A kind of preparation method of cubic precipitated calcium carbonate

A technology of precipitated calcium carbonate and cubic shape, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of maintaining the temperature at 50-60°C, high pH value of the product, and difficulty in popularization and application, etc., to achieve inhibition of dissolution and particle size Effective control and pH value control, simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

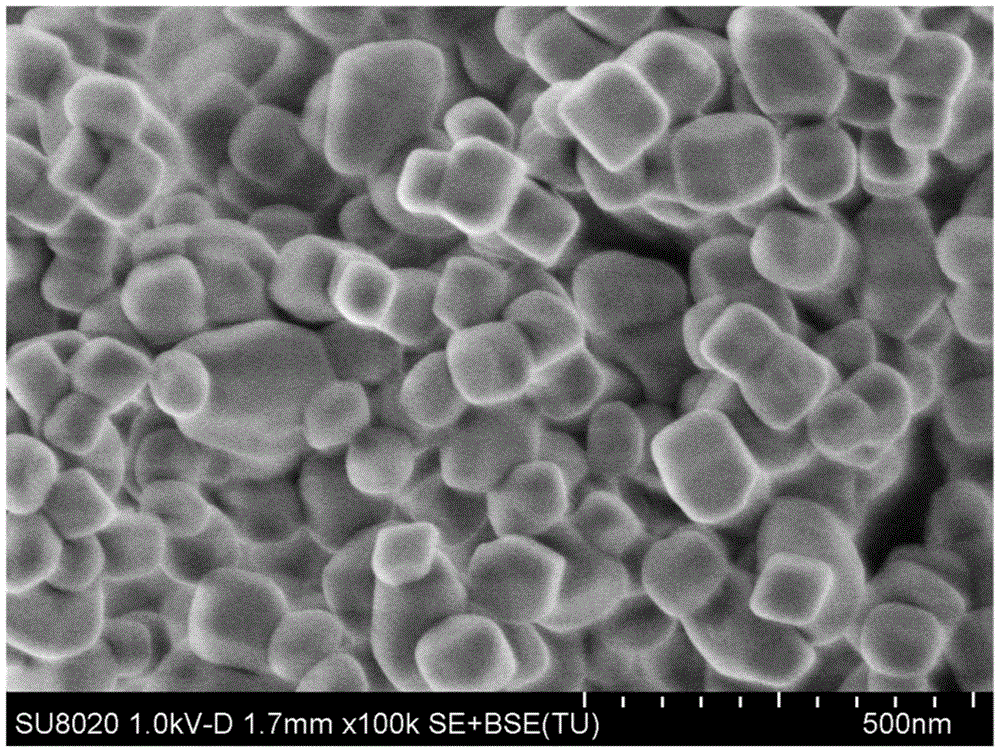

Image

Examples

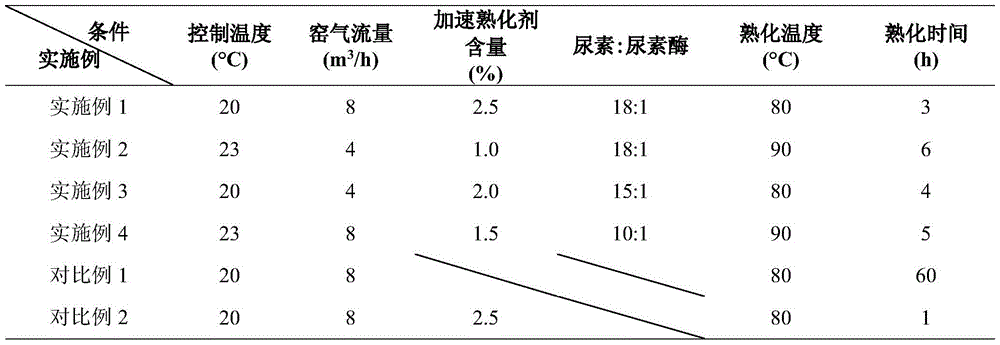

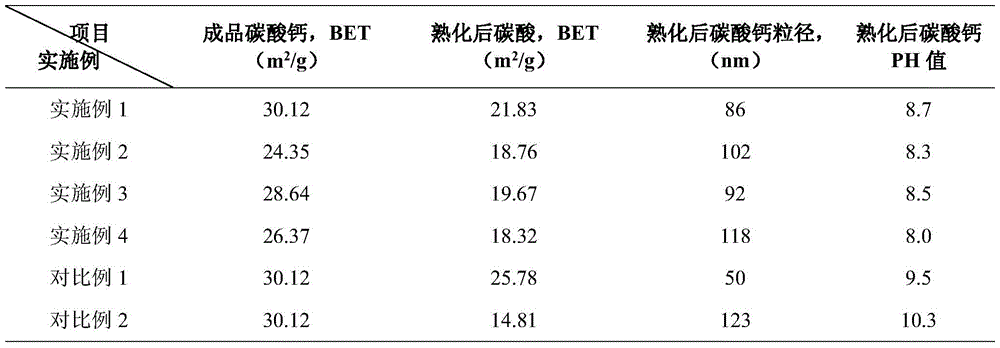

Embodiment 1

[0030] (1) Adjust the specific gravity of milk of lime refined and aged for 48 hours to 1.055, keep the temperature at 20°C, and then transfer it to a bubbling carbonation reactor with stirring.

[0031] (2) Pass the purified and cooled lime kiln gas into the carbonation reaction kettle for carbonation reaction, the kiln gas flow rate is 8m 3 / h carried out, wherein the carbon dioxide volume content was 33%, when the pH value of the reaction mixture dropped to 7.0, the carbonation reaction was stopped, and the specific surface area (BET) of the finished product calcium carbonate was 30.12m 2 / g.

[0032] (3) Add an accelerated curing agent to the calcium carbonate slurry obtained in step (2), then heat and cure it, and keep it in the temperature range of 80° C. for 3 hours.

[0033] (4) Adjust the temperature of the calcium carbonate slurry obtained in step (3) to 90° C., add a surface treatment agent, and complete the surface treatment after stirring for 60 minutes.

[0034...

Embodiment 2

[0039] (1) Adjust the specific gravity of milk of lime refined and aged for 48 hours to 1.055, keep the temperature at 23°C, and then transport it to a bubbling carbonation reactor with stirring.

[0040] (2) Pass the purified and cooled lime kiln gas into the carbonation reaction kettle for carbonation reaction, the kiln gas flow rate is 4m 3 / h carried out, wherein the carbon dioxide volume content was 33%, when the pH value of the reaction mixture dropped to 7.0, the carbonation reaction was stopped, and the specific surface area (BET) of the finished product calcium carbonate was 24.35m 2 / g.

[0041] (3) Add an accelerated curing agent to the calcium carbonate slurry obtained in step (2), then heat and cure it, and keep it in the temperature range of 90° C. for 3 hours.

[0042] (4) Adjust the temperature of the calcium carbonate slurry obtained in step (3) to 90° C., add a surface treatment agent, and complete the surface treatment after stirring for 60 minutes.

[004...

Embodiment 3

[0048] (1) Adjust the specific gravity of milk of lime refined and aged for 48 hours to 1.055, keep the temperature at 20°C, and then transfer it to a bubbling carbonation reactor with stirring.

[0049] (2) Pass the purified and cooled lime kiln gas into the carbonation reaction kettle for carbonation reaction, the kiln gas flow rate is 4m 3 / h carried out, wherein the carbon dioxide volume content was 33%, when the pH value of the reaction mixture dropped to 7.0, the carbonation reaction was stopped, and the specific surface area (BET) of the finished product calcium carbonate was 28.64m 2 / g.

[0050] (3) Add an accelerated curing agent to the calcium carbonate slurry obtained in step (2), then heat and cure it, and keep it in the temperature range of 80° C. for 4 hours.

[0051] (4) Adjust the temperature of the calcium carbonate slurry obtained in step (3) to 90° C., add a surface treatment agent, and complete the surface treatment after stirring for 60 minutes.

[0052]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com