Flash drying method for fruits and vegetables through pulse pressure difference

A technology of flash drying and pulsating pressure, which is applied in food preservation, food preparation, food science, etc. It can solve the problems of long drying time, high energy consumption, and low degree of product standardization, achieve crispy taste and texture, and improve drying efficiency , The effect of shortening the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, the method for pulsating differential pressure flash drying apples

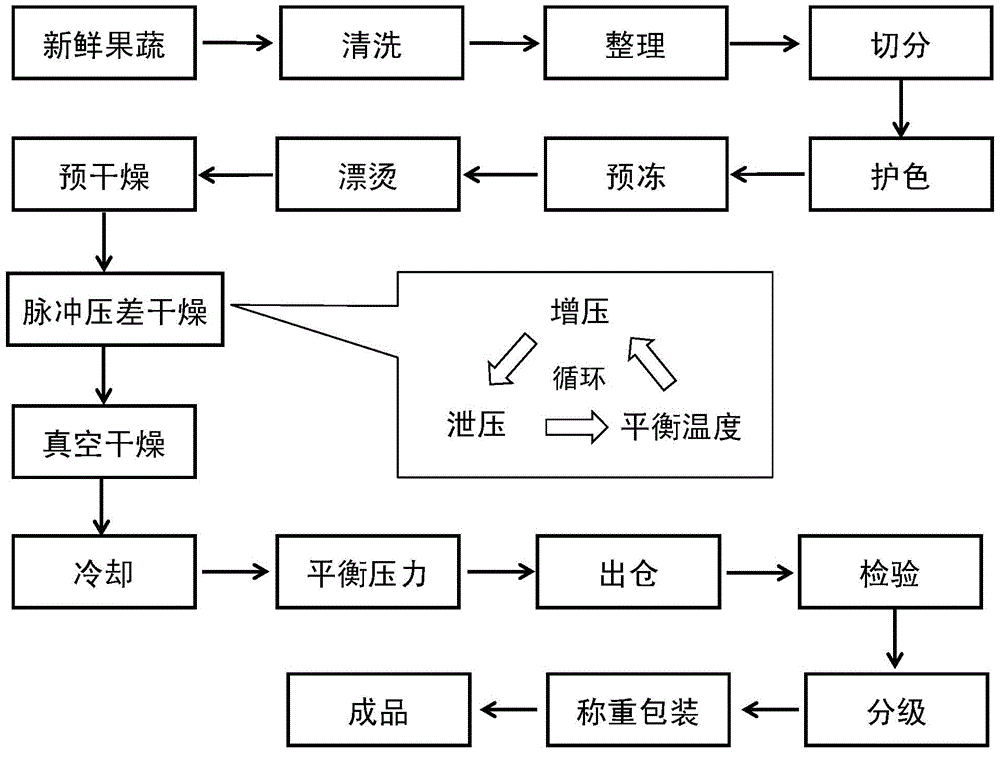

[0043] The schematic flow sheet of drying method of the present invention is as figure 1 shown.

[0044] (1) apple pretreatment;

[0045] 1) Select complete fresh apples with similar maturity and size, remove damaged, insect-pest and rotten defective fruits, and wash them with clean water;

[0046] 2) Peel the cleaned apples with a tool (or machine), and simultaneously remove the cores with a corer to obtain apple pulp;

[0047] 3) Slicing: the apple pulp is sliced by a slicer (or manually) to obtain apple slices with a thickness of 8mm;

[0048] 4) Color protection: apple slices and color protection agent are mixed according to the mass of 1:5, and apple slices are soaked in the color protection agent for 30 minutes, wherein the mass percentage concentration of citric acid in the color protection agent is 1%, calcium chloride The mass percentage concentration is 1.5%, and the mass ...

Embodiment 2

[0078] Embodiment 2, the method for pineapple pulsating differential pressure flash drying

[0079] The schematic flow sheet of drying method of the present invention is as figure 1 shown.

[0080] (1) jackfruit pretreatment;

[0081] 1) Select the pineapple fruit of the dry bract variety with less fresh insect-free bract juice and tighter flesh quality at about medium ripeness, and remove the defective fruit with damage, insect pests and rot;

[0082] 2) Peel the jackfruit, remove the inflorescence axis, remove the tendon and bract, remove the seeds, and cut it into strips of 0.5cm×0.5cm×5cm longitudinally;

[0083] 3) Pre-freezing: Put the sliced jackfruit strips in a vacuum freeze-drying tray, and place them in an environment of about -40°C for pre-freezing for 3 hours until all the jackfruit is frozen. After freezing, store the fruits and vegetables at -18°C for later use;

[0084] 4) Blanching: Blanch the jackfruit strips at 100°C for 5 minutes;

[0085] 5) Pre-dry...

Embodiment 3

[0103] Embodiment 3, the method for papaya pulsating differential pressure flash drying

[0104] The schematic flow sheet of drying method of the present invention is as figure 1 shown.

[0105] (1) papaya is pretreated;

[0106] 1) Select complete fresh papaya with similar maturity and size, remove damaged, insect-pest and rotten defective fruits, and wash them with clean water;

[0107] 2) The papaya after cleaning is peeled with a tool, and the papaya seeds are removed at the same time to obtain papaya pulp;

[0108] 3) Cutting: Cut the papaya pulp into cubes of 10mm×10mm×10mm;

[0109] 4) Color protection: Carry out color protection treatment on the diced papaya after cutting, mix the diced papaya and the color protection agent according to the mass ratio of 1:5, soak for 20 minutes, wherein the mass concentration of vitamin C in the color protection agent is 1% , The mass concentration of calcium chloride is 1.5%, pull out after soaking, and drain the water;

[0110]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com