Internal Stress Soaking Tester for Plastic Products

A technology of plastic products and internal stress, which is applied in the field of laboratory testing instruments to achieve the effects of avoiding physical damage, improving work efficiency, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, and the present invention is not limited to the following embodiments.

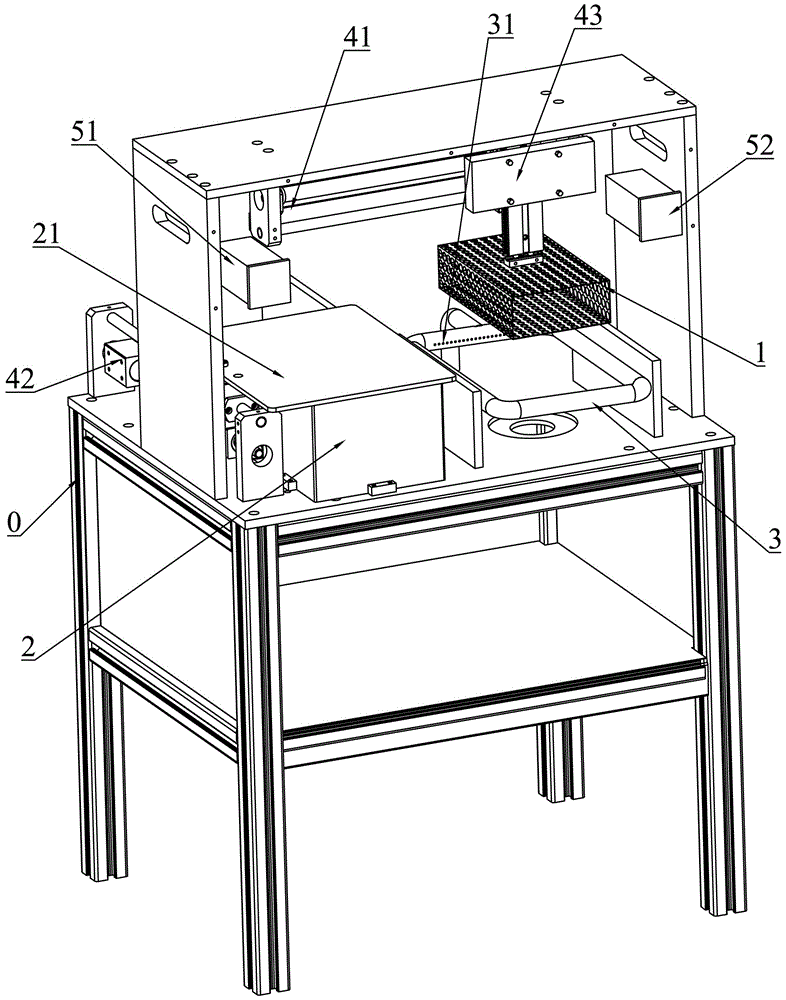

[0019] Such as figure 1 Shown is a schematic structural view of an embodiment of the plastic internal stress immersion testing machine provided by the present invention. The plastic internal stress immersion testing machine in this embodiment is mainly composed of the following parts: 1) frame 0; 2) product transfer cage 1, used to place plastic products; 3) solvent vessel 2, with an opening at the top, used for storage and testing The soaking solvent used can be made of glass, and a vessel cover 21 is arranged on it; 4) The flushing water pipe 3 is used for flushing plastic products; 5) The driving mechanism includes a first horizontal driving mechanism 41, a second horizontal driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com