Biological oxygen demand microbe sensor sensitive membrane activating process and automatic activating apparatus

A microbial sensor, biochemical oxygen demand technology, applied in biochemical equipment and methods, microbial determination/inspection, testing water, etc., can solve problems such as time-consuming, time-consuming, cumbersome, etc., to ensure reproducibility and stability performance, saving manpower and time, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

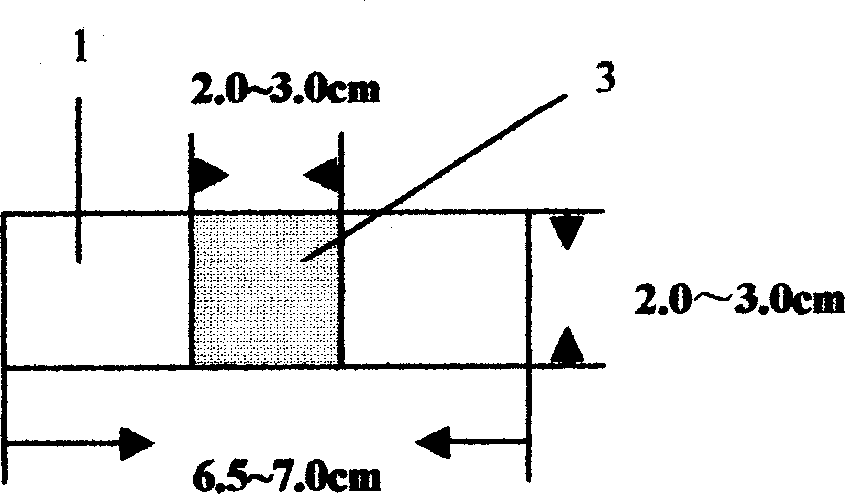

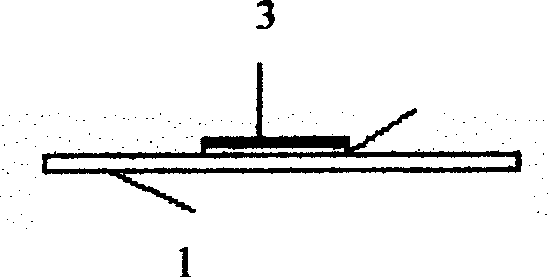

[0040] see figure 1 and 2 The said biochemical oxygen demand (BOD) microbial sensor of the present invention is a kind of optical fiber photochemical BOD microbial sensor. The optical fiber photochemical BOD microbial sensor sensitive film is composed of a transparent optical glass sheet 1, an oxygen sensing film 2 and a bacterial film 3. The oxygen sensing film 2 is set in the middle of the upper surface of the transparent optical glass sheet 1, and the bacterial film 3 is fixed on the oxygen sensor on film 2. The biofilm 3 adopts the mixed biofilm. The size of the transparent optical glass sheet 1 is 6.5-7.0 cm in length and 2.0-3.0 cm in width, and the length and width of the oxygen sensing film 2 and the biofilm 3 are both 2.0-3.0 cm.

[0041] Said glucose-glutamic acid standard solution (GGA solution) is to accurately weigh each 0.0750g of analytically pure glucose and glutamic acid, and be settled to 100mL with the above phosphate buffer solution, and the solution obt...

Embodiment 2

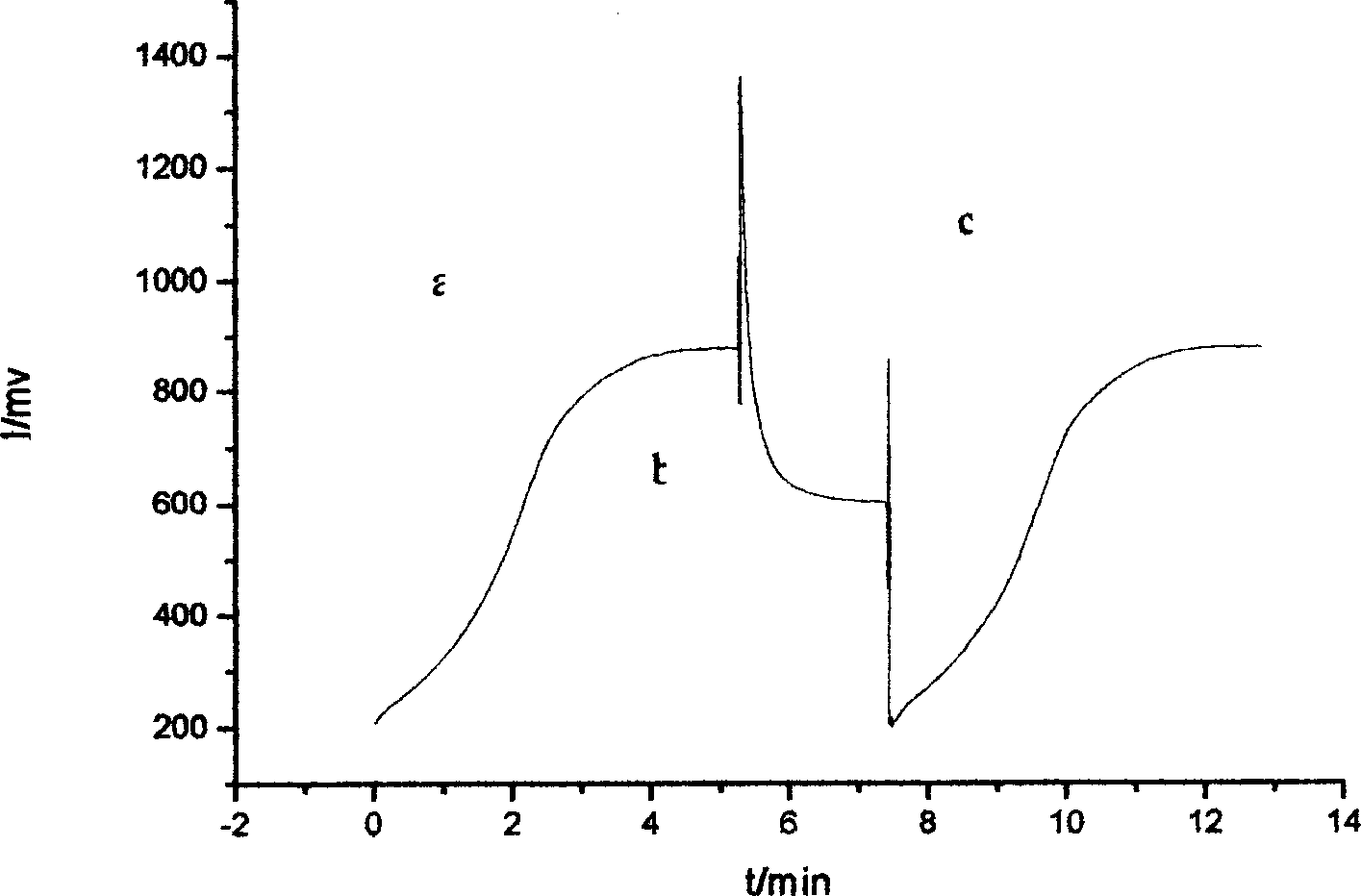

[0050] The steps of the automatic activation method for the biochemical oxygen demand microbial sensor sensitive film of the present invention are:

[0051] Add GGA solution with a concentration of 50-200mg / L into the water tank, and immerse the pump in the GGA solution; set the soaking time and aeration time of the sensitive membrane through the dial switch on the control circuit, the soaking time is 5-60min, The aeration time is 1 to 5 minutes; take out 3 to 9 pieces of sensitive film from the refrigerator, put them into the card slot of the activation tank, turn on the power of the activation device, the solenoid valve is in the closed state, the pump starts to rotate, and the GGA solution in the water tank Pump it into the activation tank; the liquid level begins to rise and gradually submerge the sensitive membrane. When the liquid level rises to the high level electrode, the pump stops working, and the sensitive membrane is soaked in the GGA solution; after the soaking ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com