Coupling multistage device with active carbon purifying waste gas

A technology for purifying waste gas and activated carbon, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of single bed structure of purification equipment, insufficient utilization of activated carbon, corrosion of purification equipment, etc., and achieve full utilization of device space. , The effect of full utilization of activated carbon and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] The features of the present invention will be explained more clearly with reference to the following examples. However, the examples should not be considered as limiting the scope of the invention.

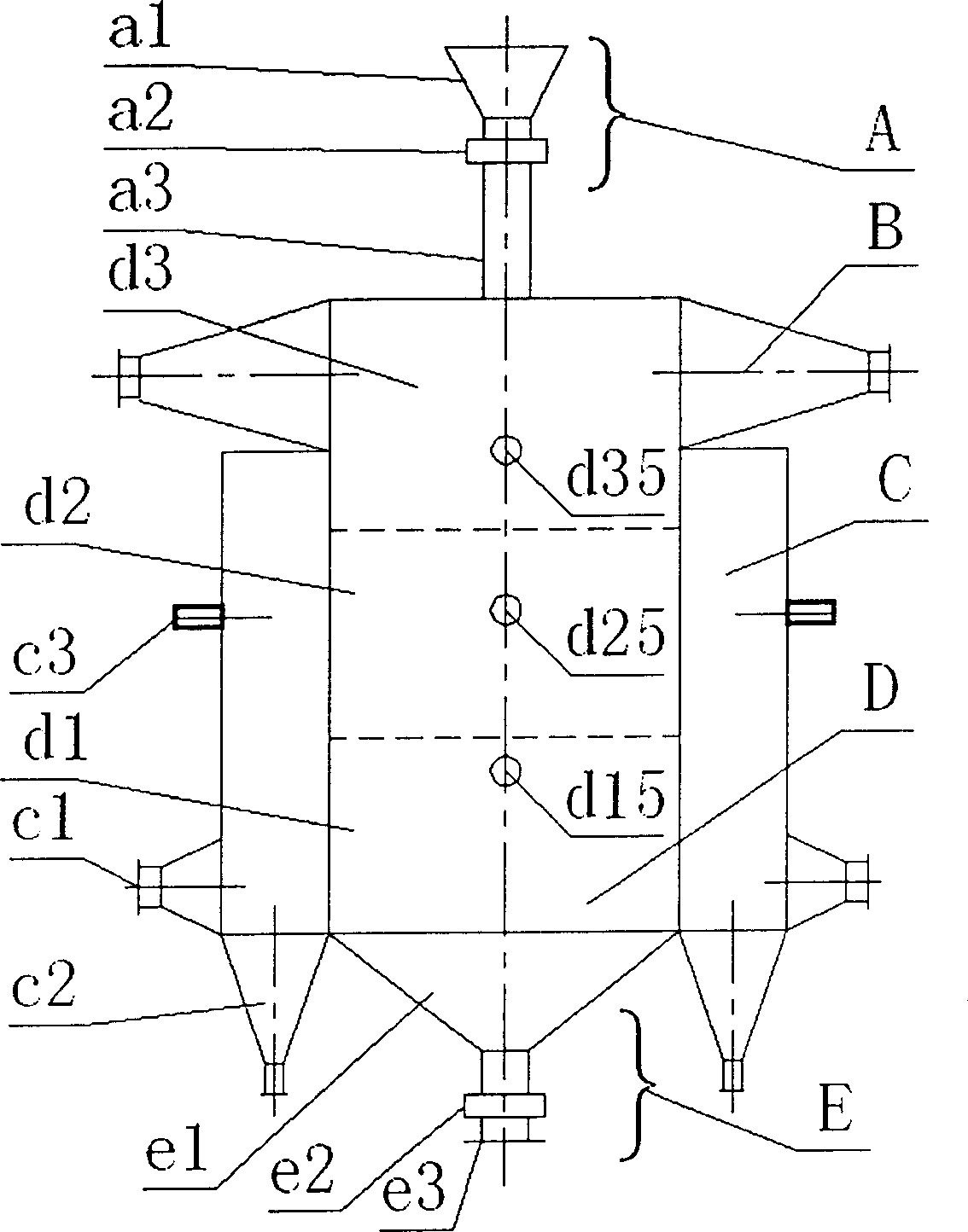

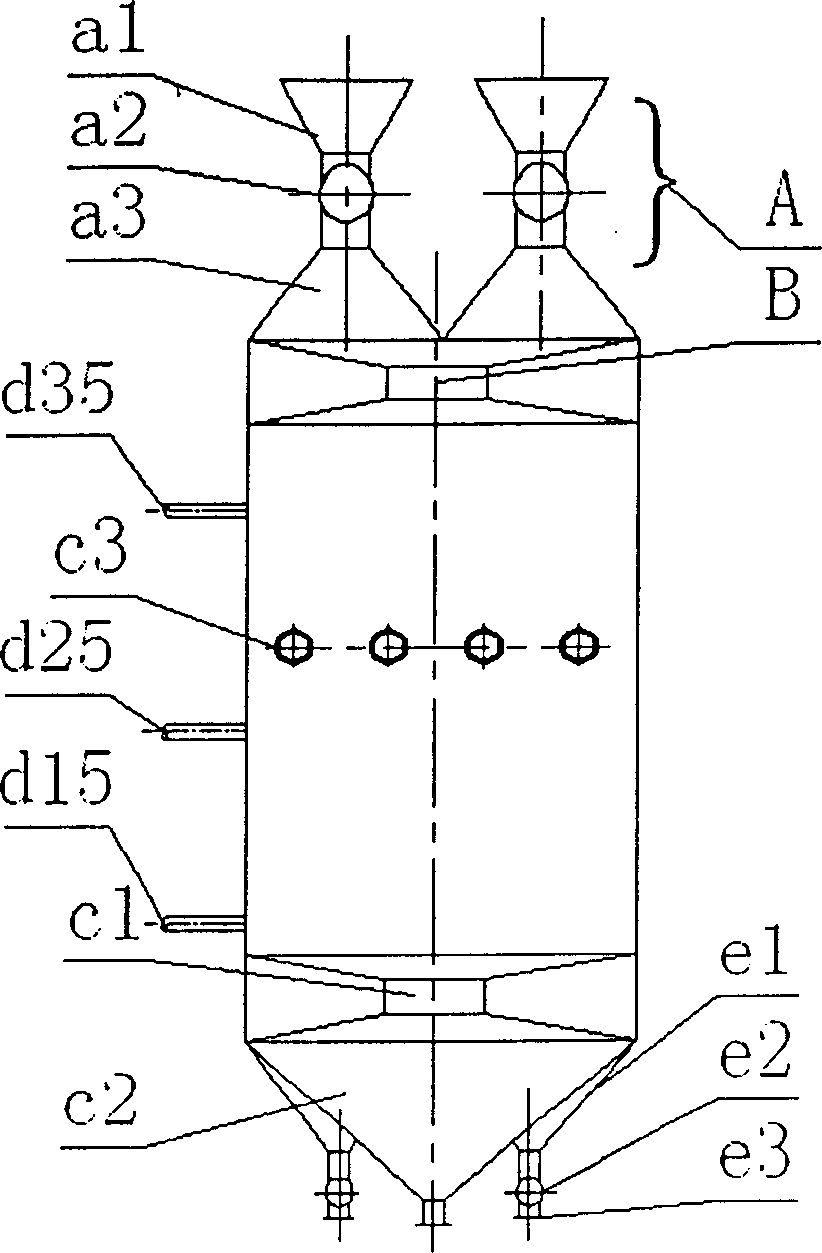

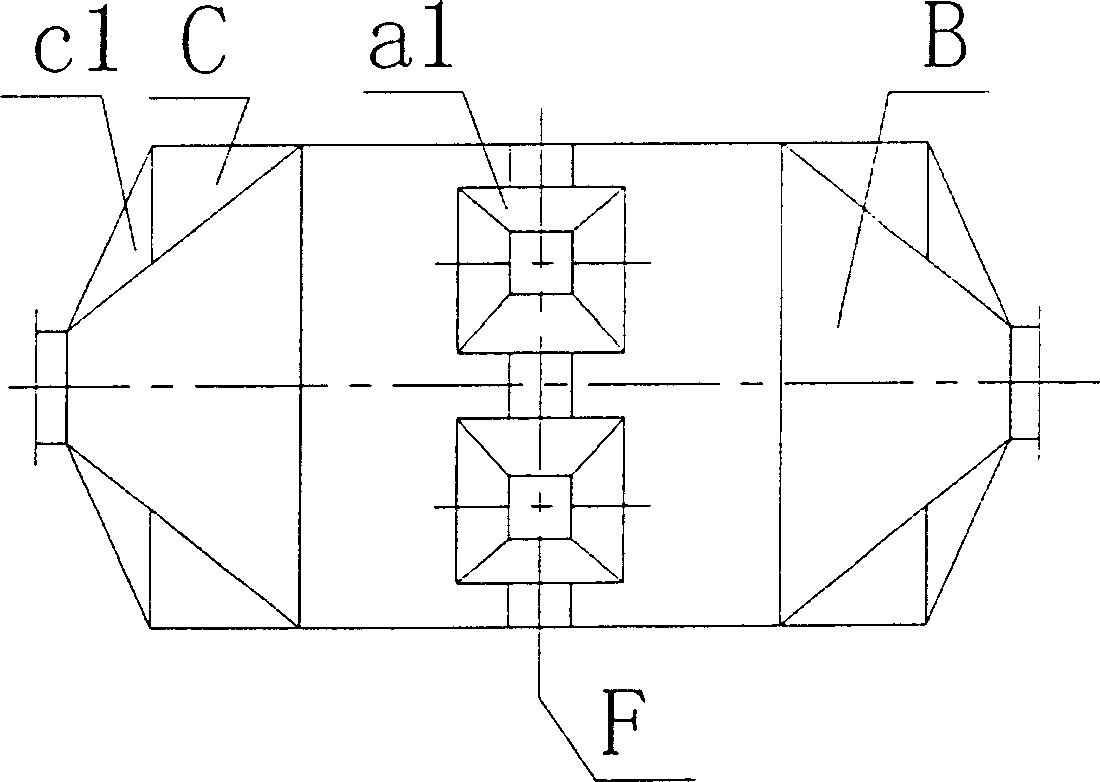

[0039] It can be seen from the drawings that the device of the present invention is composed of two feeding mechanisms A, two clean gas outlets B, two pre-purification chambers C, a movable adsorption bed D and a discharging mechanism E. The feeding mechanism A is composed of a feeding hopper a1, a feeding lock valve a2 and a feeding pipe a3. The discharge mechanism E is composed of a discharge cone e1, a blanking air lock valve e2 and a material guide pipe e3. Three adsorption sections d1, d2, and d3 with the same cuboid structure are sequentially stacked in the height direction to form a mobile adsorption bed D. The top center of the adsorption s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com