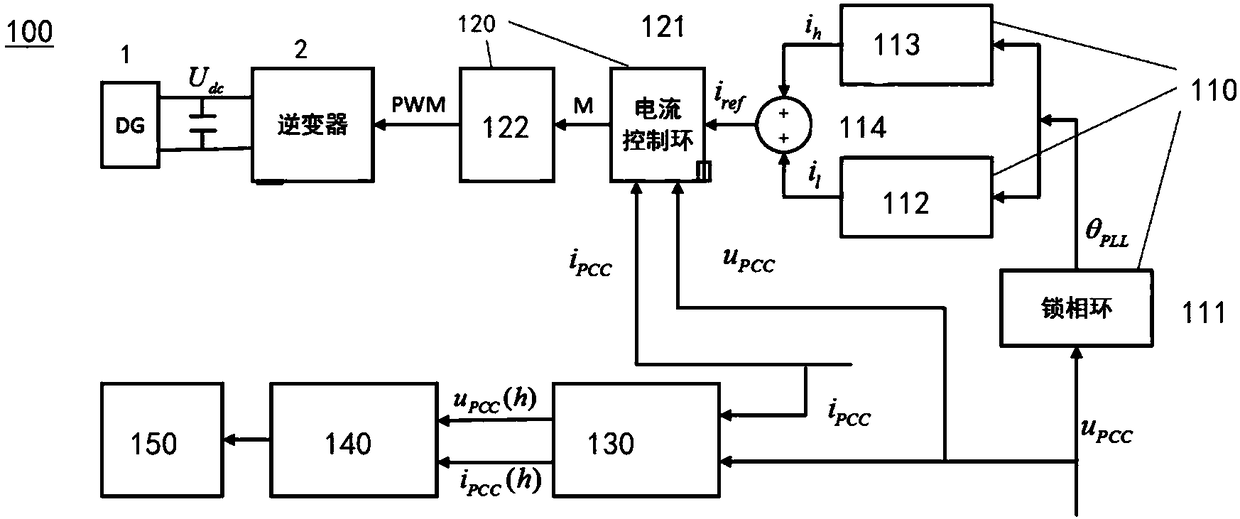

Inter-harmonic impedance-based island detection system and detection method

InactiveCN108152672AEasy to measureAccurate and effective detectionFault locationVoltage amplitudeEngineering

The invention provides an inter-harmonic impedance-based island detection system and a detection method thereof. The system comprises a reference signal generation module used for generating a corresponding inter-harmonic reference signal according to a voltage signal at a common coupling point; a driving module used for carrying out pulse width modulation on the inter-harmonic reference signal and driving an inverter to work by adopting a current signal at the common coupling point; a signal detection module used for detecting the inter-harmonic content of the voltage signal and the current signal in real time, and obtaining the voltage amplitude value and the current amplitude value of a preset inter-harmonic frequency; an impedance monitoring module used for obtaining the inter-harmonicimpedance of the preset inter-harmonic frequency according to the voltage amplitude value and the current amplitude value; and an island judging module used for judging whether the difference value between the inter-harmonic impedance measured in real time and the inter-harmonic impedance in the grid-connected condition is not smaller than a preset value or not. If the difference value between the inter-harmonic impedance measured in real time and the inter-harmonic impedance in the grid-connected condition is not smaller than the preset value, the island effect is judged to occur. Based on the system and the method, the adverse effect of an active method on the power quality of the power grid can be effectively avoided. A small blind area can be guaranteed, and the high measurement accuracy is achieved.

Owner:BEIJING JIAOTONG UNIV

Method for sieving active component or matter and active component therefrom

InactiveCN101070556AStrong specificityHigh false negativeAntibacterial agentsMicrobiological testing/measurementActive matterAnti mrsa

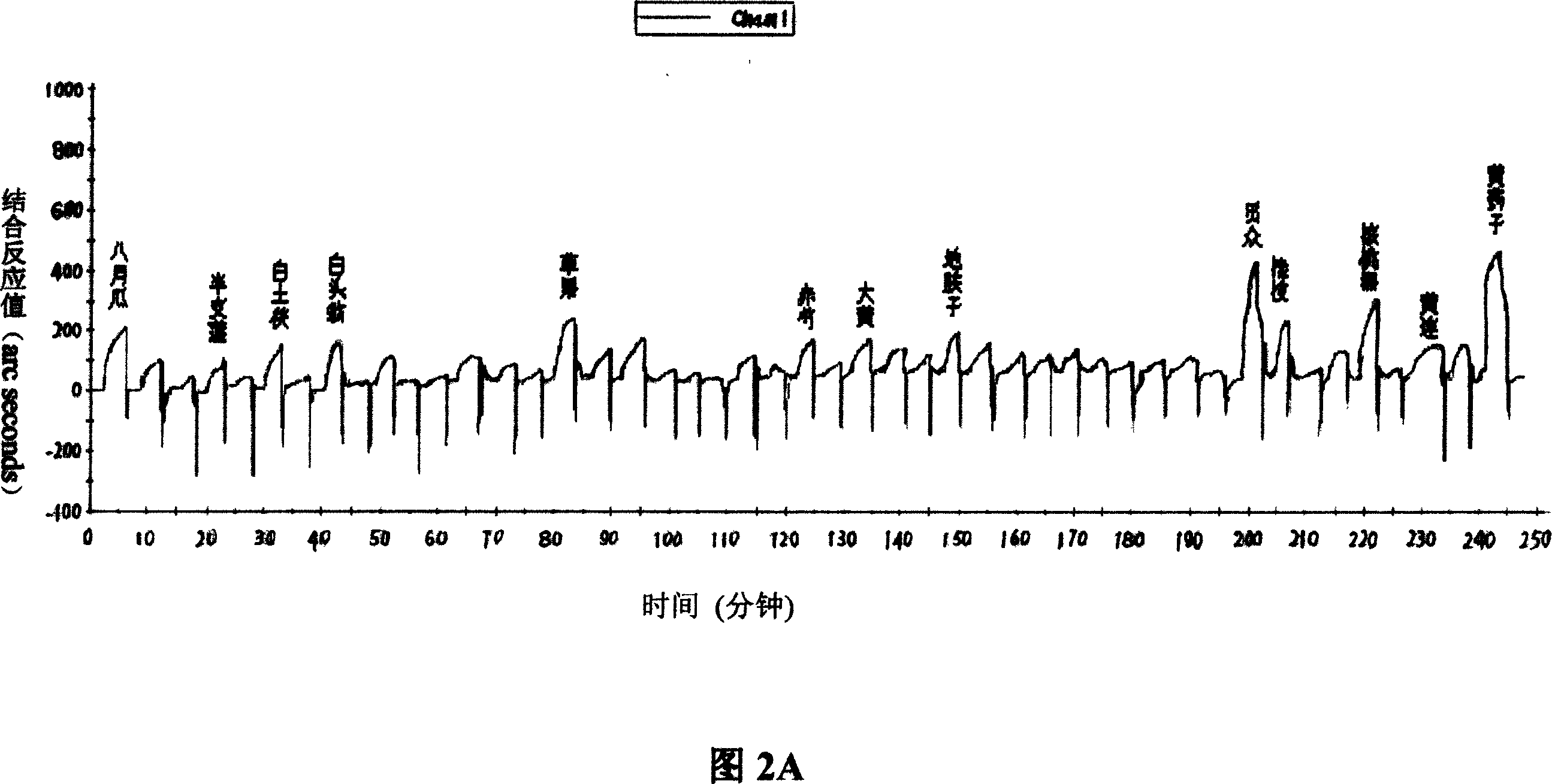

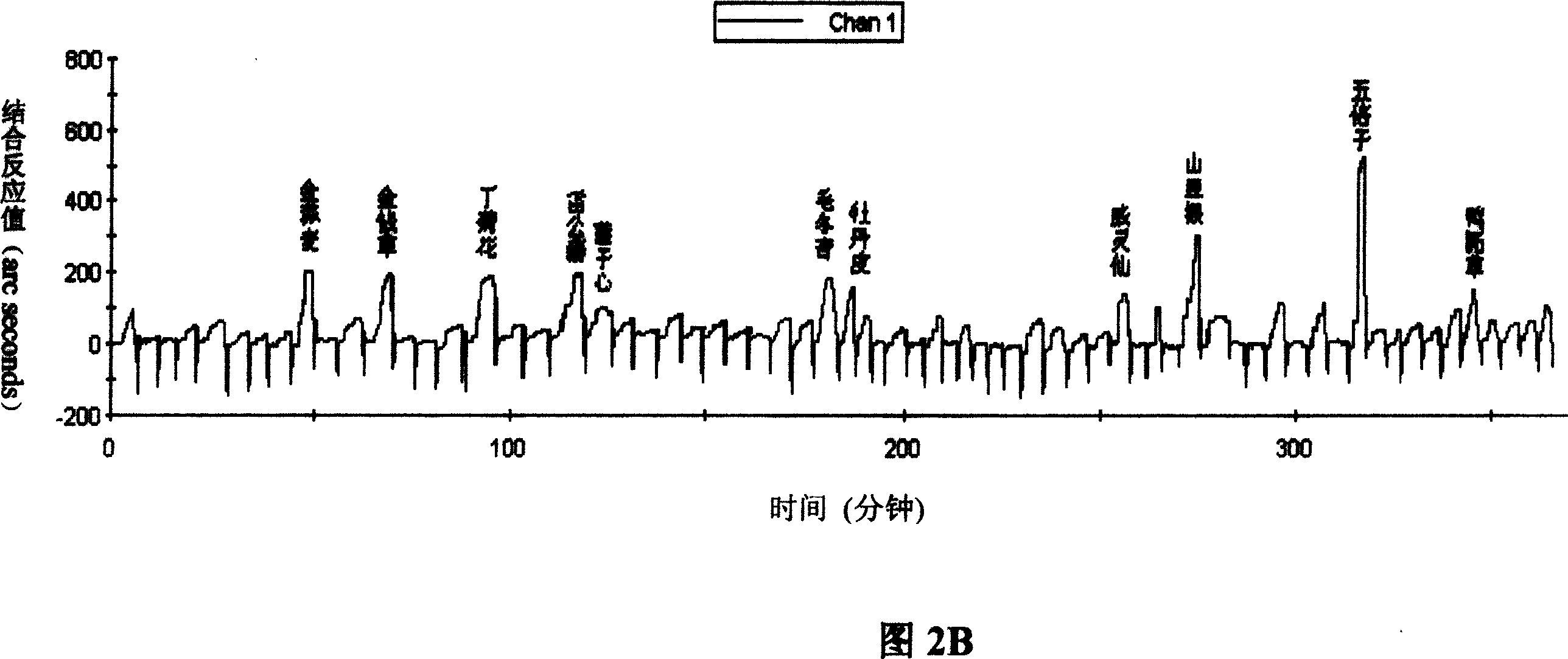

One kind of union biosensor technology and isolation technique, From natural medicine, selection and separation have the combination PBP2a active method of organizing minute or active material, the method will PBP2a coating on the sample pool biosensor match as a solid base to extract natural medicines the mobile phase of the selected combination with PBP2a in the role of natural medicine, will be an integrated component of the higher value after isolation and purification, has been a collaborative antagonistic MRSA activity combined with PBP2a occurred role of the active component, the Preparation synergistic components can be used to beta - lactam antibiotics treatment of MRSA infection drugs or lead compounds. This method has time-saving, the high flux, to reduce effort, the specificity to be strong, the result accurate, can real-time monitoring many kinds of merits.

Owner:ARMY MEDICAL UNIV

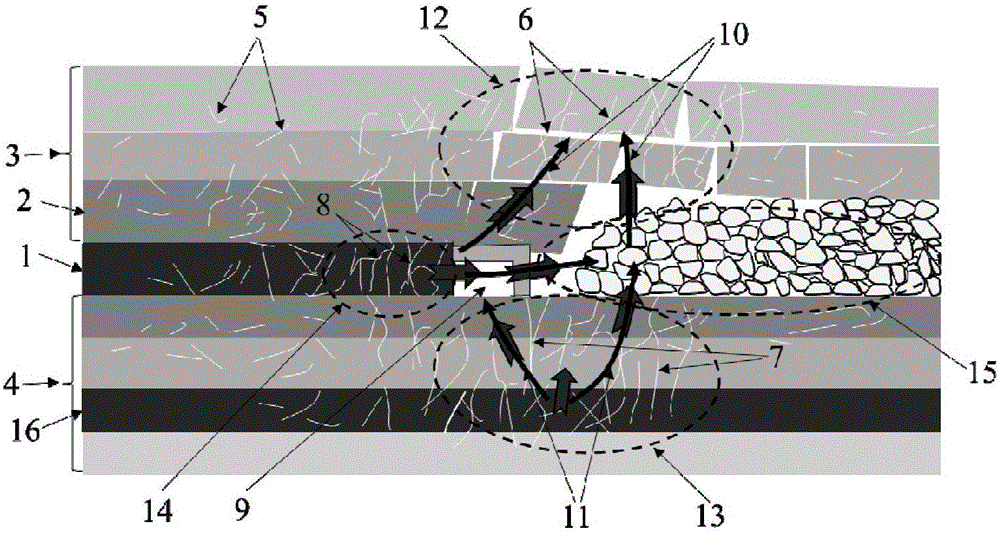

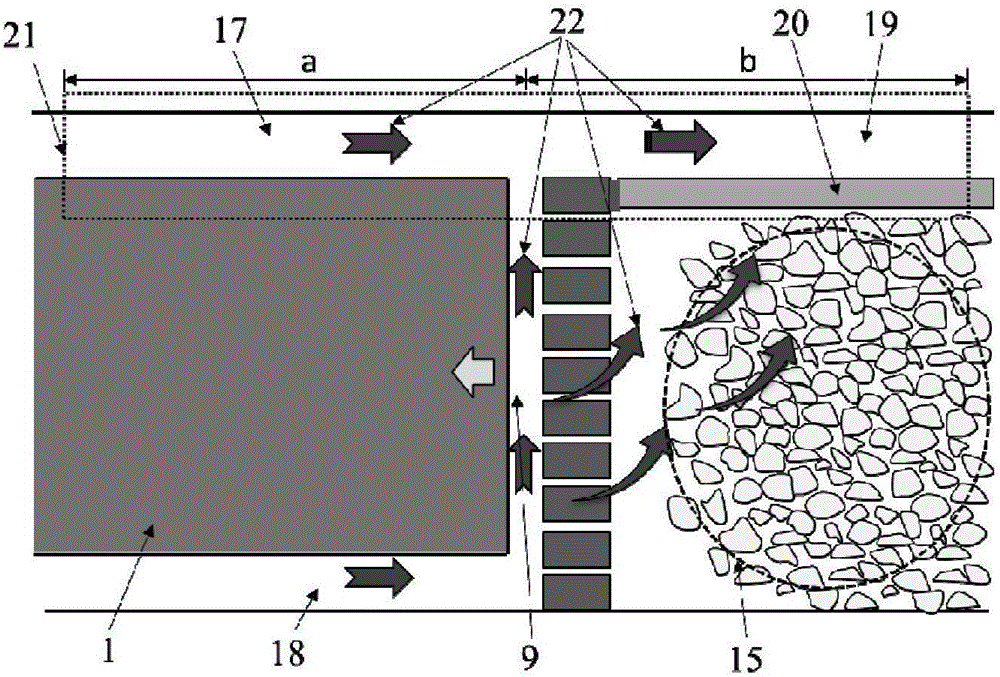

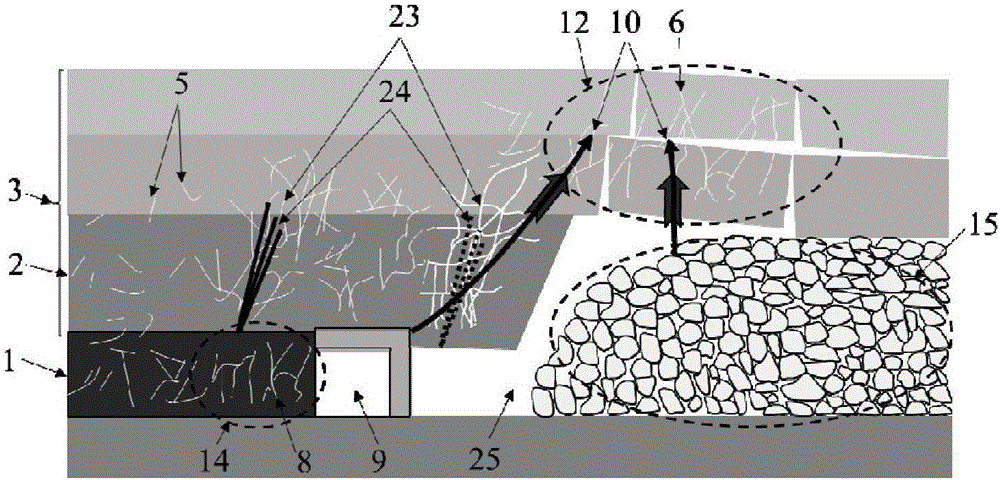

Coal seam stope advantageous gas transport pathway staged construction method

ActiveCN106837408ABuild step by stepEasy dischargeFluid removalTunnel/mines ventillationTransport pathwaysHole drilling method

The invention discloses a coal seam stope advantageous gas transport pathway staged construction method, particularly suitable for step-by-step construction of deep coal seam group first mining layer stope coal and rock mass inside-outside gas transport pathways. The method comprises the steps of firstly forming a gas transport pathway is preliminarily in a stope by mining action of first mining layer mining; then actively constructing in an outer space and an inner part of a coal and rock mass to form advantageous gas transport pathways by a deep entry retaining construction and stabilization method and a manual guide presplitting drilling method; finally, under the action of mining stress, further forming mutually communicated stope advantageous gas transport pathway systems. The mining stress action and a manual active method are combined to realize step-by-step construction of deep coal seam group area-local-area stope gas transport pathways, the problems that deep coal seam stope gas transport pathways are difficult to form, and efficient flowing and enrichment of gas is difficult to realize are solved, concentrated flow guide governance on the gas is facilitated, and the method has wide application value.

Owner:CHINA UNIV OF MINING & TECH

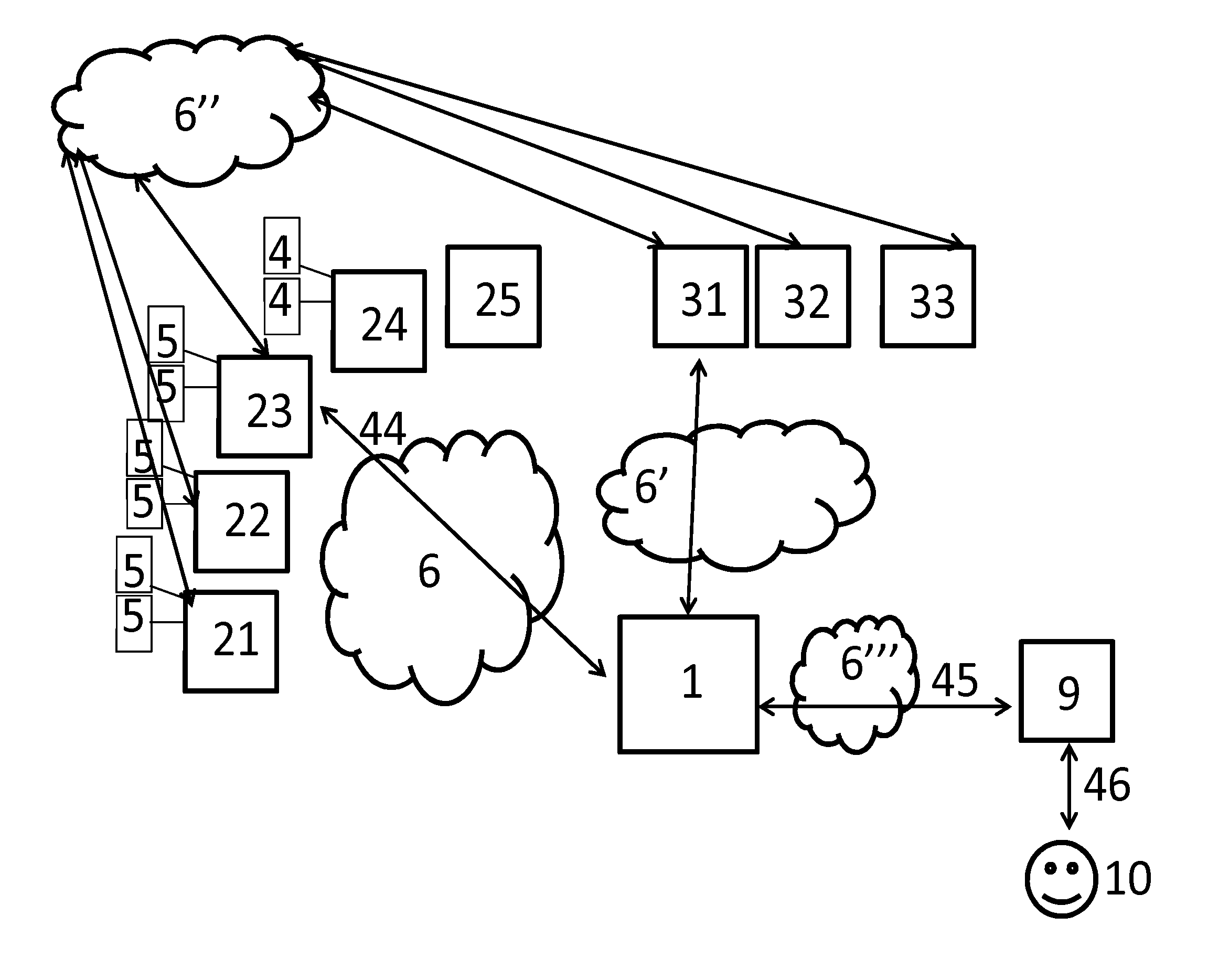

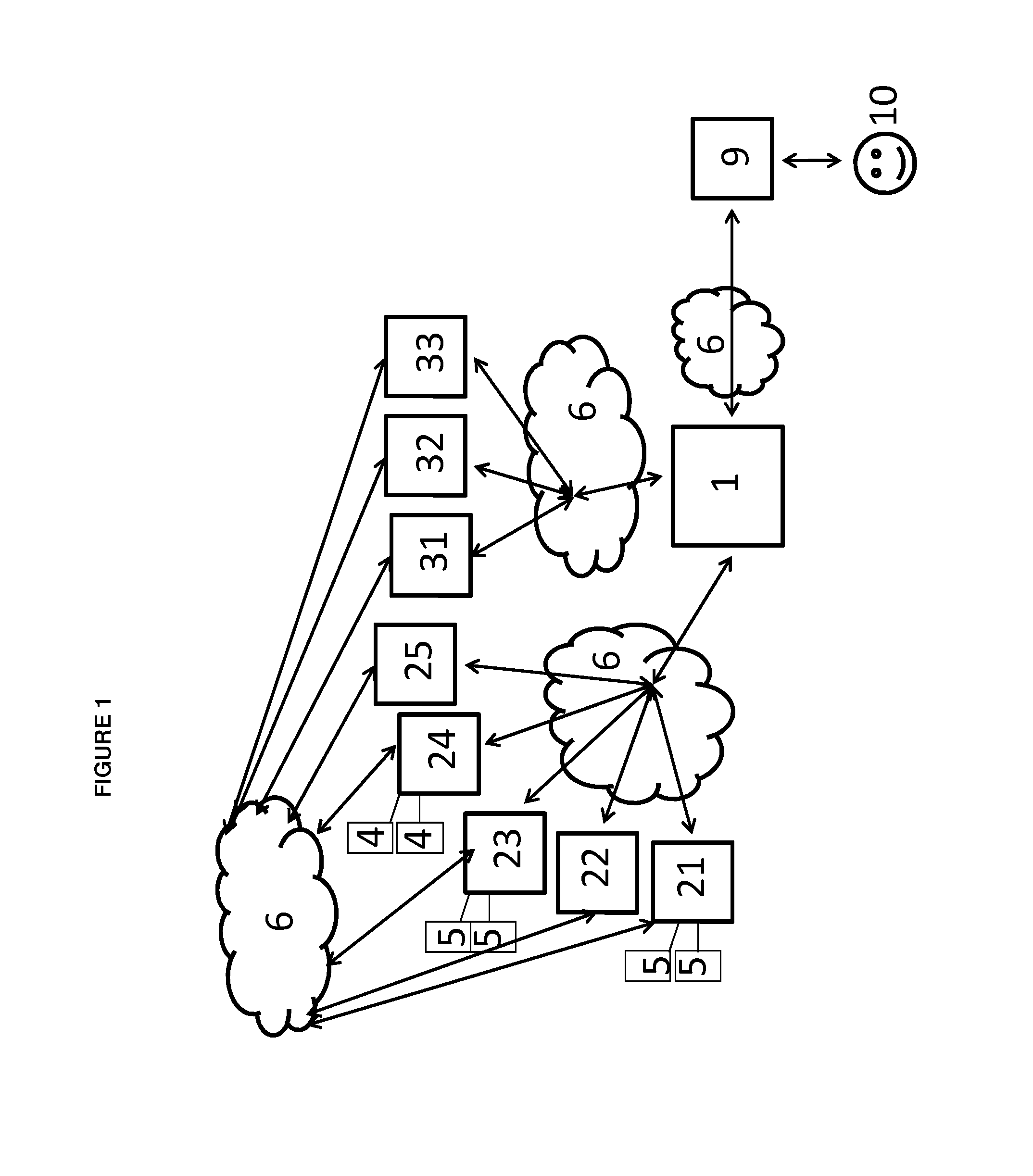

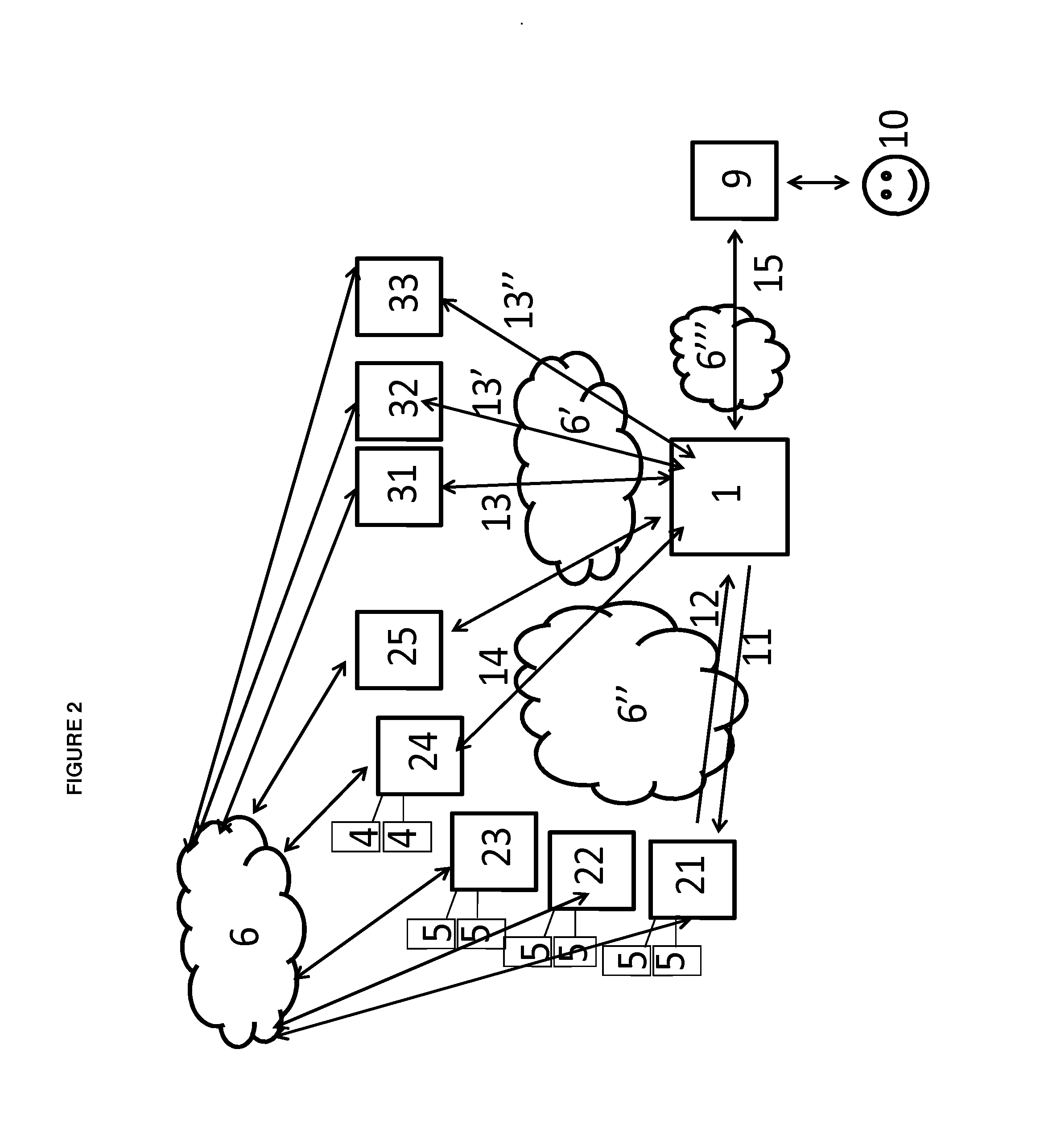

Proactive method and system of searching and/or inferring and/or sending information

The present invention relates to a method and system of searching and / or inferring and / or sending information to an application which includes sending information to said application. This information is related to the events of a user or of his contacts or of a provider, and contains information of products and / or services related to said events. The system contains data tables of the user, his contacts, the product and / or service providers and their products and / or services.

Owner:URIBE ETXEBARRIA JIMENEZ XABIER

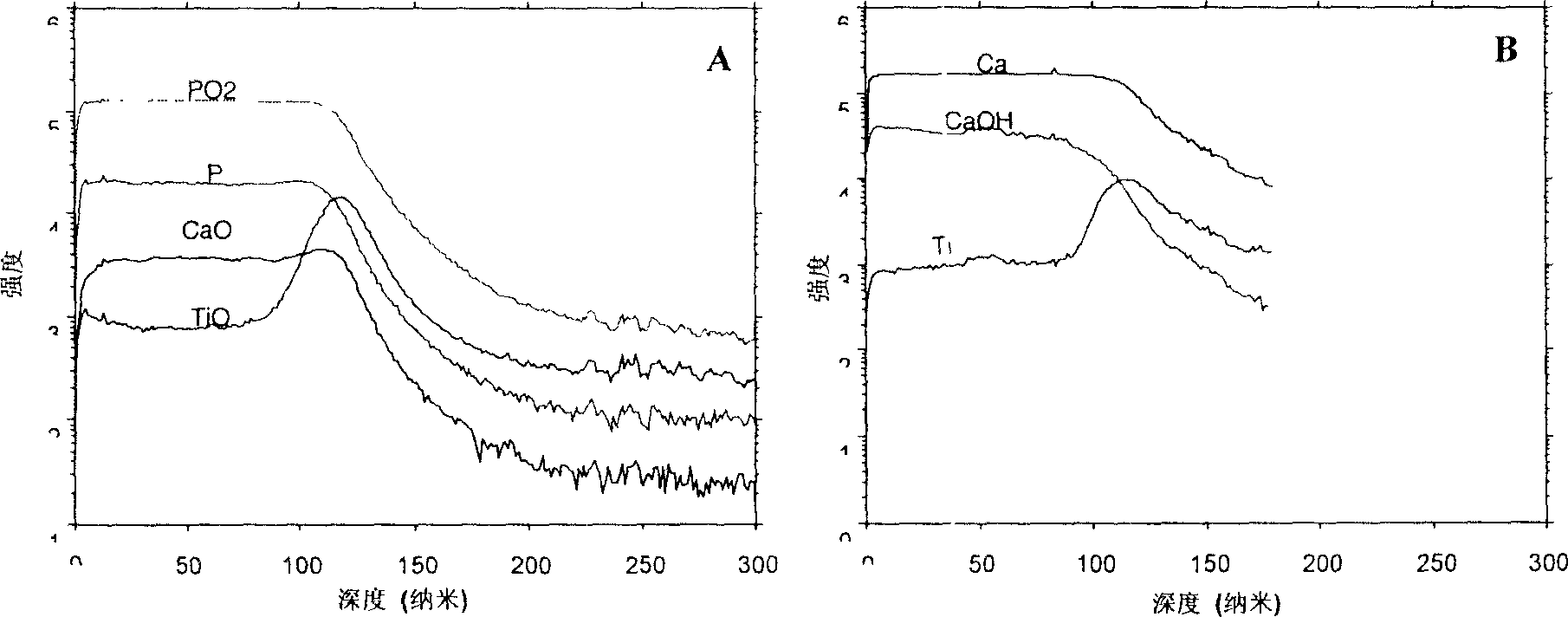

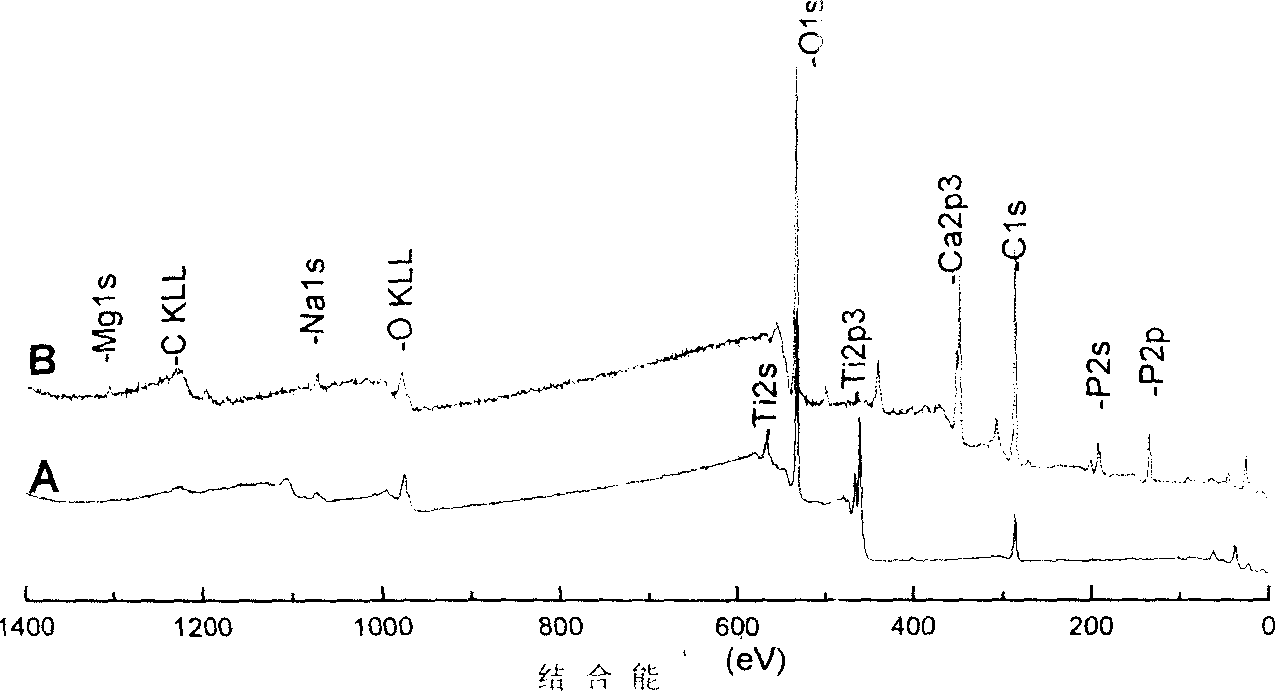

Surface activating method of medical metal material

InactiveCN1680632AAvoid impact on mechanical propertiesAvoid problems such as corrosionElectrolytic inorganic material coatingSupporting electrolytePhosphate

A surface-active method of metal material for medical use. It adopts three poles system. Negative pole is metal material. Positive pole is inert material. Fit them and reference electrode to electrolyte solution containing supported electrolyte solution. Soluble calcium salt and phosphate at pH2.5-6.5.Hold negative potential to be at -1 to -4V by way of constant potential or apply to electronic current 1-5Ma at constant value for 2 to 20min. Get sample of negative pole, wash and dry it.

Owner:SICHUAN UNIV

Process for manufacturing paper pulp by active method and with fresh bamboo as raw material

InactiveCN109811570AIntegrity guaranteedNo pollution in the processNon-woody plant/crop pulpFiberUltra high pressure

The invention provides a process for manufacturing paper pulp by an active method and with fresh bamboo as a raw material. The process comprises the steps that bamboo cutting is performed; slicing isperformed; ultra-high pressure grading rolling is performed, specifically, bamboo chips are placed in a rolling roll for grading rolling, wherein grading rolling includes four to six grades of rolling, and the rolling pressure of each grade is gradually increased; thread rolling is performed; primary filtration extrusion is performed to obtain initially filtered bamboo pulp; secondary filtration extrusion is performed, specifically, water is added to the initially filtered bamboo pulp and then heating and stirring are performed, then physical filtration and secondary extrusion are sequentiallyperformed to obtain re-filtered bamboo pulp, and the total time is not more than 72h from the beginning of raw bamboo cutting to secondary filtration extrusion; and a biological enzyme is softened and released. The process rapidly separates lignin, amino acid, flavone, proteins and the like from bamboo fiber when lignin, amino acid, flavone, proteins and the like are still in a liquid state, is conducive to maintaining the integrity of the bamboo fiber to the utmost extent, is simple in operation and low in cost, is energy-saving, environmentally friendly and low-carbon, and is worth popularizing and applying.

Owner:樊士英

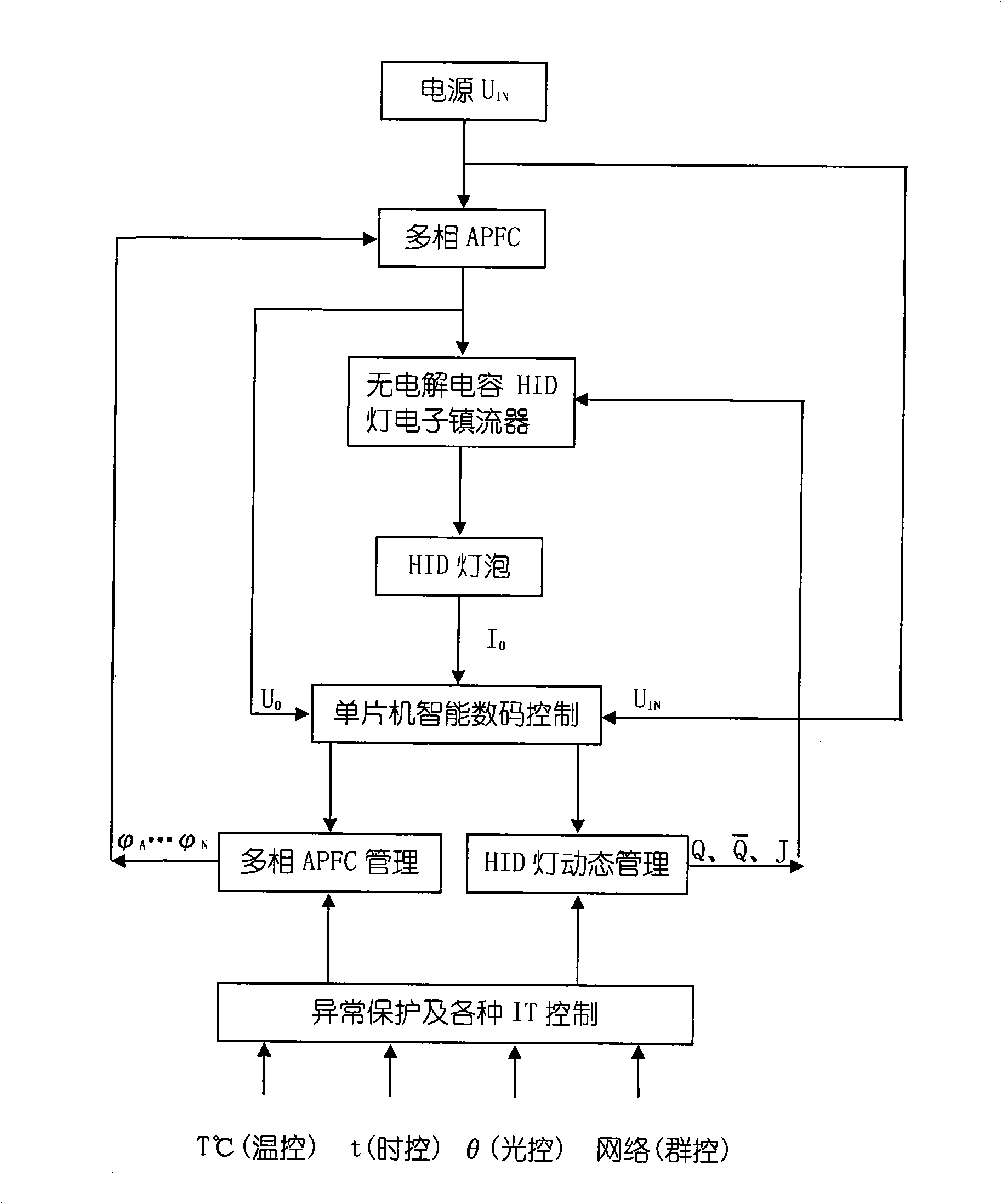

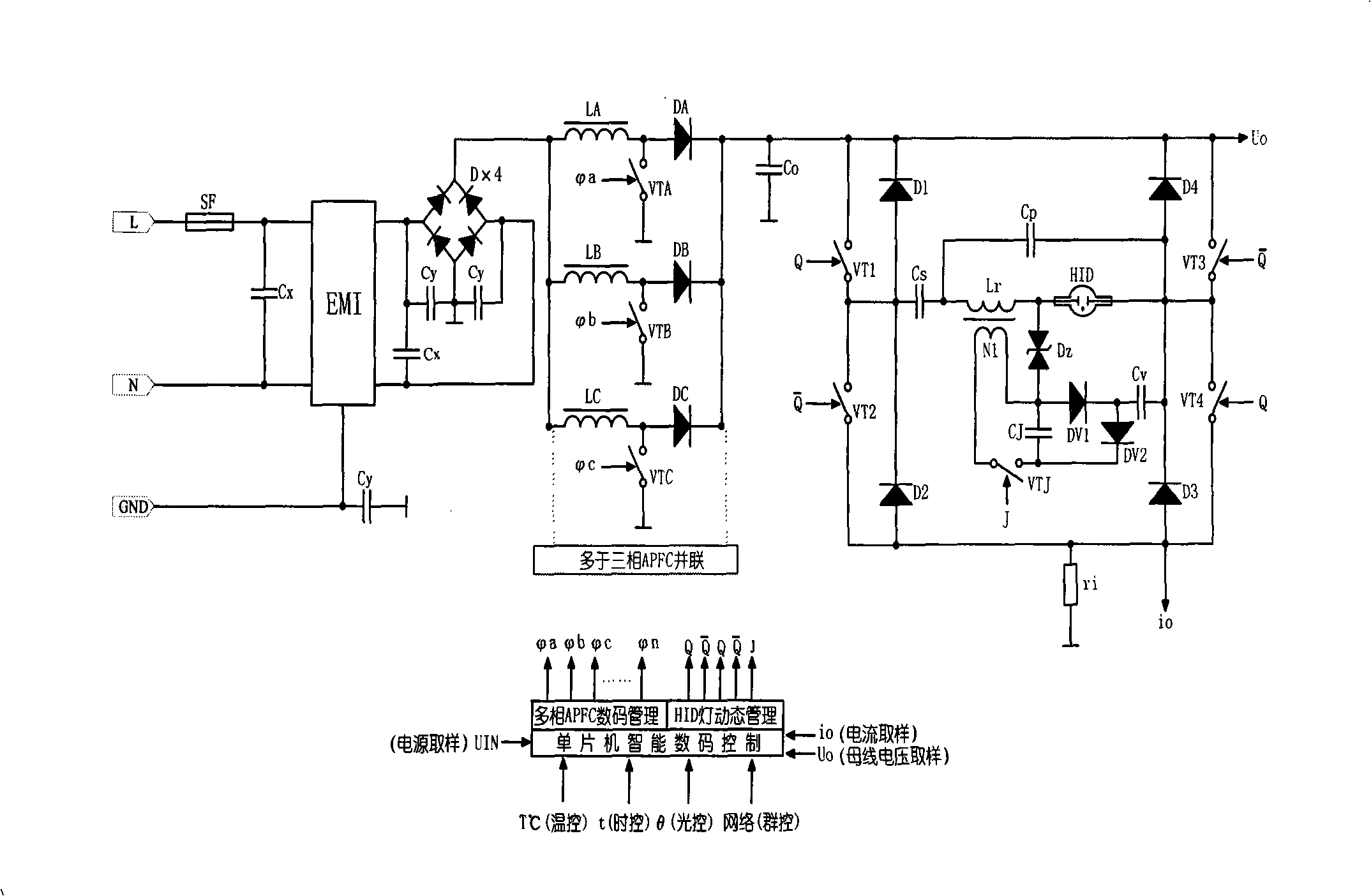

Control method for electronic ballast of HID light without electrolytic capacitor

InactiveCN101309538AImprove reliabilityElectrical apparatusElectric lighting sourcesCapacitanceActive power factor correction

The invention provides a method for controlling an electronic ballast which is matched with a HID light and has no electrolytic capacitor, the technical proposal adopts a single chip microcomputer software, to generate a multiphase high-frequency wave pulse packet, a plurality of groups of high-frequency square wave impulse with different phases are used to respectively control the and the of a multi-phase electronic power electronic switch, and to realize an active method for restraining dc bus ripple by using active power differential electric energy to substitute the traditional method of restraining the dc bus ripple through by using passive electrolytic capacitor storage charge through realizing a multi-phase high frequency APFC (active power factor Correction) method. Bu adopting the technical proposal, the reliability of the HID light electronic ballast is greatly improved, and the performance price ratio surpasses the traditional HIG light electronic ballast with electrolytic capacitor.

Owner:深圳唐微科技发展有限公司

Ultrasonic-control electric rice cooker

The invention relates to an ultrasonic-control electric rice cooker, belonging to the technical field of household electric appliances. In order to overcome the defect that the working mode of the electric rice cooker in the prior art must depend on measuring the change of the temperature of an inner pot in a mechanical contact way and monitoring the change of vocal prints of the inner pot to obtain temperature change as a control basis, the ultrasonic-control electric rice cooker takes the following measures that an ultrasonic generator and an ultrasonic receiver are installed on the electric rice cooker, and the ultrasonic receiver is connected with a vocal print recognition circuit. Physical information such as the internal temperature and the water condition of the inner pot of the electric rice cooker is obtained by actively transmitting ultrasonic waves towards the inner pot of the electric rice cooker and by adopting an active method of analyzing ultrasonic vocal print electric signals received by the ultrasonic receiver. The benefits of taking the measures are that the ultrasonic waves at the most sensitive frequency band can be selected according to the characteristics of the inner pot of the electric rice cooker, more, clearer, more accurate and more reliable physical information such as the internal temperature and the water change of the inner pot of the electric rice cooker can be obtained, and a reliable basis is provided for a control circuit.

Owner:中山市开盈科技有限公司

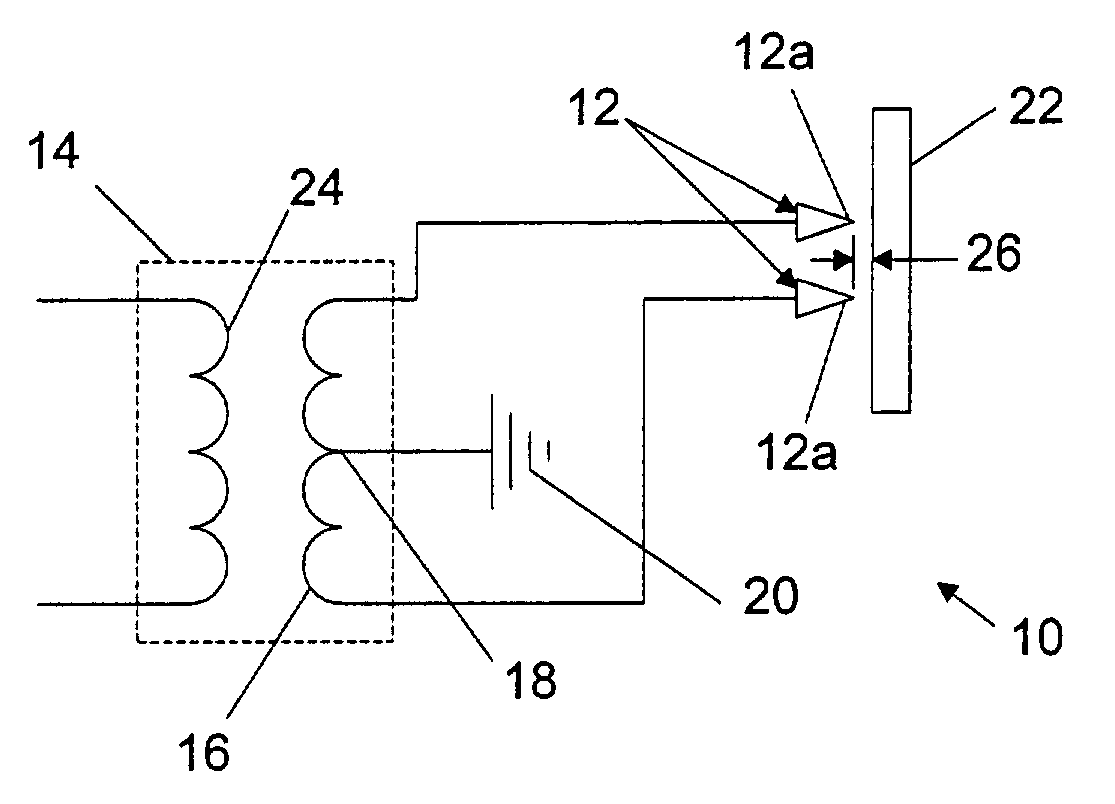

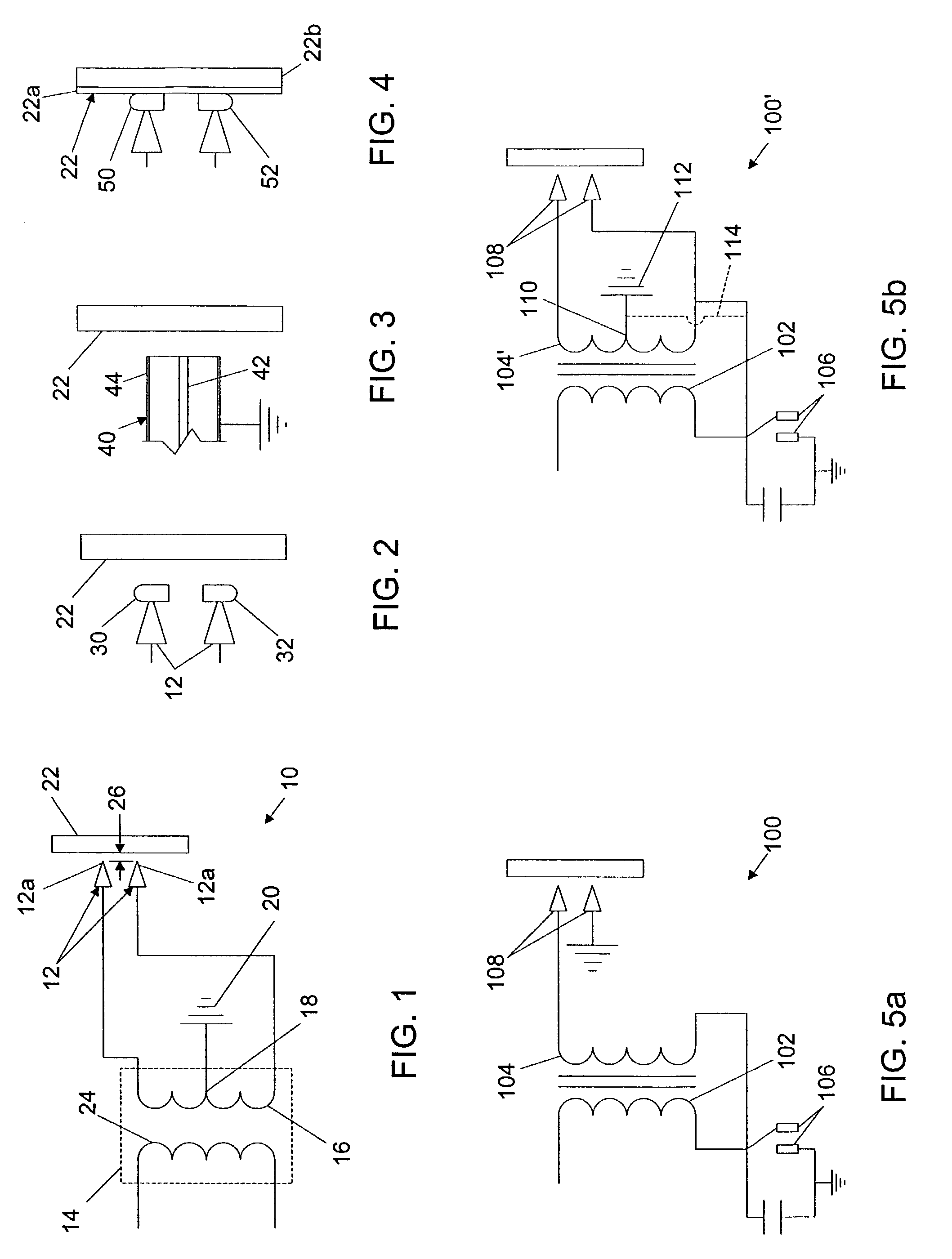

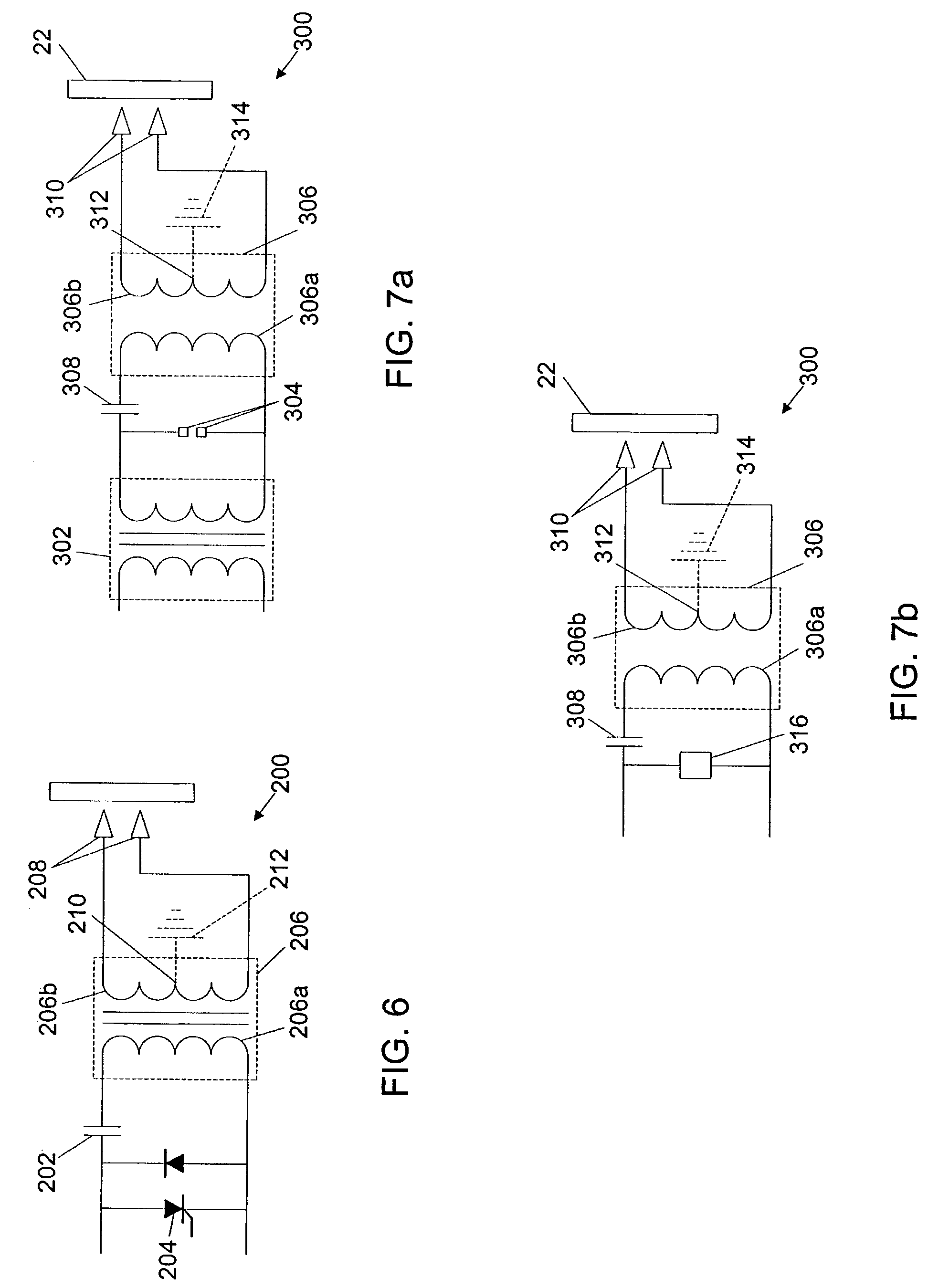

Active method and system of establishing electrical contact

InactiveUS7166853B2Semiconductor/solid-state device detailsSolid-state devicesCapacitanceElectricity

A system for electrically contacting a semiconductor wafer during implanting of the wafer includes one or more pairs of closely spaced contacts located adjacent the semiconductor wafer and a driving circuit connected to the contacts to provide a discharge from one contact to the semiconductor wafer and from the semiconductor wafer to the other contact of each pair of contacts. The contacts can be spaced apart from the wafer and the tips of the contacts closest to the wafer may have sharp points to aid in the establishment of corona at lower drive voltages. Alternately, the contacts may be rounded and may contact the wafer. The driving circuit may be adapted from a pulsed discharge circuit, such as a Kettering ignition circuit, a capacitance discharge ignition circuit, or a blocking oscillator circuit. Alternately, the driving circuit may be adapted from a continuous discharge circuit, such as a Tesla coil circuit.

Owner:VARIAN SEMICON EQUIP ASSOC INC

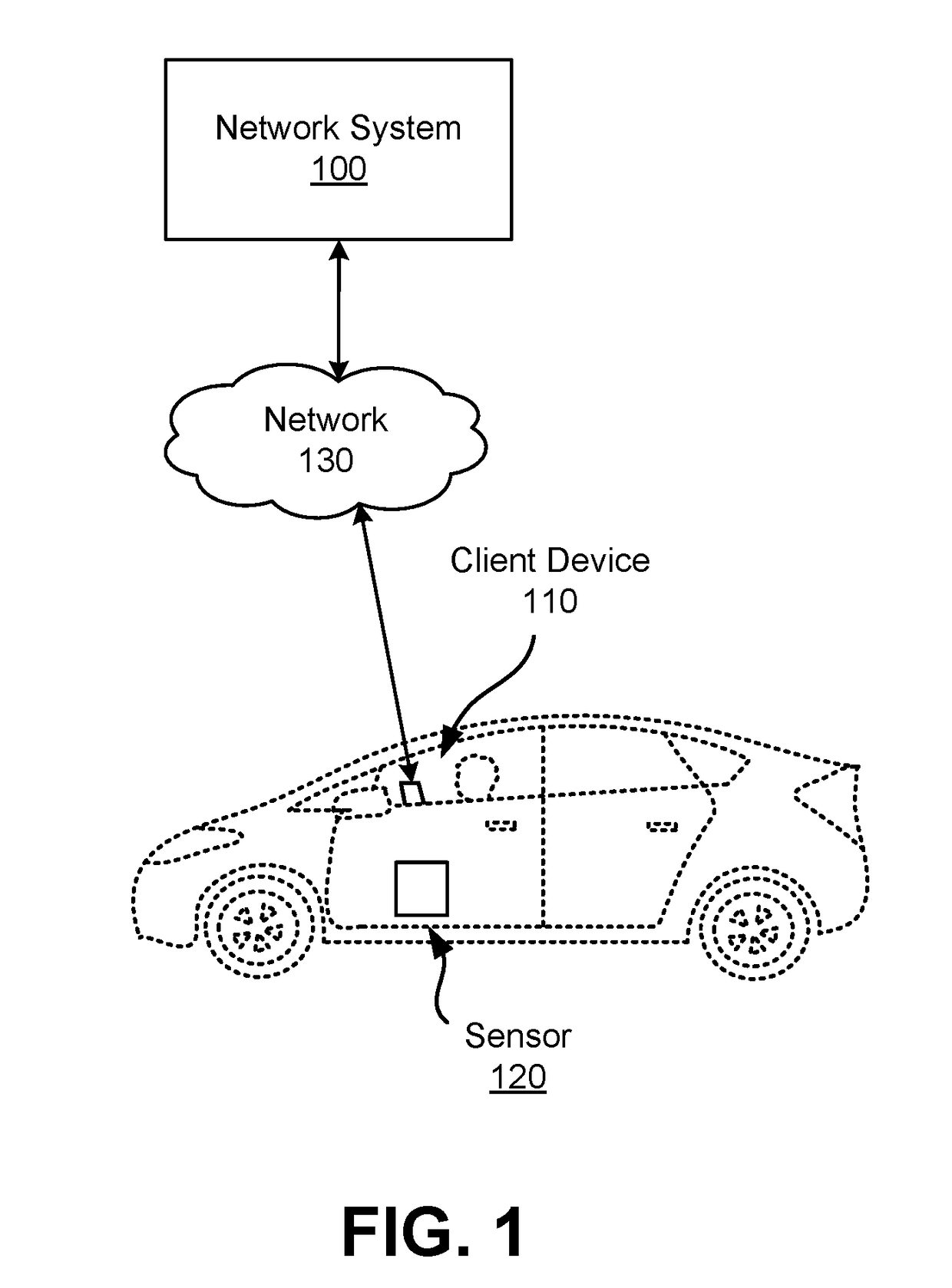

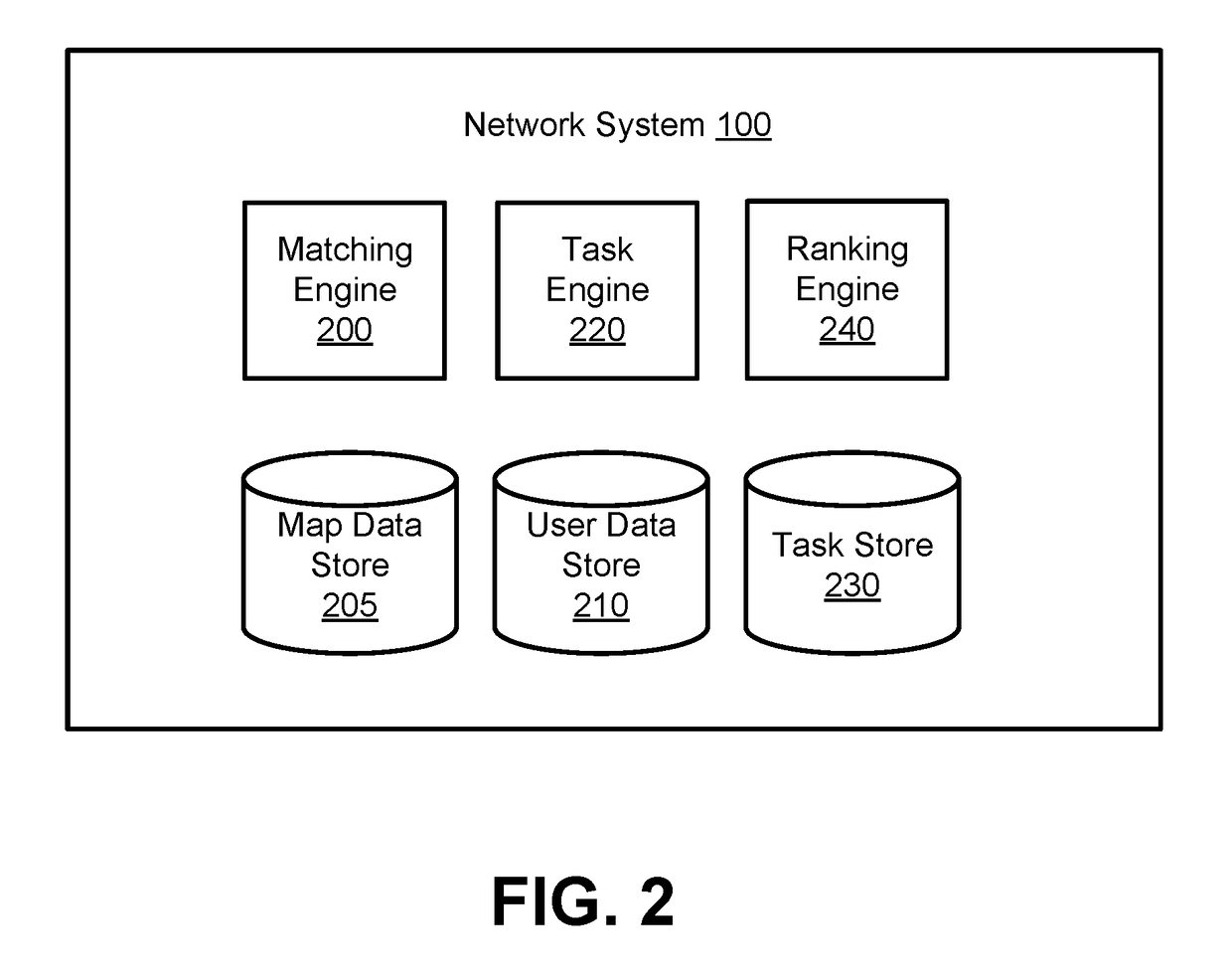

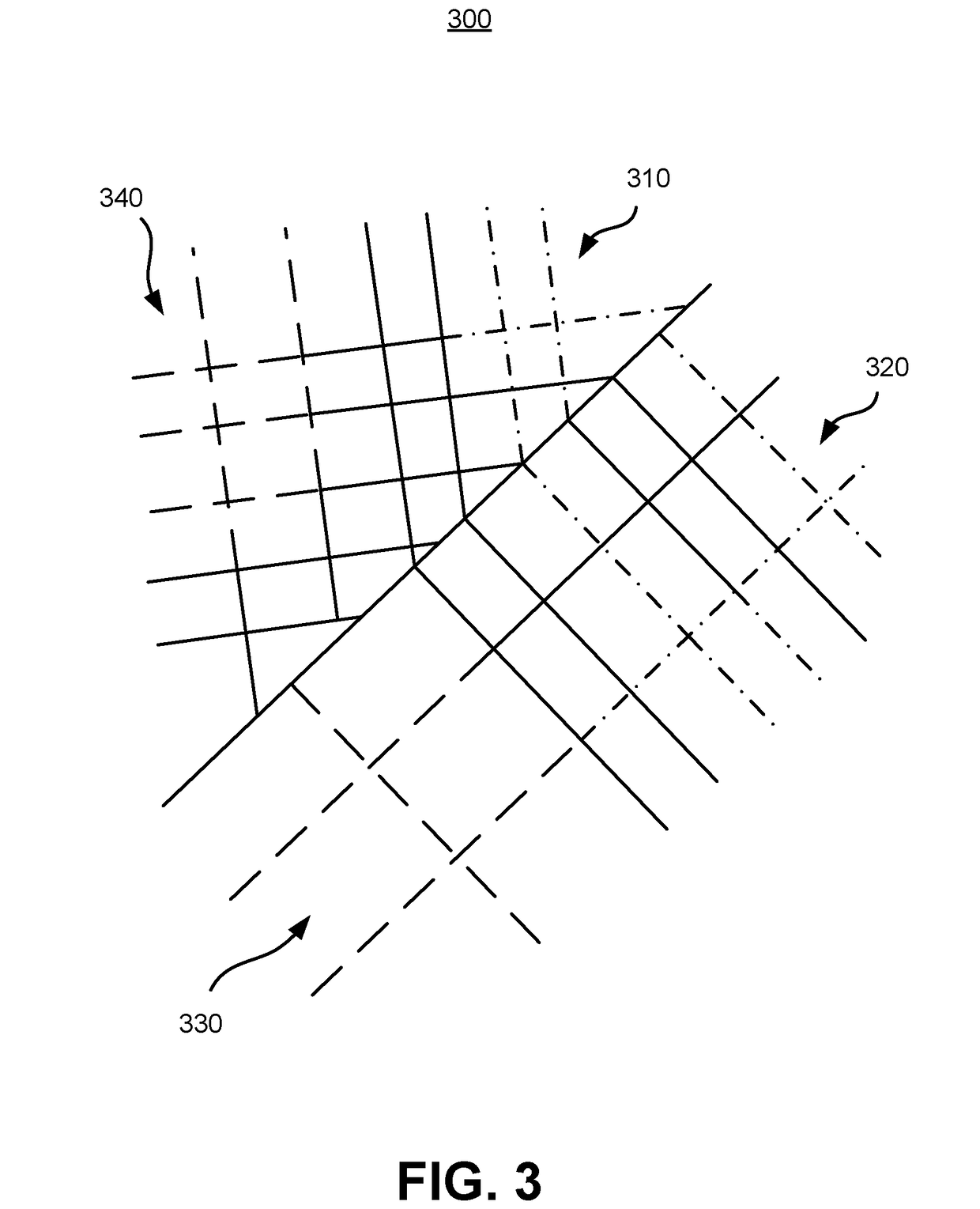

Targeted Sensor Data Collection for Generating Map Information

InactiveUS20190034948A1Great likelihoodInstruments for road network navigationDiscounts/incentivesIdle timeGeographic regions

Owner:UBER TECH INC

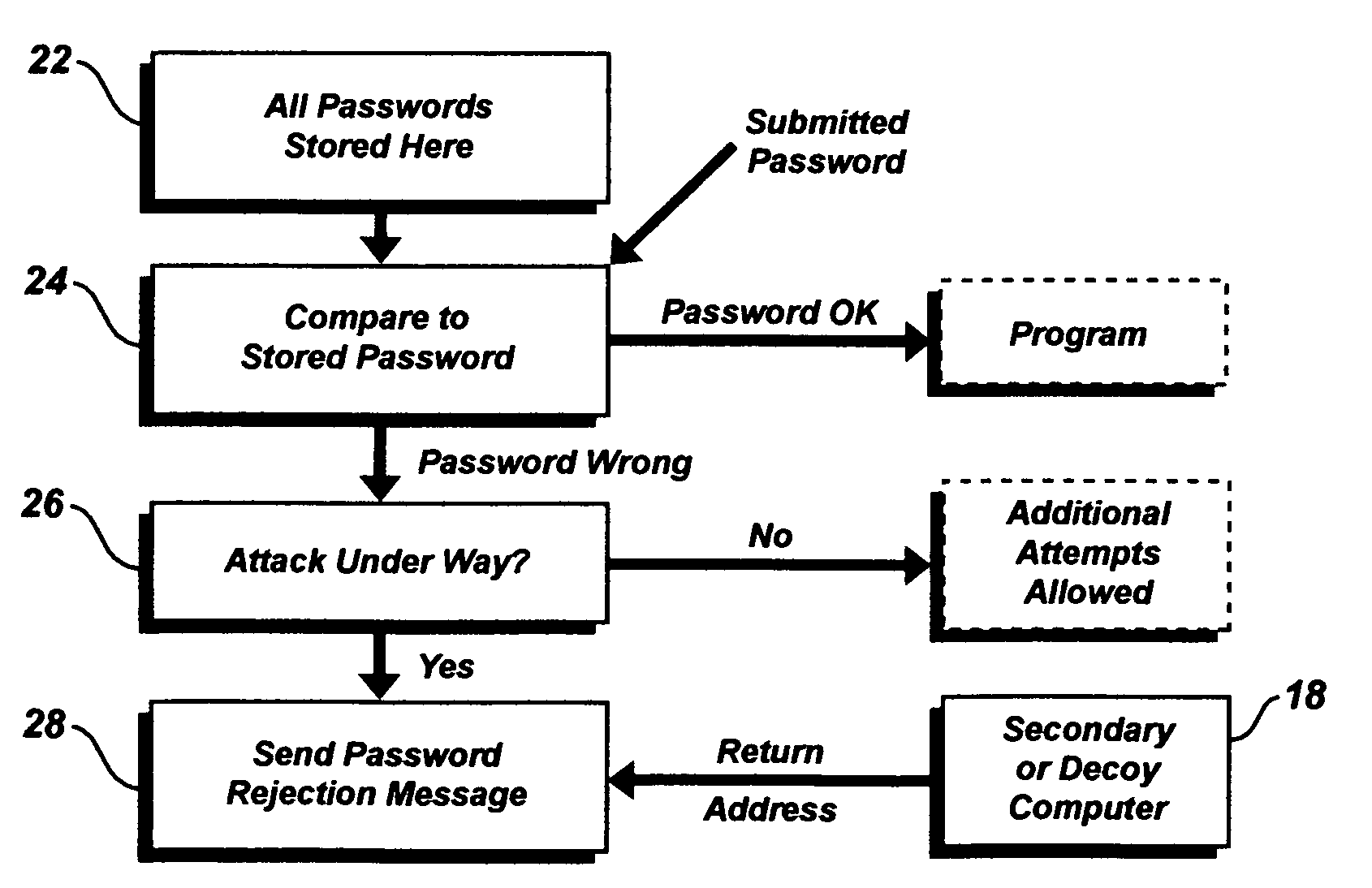

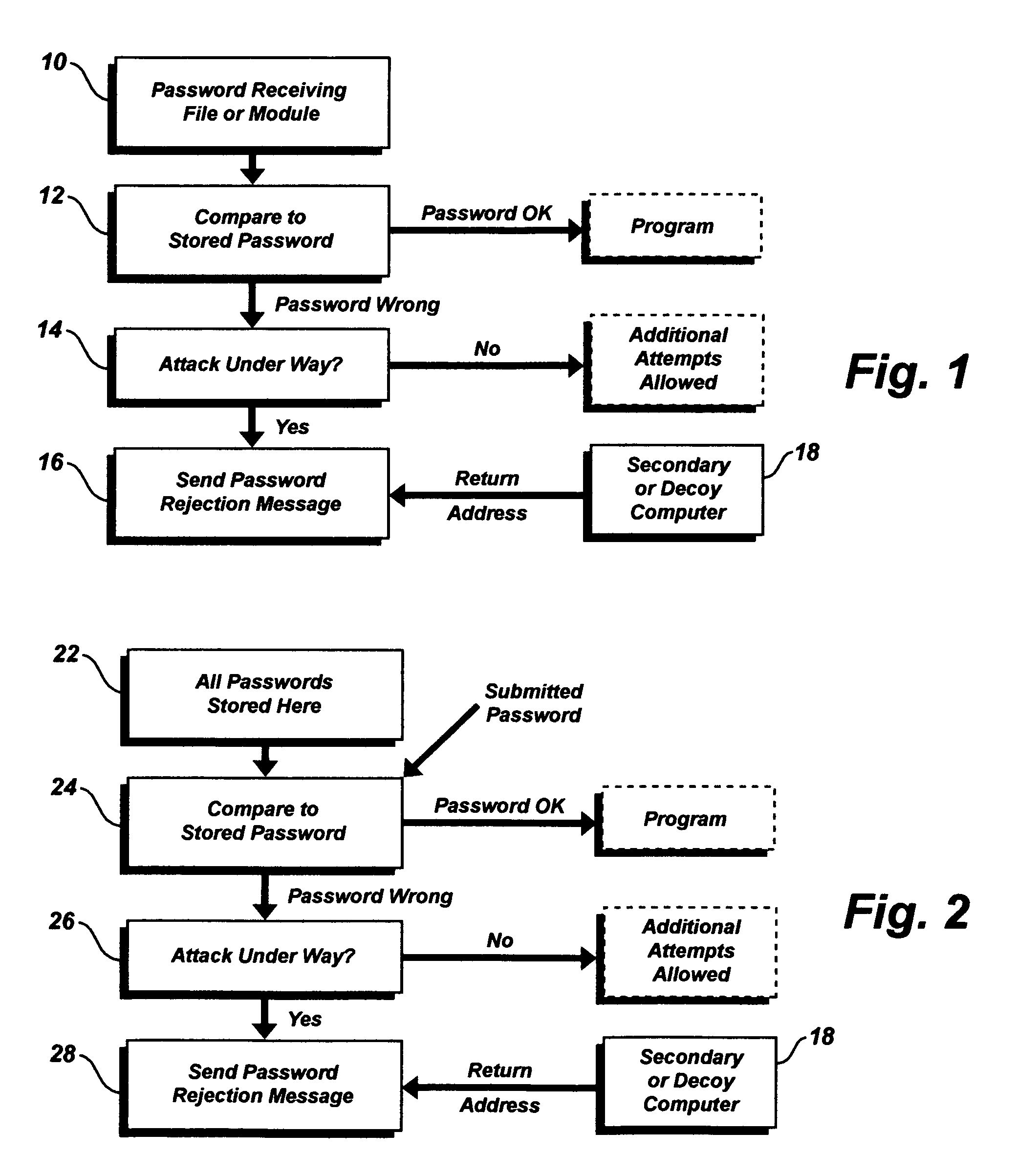

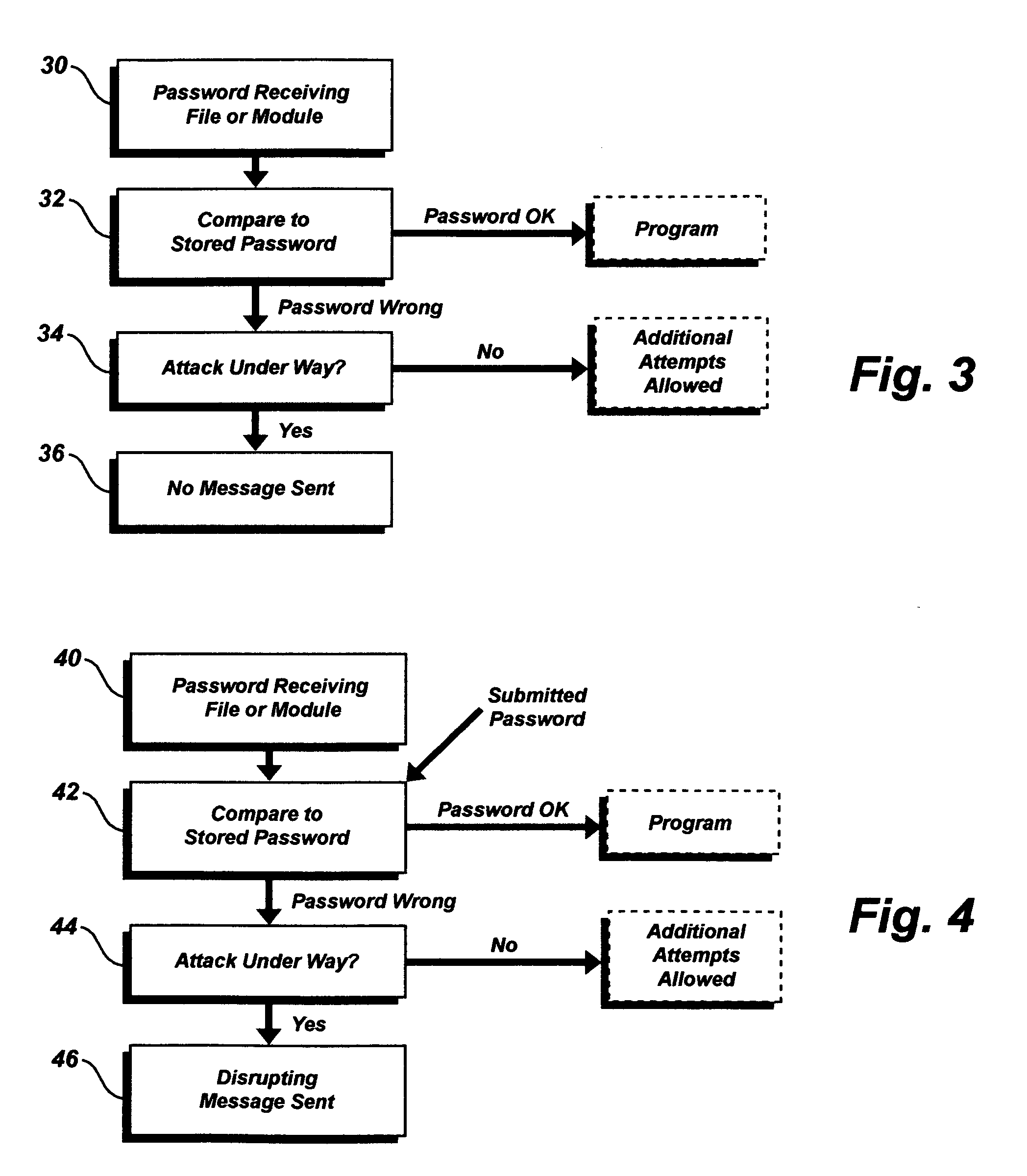

Automatic proactive means and methods for substantially defeating a password attack

Automatic proactive means and methods for substantially defeating a password attack against a computer having a password-protected program installed in it. These means and methods range from not responding at all, to responding with instructions to disrupt the ability of the computer having the attack program in it to continue the attack.

Owner:WILDENSTEINER OTTO MELVIN

Biological oxygen demand microbe sensor sensitive membrane activating process and automatic activating apparatus

InactiveCN1824790ASoaking time is adjustable and precisely controlledPrecise control of soaking timeMicrobiological testing/measurementTesting waterActivation methodMicroorganism

This invention is biochemical oxygen needing microorganism sensor sensitive membranes activation method and its auto active equipment. It relates to a microorganism sensor, it provides a manual active method used to BOD microorganism sensor sensitive membranes and auto activation method and its auto active equipment. When manual method is used, the membranes is soaked to fluorescence signal stable in GGA solution, then GGA solution is discharged and the membranes is aerated to the signal stable. The membranes are soaked with new GGA solution to dynamic balance, soak and aeration is done several times for multiple activations. The equipment is set with basin, pump, control circuit, active slot, liquid level pole and electromagnetic valve. Then auto method is used, the pump is soaked in the GGA solution, the membranes soaking and aeration time is controlled, then the membrane is dropped into the active slot, then the GGA solution in the water slot is taken into the active slot. The membrane is soaked into GGA solution and serration, then soaking and aeration is repeated.

Owner:XIAMEN UNIV

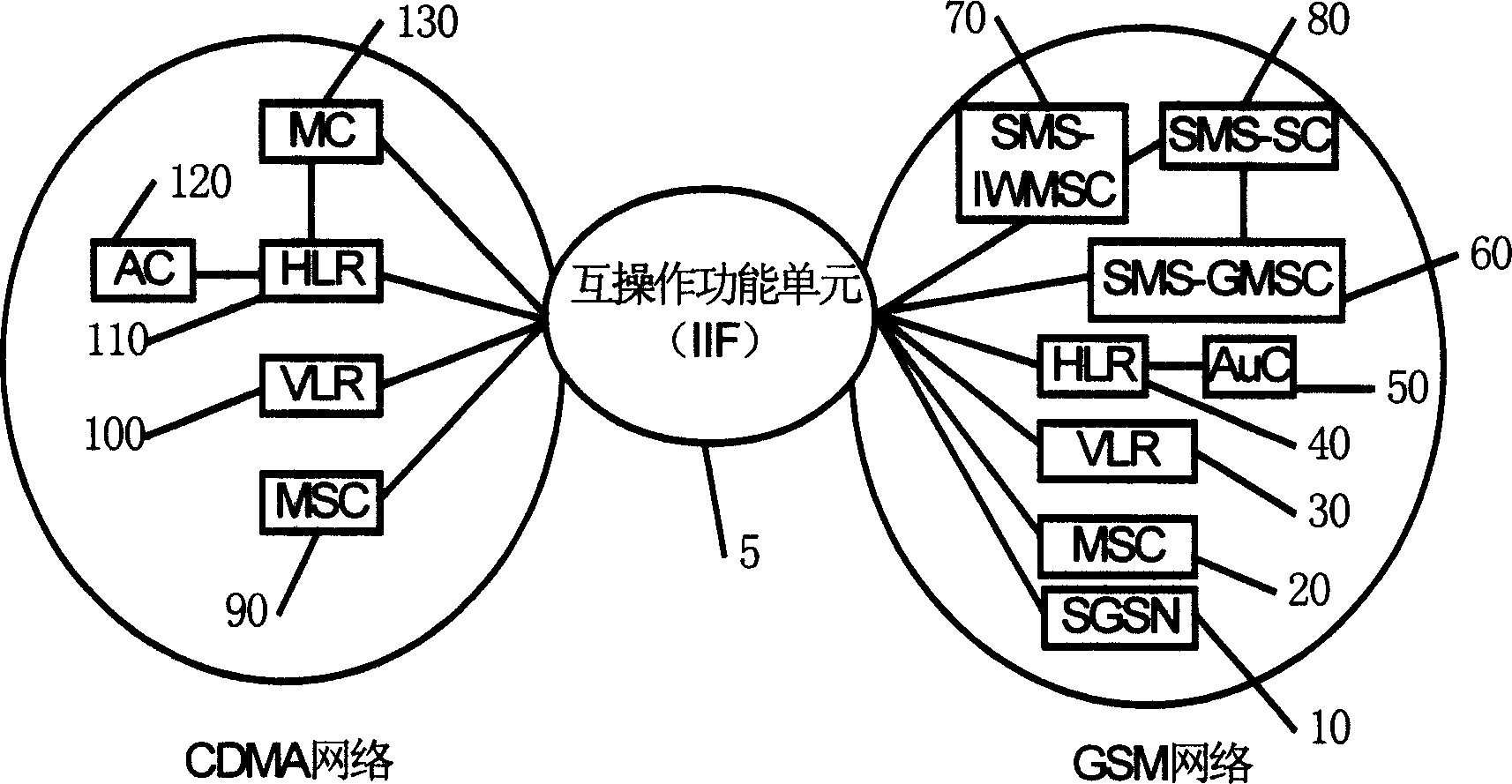

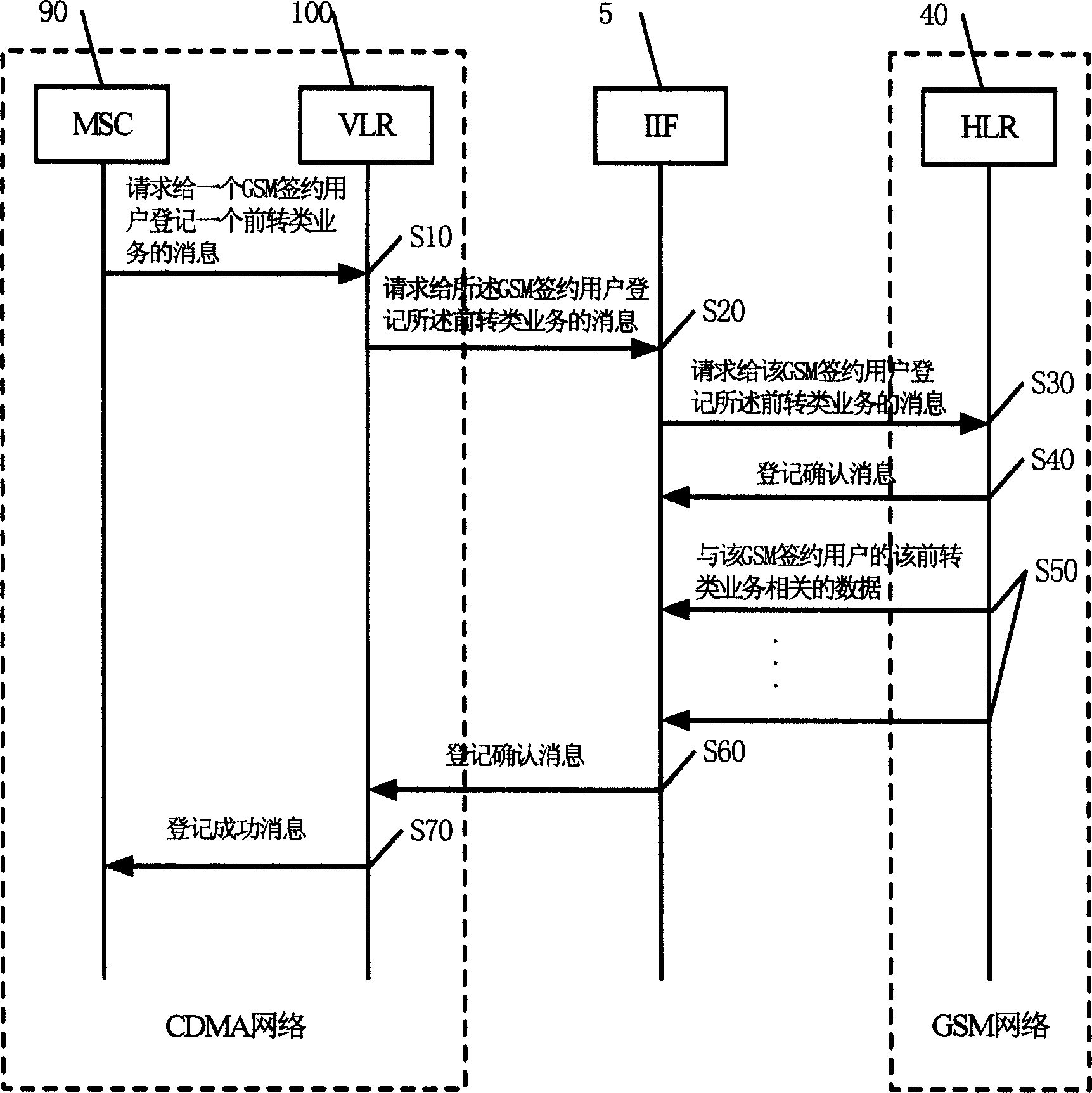

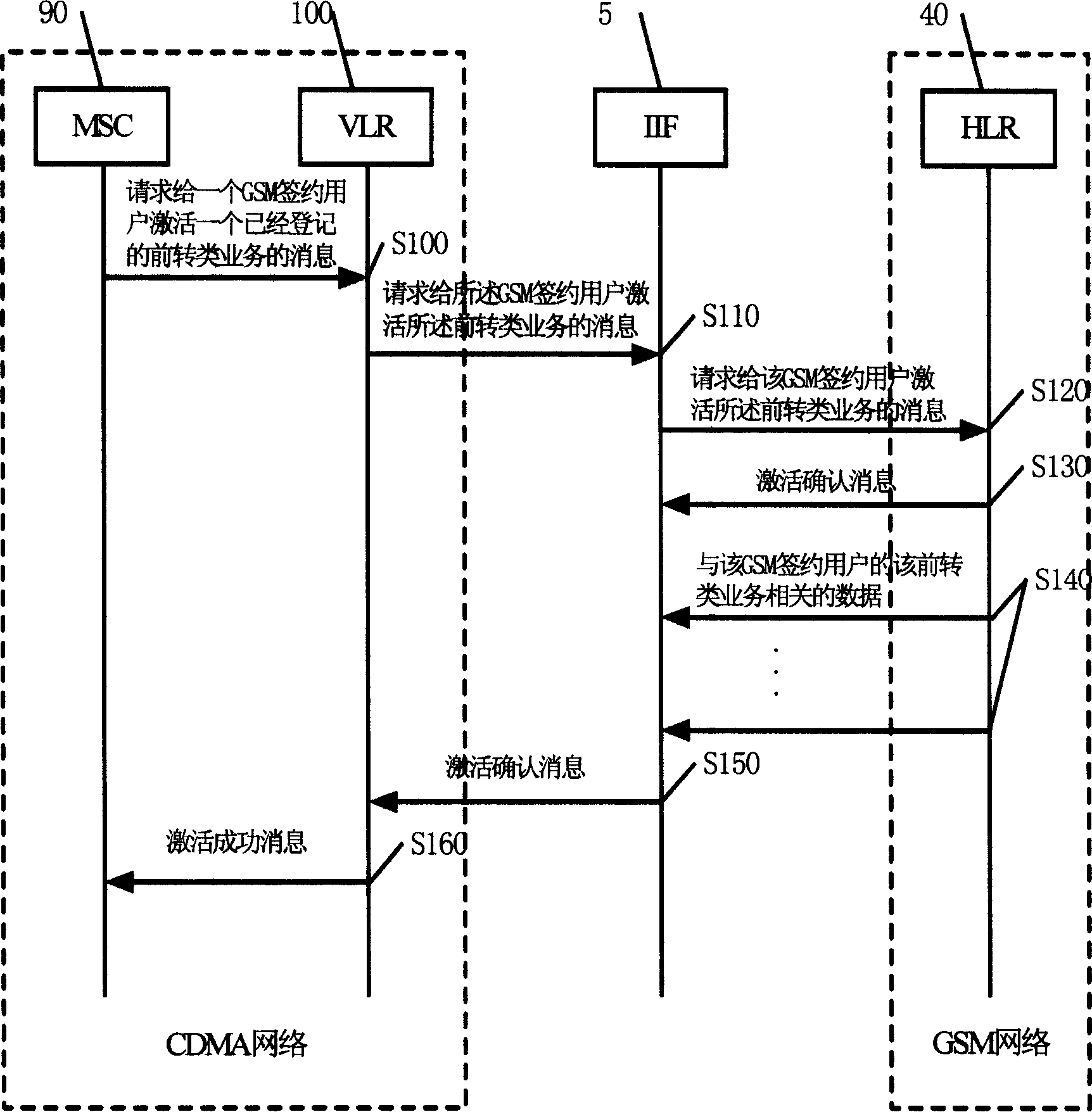

Complement service active method and device of mobile communicaton network

ActiveCN1561134AReduce cloggingRadio/inductive link selection arrangementsNetwork data managementActivation methodProcessor register

This invention provides an attached service activation method and a device for users panning to un-sign mobile communication networks which uses one time of activation operation to finish the function reached by registration operation and activate operation to the forward services, so HLR registers and activates a forward attached service only in one time and only needs to send one time of data related to the user requested forward attached service so as to reduce network block.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

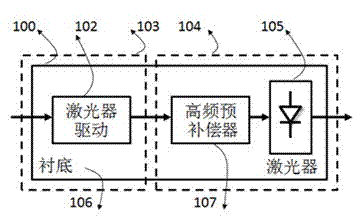

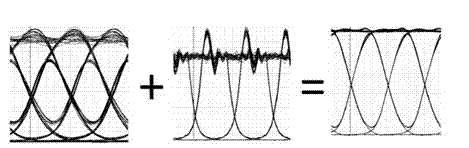

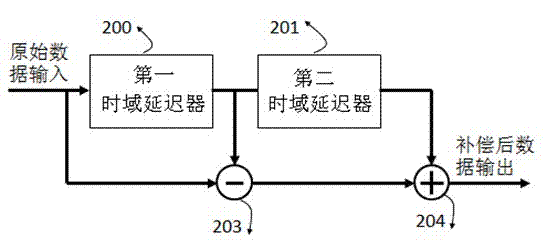

Integrated optical chip with high-frequency precompensation and high-speed optical communication device

ActiveCN102820918AReduced requirements for high-speed characteristicsLow costElectromagnetic transmissionOptical communicationCeramic substrate

The invention discloses an integrated optical chip with high-frequency precompensation. The integrated optical chip is characterized in that active devices (such as a laser, an optical amplifier, a detector and a modulator) and an integrated circuit (IC) are integrated on a same substrate (such as a silicon substrate, an indium phosphide substrate or a ceramic substrate) in a single or hybrid manner. Based on different application backgrounds, an integrated high-frequency precompensation method can be realized by an active method, also can be realized by a passive method, so that the advantages similar to those of a large-scale integrated circuit such as low cost, small size, low power consumption, flexible expansion and high reliability can be achieved.

Owner:SUZHOU CREALIGHTS TECH

Beta-zeolite catalyst activation method and its uses in ethyl benzene synthesis

The invention discloses an active method of beta zeolite catalyst, which is characterized by the following: adapting inert gas with less than 0.1%(V / V) water content to pass the catalytic bed layer at 100-5000 mg / (g)h , 350-600 Deg C for 0.5-10h; fitting for benzene and ethane alkyl to synthesize ethylbenzene, benzene and diethyl benzene and or multiple ethylbenzene alkyls to produce ethylbenzene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

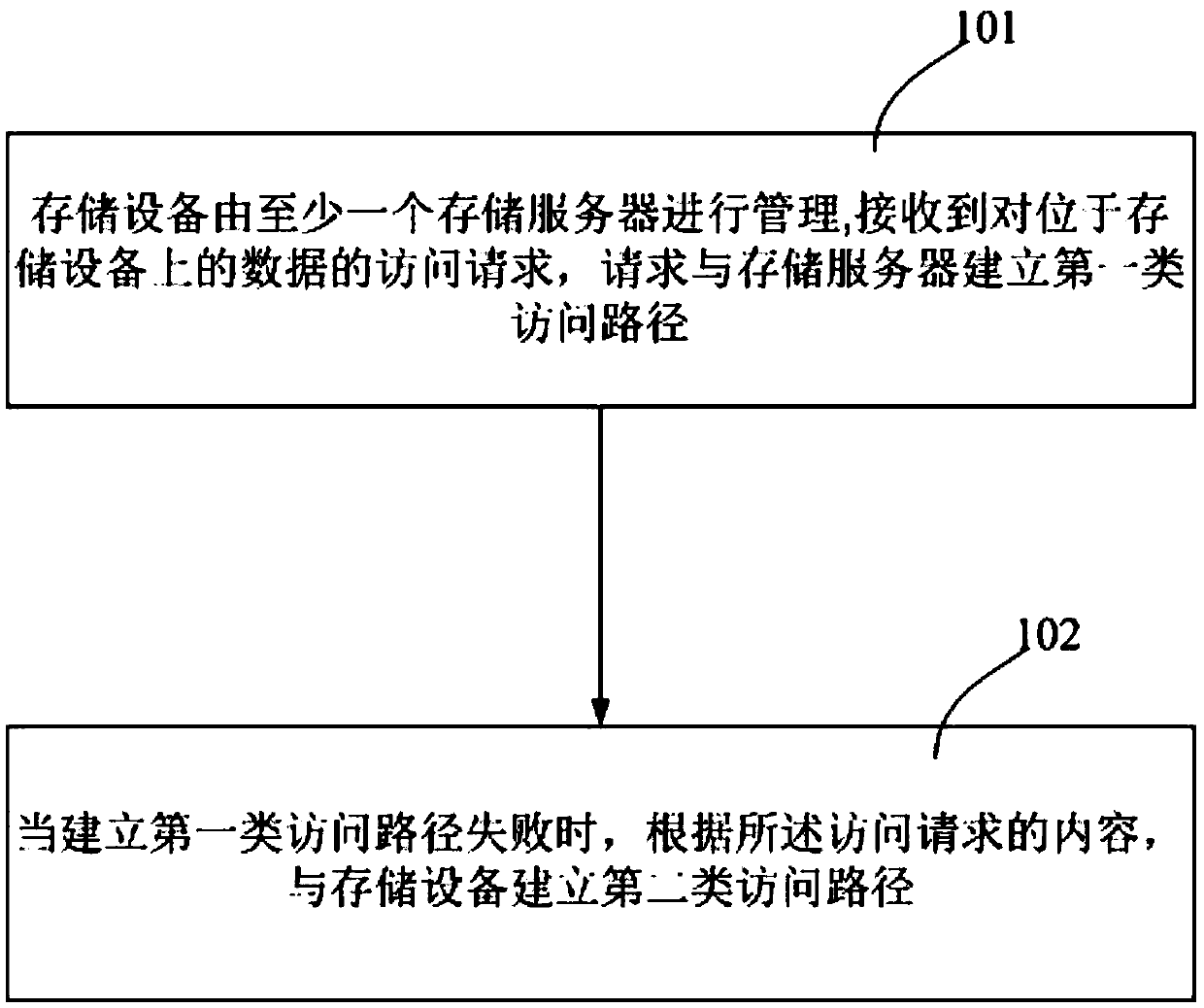

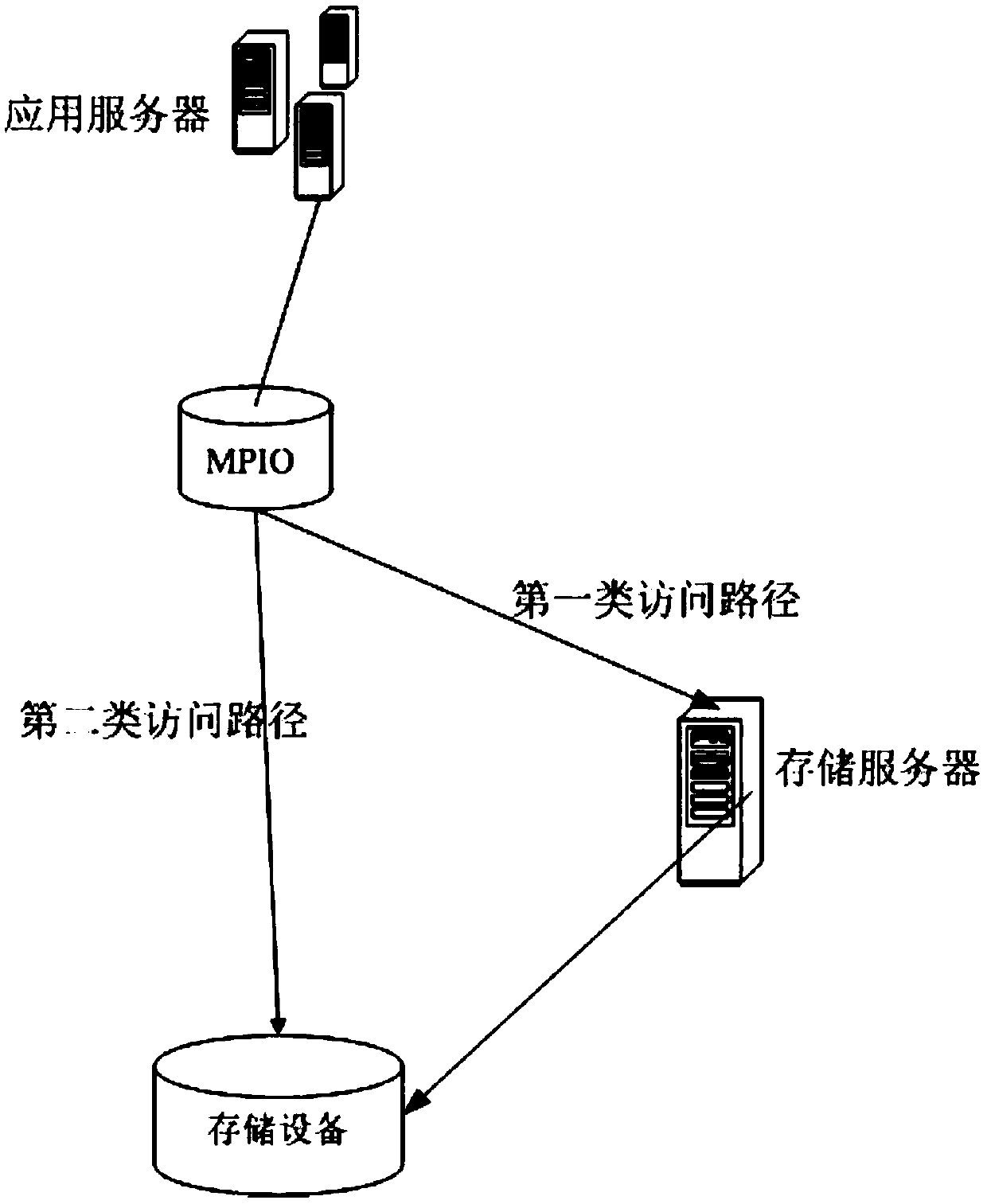

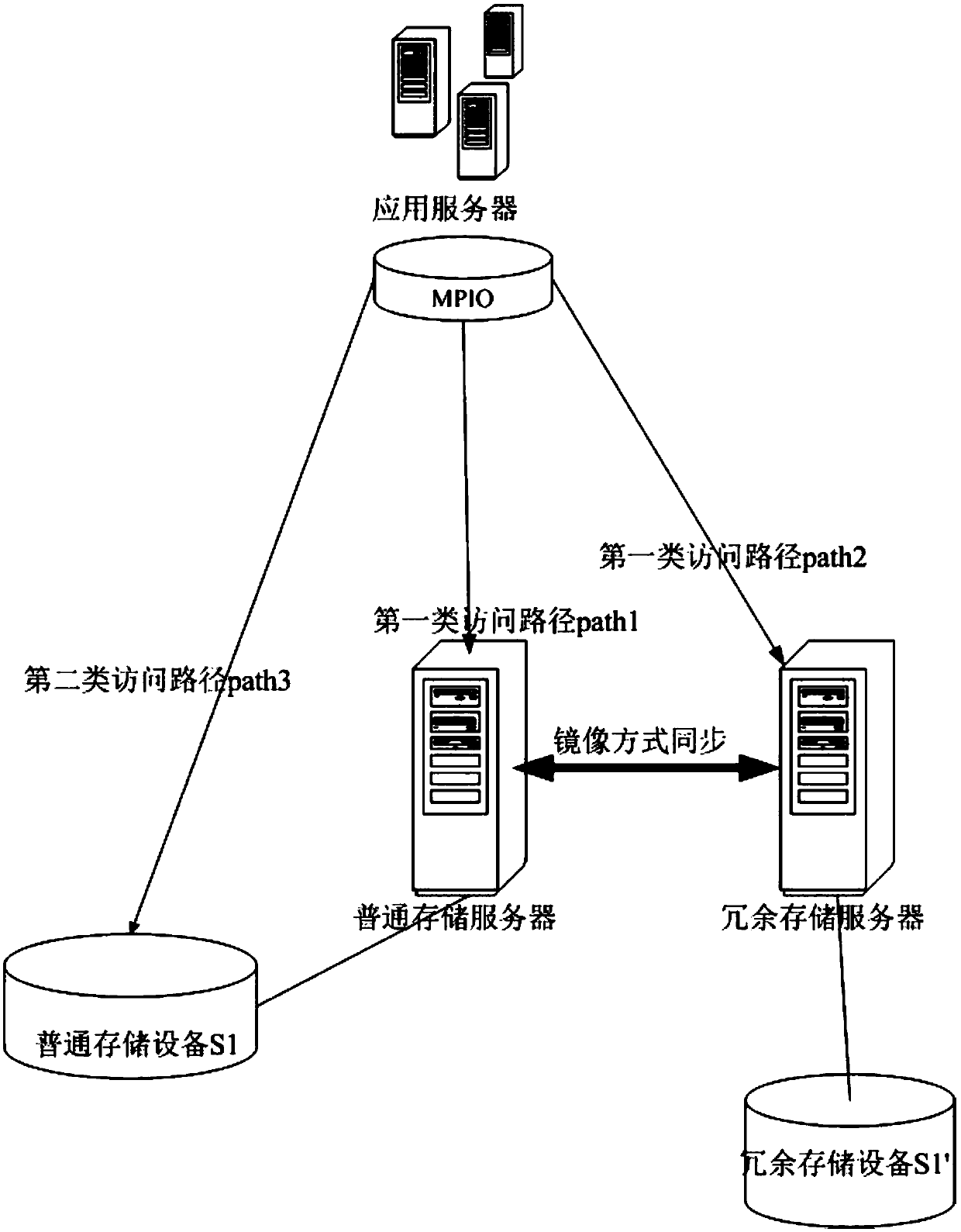

A remote dual-active method for a distributed data center, an application server and a network

InactiveCN109597710AAchieve data redundancyAchieving Path RedundancyRedundant operation error correctionData synchronizationApplication server

The embodiment of the invention provides a remote dual-active method for a distributed data center, which is applied to two storage servers. The storage equipment is managed by at least one storage server. The method comprises the following steps: receiving an access request for data located on a storage device, and requesting to establish a first type of access path with a storage server; And when the establishment of the first type of access path fails, establishing a second type of access path with the storage device according to the content of the access request. When the storage device cannot be accessed through the virtual storage platform, the storage device is directly accessed according to the access request, the content and format of data in the storage device cannot be changed,and path redundancy of data access is achieved. When one of the two storage servers breaks down, the storage service is automatically switched to the redundant server, and when the fault is repaired,storage data synchronization of the two servers is achieved through automatic reverse synchronization, so that data redundancy of data access is achieved.

Owner:杭州信核数据科技股份有限公司

Ultrasonic Control Rice Cooker

Owner:中山市开盈科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com