Removal tower and method for collaboratively desulfurizing and removing PM2.5 (Particulate Matter 2.5) in smoke

A PM2.5, removal tower technology, applied in the field of flue gas purification, achieves the effect of simple overall structure, improved purification efficiency, and improved flue gas purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the drawings.

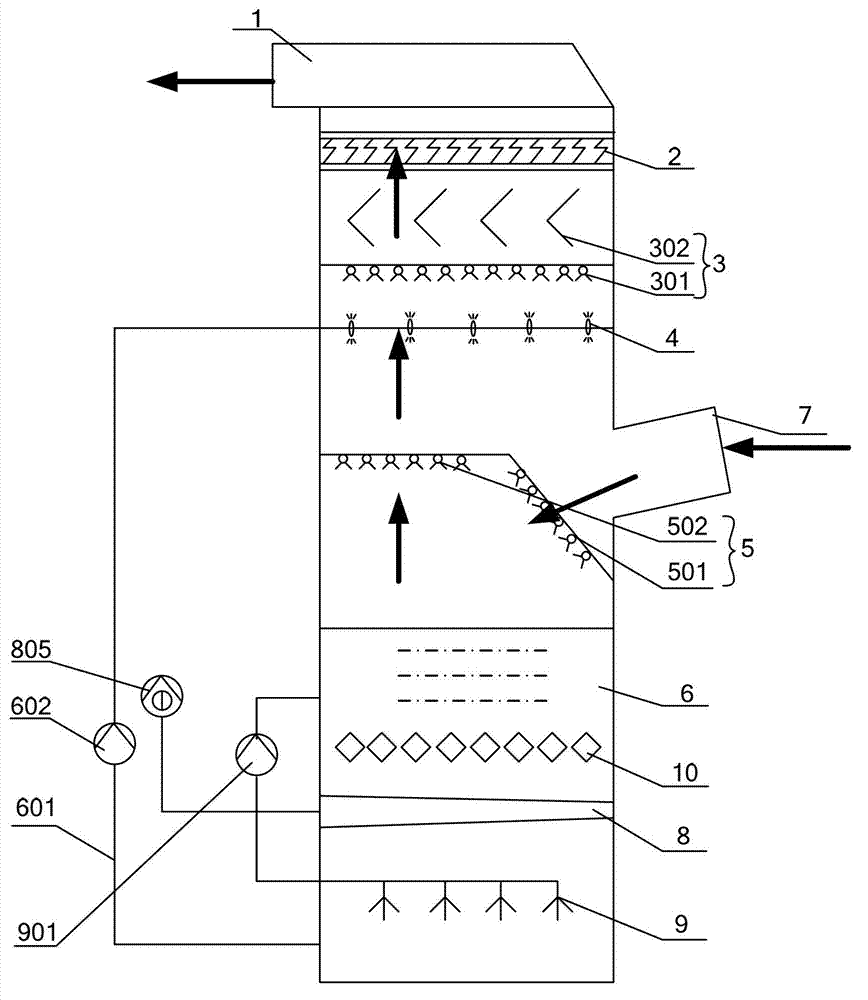

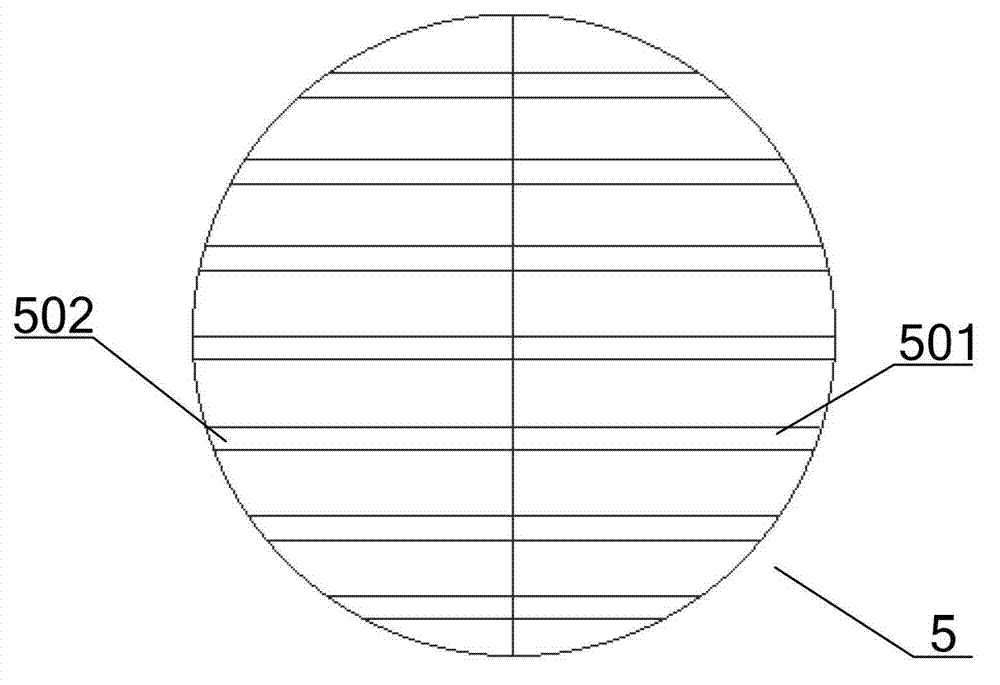

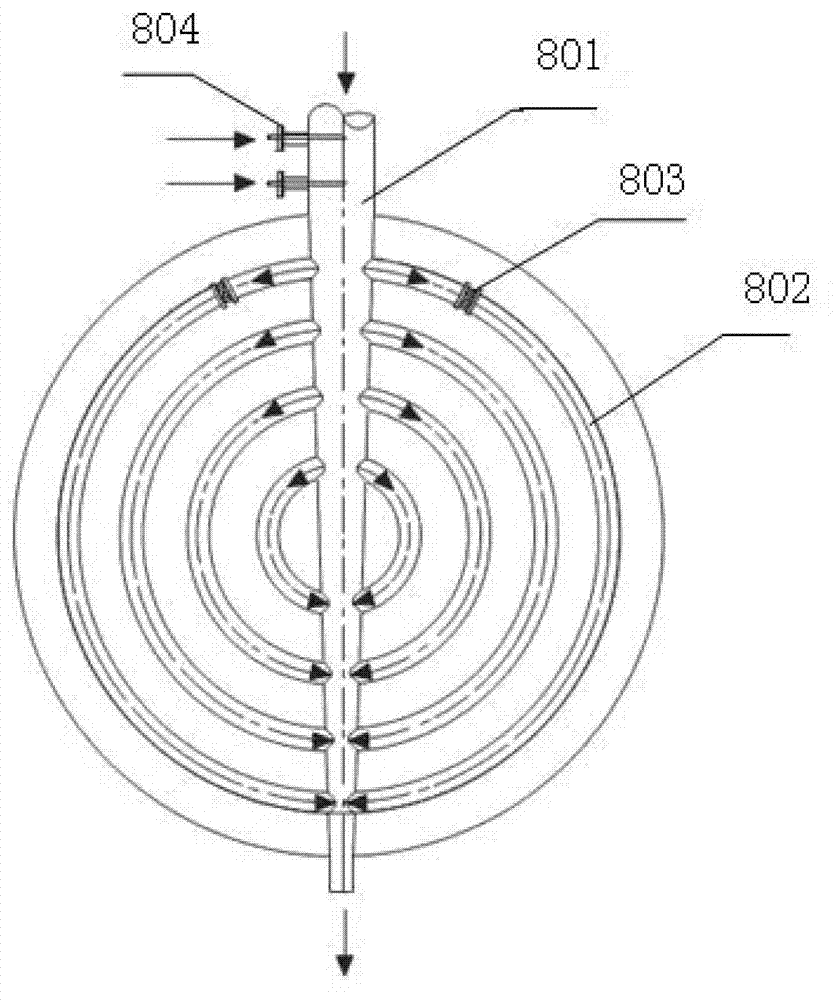

[0045] figure 1 It is an embodiment of the present invention for collaborative desulfurization and removal of PM in flue gas 2.5 The schematic diagram of the removal tower, such as figure 1 As shown, this embodiment provides a collaborative desulfurization and removal of PM in flue gas 2.5 In the removal tower, the removal tower is sequentially arranged from top to bottom: flue gas outlet flue 1, demister 2, phase change condensation zone 3, slurry spray layer 4, first flue gas humidification device 5 and The slurry tank 6 is provided with an oxidation isolation device 10, an oxidation air distribution device 8 and a stirrer 9 in sequence from top to bottom. The slurry tank 6 is connected to the slurry spray layer 4 through the slurry pipeline 601 and the circulating pump 602. The tower body of the removal tower between the slurry spray layer 4 and the flue gas humidification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com