Wastewater treatment system of enhanced membrane aeration biofilm reactor and application of system

A membrane aeration biofilm, wastewater treatment system technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. problems such as low oxygen utilization rate, to achieve the effect of increasing biomass, reducing aeration energy consumption, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

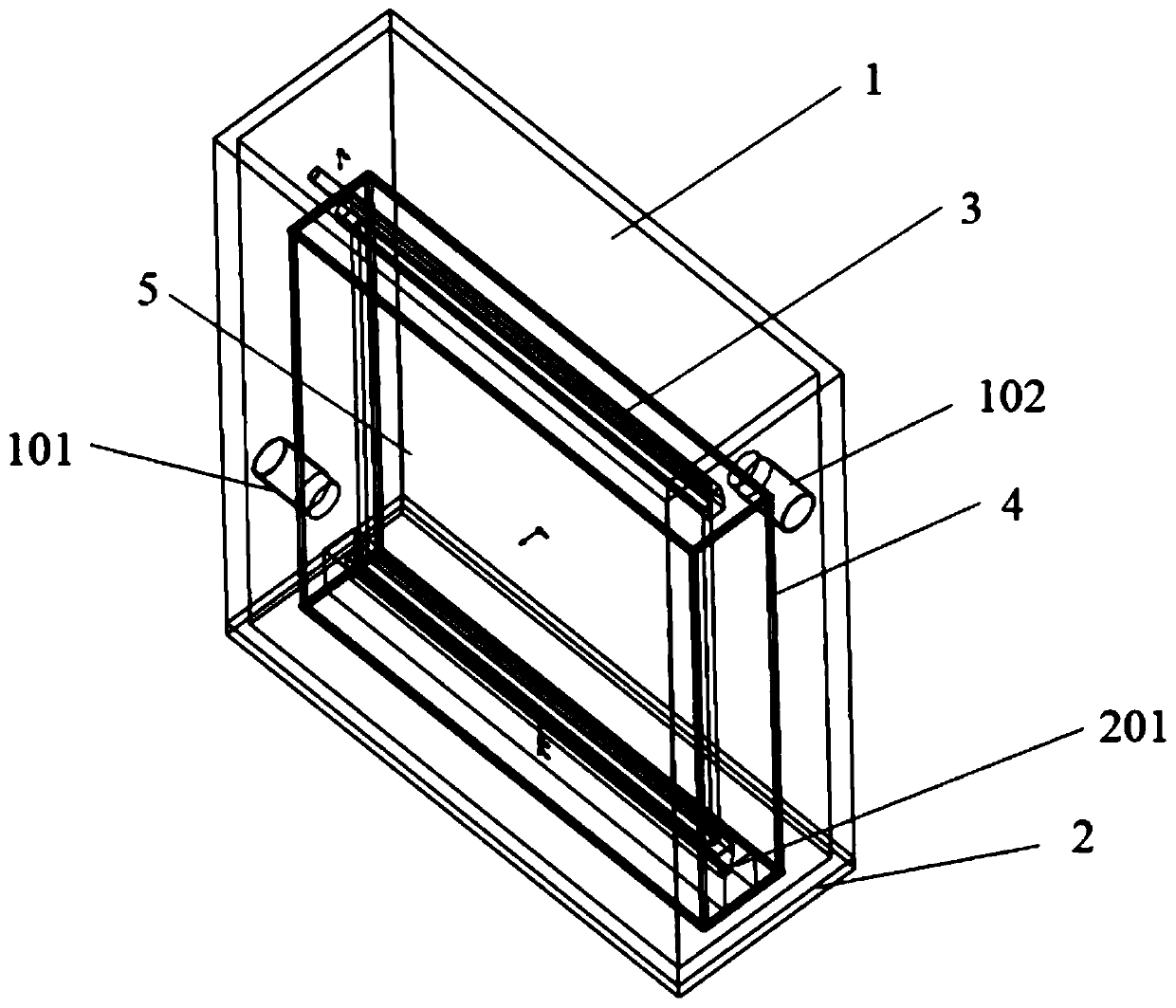

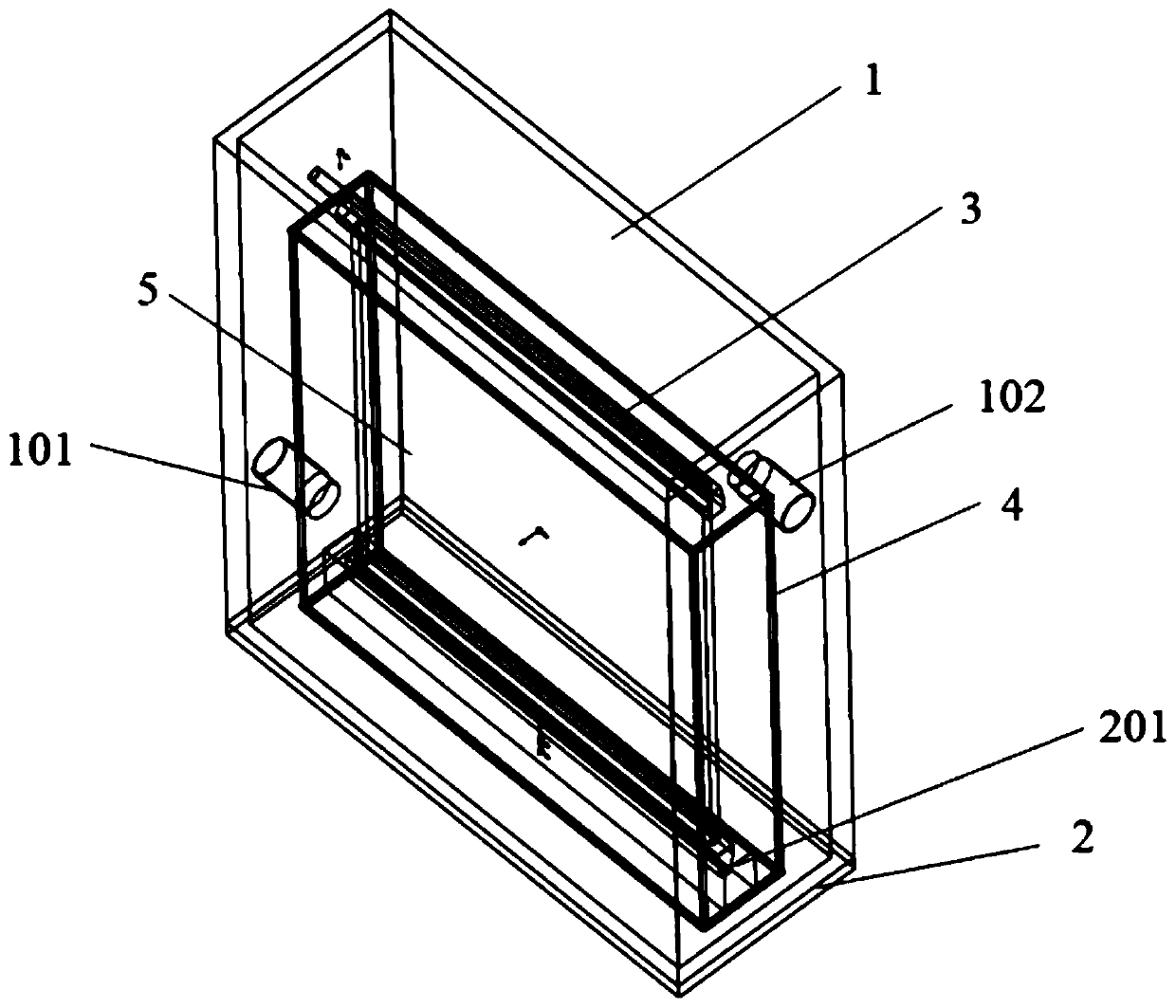

[0050] Such as figure 1 As shown, this embodiment discloses a wastewater treatment system of an enhanced membrane aerated biofilm reactor, including: a main reactor box 1, a reactor base 2, a filler frame 4 and an MBR membrane 3;

[0051] Wherein, the reactor base 2 is fixedly arranged on the bottom of the main reactor box 1;

[0052] The packing frame 4 is a frame structure similar to the structure of the main reactor box 1, and is fixedly arranged inside the main reactor box 1;

[0053] The reactor base 2 is provided with an MBR film slot 201, and the MBR film 3 can be fixedly arranged in the inner space of the packing frame 4 by means of the MBR film slot 201;

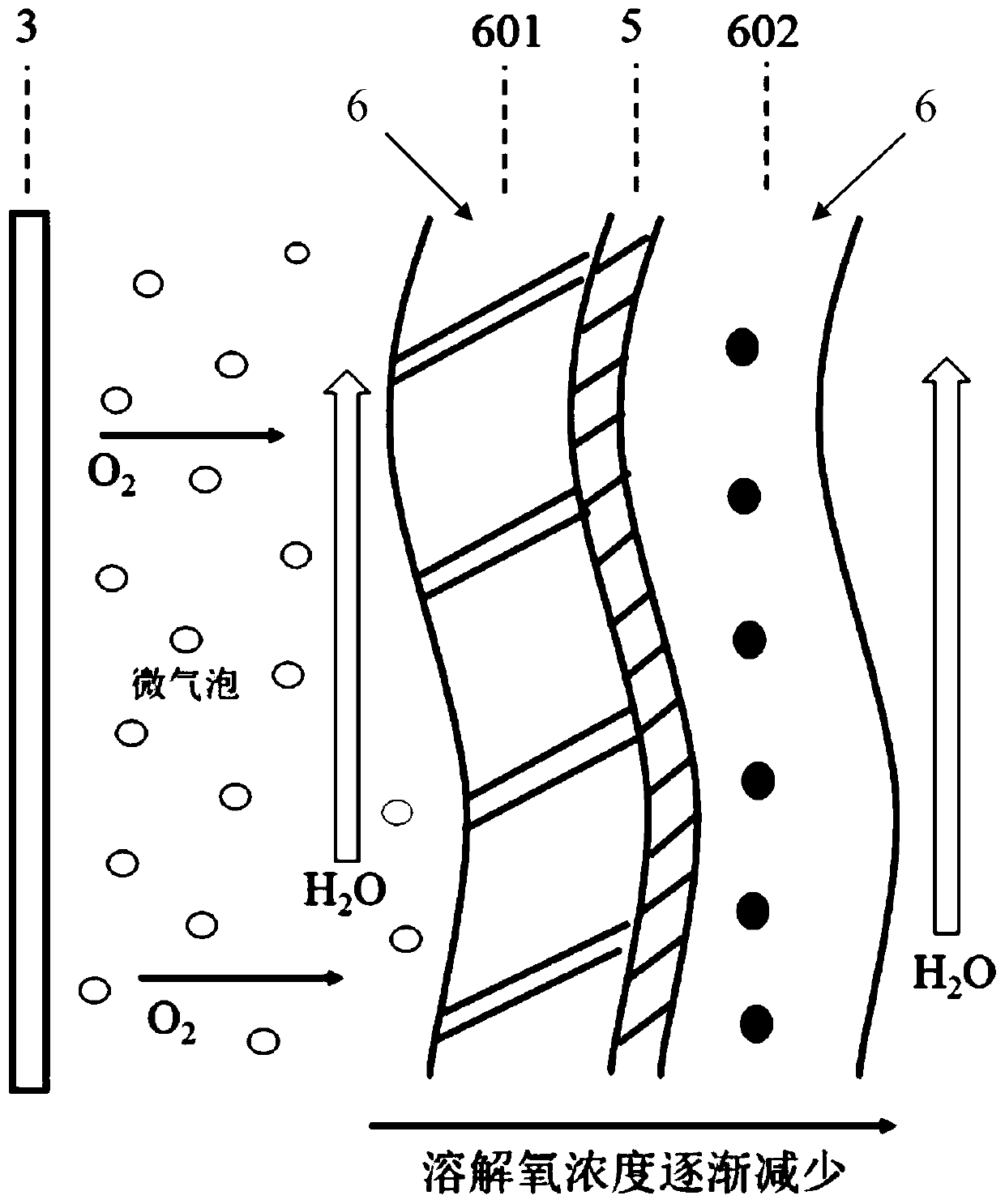

[0054] Hang soft fiber packing layers 5 on the packing frames 4 on both sides of the MBR membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com