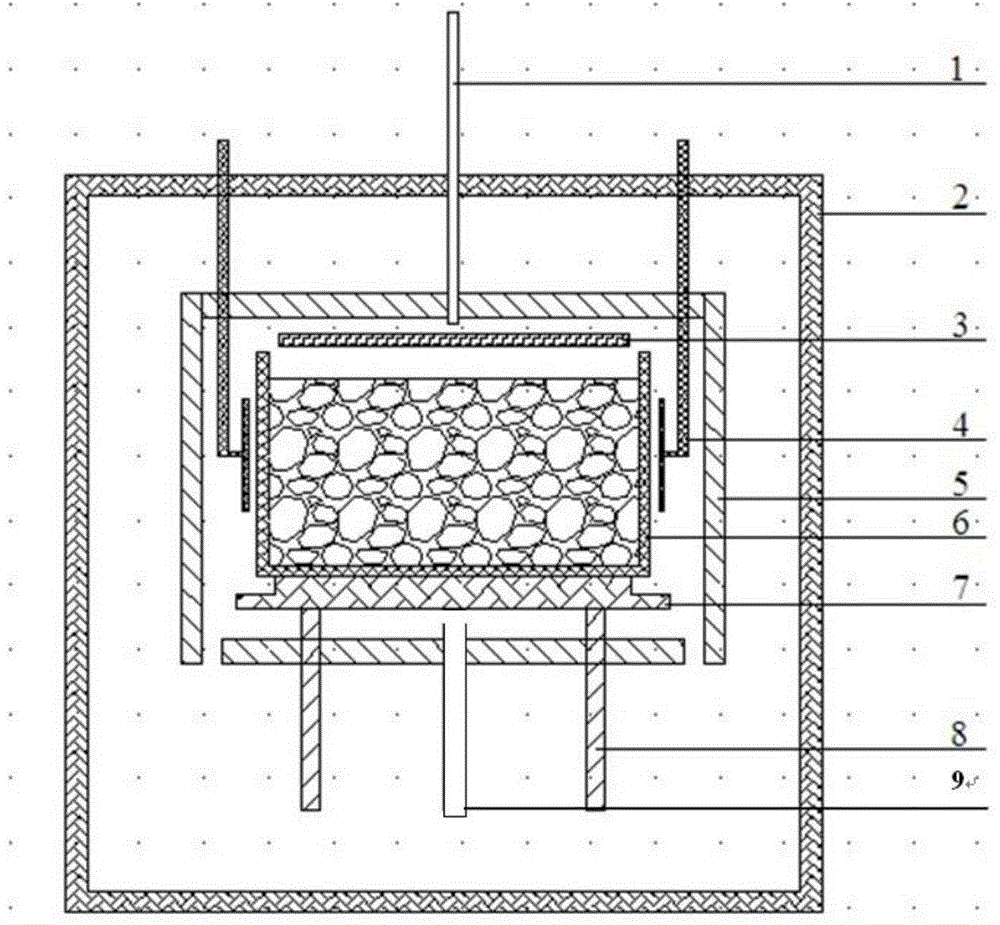

Polysilicon semi-fusion casting device adopting bottom air cooling and technology using the same

A polysilicon and air-cooling technology, which is applied in the growth of polycrystalline materials, crystal growth, chemical instruments and methods, etc., can solve the problems of prolonging the production cycle, prolonging the melting time, and increasing labor costs, so as to save time and cost and reduce production costs , The effect of saving the cost of heating field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A process for preparing polycrystalline silicon ingots, comprising the following process steps:

[0029] ① Preheating: Put the crucible 6 filled with silicon material into the ingot casting device, evacuate to 0.8Pa, keep the vacuum and make the temperature in the crucible 6 reach 1175°C within 3 hours;

[0030] ② Melting: Open the top pipe 1 to feed argon gas, the flow rate of argon gas is 20L / min, the pressure in the furnace is kept at 40kPa, and it reaches 1550°C within 2 hours, and then keeps warm at 1550°C until only the silicon material with a height of 3cm at the bottom is left Not melted; during this process, the bottom pipe 9 and the top pipe 1 are fed with argon gas at the same time, the argon flow rate of the top pipe 1 is 20L / min, and the argon flow rate of the bottom pipe 9 is adjusted between 10L / min~50L / min, Ensure that the temperature at the bottom of the crucible is always at 1380°C;

[0031] ③Crystal growth: The temperature is lowered from 1550°C to 1...

Embodiment 2

[0035] A process for preparing polycrystalline silicon ingots, comprising the following process steps:

[0036] ① Preheating: Put the crucible 6 filled with silicon material into the ingot casting device, evacuate to 1 Pa, keep the vacuum and make the temperature in the crucible 6 reach 1175°C within 5 hours;

[0037] ② Melting: Open the top pipe 1 to feed argon gas, the flow rate of argon gas is 30L / min, the pressure in the furnace is kept at 60kPa, and it reaches 1560°C within 3 hours, and then keeps warm at 1560°C until only the silicon material with a height of 1cm at the bottom is left Not melted; during this process, the bottom pipe 9 and the top pipe 1 are fed with argon gas at the same time, the argon flow rate of the top pipe 1 is 30L / min, and the argon flow rate of the bottom pipe 9 is adjusted between 10L / min~50L / min, Ensure that the temperature at the bottom of the crucible is always at 1390°C;

[0038] ③Crystal growth: the temperature is lowered from 1560°C to 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com