Surface activating method of medical metal material

A metal material and surface activation technology, applied in the field of preparation of biomedical metal materials, can solve the problems of poor bonding ability between coating and substrate, cumbersome operation, time-consuming, etc., to avoid poor bonding strength, simple operation and short processing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First take NaCl 680mmol, CaCl 2 12.5mmol, Na 2 HPO 4 .2H 2 O 5mmol, MgCl 2 .6H 2 O7.5mmol, NaHCO 3 12.6mmol, add 40 milliliters of 1mol / l HCl measured together into deionized water, stir, mix and dissolve, and continue to use deionized water to make up to 1 liter as electrolyte solution, then adjust the pH of the solution with tris The value is 6, which is reserved in the electrolytic cell.

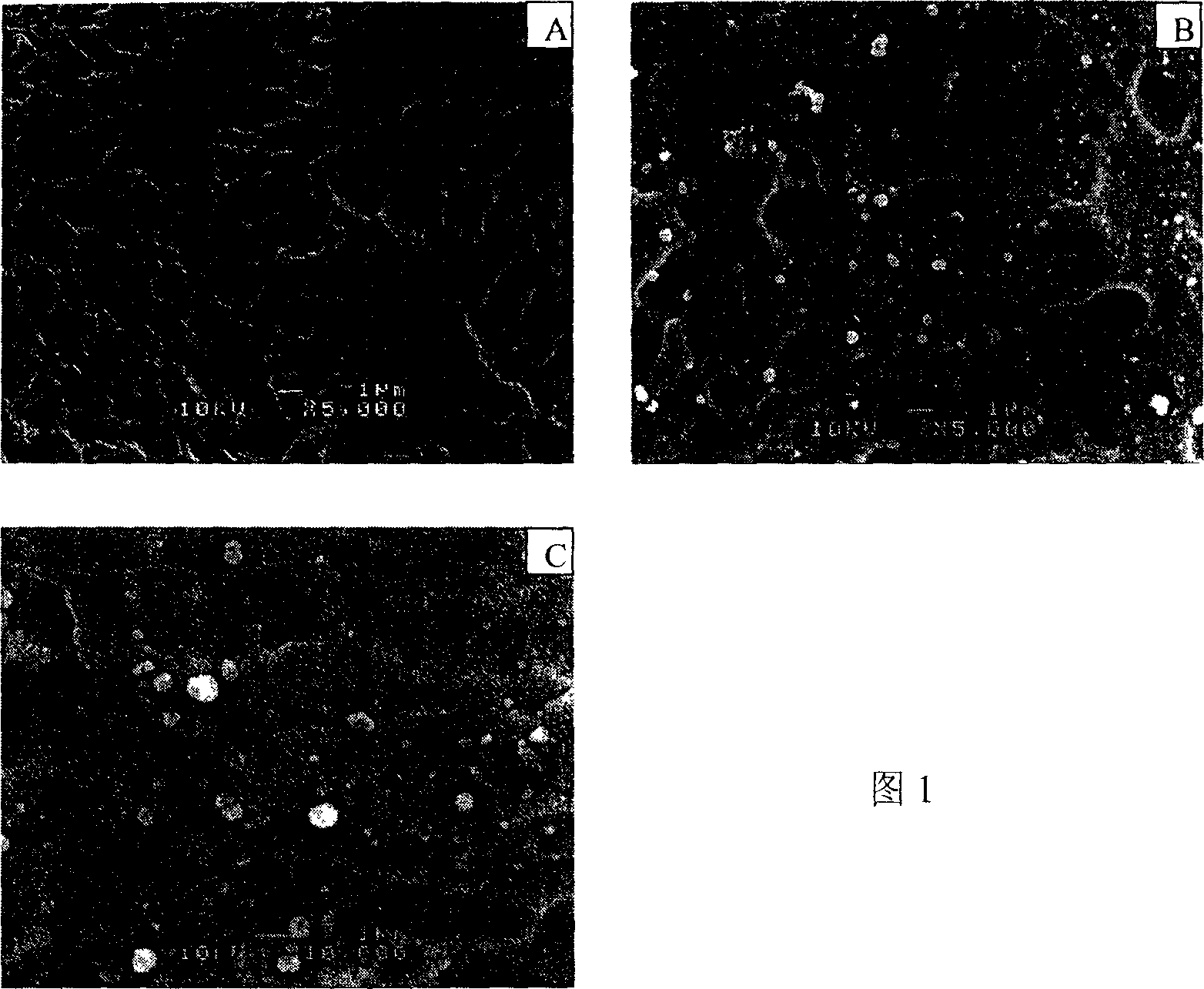

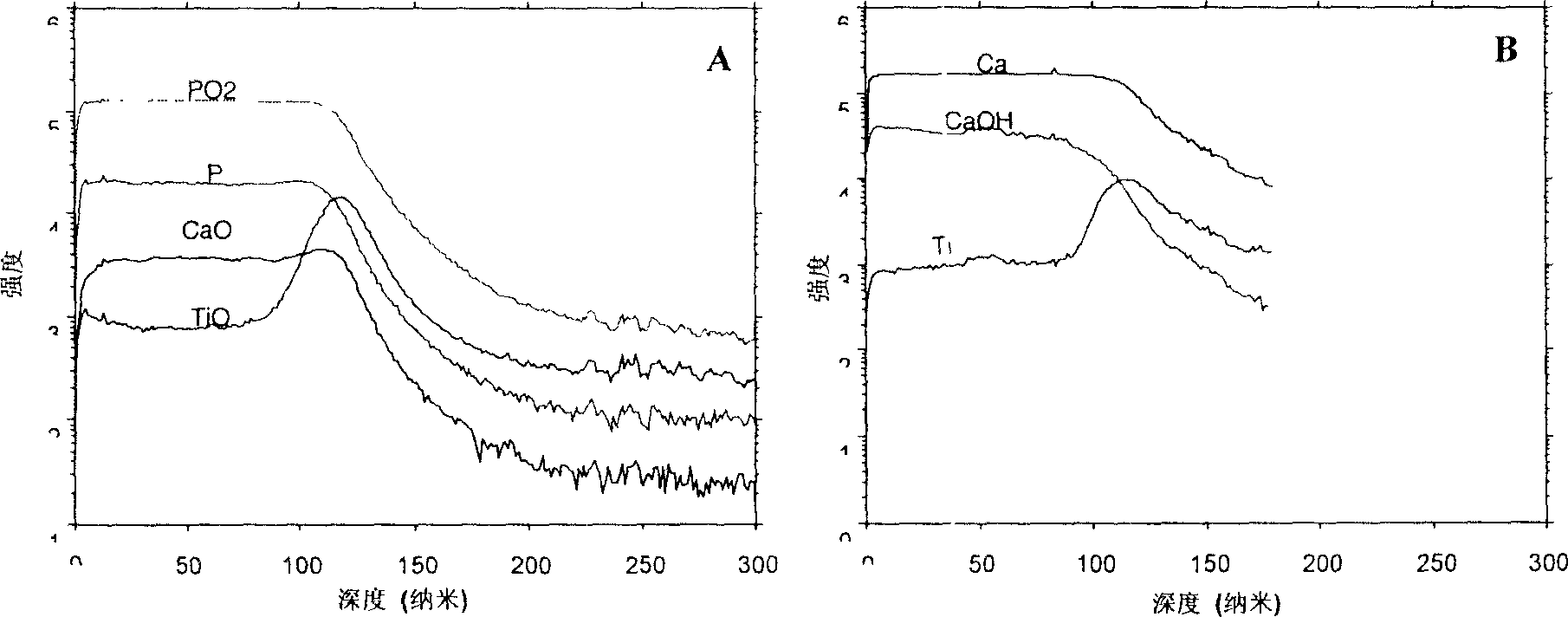

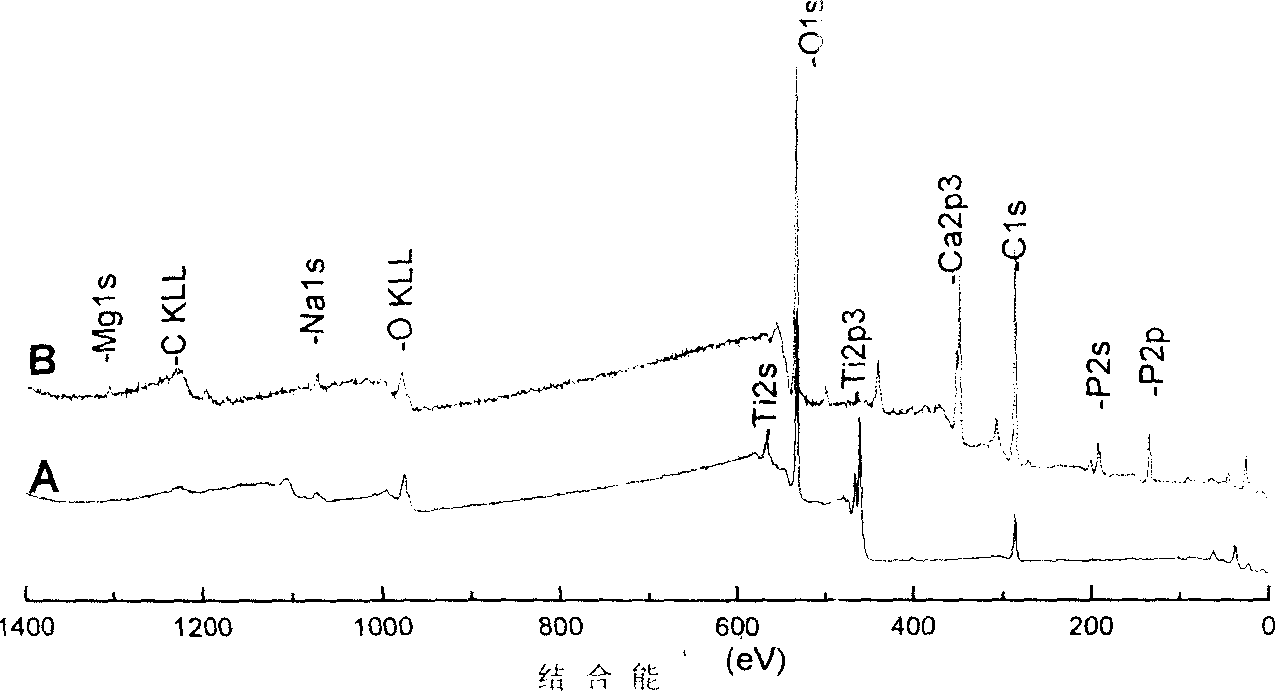

[0024] First connect titanium to a copper wire by spot welding, and seal the weld with epoxy resin, then place it together with a platinum electrode as an anode and a saturated mercurous sulfate / mercury electrode as a reference electrode, and place it in the electrolyte solution in the electrolytic cell and connected to the potentiostat; select the constant potential mode from the potentiostat, set the potential to -2V, treat for 10 minutes, take out the cathode sample, wash it with deionized water, and then put it in an oven for drying at 40°C , it can be observed that th...

Embodiment 2

[0026] First, take KCl 600mmol, CaCl 2 12.5mmol, Na 2 HPO 4 .2H 2 O 5mmol, MgCl 2 .6H 2 O7.5mmol, K 2 CO 3 12.6mmol, add 10 milliliters of 1mol / l HCl measured together into deionized water, stir, mix and dissolve, and continue to use deionized water to make up to 1 liter as electrolyte solution, then adjust the pH of the solution with tris The value is 4, which is reserved in the electrolytic cell.

[0027] First connect the stainless steel with a copper wire by spot welding, and seal the weld with epoxy resin, then put it together with the platinum electrode as the anode and the saturated mercurous sulfate / mercury electrode as the reference electrode, and place it in the electrolyte solution in the electrolytic cell and connected to the potentiostat; select the constant potential mode from the potentiostat, set the potential to -1.6V, treat for 5 minutes, take out the cathode sample, wash it with deionized water, and then put it in an oven to dry at 40°C After dryin...

Embodiment 3

[0029] First take NaCl 350mmol, CaCl 2 15mmol, Na 2 HPO 4 .2Hx 2 O 2.5mmol, MgCl 2 .6H 2 O5mmol, Na 2 CO 3 6mmol, add 20 milliliters of 1mol / l HCl measured together into deionized water and stir to mix and dissolve, and continue to use deionized water to make up to 1 liter as electrolyte solution, then adjust the pH value of the solution with tris It is 5, and it is reserved in the electrolytic cell.

[0030] First connect the titanium alloy to a copper wire by spot welding, and seal the welding place with epoxy resin, then place it together with the platinum electrode as the anode and the saturated mercurous sulfate / mercury electrode as the reference electrode, and place it in the electrolyte in the electrolytic cell solution, and connected to the potentiostat; select the constant potential mode from the potentiostat, set the potential to -2V, treat for 7 minutes, take out the cathode sample, wash it with deionized water, and then put it in an oven to dry at 40°C Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com