Integrated system for industrial flue gas desulfurization and dewhitening and method thereof

An industrial flue gas and whitening technology, applied in the field of integrated systems, can solve the problems of high energy consumption and the inability to reduce the dew point of outlet flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

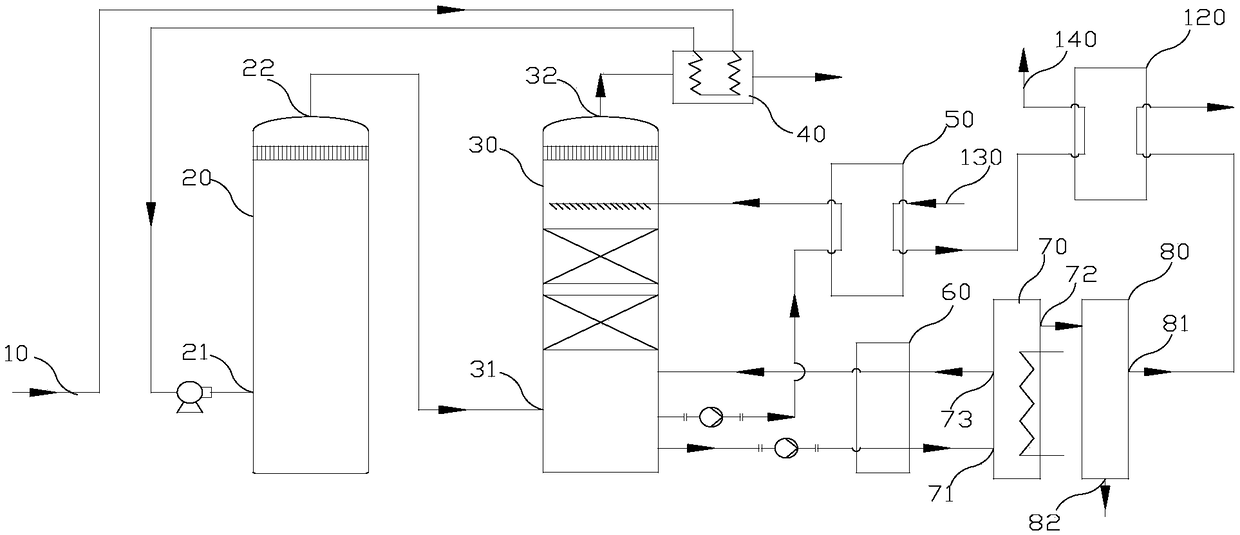

[0095] (1) Integrated system for industrial flue gas desulfurization and desulfurization

[0096] like figure 1 The shown integrated system for desulfurization and desulfurization of industrial flue gas, the integrated system has a desulfurization tower 20, a desulfurization unit 30 and a flue gas heat converter; the desulfurization tower 20 is provided with a first flue gas inlet 21 and a first flue gas inlet 21. The gas outlet 22, the dewhitening unit 30 is provided with a second flue gas inlet 31 and a second flue gas outlet 32; the flue gas heat converter is used to transfer the heat of the industrial flue gas in the industrial flue gas conveying pipe 10 to the second flue gas The dry flue gas discharged from the flue gas outlet 32 is then sent to the first flue gas inlet 21; the first flue gas outlet 22 is communicated with the second flue gas inlet 31; the bleaching unit 30 is provided with a first circulation loop and The second circulation loop; the first circulatio...

Embodiment 2

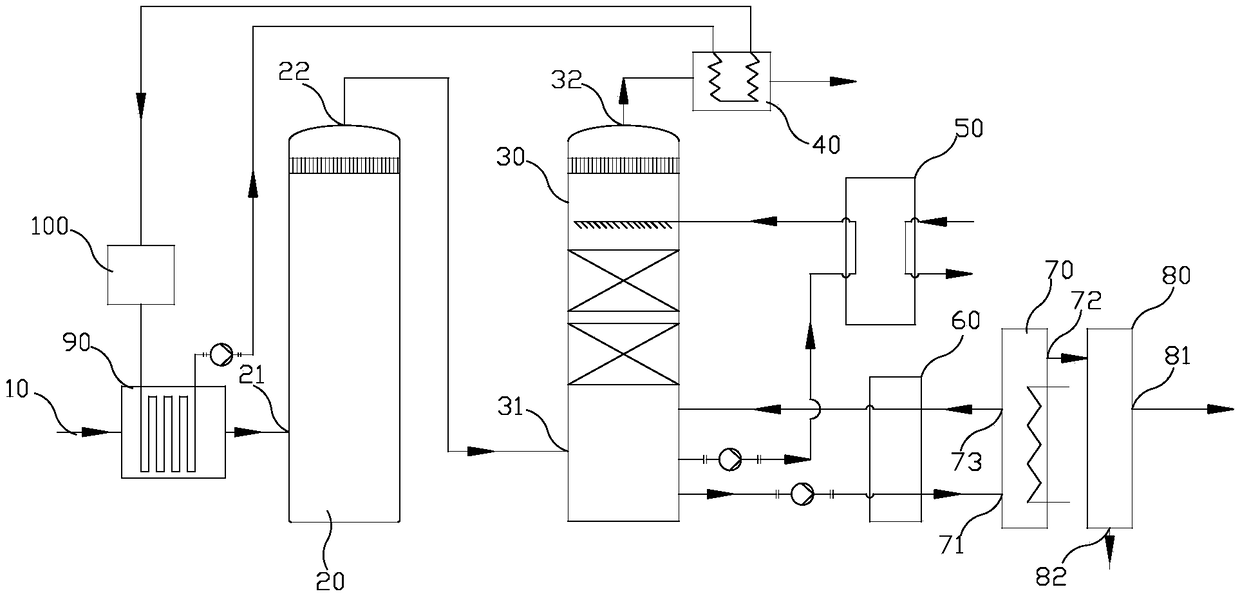

[0113] (1) Integrated system for industrial flue gas desulfurization and desulfurization

[0114] like figure 2 The integrated system for desulfurization and whitening of industrial flue gas shown, the flue gas heat exchanger is composed of a flue gas cooler 90 and a reheater 40, and the types of the flue gas cooler 90 and the reheater 40 are both partition wall types In the heat exchanger, the cold fluid channel of the flue gas cooler 90 is communicated with the hot fluid channel of the reheater 40 to form a cooling medium circuit. The cooling medium circuit is provided with a conveying pump. The thermal fluid channel of the 1st flue gas is communicated with the first flue gas inlet 21; wherein, the cooling medium circuit is a cooling water circuit, and the cooling medium circuit is provided with a water tank 100; Except that the integrated system of Example 1 is different, the rest are the same as the integrated system of Example 1.

[0115] (2) The method of adopting the...

Embodiment 3

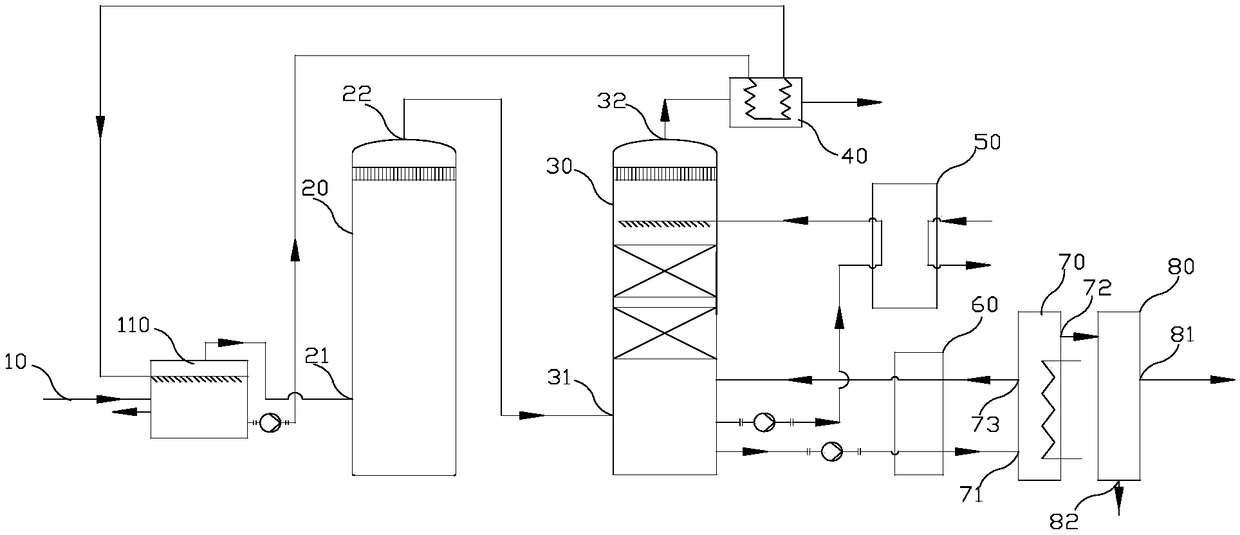

[0122] (1) Integrated system for industrial flue gas desulfurization and desulfurization

[0123] like image 3 The shown integrated system for desulfurization and desulfurization of industrial flue gas, the flue gas heat exchanger is composed of a condenser 110 and a reheater 40, the reheater 40 is a partition heat exchanger, and the condenser 110 is provided with The third flue gas inlet, the third flue gas outlet, the overflow port and the condensate outlet, the condenser 110 is provided with a spray pipe; the condensate outlet is sequentially communicated with the hot fluid channel and the spray pipe of the reheater 40; industrial The flue gas conveying pipe 10 is communicated with the third flue gas inlet, and the third flue gas outlet is communicated with the first flue gas inlet 21; an infusion pump is provided on the pipe connecting the condensate outlet with the hot fluid passage of the reheater 40; wherein, The condenser 110 is used for the contact between the indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com