Carbon quantum dot/attapulgite nanocomposite as well as preparation method and application thereof

A technology of nanocomposite materials and carbon quantum dots, which is applied in the field of carbon quantum dots/attapulgite nanocomposite materials and their preparation, and can solve the problems of high temperature and high pressure, expensive hydrogen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 0.32g, 0.9mol L of citric acid -1 Add 1mL of hydrogen peroxide and 1g of attapulgite into 10ml of deionized water and ultrasonically stir thoroughly, then transfer the mixed solution to a hydrothermal reaction kettle, react at 160°C for 8h, wash thoroughly with water and absolute ethanol, and place in an oven at 80°C drying, and then grinding to obtain the CQDs / ATP nanocomposite material.

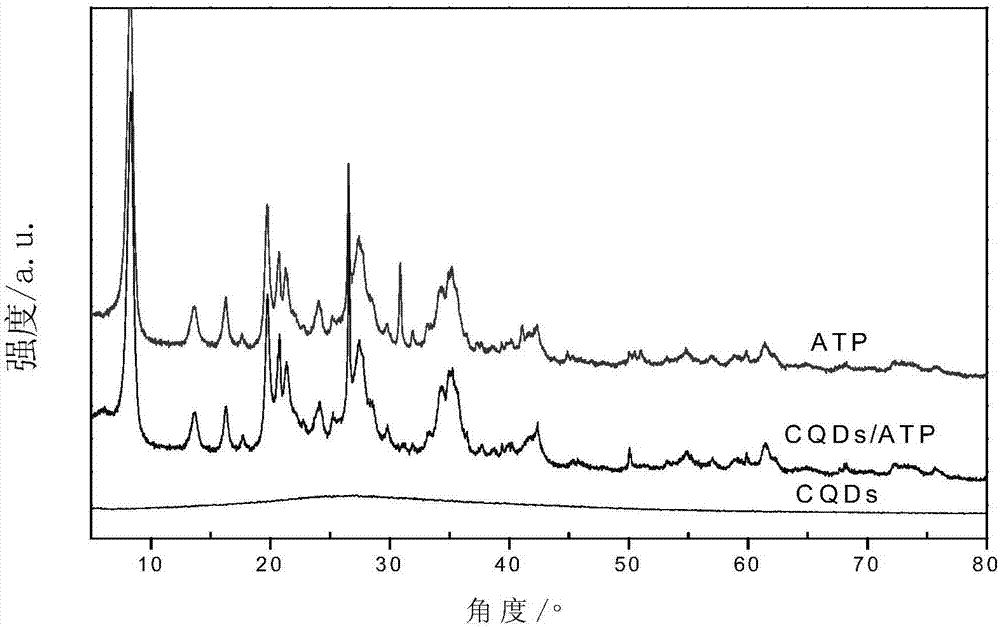

[0017] X-ray powder diffraction was performed on the obtained CQDs / ATP nanocomposites, as figure 1 As shown, the characteristic peaks of carbon quantum dots and attapulgite appeared in the XRD of the composite material, indicating that carbon quantum dots and attapulgite were successfully composited;

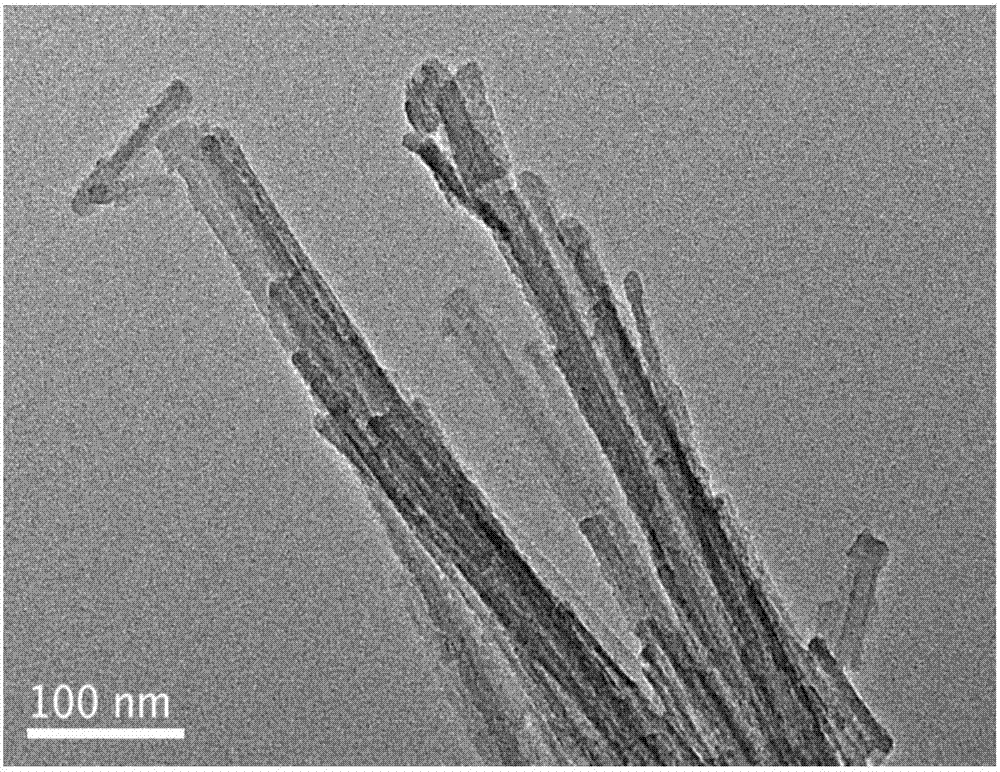

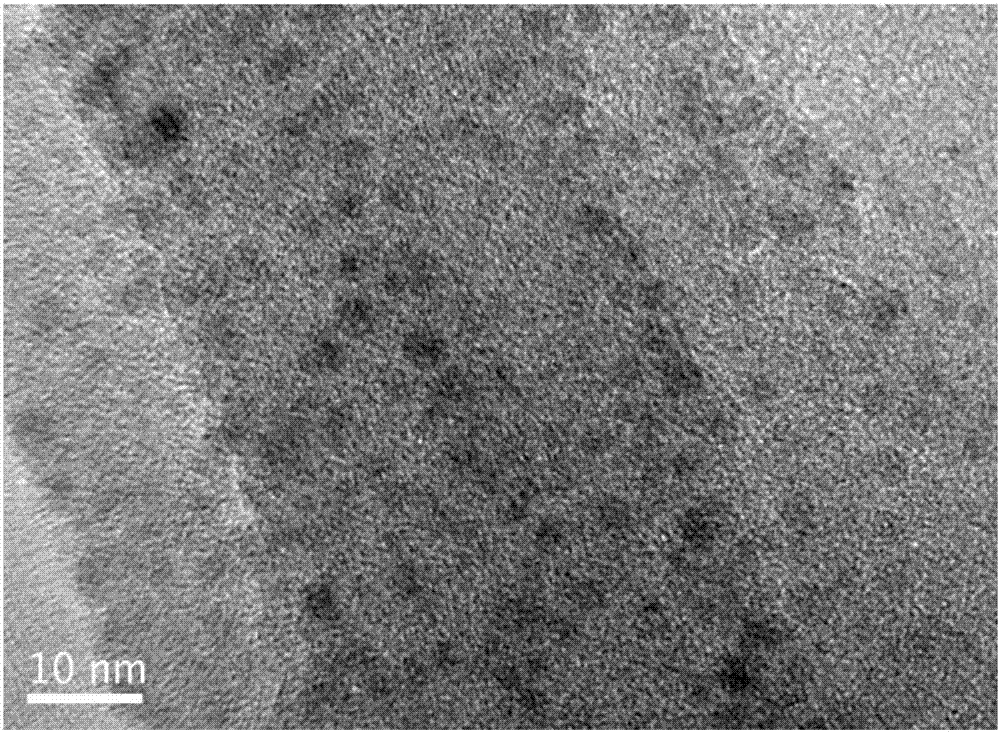

[0018] The morphology of CQDs / ATP nanocomposites was observed by transmission electron microscopy: TEM images of ATP are shown in figure 2 As shown, the attapulgite presents a nanorod-like structure; the TEM image of the obtained CQDs / ATP in this example is shown in image 3 ...

Embodiment 2

[0028] Weigh 0.12g, 0.9mol L of citric acid -1 Add 0.375mL of hydrogen peroxide and 1g of attapulgite into 10ml of deionized water and ultrasonically stir thoroughly, then transfer the mixed solution to a hydrothermal reaction kettle, react at 120°C for 24h, wash thoroughly with water and absolute ethanol, and place in an oven at 80°C The CQDs / ATP nanocomposite can be obtained after drying in medium temperature and then grinding. Subsequent detection was as in Example 1.

Embodiment 3

[0030] Weigh 0.21g, 0.9mol L of citric acid -1 Add 0.66mL of hydrogen peroxide and 1g of attapulgite into 10ml of deionized water and ultrasonically stir thoroughly, then transfer the mixed solution to a hydrothermal reaction kettle, react at 140°C for 20h, wash thoroughly with water and absolute ethanol, and place in an oven at 80°C The CQDs / ATP nanocomposite can be obtained after drying in medium temperature and then grinding. Subsequent detection was as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com