Coal seam stope advantageous gas transport pathway staged construction method

A technology of migration channel and construction method, applied in the field of stepped construction of dominant gas migration channel in coal seam stope, can solve the problems of large gas, difficult diversion, poor flow, etc., and achieve favorable migration and efficient enrichment. , the effect of facilitating discharge and centralized extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0023] The stepwise construction method of the dominant gas migration channel in the coal seam stope of the present invention, the specific steps are as follows:

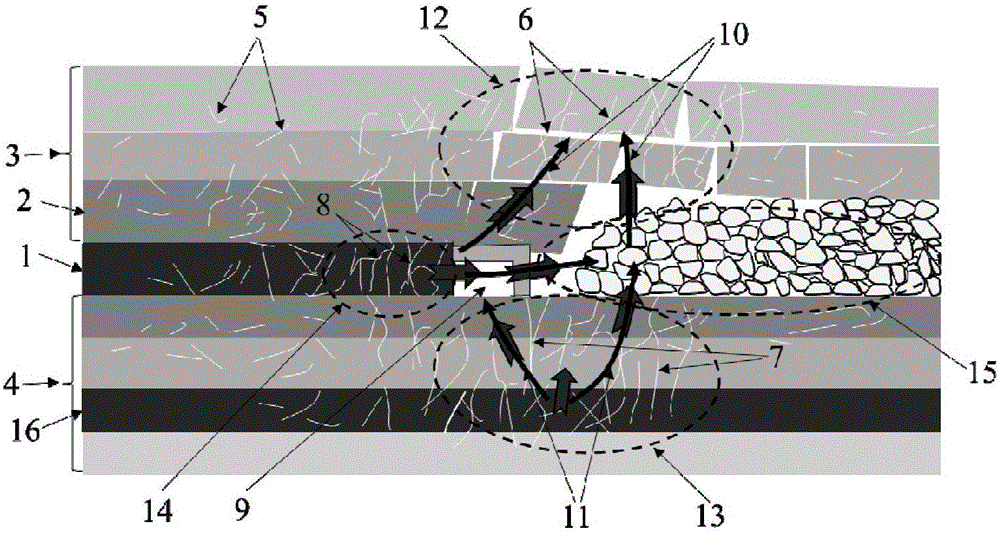

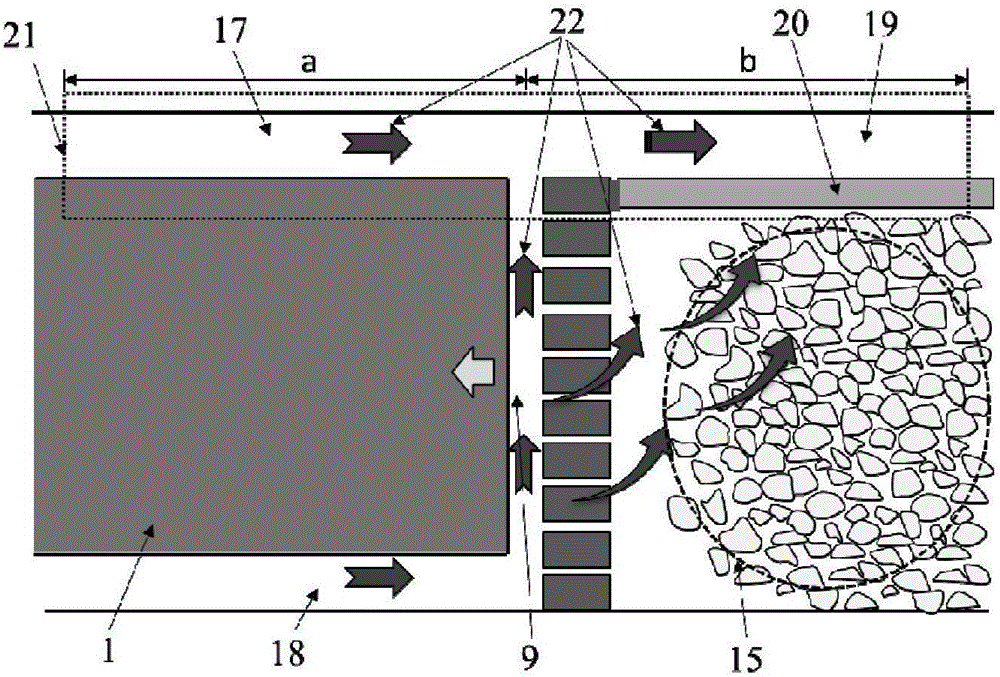

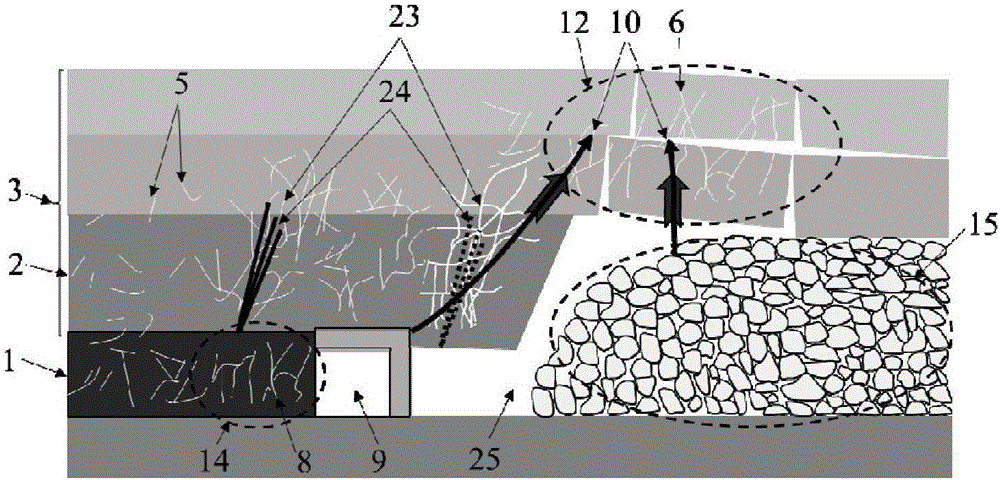

[0024] a. If figure 1 and figure 2 As shown, the first mining layer 1 is conventionally mined, the working face 9, the auxiliary air inlet 17, and the main air inlet 18 form a gas migration channel outside the coal and rock mass of the stope. Under the influence of the effect, the mining fractures 5 in the coal seam continue to develop, and the intralayer mining fractures 8 are formed in the first mining layer 1, and the roof vertical fractures 6 and the floor penetration fractures 7 are formed in the roof rock layer 3 and the floor rock layer 4 respectively. ;

[0025] b. After the working face 9 advances along with the mining, the entry retaining wall 20 is quickly built in the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com