Front coal gasification grate-firing device and combustion method thereof

A combustion method and coal gasification technology, which are applied to coal gasification layer combustion devices, pre-coal gasification layer combustion devices and their combustion fields, can solve problems such as high NOx, improve combustion efficiency, have strong coal adaptability, and reduce solids Effects of incomplete combustion losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

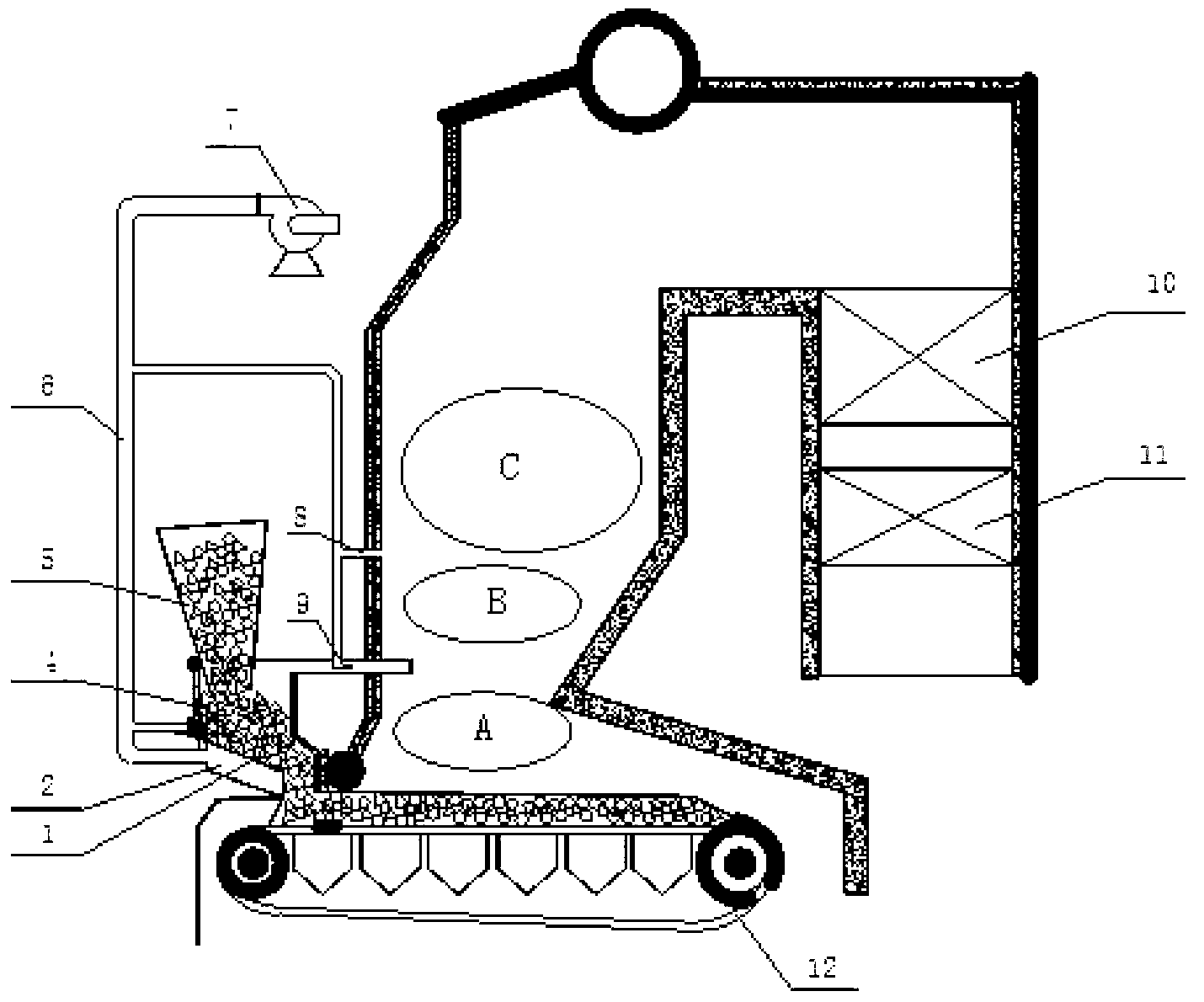

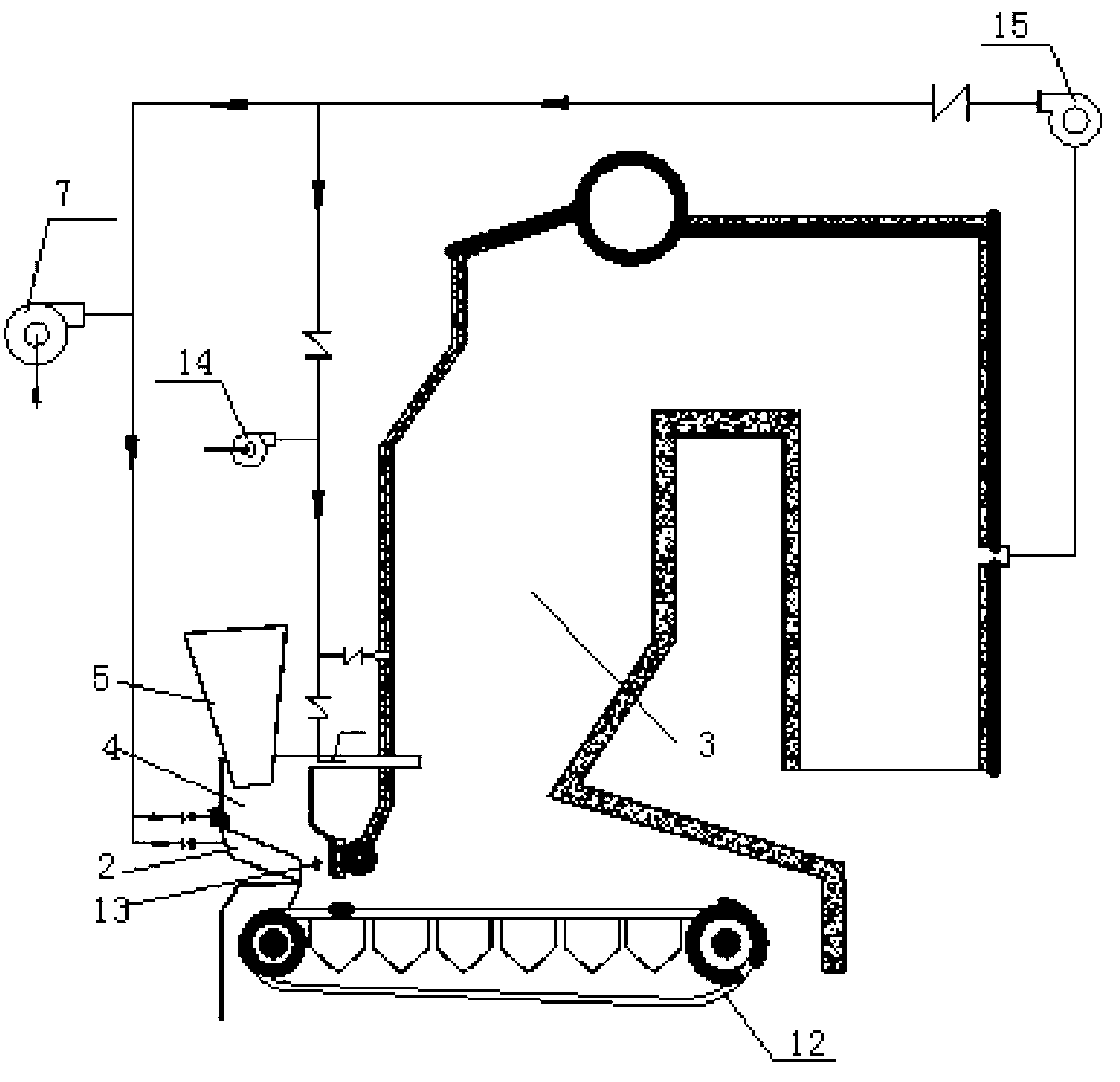

[0038] Such as Figure 1~2 As shown, the present invention includes a coal hopper 5, a coal gasification chamber 4 and a coke discharge pipe connected in sequence. The top of the coal gasification chamber 4 is provided with a gas pipe, and the gas pipe is provided with an injection nozzle 9. The ejector air duct is communicated with the secondary air duct 8, and the injection nozzle 9 is parallel to the secondary air duct 8, and the nozzle of the ejection nozzle 9 faces the furnace 16, and the secondary air duct 8 and the gas pipe are arranged parallel up and down, and the two Both are connected to the furnace 16; the bottom of the coal gasification chamber 4 is installed with a bottom bellows 2, and the bottom bellows 2 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com