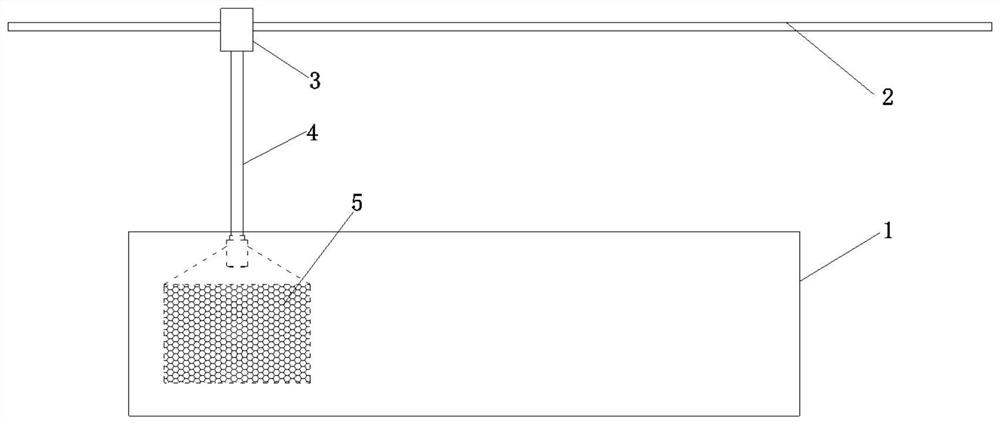

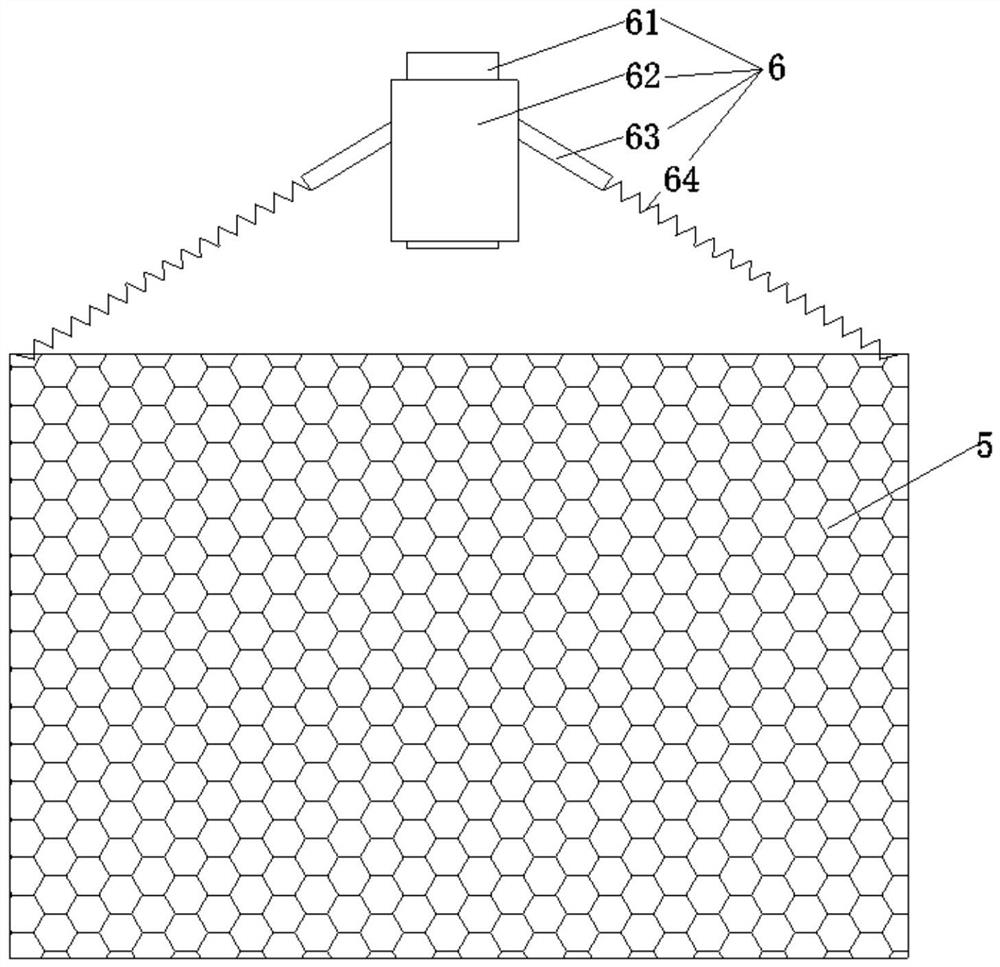

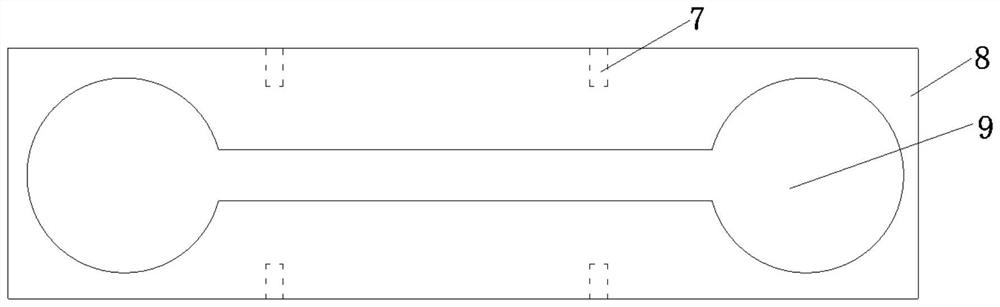

Hami melon combined drying method and device

A combined drying and cantaloupe technology, which is applied in food drying, food science, food ingredients, etc., can solve the problems that the crispness of cantaloupe slices needs to be improved, and the material is prone to browning, so as to achieve the effect of promoting sufficient soaking and improving soaking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Hami melon combined drying method comprises the following steps:

[0038] Step 1, pretreatment: the Hami melon slices to be treated are soaked in a pretreatment solution at 85°C for 55 seconds, wherein the pretreatment solution includes sodium chloride with a mass fraction of 1%, konjac flour with a mass fraction of 1%, and a mass fraction of 0.5% % soybean lecithin, the solvent is water, wherein the thickness of the Hami melon slice to be treated is 0.3cm;

[0039] Step 2, drying the pretreated Hami melon slices. Using hot air drying and variable temperature and pressure difference puffing drying, the hot air drying temperature is 50°C, dried to a moisture content of 15%, the conditions of variable temperature and pressure difference puffing drying are: puffing temperature is 80°C, puffing pressure is 0.2MPa, stagnation time is 5min , the evacuation temperature is 70°C, and the evacuation time is 90min. After drying, the moisture content of the cantaloupe slices was ...

Embodiment 2

[0041] Hami melon joint drying method comprises the following steps:

[0042] Step 1, pretreatment: the Hami melon slices to be treated are soaked in a 95°C pretreatment solution for 70s, wherein the pretreatment solution includes sodium chloride with a mass fraction of 2%, konjac flour with a mass fraction of 3%, and konjac flour with a mass fraction of 1 % soybean lecithin, the solvent is water, wherein the thickness of the Hami melon slice to be treated is 1cm;

[0043] Step 2, drying the pretreated Hami melon slices. Using hot air drying and variable temperature and pressure difference puffing drying, the hot air drying temperature is 60°C, dried to a moisture content of 25%, the conditions of variable temperature and pressure difference puffing drying are: puffing temperature is 90°C, puffing pressure is 0.3MPa, stagnation time is 5min , the evacuation temperature is 70°C, and the evacuation time is 90min. After drying, the moisture content of the cantaloupe slices was ...

Embodiment 3

[0045] Hami melon combined drying method comprises the following steps:

[0046] Step 1, pretreatment: the Hami melon slices to be treated are soaked in a 90°C pretreatment solution for 60s, wherein the pretreatment solution includes sodium chloride with a mass fraction of 1.5%, konjac flour with a mass fraction of 2%, and a mass fraction of 0.8% % soybean lecithin, the solvent is water, wherein the thickness of the Hami melon slice to be treated is 0.7cm;

[0047] Step 2, drying the pretreated Hami melon slices. Use hot air drying and variable temperature and pressure difference puffing drying. The hot air drying temperature is 55°C, and the moisture content is 20%. , the evacuation temperature is 70°C, and the evacuation time is 90min. After drying, the moisture content of the cantaloupe slices was 6.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com