Composite type energy-absorbing anti-creeper of rail vehicle

A rail vehicle and composite technology, applied in the field of composite energy-absorbing anti-climbing devices, can solve the problems of non-uniform shape and size of foam material cells, low energy-absorbing efficiency, poor controllability of compression, etc., so as to improve energy absorption. and partial load resistance, improved crashworthiness, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

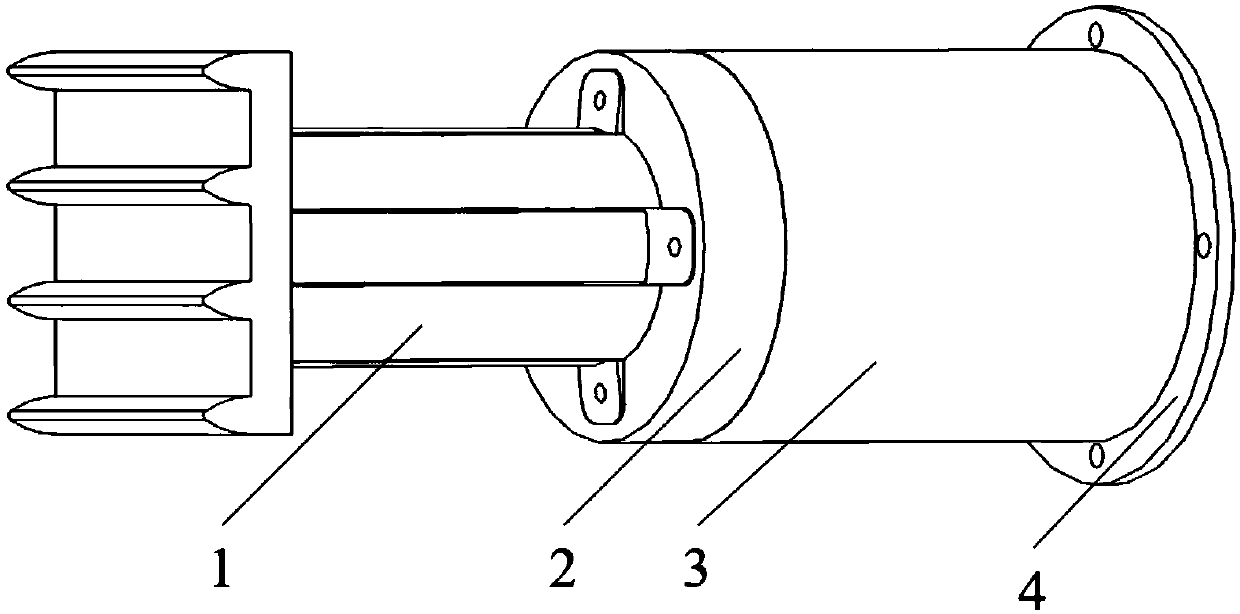

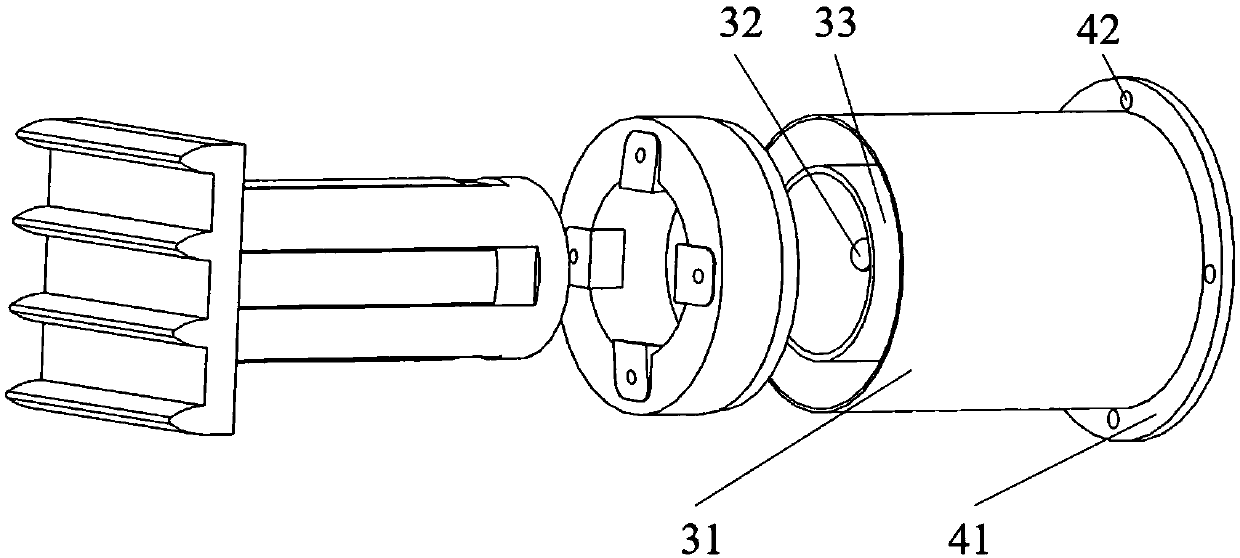

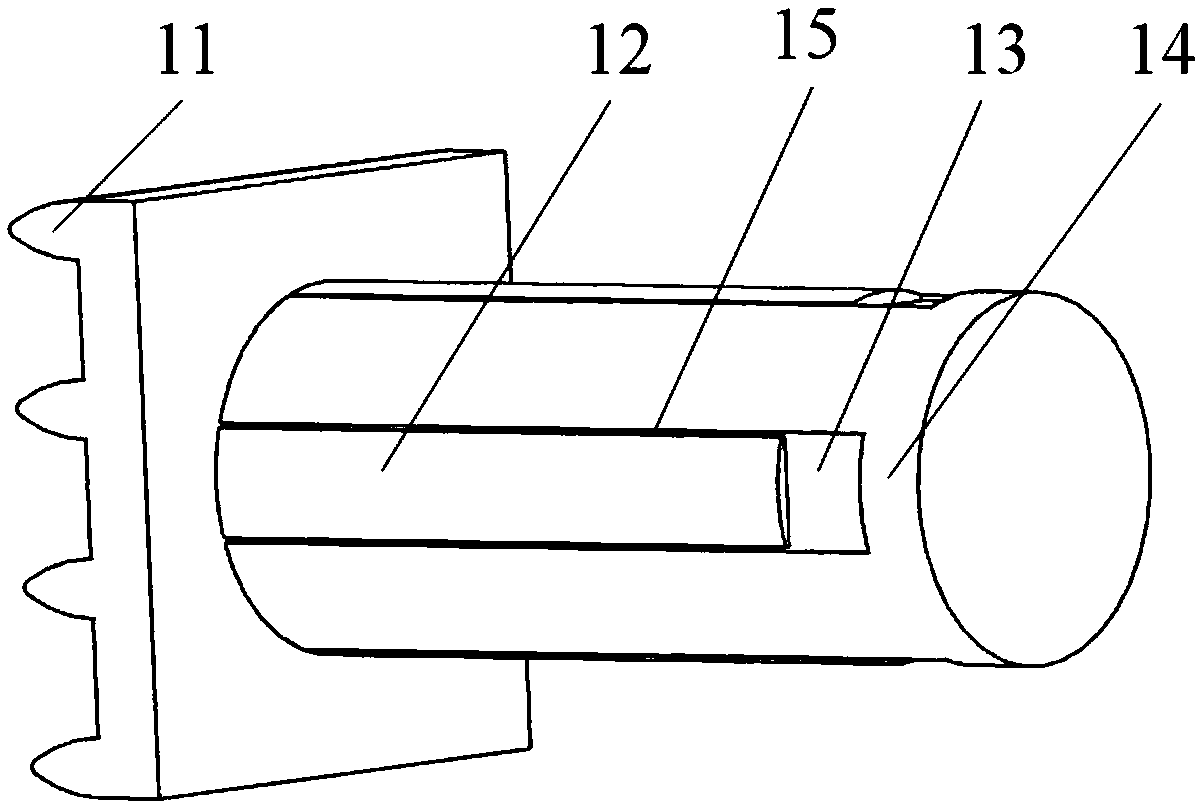

[0036] like Figure 1-Figure 7 As shown, the present invention discloses a composite rail vehicle energy-absorbing anti-climbing device, which mainly consists of an anti-climbing gear part 1, a flange assembly 2, a hydraulic cylinder body 3 and a mounting base 4, wherein the mounting base 4 and the flange assembly 2. It is sealed and installed at both ends of the hydraulic cylinder 3. The anti-climbing gear part 1 includes the anti-climbing gear 11, the piston rod 12 and the piston 14. There are four mounting bolts on the circumference of the mounting bottom plate 41 of the mounting base 4. Holes 42, the entire anti-climbing device is connected together with the vehicle chassis through the mounting holes 42.

[0037] Wherein, anti-climbing tooth 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com