Antibacterial silk product loaded with nanometer copper and preparation method thereof

A nano-copper and silk technology, applied in textiles, papermaking, animal fibers, yarns, etc., can solve problems such as poor bonding fastness, low adhesion, and inability to meet practical application requirements, and achieve the effect of avoiding chemical reagent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

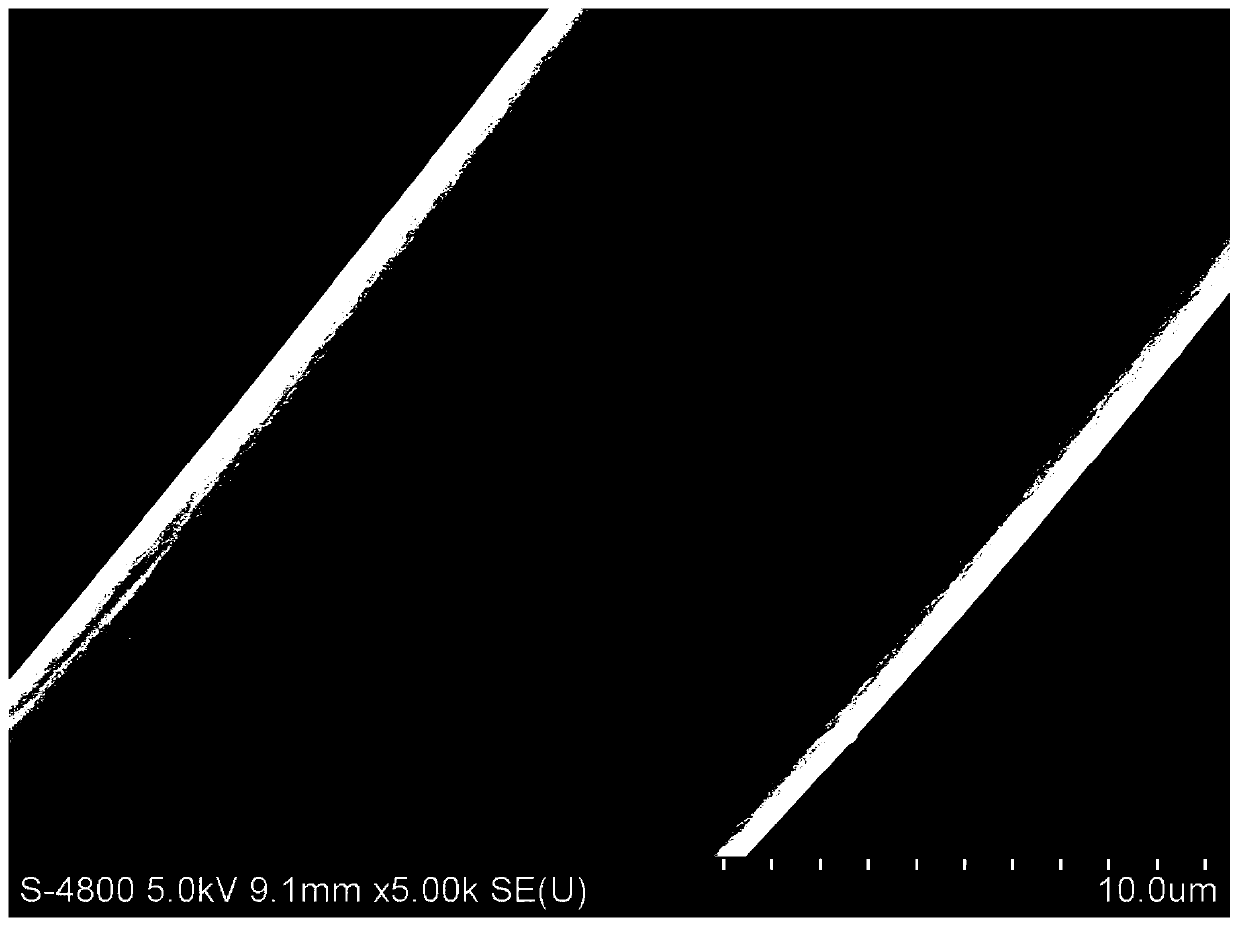

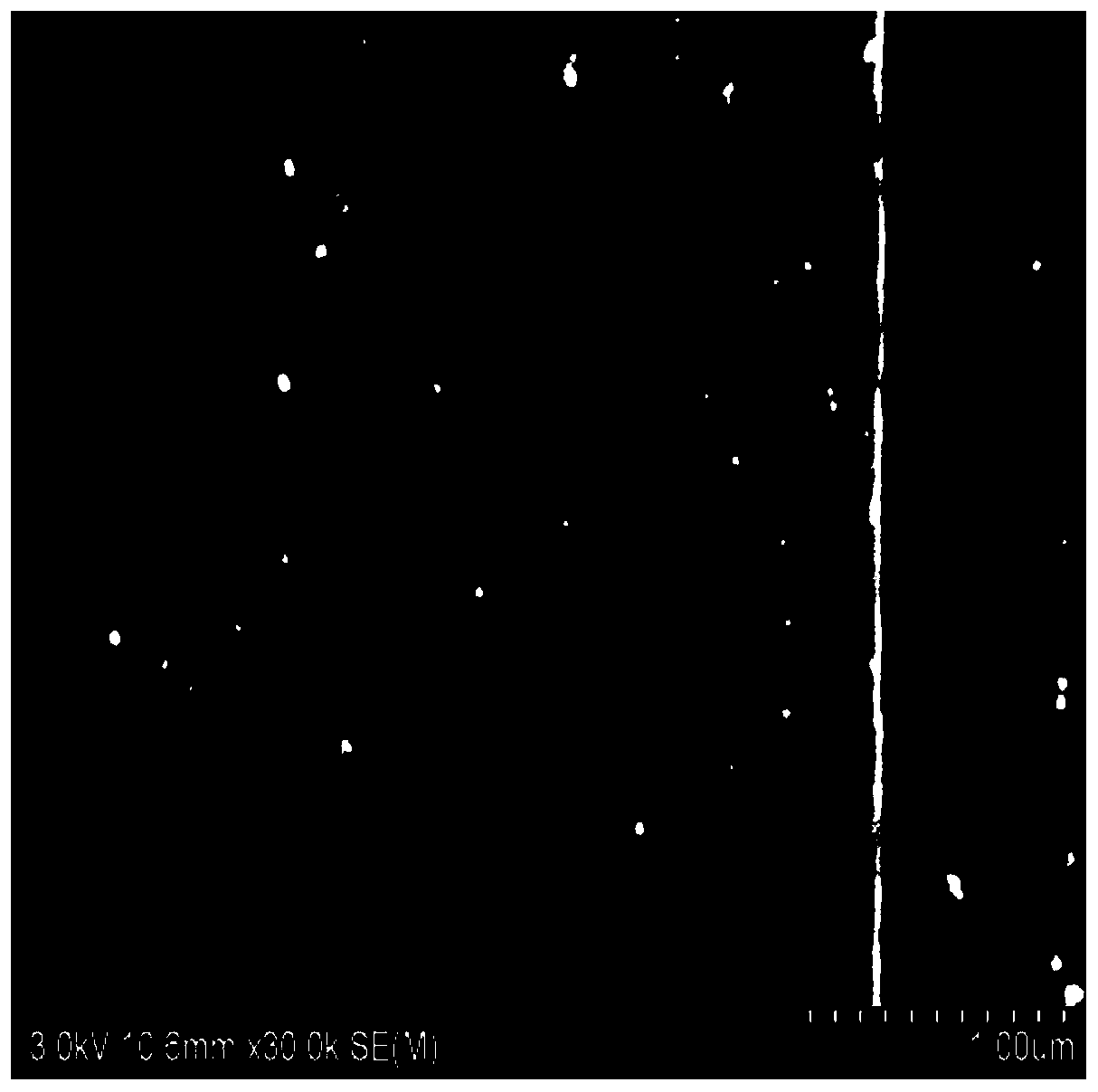

[0034]Configure an aqueous solution of 90% formic acid by mass fraction, then add copper nitrate to the formic acid solution, and stir for 5 minutes in the dark to dissolve, and configure a copper nitrate formic acid solution with a mass concentration of 5%; immerse the natural degummed mulberry silk in red yeast rice with a mass concentration of 0.5% In the fungal phosphate buffer solution, add the above-mentioned copper nitrate formic acid solution after 20 minutes at 15°C, and keep it in the dark for 1h at a temperature of 4°C; irradiate the soaked silk with a UV lamp at a power of 10W for 12h; fully water the obtained silk After washing and natural drying, the antibacterial mulberry silk fiber product is obtained; after testing, the nano-copper content in the fiber is about 8wt%; X-ray diffraction test is carried out, and the X-ray diffraction angle 2θ is 43.53°, 50.24°, 74.91°, 89.88°, These characteristic diffraction angles are consistent with the peak value of the copper...

Embodiment 2

[0037] Configure a mass fraction of 98% formic acid aqueous solution, then add copper sulfate pentahydrate to the formic acid solution, and magnetically stir in the dark for 15 minutes to dissolve, configure a copper sulfate formic acid solution with a mass concentration of 10%; immerse the natural degummed mulberry silk fiber with a mass concentration of 0.8% In the Monascus phosphate buffer solution of Monascus, add the above-mentioned copper sulfate formic acid solution after 30 minutes at 15°C, and keep it in the dark for 5h, at a temperature of 2°C; irradiate the soaked silk with a UV lamp, with a power of 30W, for 8h; The degummed mulberry silk is fully washed with water, and after natural drying, the antibacterial degummed mulberry silk is obtained; after testing, the nano-copper content in the fiber is about 12wt%; mechanical property tests show that the tensile strength reaches more than 95% of that before treatment.

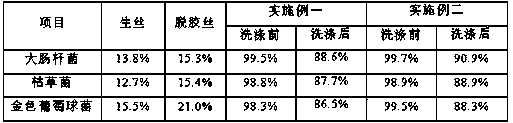

[0038] The antibacterial test adopts the antibacte...

Embodiment 3

[0043] Configure mass fraction 80% trifluoroacetic acid ethanol solution, then add copper fluoride to the solution, avoid light and magnetically stir for 30min to dissolve, configure copper fluoride trifluoroacetic acid solution with mass concentration of 10%; immerse degummed natural tussah silk in mass concentration In the 0.6% Monascus phosphate buffer solution, add the above-mentioned copper fluoride trifluoroacetic acid solution at 10°C for 20 minutes, and keep it in the dark for 2 hours at a temperature of 1°C; irradiate the soaked silk with a UV lamp with a power of 50W , irradiated for 10 hours; the obtained degummed natural tussah silk was fully washed and dried naturally to obtain the antibacterial tussah silk fiber. After testing, the nano-copper content in the fiber is about 13wt%; X-ray diffraction test shows that a large amount of nano-copper exists inside the silk, and the X-ray diffraction test pattern shows the Nano-copper characteristic diffraction peak, tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com