Device and method for controlling material dipping time in electrophoretic painting

A technology of electrophoretic coating and time, applied in the direction of electrolytic coating, electrophoretic plating, coating, etc., can solve the problem that product quality cannot be effectively controlled, and achieve the effect of reducing labor intensity and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

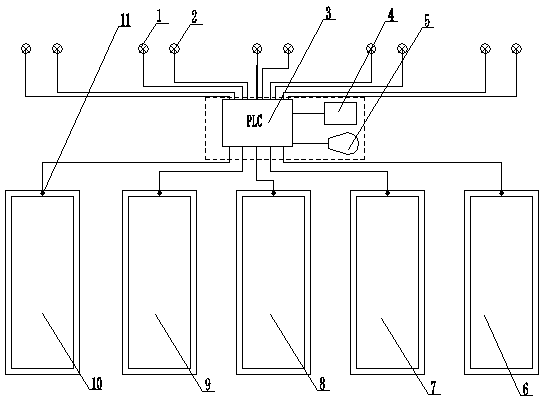

[0017] like figure 1 The shown device for controlling the dipping time of electrophoretic coating has a programmable logic controller (PLC) 3, and the electrophoretic coating tank includes a pre-degreasing tank 10, a main degreasing tank 9, a surface conditioning tank 8, a phosphating tank 7, The electrophoresis tank 6, the pre-degreasing tank 10, the main degreasing tank 9, the surface conditioning tank 8, the phosphating tank 7, and the electrophoresis tank 6 respectively have a position sensor 11 electrically connected to a programmable logic controller (PLC) 3, the said The programmable logic controller (PLC) 3 is electrically connected with a material indicator 1 and a timing indicator that reflect the production status of the pre-degreasing tank 10 , the main degreasing tank 9 , the surface adjustment tank 8 , the phosphating tank 7 and the electrophoresis tank 6 respectively. 2. The programmable logic controller (PLC) 3 is electrically connected with an alarm 5 and a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com