Methods for controlling temperatures in the environments of gas and oil wells

a technology for oil wells and environments, applied in the direction of fluid removal, borehole/well accessories, insulation, etc., can solve the problems of limiting the transfer of heat subsequently, further melting, etc., and achieves the effects of reducing the melting of glaciers, reducing the melting point, and reducing the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

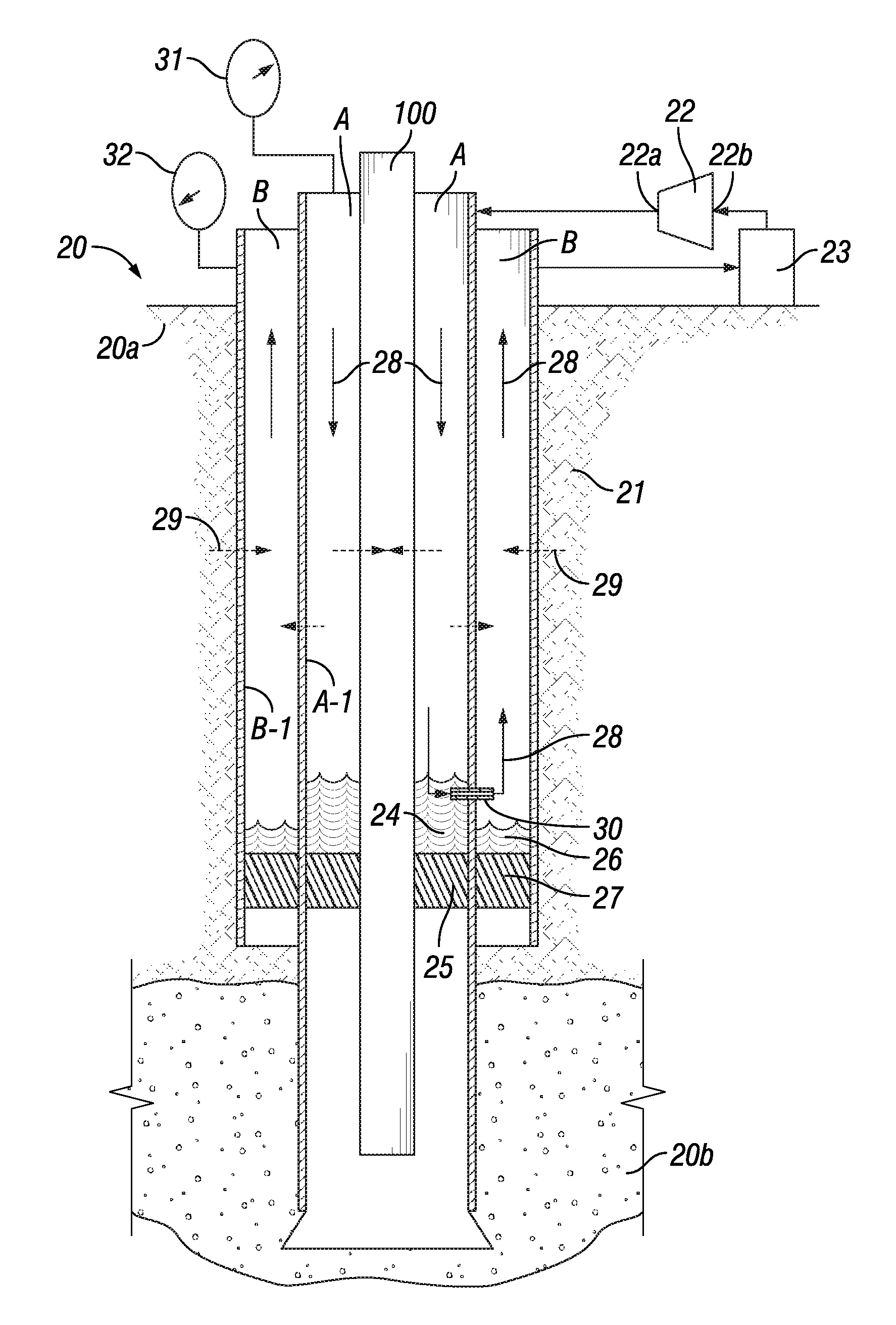

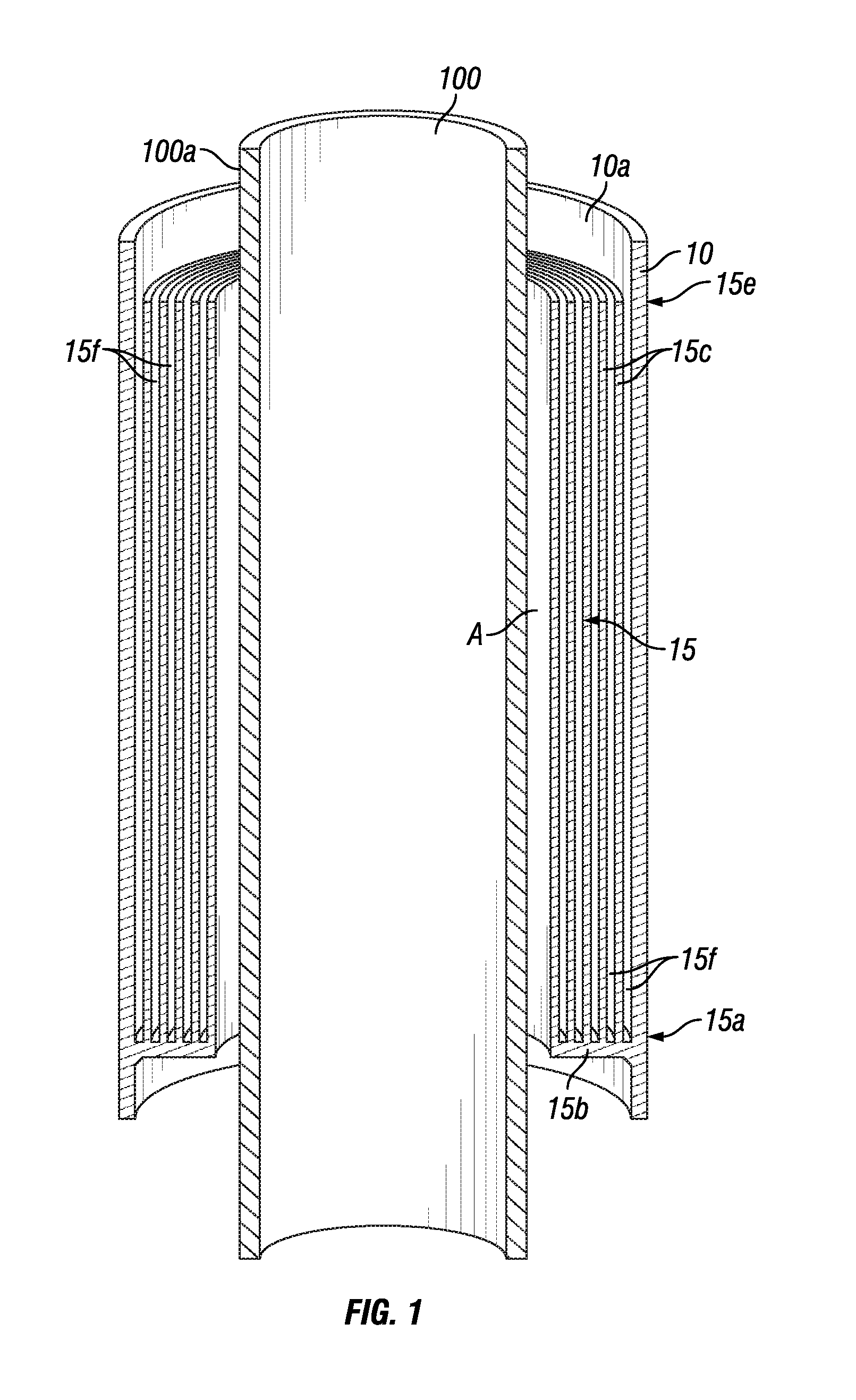

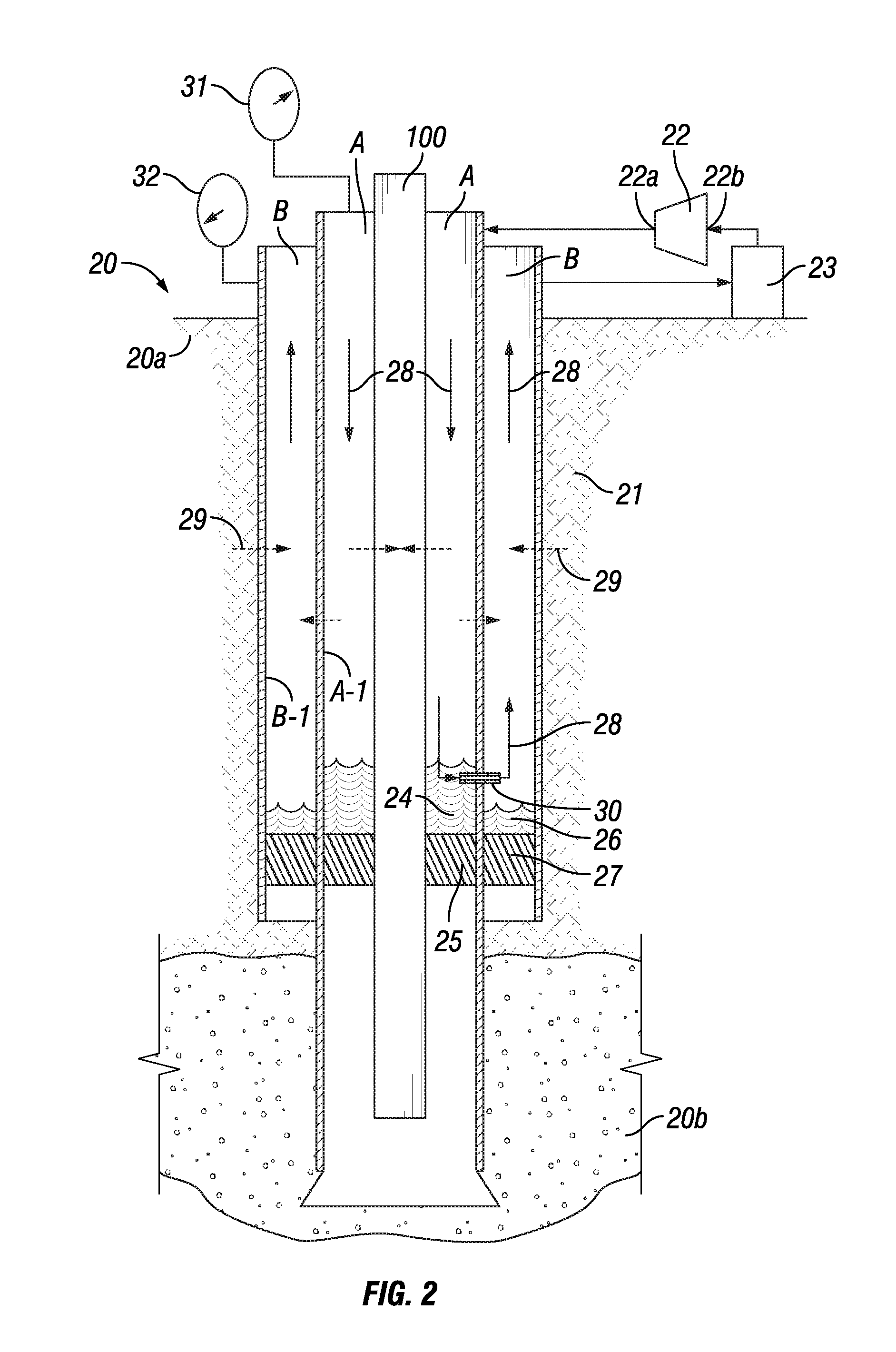

[0058]In one aspect, the present invention relates to ice-laden environments such as those in permafrost areas where a proactive approach is taught herein (1) limiting the consequences of the transfer of heat from the relatively hot produced fluids into the ice in the environment surrounding the production string, impeding the melting of ice, and thereby (2) limiting the transfer of heat. In this aspect, the present invention teaches the deployment of cold hydrate-forming fluids into the external ice-laden environment near the production string. If subsequently the transfer of heat leads to the melting of some of this ice, the previously deployed cold hydrate-forming fluids will convert the melt-water into hydrate form. The melting point of the hydrates will typically be much higher than that of ice, so subsequent melting will be diminished or eliminated. Additionally, the thermal conductance of melt-water is higher than those of ice or hydrate; consequently, the elimination of melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com