Patents

Literature

82results about How to "Increase gasification strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

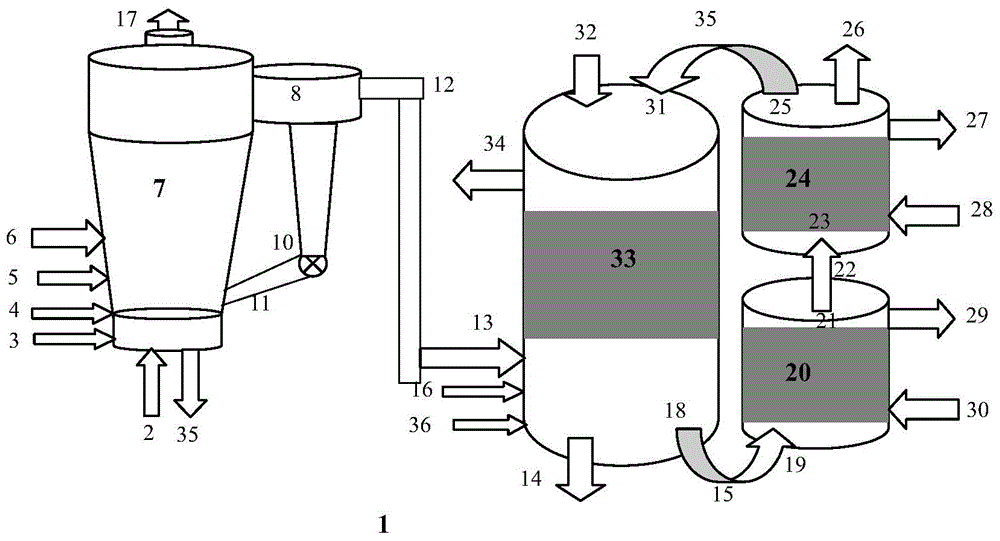

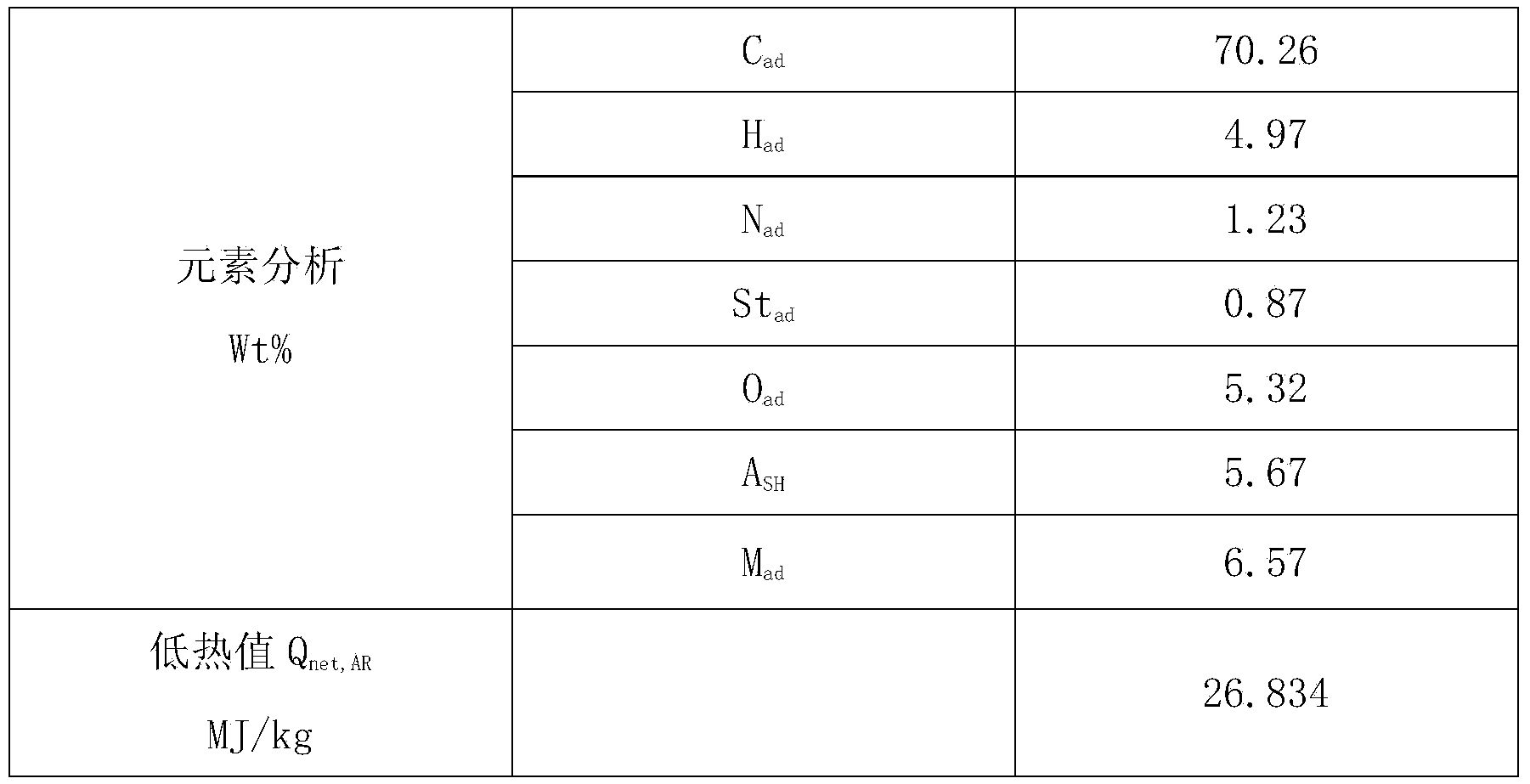

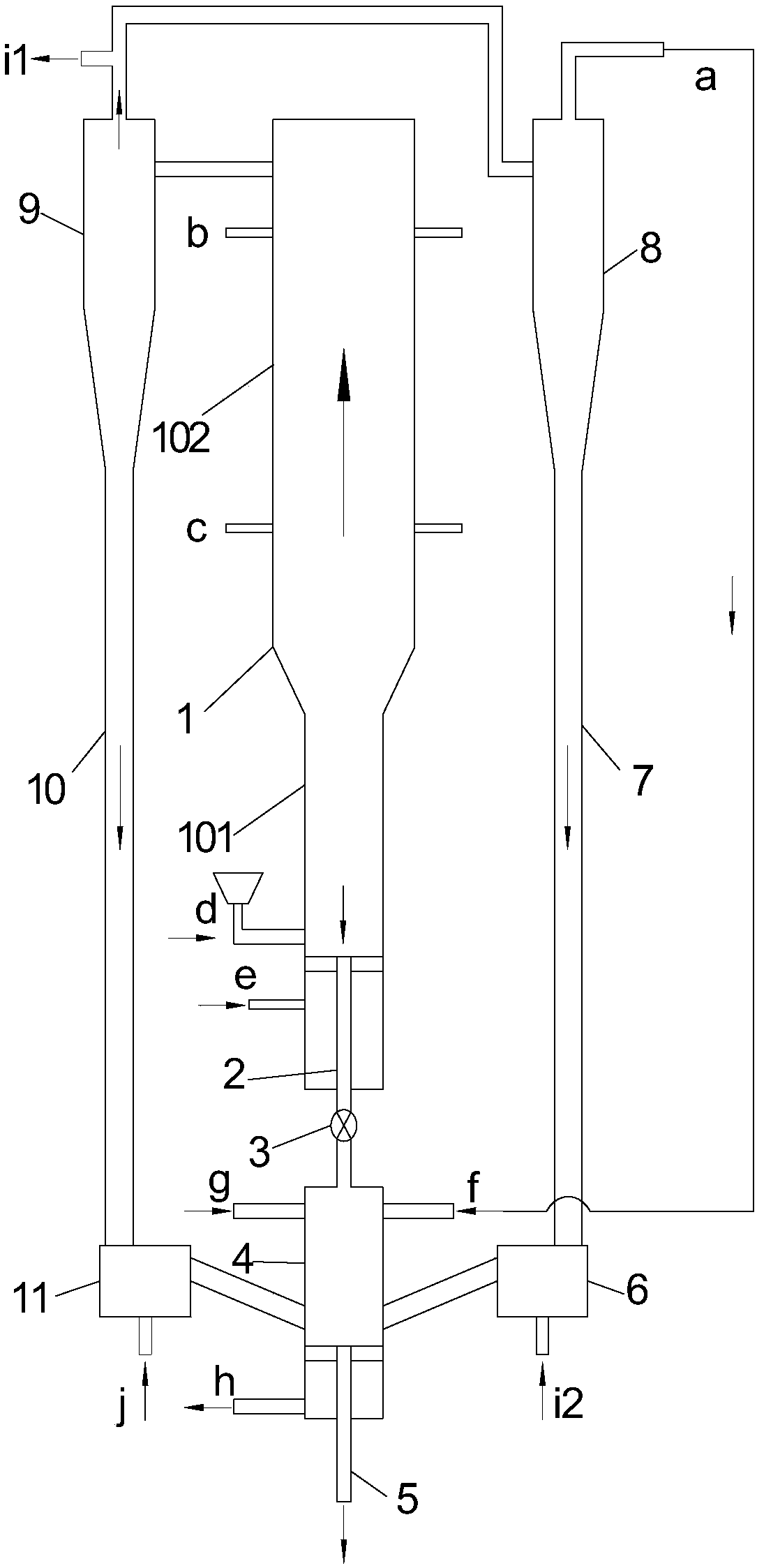

Method for producing coal gas by staged gasification of pulverized coal

InactiveCN102277200AAchieve desulfurizationAdaptableGranular/pulverulent flues gasificationCycloneSuperheated steam

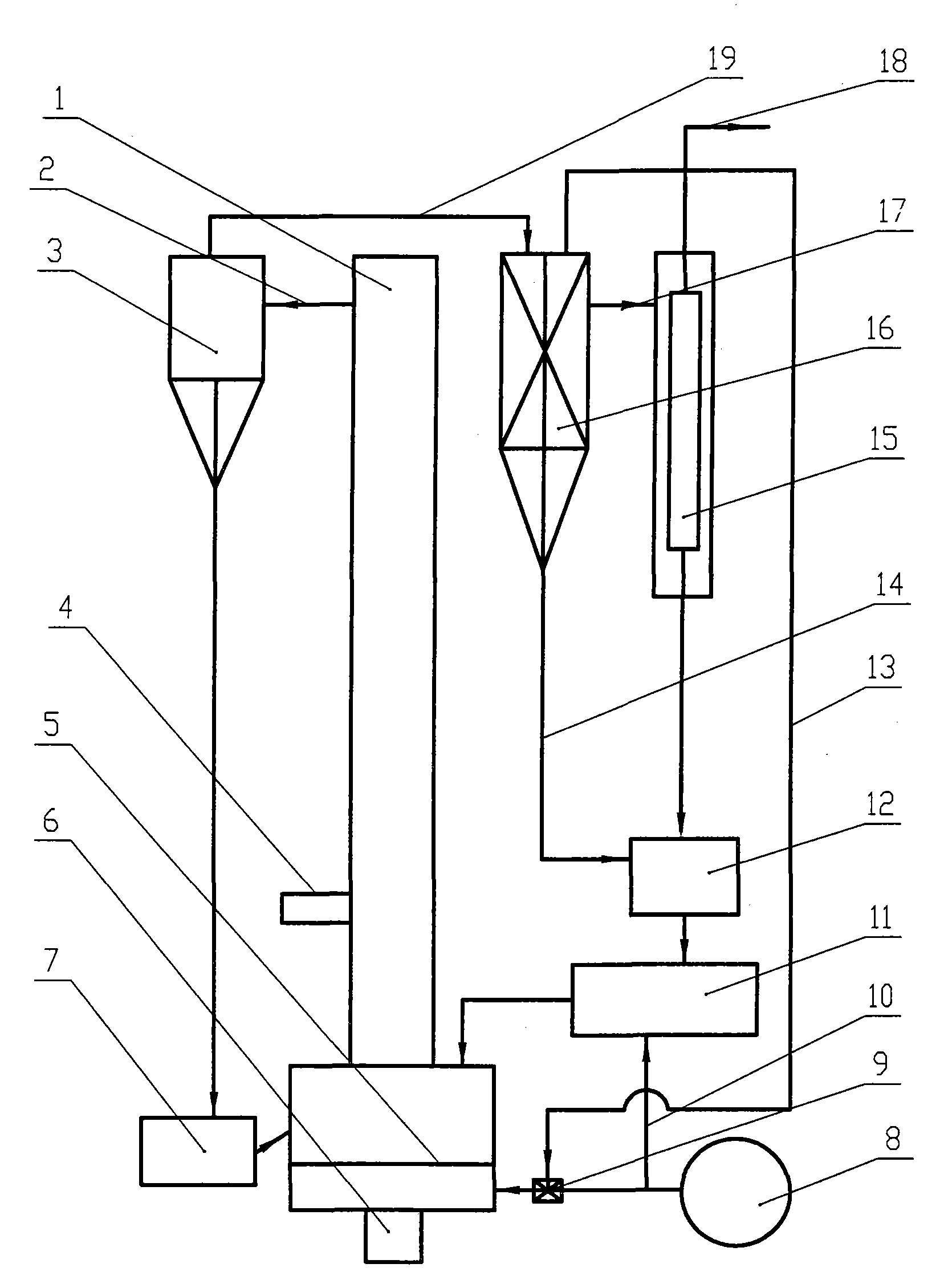

The invention relates to a method for producing coal gas by staged gasification of pulverized coal. The steps are as follows: the pulverized coal fed into the furnace is mixed with rapidly fluidized high-temperature particles and gasification gas in a fluidized bed, and the pulverized coal of small and medium particles flows upwards. Pyrolysis at a high temperature of 900-1000°C, enter the cyclone separator through the gas-solid mixing pipeline for separation, the medium particles return to the lower part of the main body of the circulating fluidized bed through the first-stage feeder, and the gas carries small particles out of the upper port of the cyclone separator, and passes through the high temperature The gas pipeline enters the superheated steam heat exchanger for heat exchange and separation, and then enters the circulation separator, and the gas is discharged from the gas outlet for users. The invention has the characteristics of integrated circulating fluidized bed and entrained flow bed, high gasification intensity, flexible adjustment of production load, stable and reliable operation, high operation rate, reduced gas production cost, and no phenolic water pollution.

Owner:舒克孝

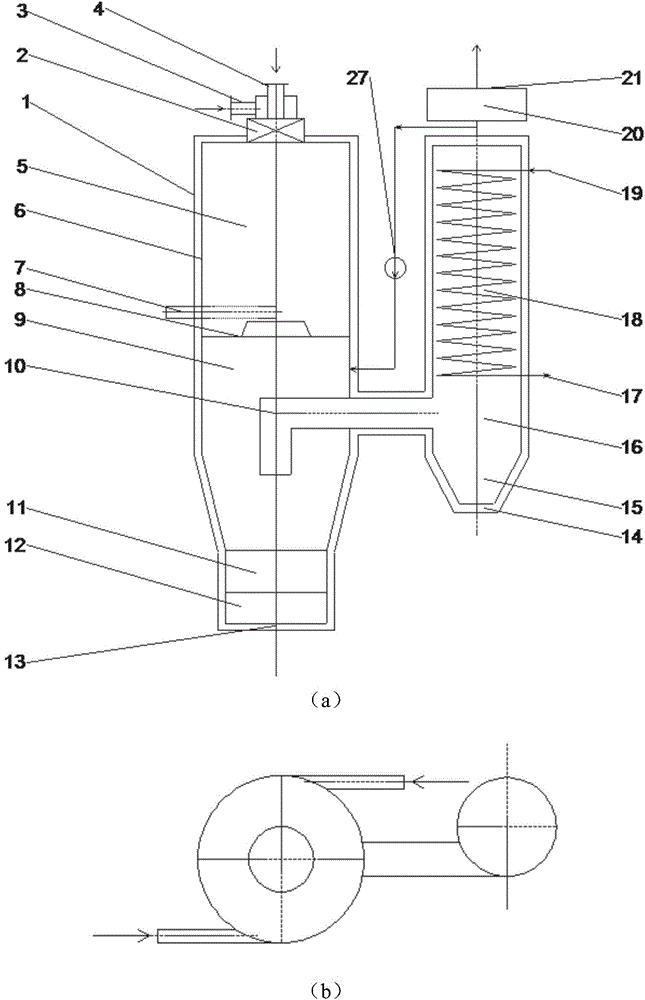

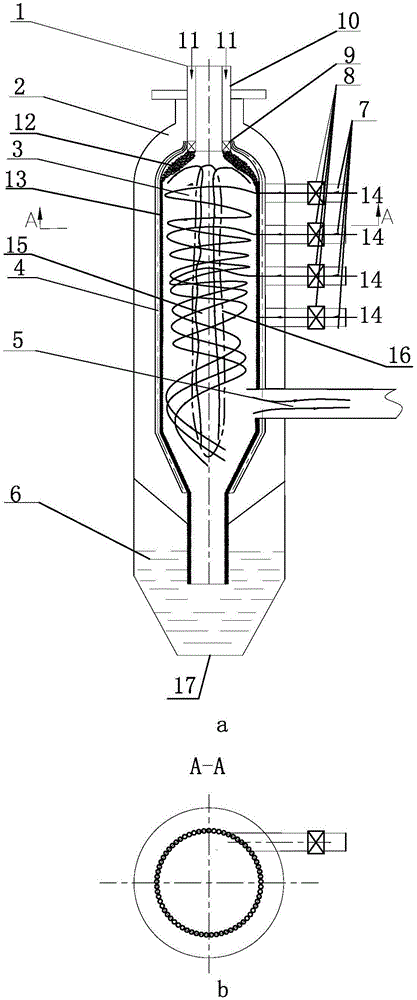

Double-flow biomass gasified gas purification device

InactiveCN102079998AHigh calorific valueIncrease contact areaBulk chemical productionCombustible gas productionReaction temperatureMoisture

The invention relates to a gasified gas purification device, in particular to a double-flow biomass gasified gas purification device, which solves the problems of low reaction temperature of a gasification furnace, abundant generated tar and wastewater, low gas-producing efficiency and abundant impurities and low heat value of output gas, resulted from unscientific structure of the gasification furnace. The gasified gas purification device comprises a gasification furnace, a gas flow control valve, a vortex flow oxidation-assisted control valve, a gas purifier and a fan. The gasified gas purification device provided by the invention has the advantages of increasing the reaction temperature of the furnace, wherein the temperature in oxidation, reduction and pyrolysis cylinders is between 1,300 and 1,600 DEG; increasing the gasification intensity; being capable of quickly separating moisture in biomass combustible gas so that gas quality is better; ensuring greatly reduced tar content in the combustible gas, less wastewater generated, high gas-producing efficiency and low environmental pollution due to the adoption of a mesh-type catalytic cracking device; and removing tar, moisture and ash in the gas through the gas purifier so that the heat value of the gas is improved. The gasified gas purification device is widely applied in industrial and civil fields.

Owner:林口信安建材板业有限公司

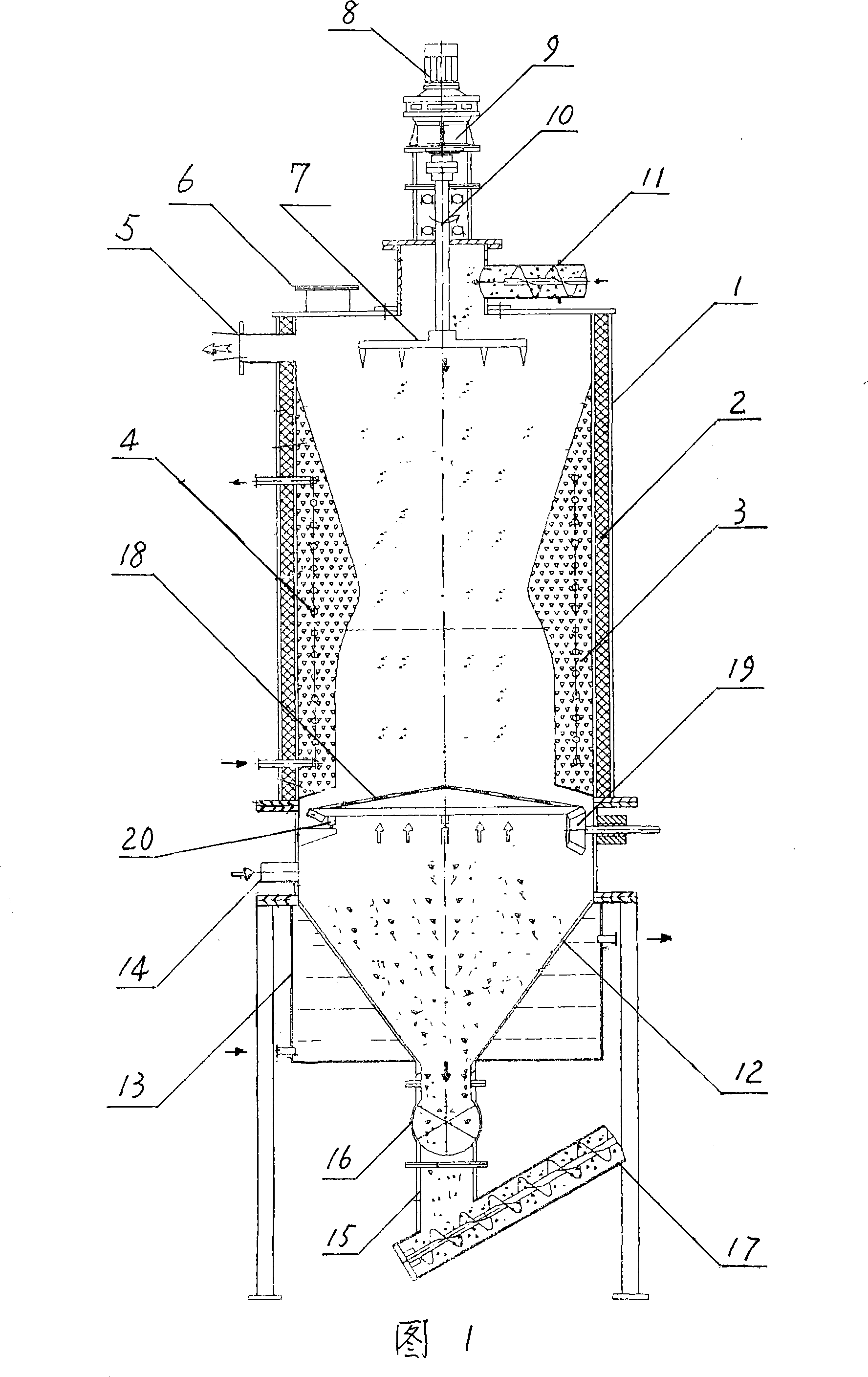

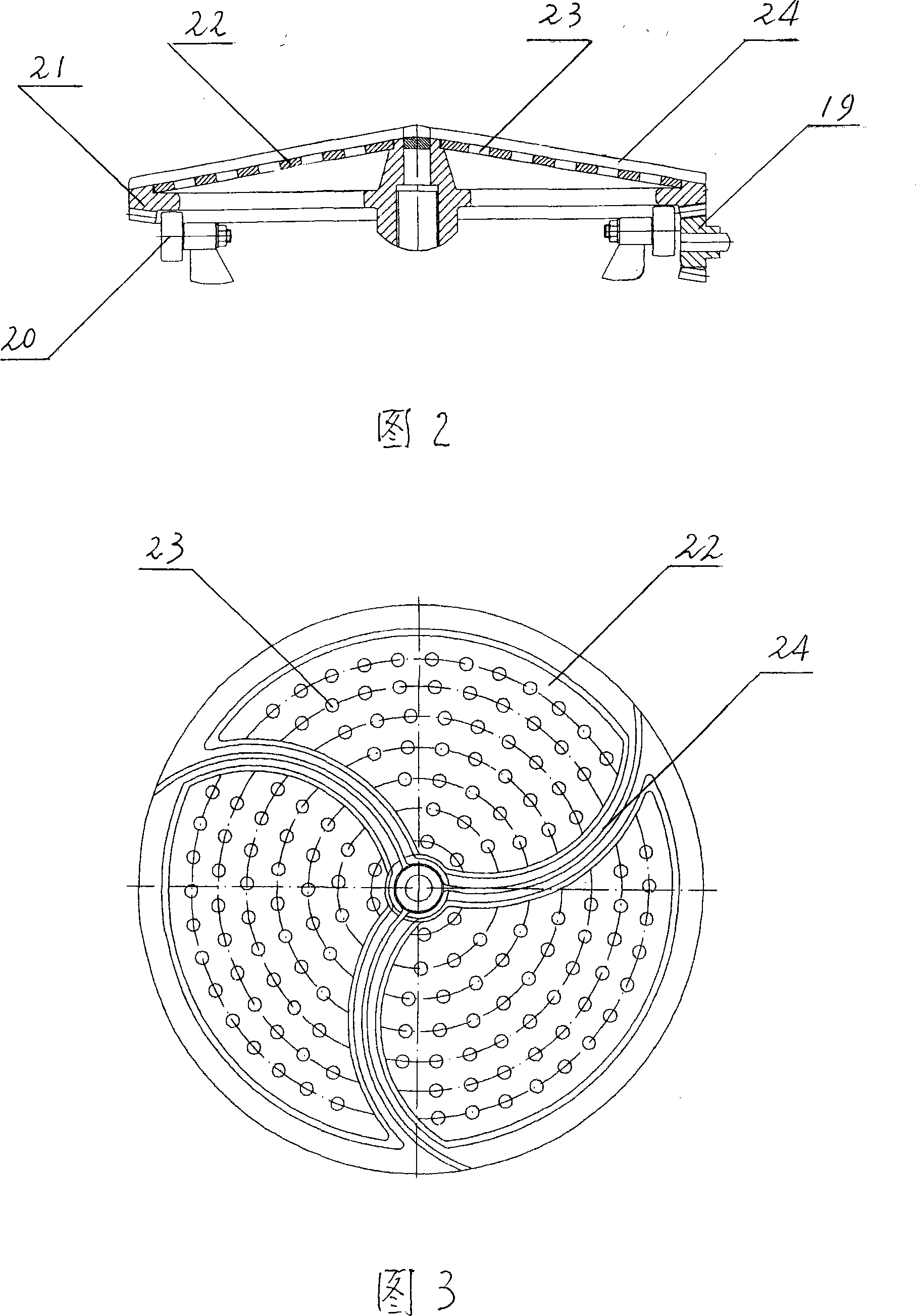

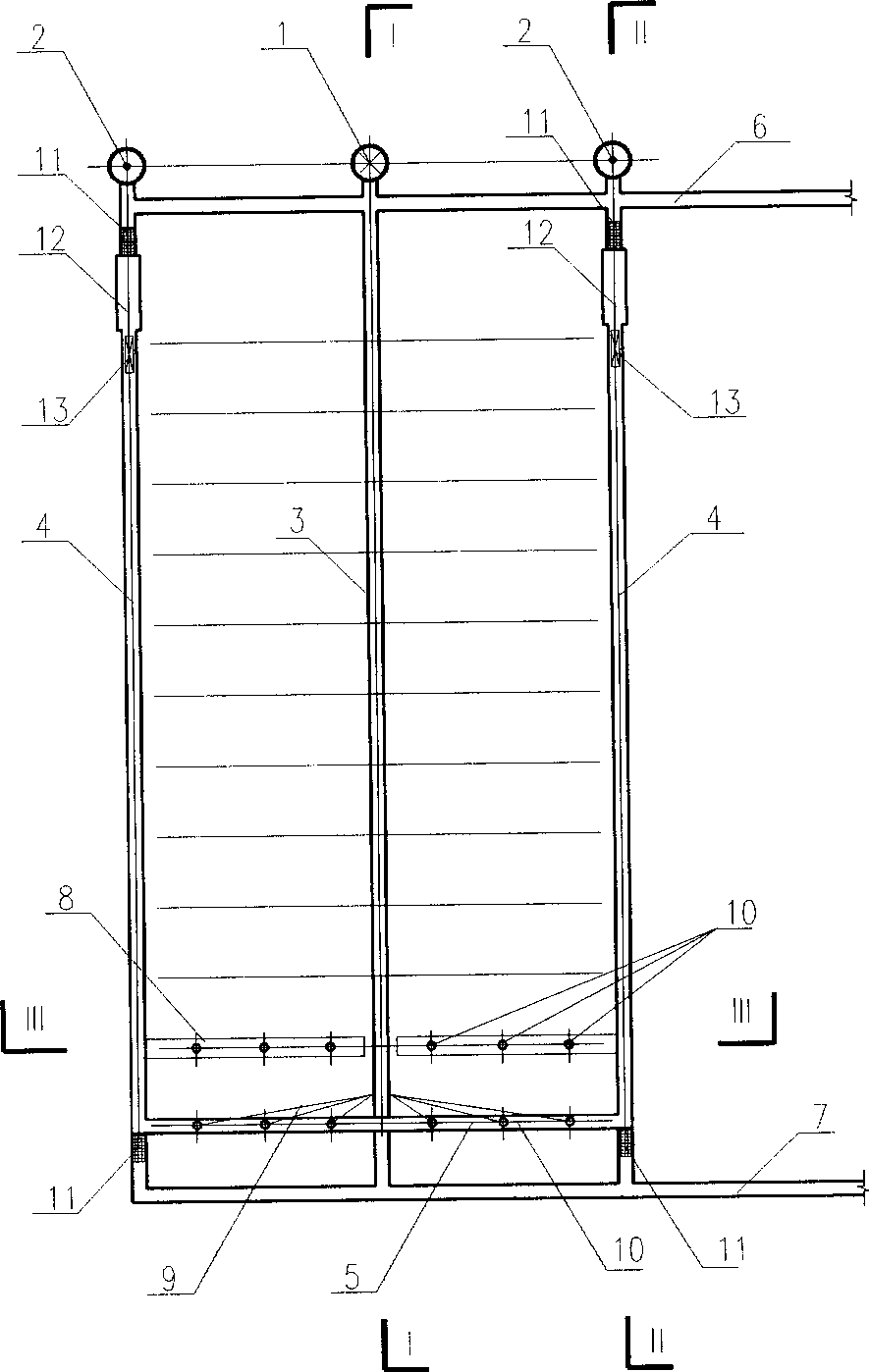

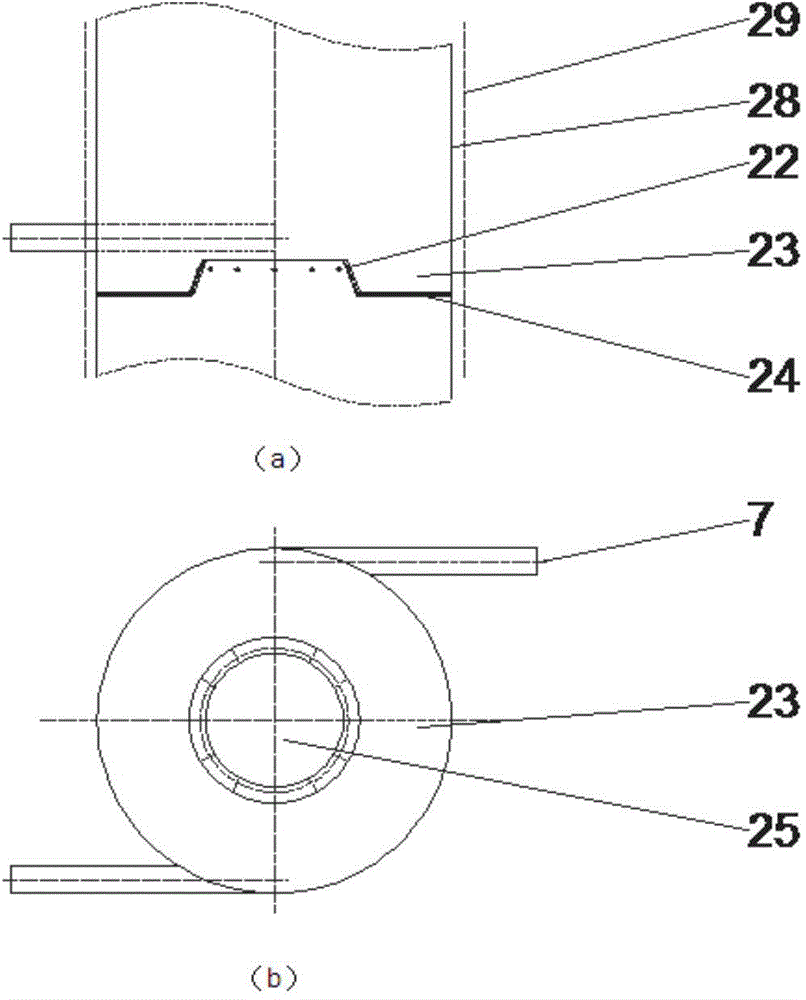

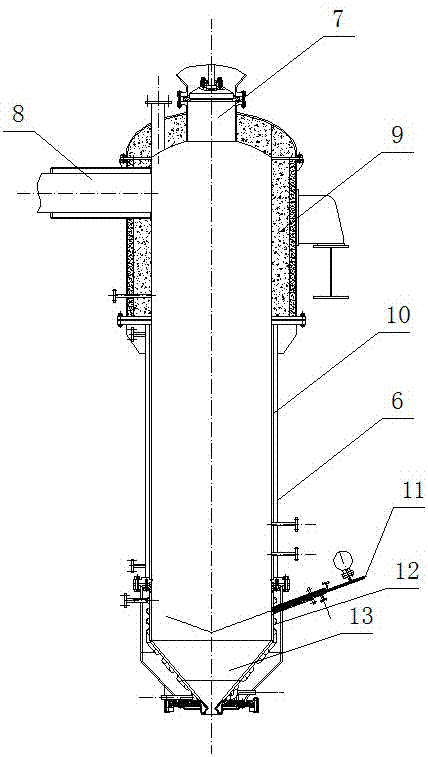

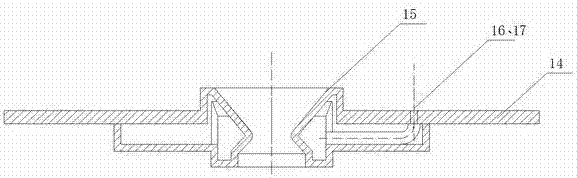

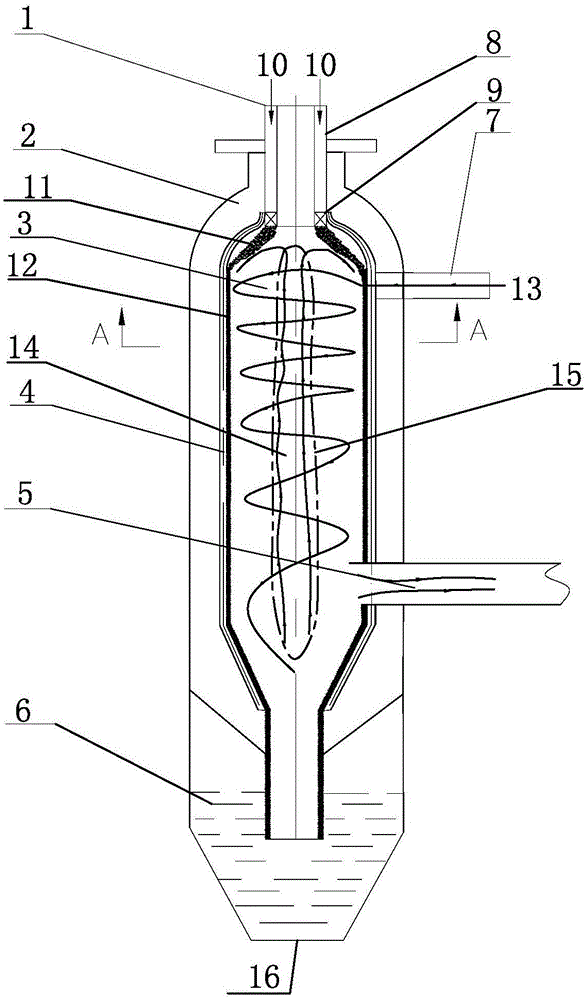

Solid biomass semi-water coal-gas producer

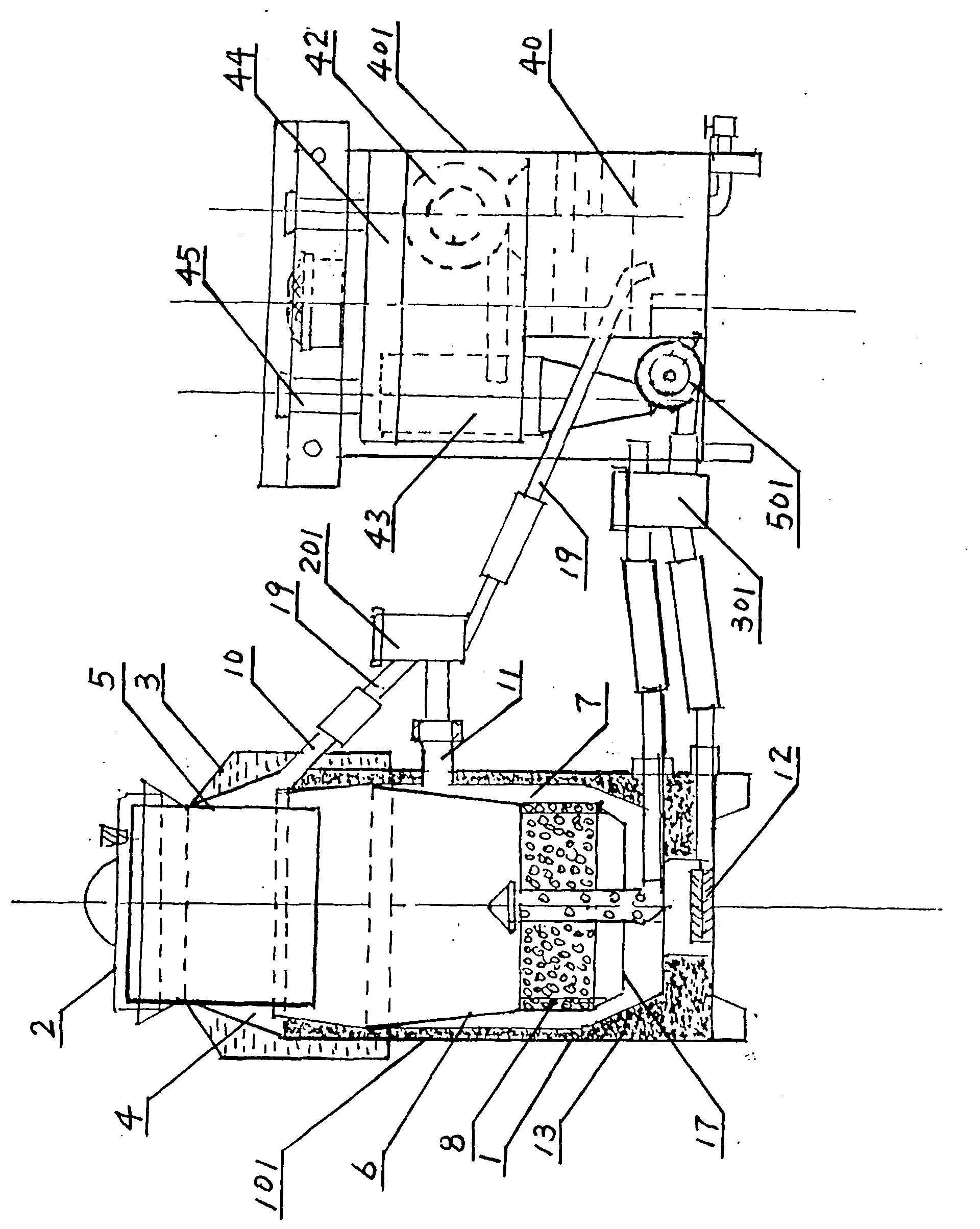

InactiveCN101230281AIncrease gasification rateQuality improvementSpecial form destructive distillationWater vaporCombustible gas

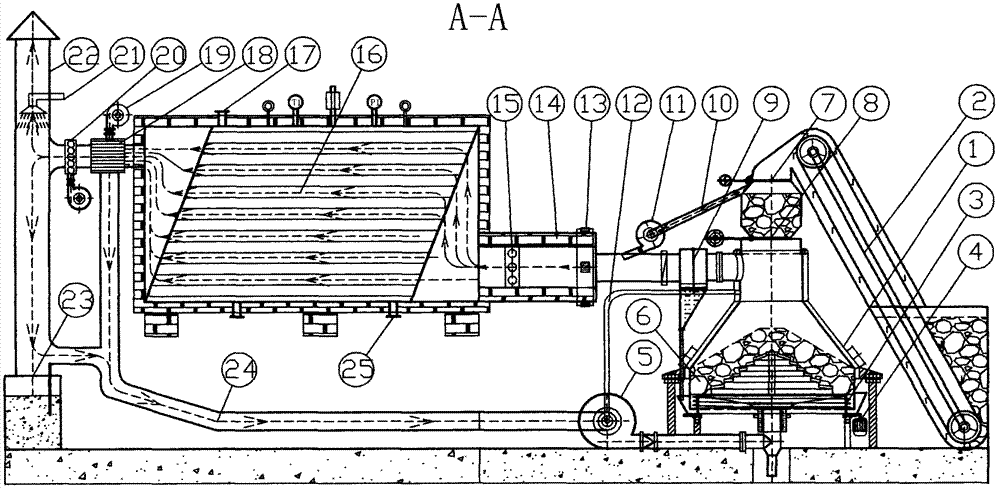

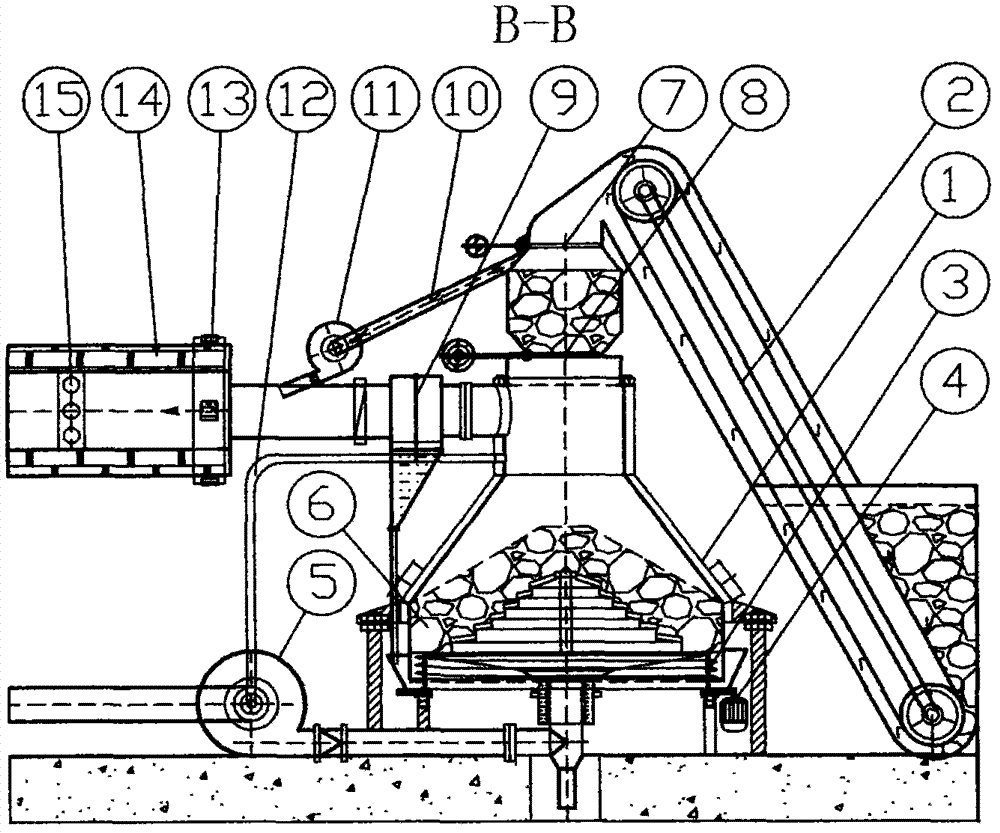

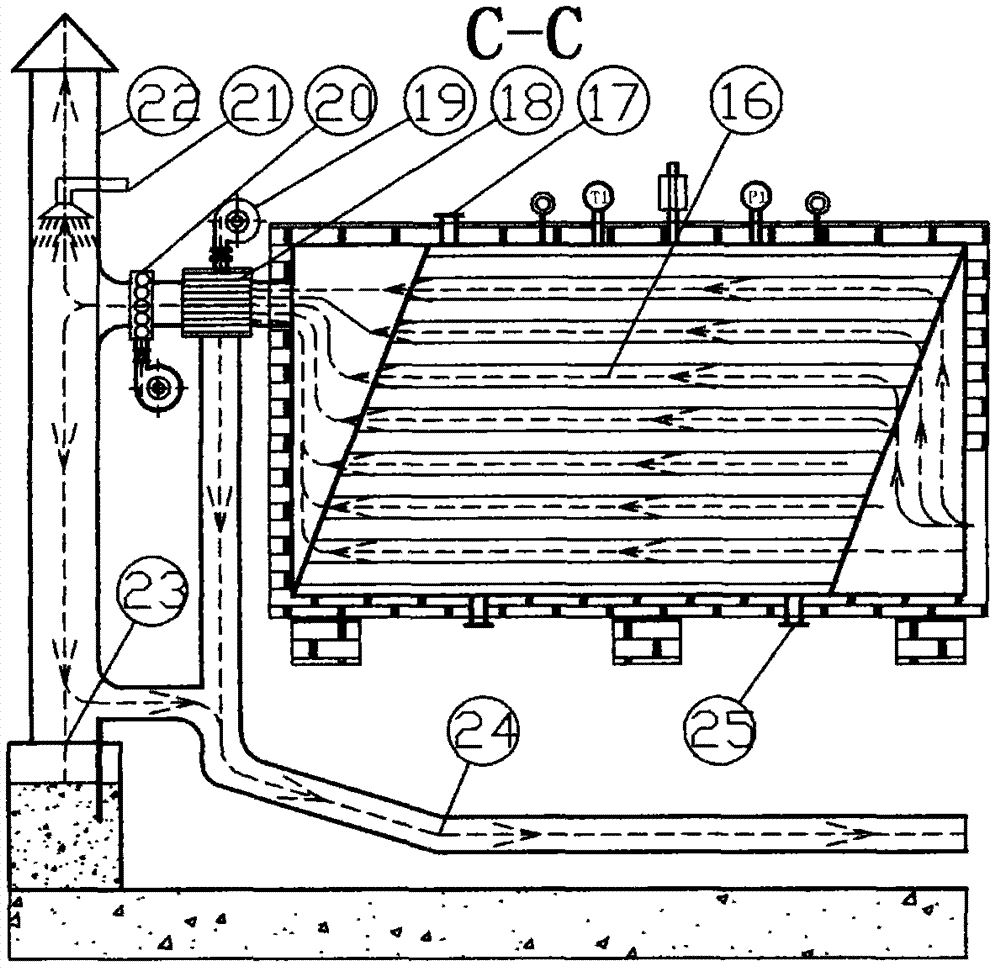

The invention provides a solid biomass semiwater gas generating furnace, which includes a furnace body, a transmission mechanism, a feeding mechanism and a residue discharging mechanism. A head preserving layer 2 and a fire resisting layer 3 are arranged in the furnace body, a heat exchanger pipe 4 is arranged in the fire resisting layer 3, and a material homogenizing harrow is arranged on the hearth. A clinker chamber 12 and a cooling water tank 13 are arranged on the underside of the furnace body 1, a gasification agent inlet 14 is arranged on the clinker chamber 12, and a clinker outlet 15 is arranged on the bottom of the clinker chamber which is connected with a spiral clinker discharger 17. A rotatable furnace grate is arranged on the interface of the hearth and the clinker chamber 12. The invention can feed material and discharge clinker continuously, ensures the continuous stability of the gasification process, uses the vapor generated by residual heat to participate in gasification reaction, improves the carbon utilization rate, and improves the gasification rate of the solid biomass. Compared with gasification furnace with uniform section, the gasification strength of the invention is improved by 1.5-2.0 times, and the combustible gas calorific value is doubled.

Owner:合肥天焱绿色能源开发有限公司

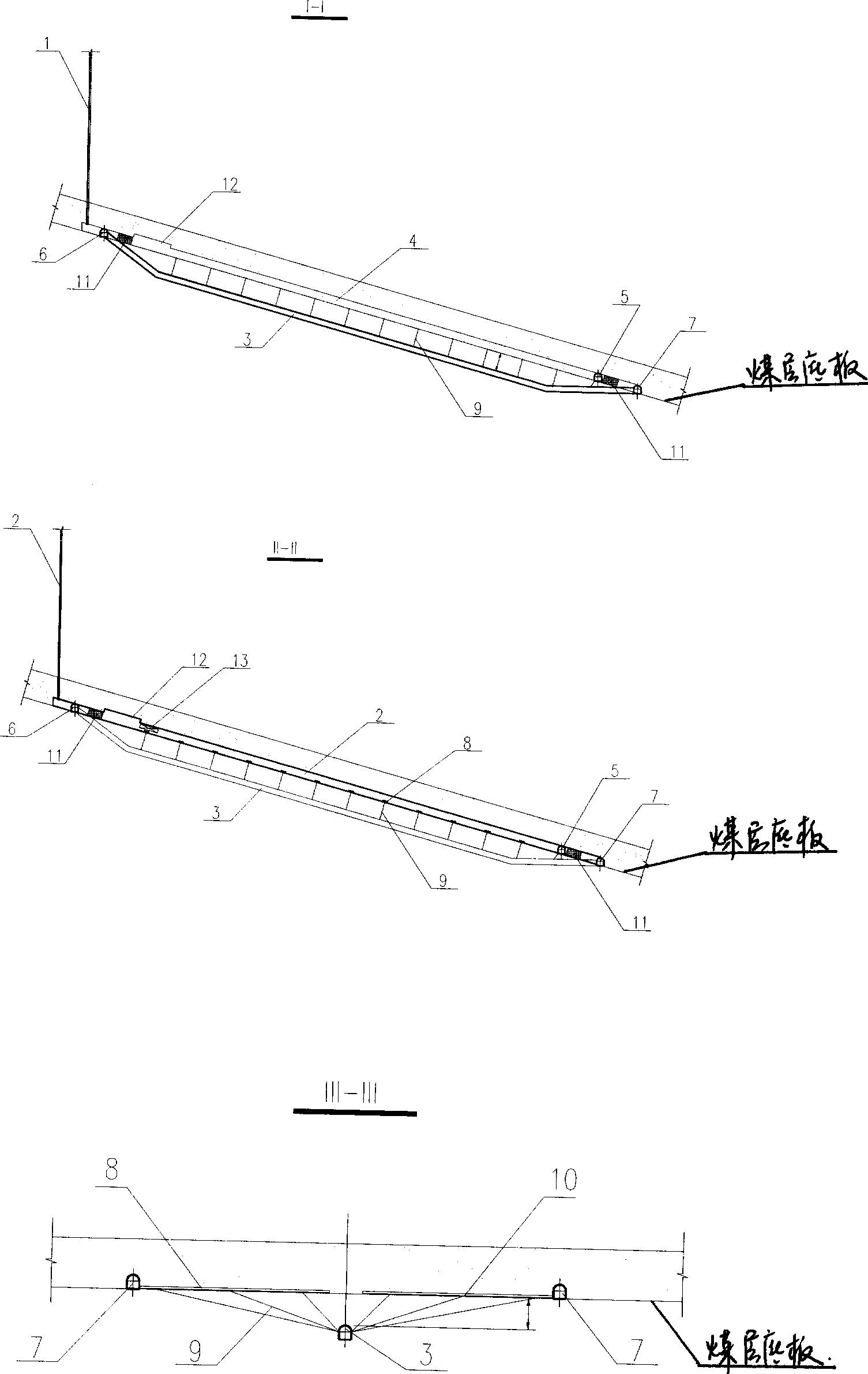

Lane control gas supply side line underground gasification furnace

InactiveCN101382062AControllable gas supply pointIncrease gasification strengthConstructionsCoal gasificationProcess engineeringEngineering

The invention provides an underground lane control gas supply side line gasification furnace. The furnace comprises a coal gas passage, multi-drill holes which are drilled directionally on the bottom of a coalbed in the coal gas passage, a gas supply lane, a gas supply pipe and a plurality of temperature pressure and flow testing instrument valves arranged in a base plate rock of the coalbed, and a gas supply branch pipe between the gas supply lane and the multi-drill holes. The system has a simple structure, easy configuration and reliable operation. The furnace capable of carrying out simultaneous multi-point gasification has the advantages of higher output, gas supply protection, controllability, adjustment as required, and the like. The furnace can solve a plurality of problems of poor gasification effect, discontinuous and unstable gas production, small gas output, low gasification rate, and the like.

Owner:ENN SCI & TECH DEV

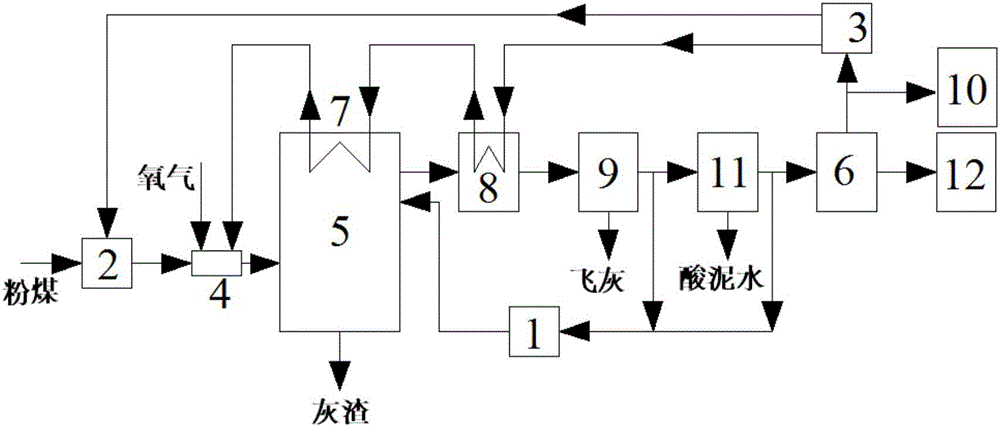

Pressure gasification process for simultaneously gasifying powdered coal and coal water slurry

ActiveCN104531219ASimple structureHigh failure rateGasification apparatus detailsGranular/pulverulent flues gasificationCoal waterBrick

The invention relates to a pressure gasification process for simultaneously gasifying powdered coal and coal water slurry. The pressure gasification process is characterized in that a purpose-made gasification furnace is used, the gasification furnace is provided with a purpose-made powdered coal burner and a start-up burner and capable of simultaneously processing the coal water slurry and the powdered coal; gasification comprises the following steps of carrying out ignition start-up, igniting the powdered coal burner, increasing the temperature and pressure of the gasification furnace and a carbon washing tower, igniting a coal water slurry burner, increasing the pressure inside a gasification chamber, and controlling continuous gasification under a specific reaction condition. The pressure gasification process disclosed by the invention can be used for solving the problems of low effective component, high requirement on the quality of coal fed into the furnace, short life of the coal water slurry burner, short operation time of a single furnace, short life of a refractory brick, low coal slurry concentration and the like of a synthetic gas obtained through the traditional coal water slurry and solving the problems of large investment, complex equipment, high comprehensive energy consumption and the like of the traditional powdered coal gasification process.

Owner:SINOPEC NINGBO ENG +2

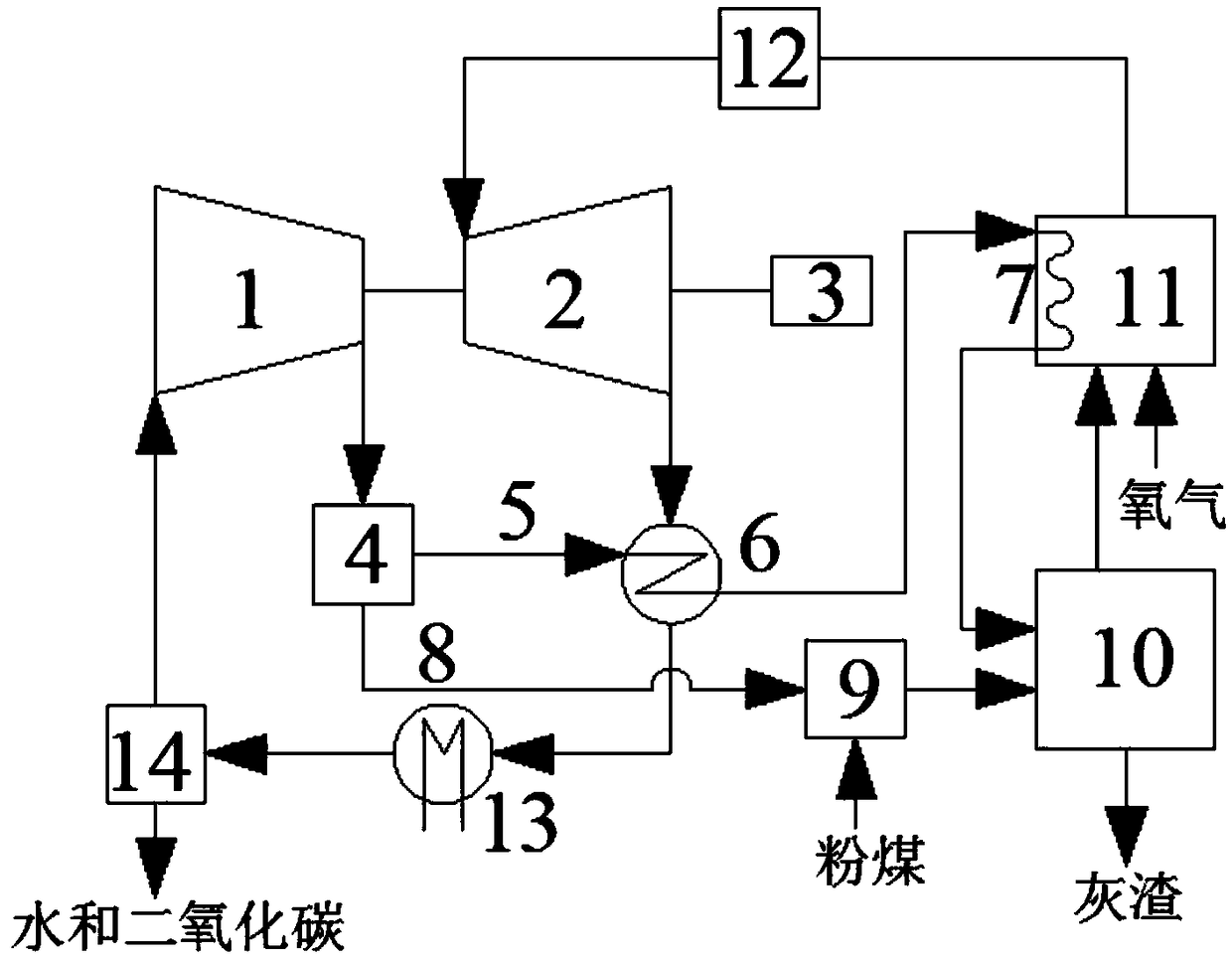

Supercritical carbon dioxide power generation and coal gasification coupled system and method

PendingCN108690661ARealize comprehensive utilizationReduce usageGasification processes detailsBulk chemical productionCombustion chamberProcess engineering

The invention provides a supercritical carbon dioxide power generation and coal gasification coupled system and method; the system comprises a supercritical carbon dioxide power generation system anda supercritical carbon dioxide coal gasification system. The supercritical carbon dioxide power generation system includes a compressor, a turbine, a power generator, a high pressure storage tank, a low pressure storage tank, a combustion chamber heat exchanger, a heat regenerator and a pre-cooler; the supercritical carbon dioxide coal gasification system includes a pulverized coal pressurizationdevice, a gasification furnace, a combustion chamber and a purifier. The system and method can adopt supercritical carbon dioxide as a gasification agent for coal gasification, and gasified coal gas is used in supercritical carbon dioxide power generation.

Owner:XIAN THERMAL POWER RES INST CO LTD

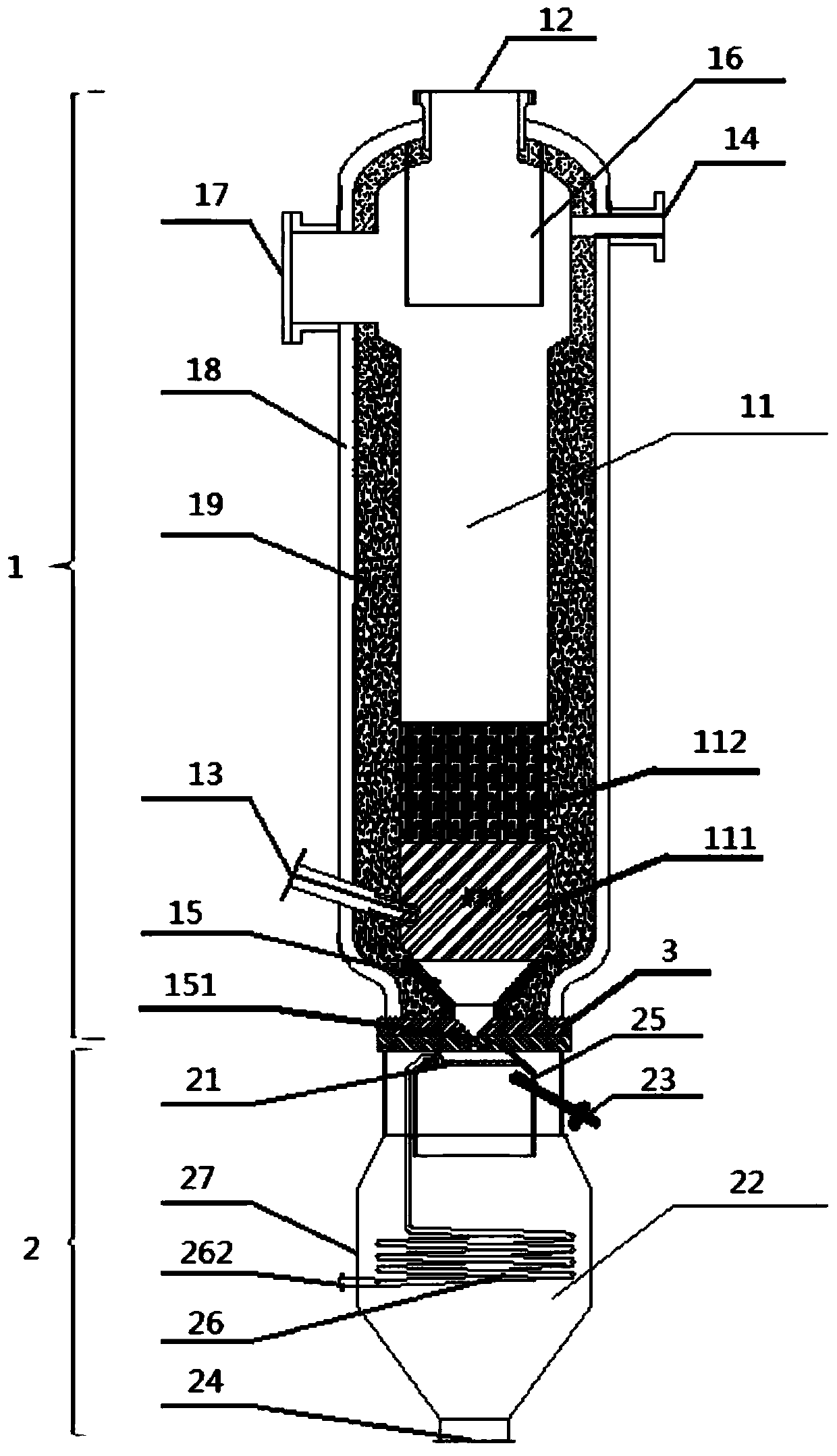

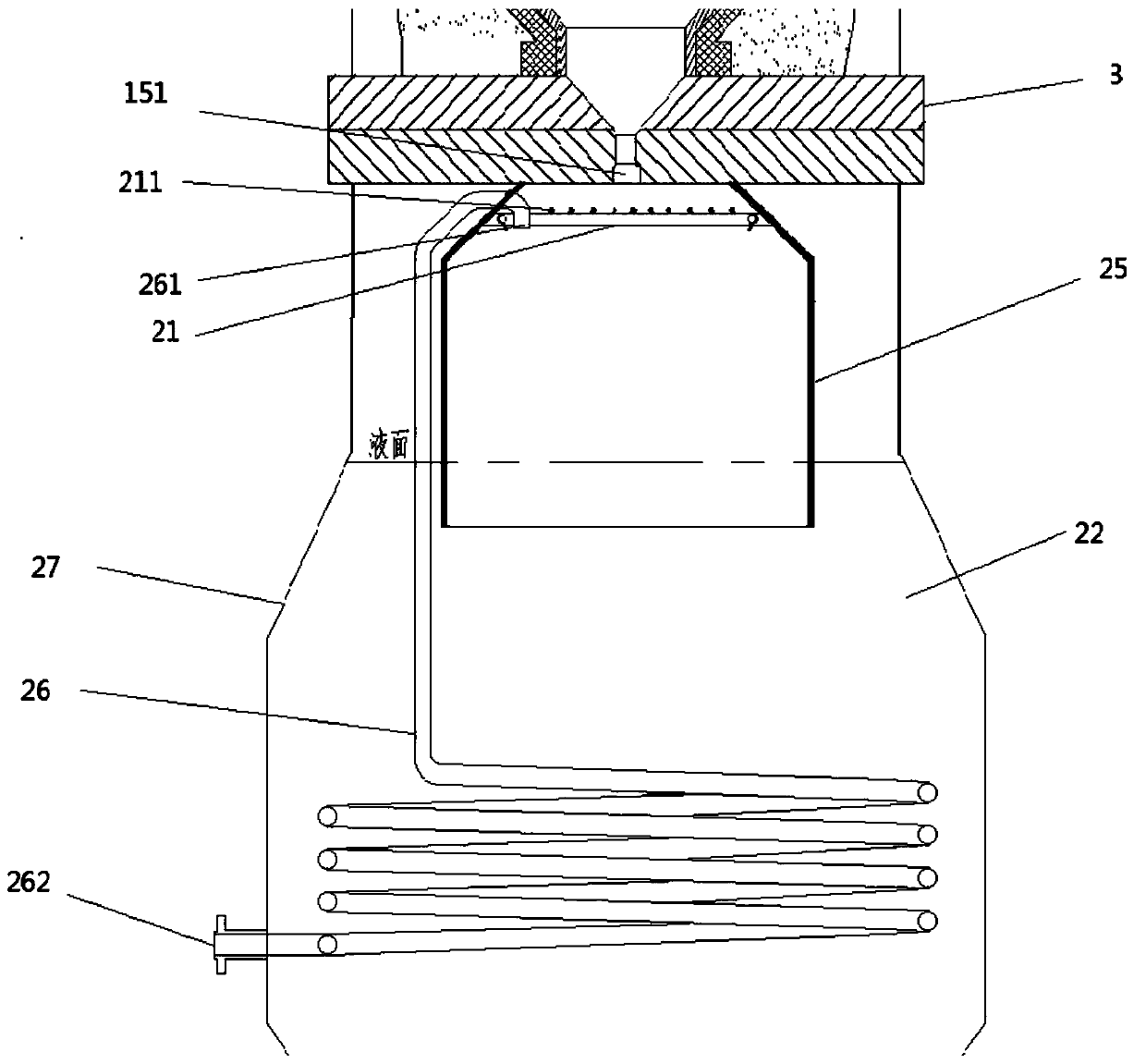

Coal gasifier for slag granulation and coal gas preparation process

ActiveCN104593085AReduce oxygen concentrationReduce the temperatureCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterSlag

The invention discloses a coal gasifier for slag granulation and a coal gas preparation process. The coal gasifier is mainly composed of a pressure-bearing housing, a slag film gasification device, an annular chamber structure slag basin, a quenching chamber, a conduit, a convection cooling section and the like. The process comprises the following steps: with pulverized dry coal or coal water slurry as a raw material, feeding the raw material to a gasification chamber to burn and gasify together with a gasifying agent from a vortex gasification burner; enabling formed liquid slag to collide with the wall surface of the gasification chamber under the vortex action, and flowing from bottom to top under the action of gravity; feeding to the slag basin of the annular chamber structure, carrying out further gasification reaction together with oxygen fed from the upper part of the slag basin, and discharging from a slag discharge hole; feeding coal gas main airflow to the quenching chamber together with liquid drops, cooling to a specific temperature, and then conveying to the convection cooling section to further lower temperature through the conduit; finally removing dust, purifying and then outputting. The liquid slag drops penetrating through the slag basin are cooled to form solid particles and are collected by a dry slag collector; and the heat is recovered by a slag cooler.

Owner:XI AN JIAOTONG UNIV +1

Novel fixed bed slag gasification reaction furnace and gas production method thereof

PendingCN107446628AImprove decomposition rateRaise the pyrolysis gasification reaction temperatureChemical industryGasification processes detailsCombustion chamberDecomposition

The invention belongs to the field of coal chemical industry and coke gasification, and relates to chemical engineering, chemical technology and chemical equipment technology, and particularly relates to a reaction furnace with fixed bed slag gasification, liquid slag removal and fractional gasification and a technology thereof. The reaction furnace comprises a gasifier furnace, a slag hole, a combustion chamber, a quench chamber and an automatic coke or coal adding machine. The invention provides the novel reaction furnace with the fixed bed slag gasification, liquid slag removal and fractional gasification which utilizes crushed coal (anthracite, bituminous coal and coke) as raw materials, and can operate under normal pressure to 0.09MPa pressure. The reaction furnace can improve the gasification temperature, carbon conversion rate and steam decomposition rate and cold coal efficiency, has a high content of effective gases, relatively simple operation and maintenance, and compact and reliable equipment, is less in investment, small in waste water quantity and safe and environmentally friendly, can convert into relatively clean water gas, and completely realizes localization.

Owner:江西昌昱实业有限公司

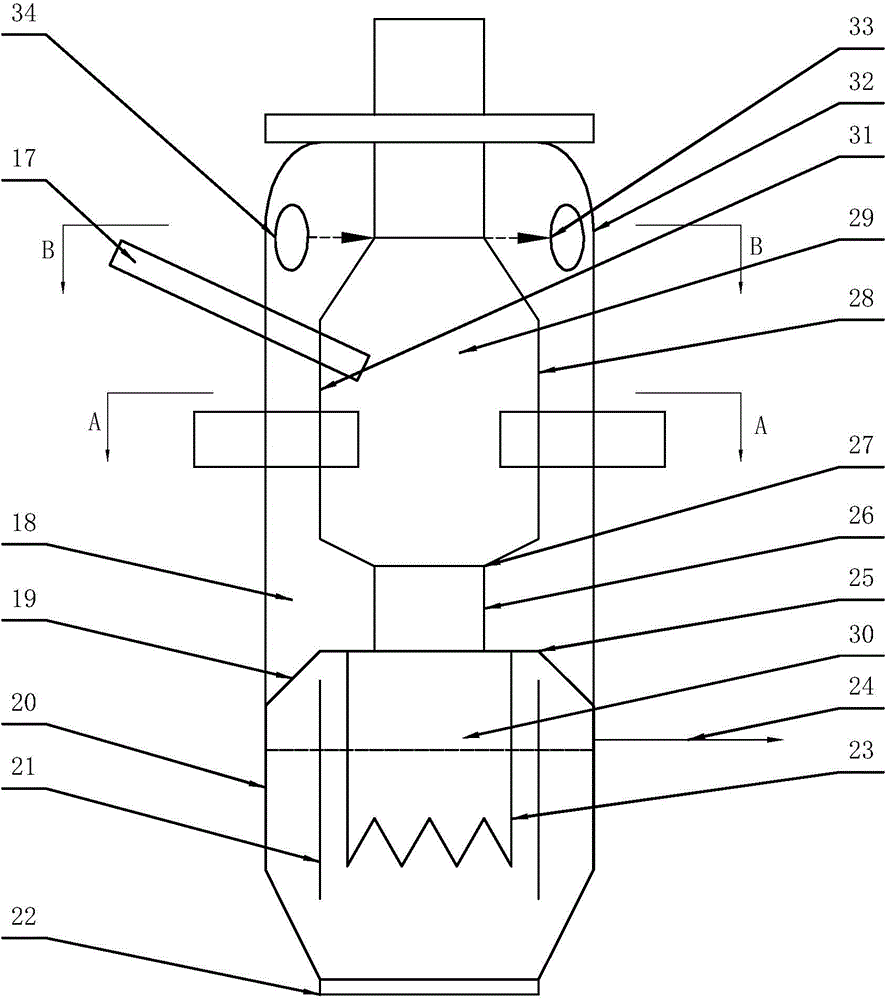

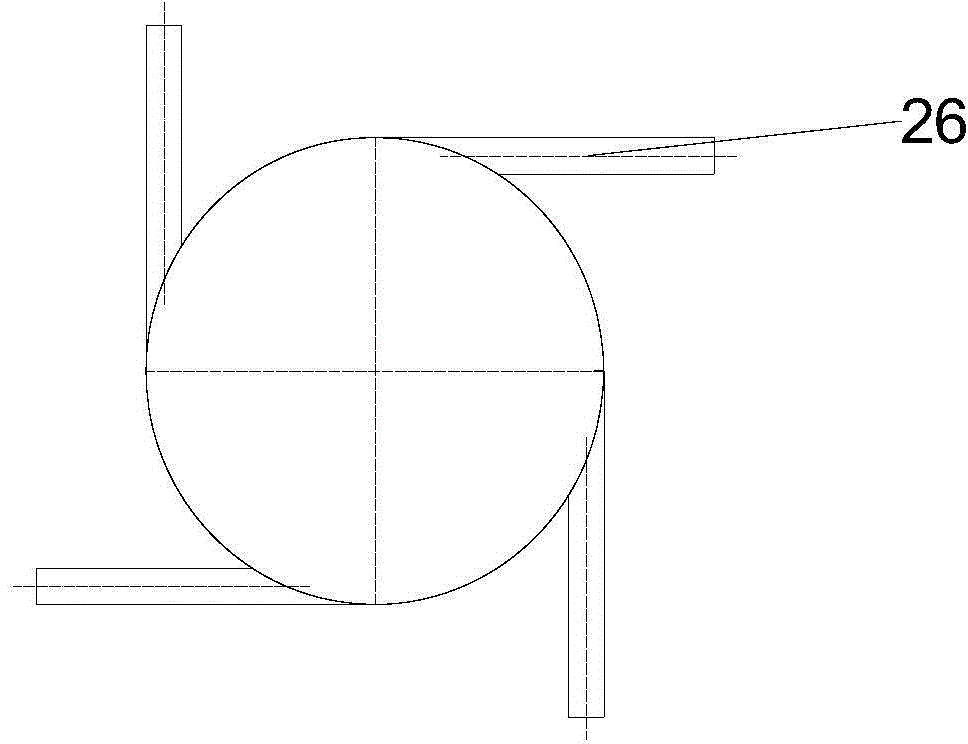

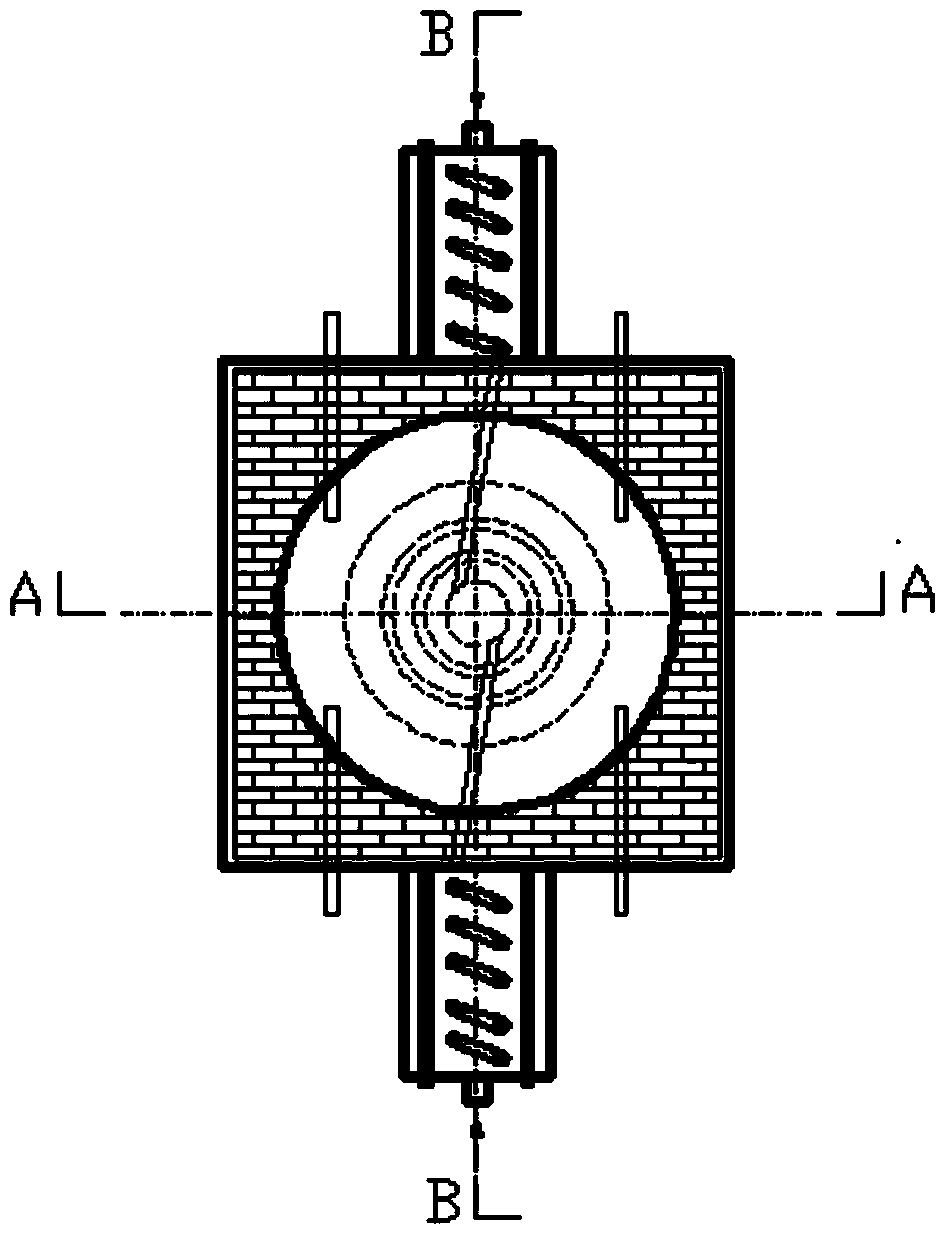

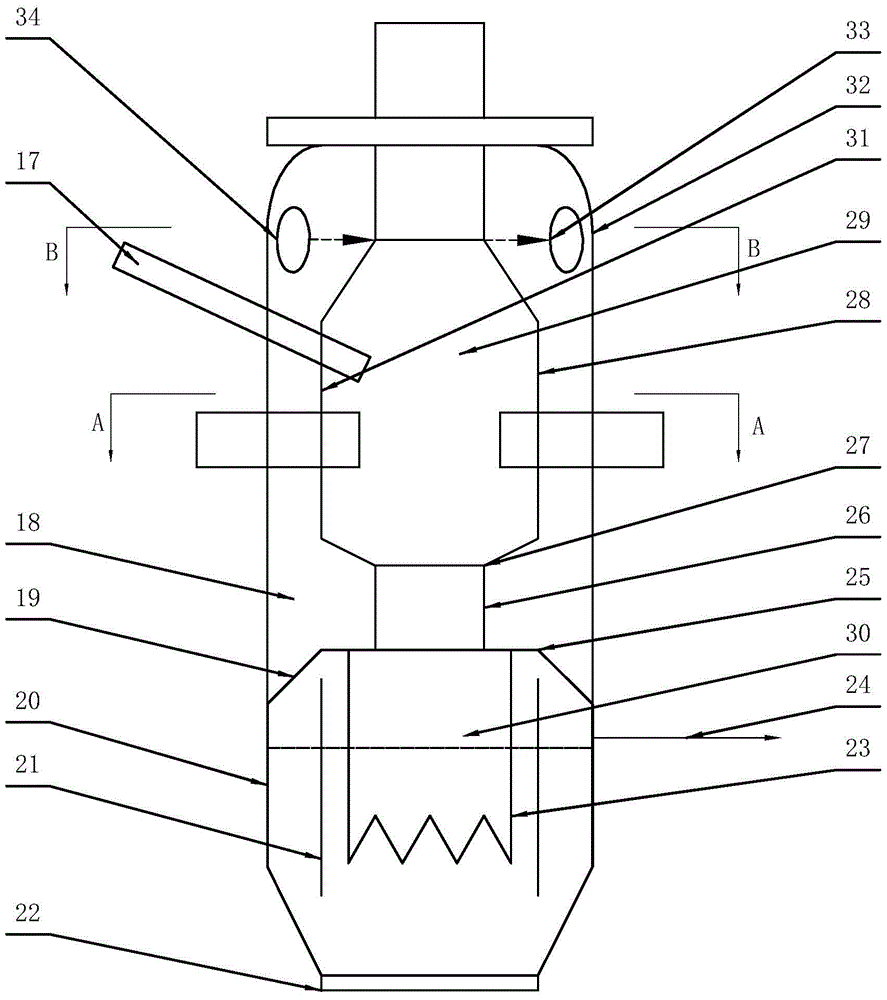

Swirl-flow type gasification furnace and swirl-flow type gasification process

InactiveCN105038860AGood technical effectIncrease gasification strengthCombined combustion mitigationGranular/pulverulent flues gasificationSlagRetention time

The invention discloses a swirl-flow type gasification furnace and swirl-flow type gasification process. The swirl-flow type gasification furnace comprises a furnace body (1), a feeding spray gun (2), a hot coal gas outlet (3) located at the top part of the furnace body, and a slag-melting chamber (4) located at the bottom part of the furnace body. According to the invention, the feeding spray gun used for entering the gasification furnace adopts tangent feeding, and the spray gun slopes down with a certain angle, so gasification raw materials are gasified in a swirl-flow form in the furnace; relative speeds of gas and solid phases are enhanced; retention time is prolonged; and gasification intensity and carbon transformation rate of the gasification furnace are improved; meanwhile, multi-layer spray-gun feeding is adopted, so classified supply of a gasifying agent is realized; reaction of the gasification raw materials and the gasifying agent in the gasification furnace is more fully; and gasification efficiency is higher.

Owner:北京柯林斯达科技发展有限公司

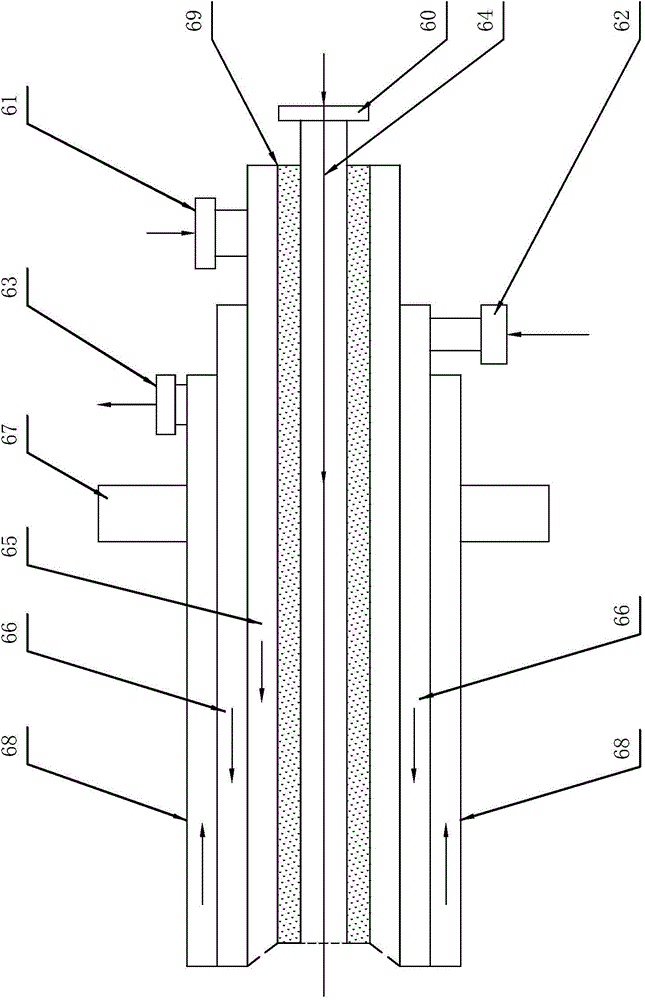

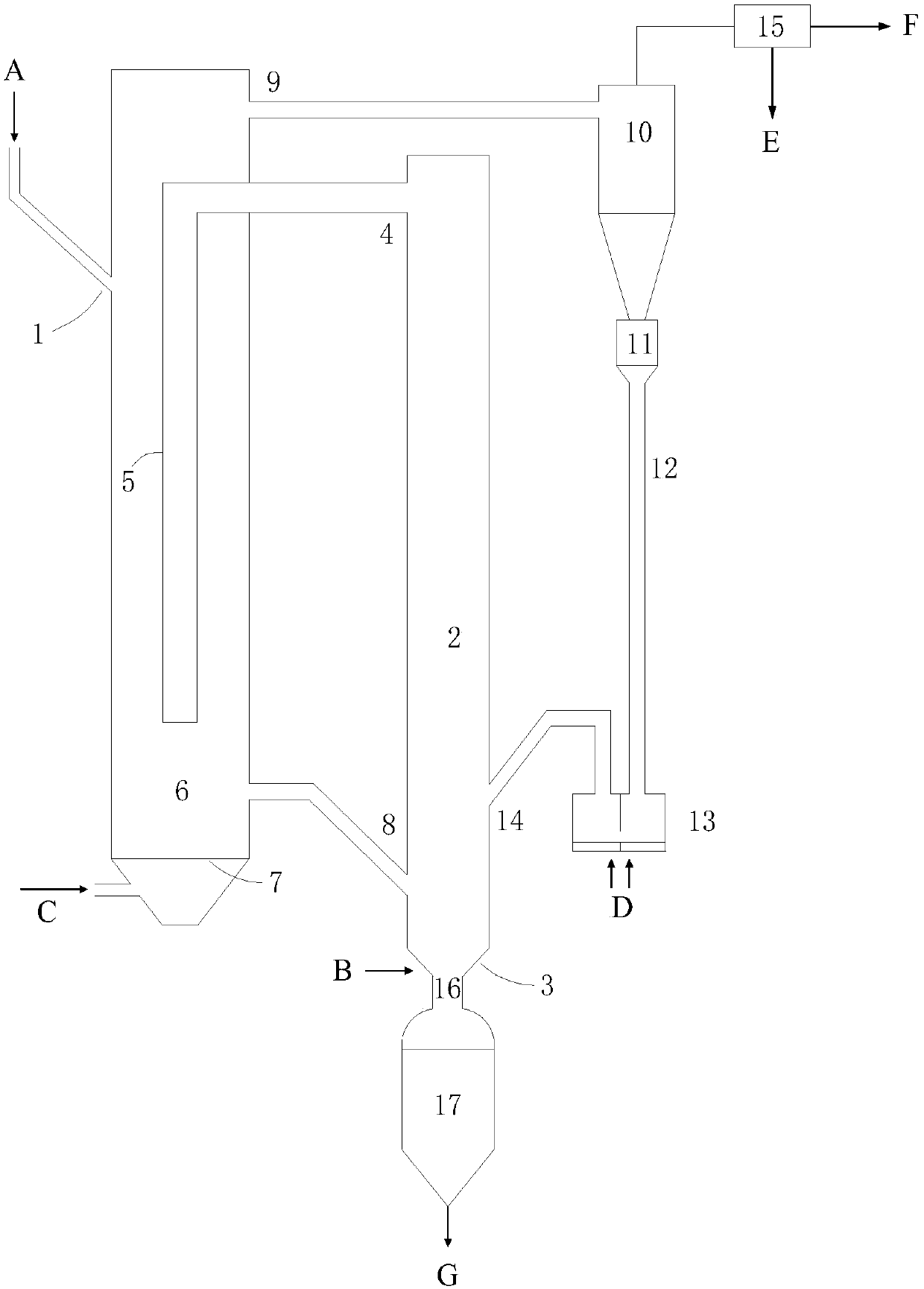

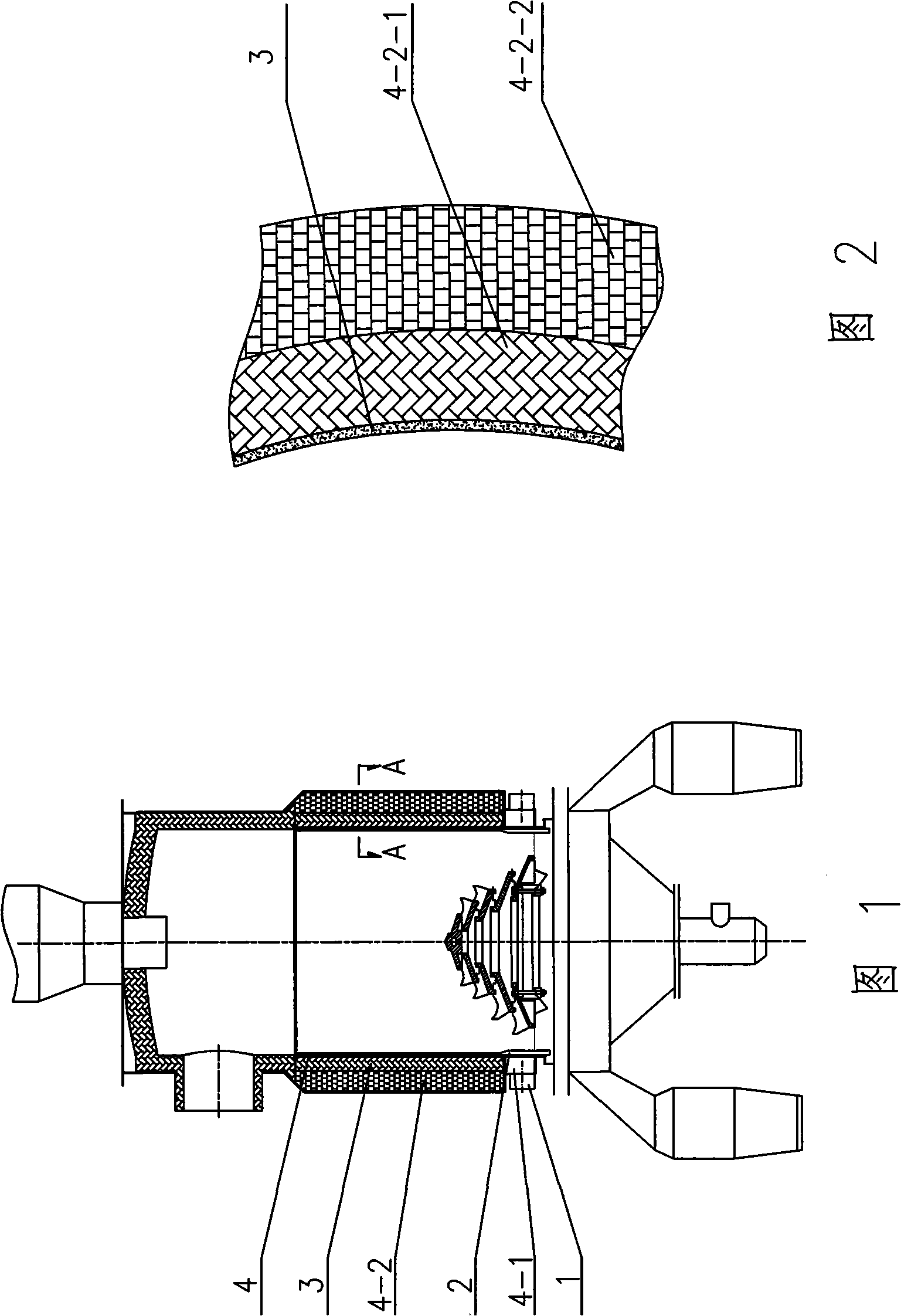

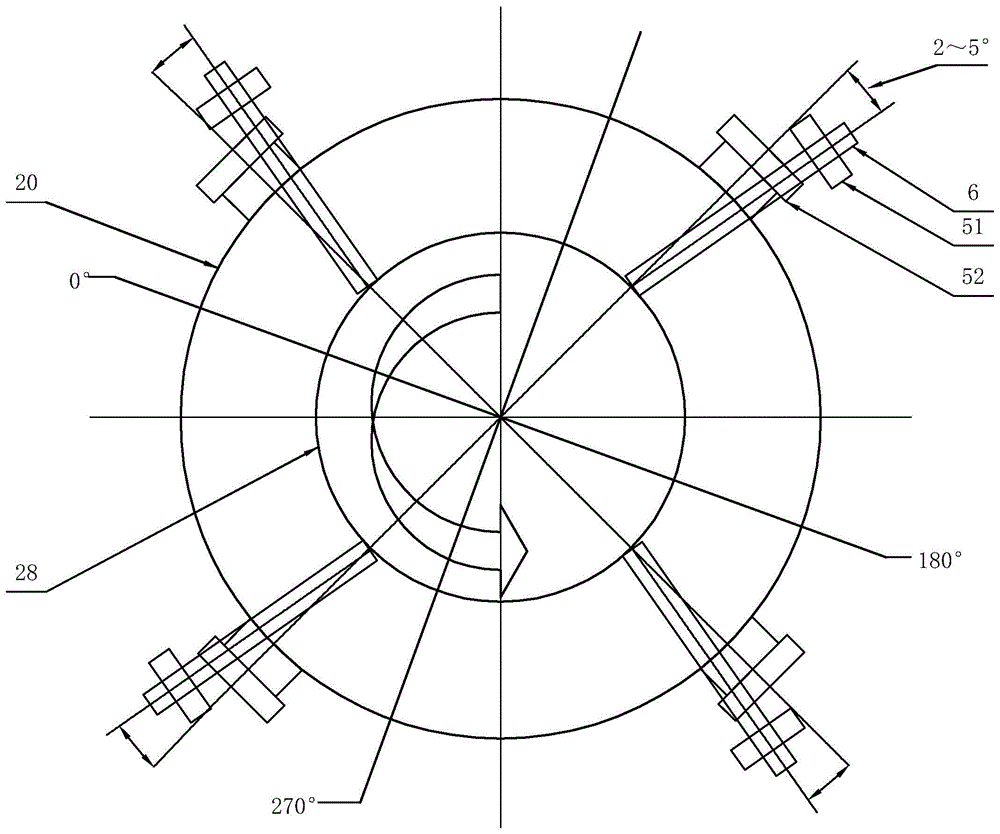

Gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method

InactiveCN105132035AUniform thicknessWell mixedGranular/pulverulent flues gasificationHearthEngineering

The invention relates to a pulverized coal gasifying device and gasifying method, in particular to a gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method. The invention aims at solving the problems that cinders are not uniformly hung on the wall surface of the gasifier in the prior art and the inner wall surface of the gasifier is burned out and corroded. A water-cooled wall of the device is installed in a gasifier body, the water-cooled wall consists of a plurality of vertical circular pipes, the water-cooled wall forms a rotary body gasifying hearth, a cinder basin is arranged at the bottom portion of the gasifier body, a synthesis gas passage is inserted into the lower portion of the gasifier body, a gasifying agent spray outlet is formed in the upper portion of the gasifier body, the gasifying agent spray outlet is inserted into the gasifying hearth along the tangential direction of the gasifying hearth, a pulverized coal burner is installed at the top portion of the gasifier body, the axis of the pulverized coal burner and the axis of the gasifying hearth are overlapped, and a pulverized coal passage with an annular cross section is arranged in the pulverized coal burner. The gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method are used for the field of coal gasification.

Owner:HARBIN INST OF TECH

Process for preparing hydrogen from deoiled asphalt employing combustion gasification and CO2 in-situ adsorption-enhanced water-gas shift reaction in in-furnace calcium-spraying circulating fluidized bed

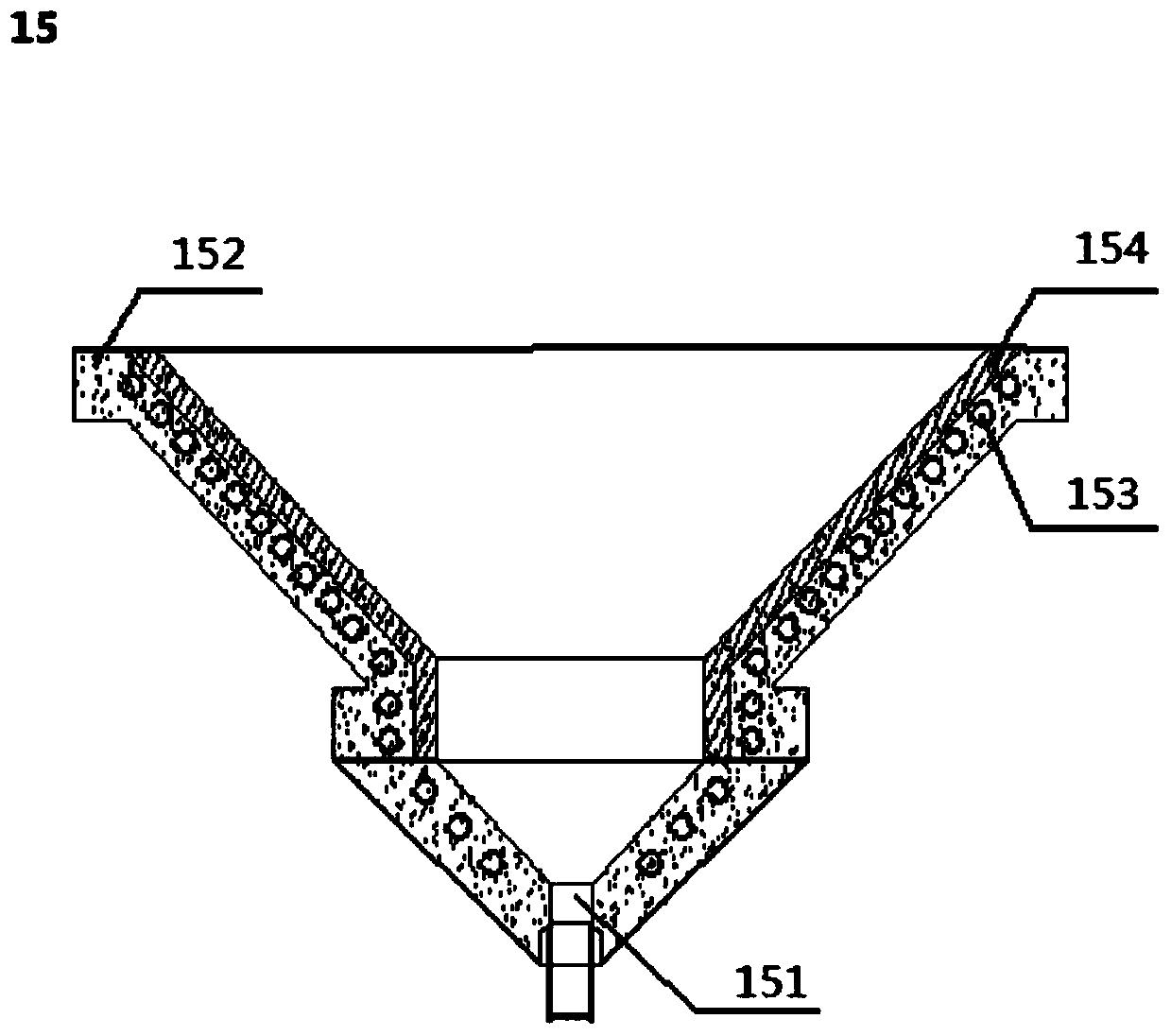

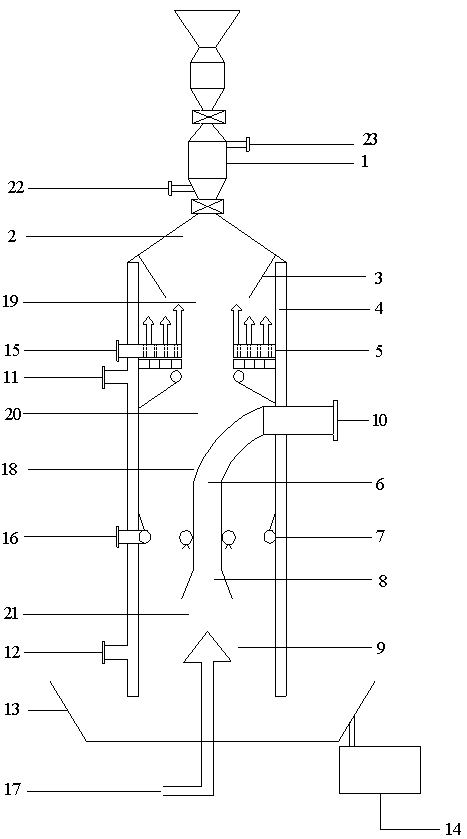

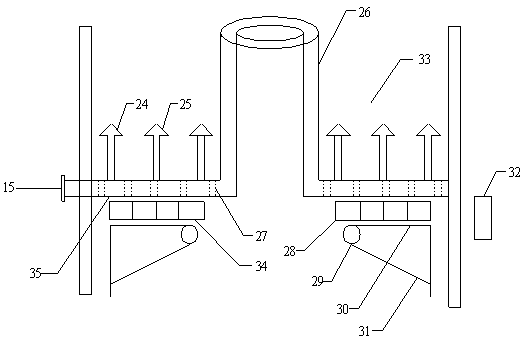

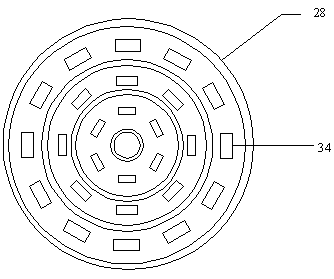

The invention discloses a process for preparing hydrogen from deoiled asphalt employing combustion gasification and CO2 in-situ adsorption-enhanced water-gas shift reaction in an in-furnace calcium-spraying circulating fluidized bed. The process comprises the following steps: gradually expanding a conical circulating fluidized bed of a hearth, carrying out partial air combustion on the deoiled asphalt on the lower part of the circulating fluidized bed, releasing heat for water vapor gasification on most of deoiled asphalt material; spraying a limestone desulfurization agent into a furnace, and carrying out desulfurization in a circulating fluidized bed furnace; feeding a synthesis gas generated by the circulating fluidized bed into a moving bed reactor; carrying out CO2 in-situ adsorption-enhanced water-gas shift reaction to prepare hydrogen; setting a water-gas shift moving bed reactor and a regenerator through the adsorption-enhanced water-gas shift reaction, so that successive and simultaneous movement, reaction and regeneration of an NiO / Al2O3 catalyst and an CaO adsorbent of adsorbing CO2 are carried out. By virtue of coupling of successive catalytic water-gas shifting and CO2 in-situ adsorption separation processes and enhanced water-gas shifting for heat and mass transfer, a high-purity hydrogen product can be continuously prepared by the synthesis gas from the circulating fluidized bed at 450-600 DEG C.

Owner:DALIAN UNIV OF TECH

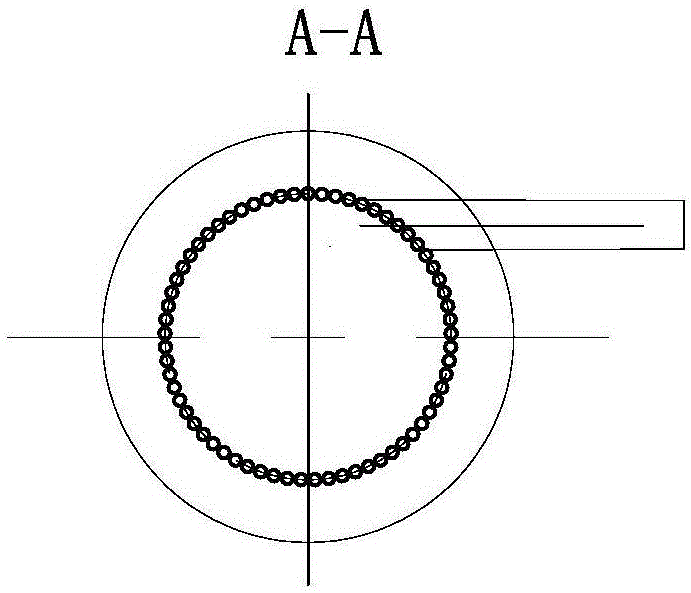

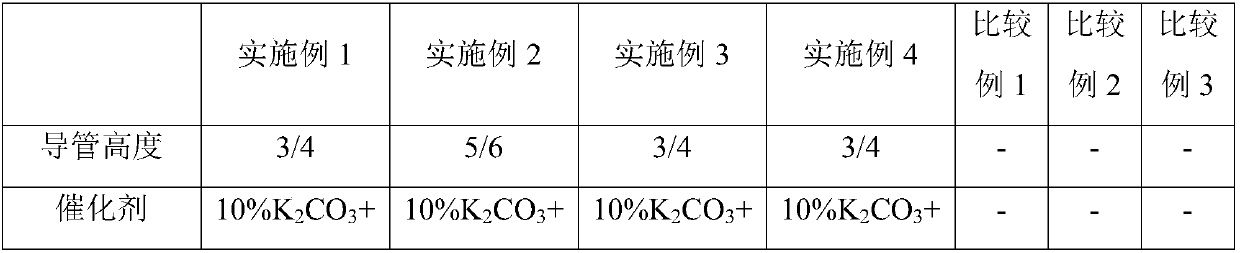

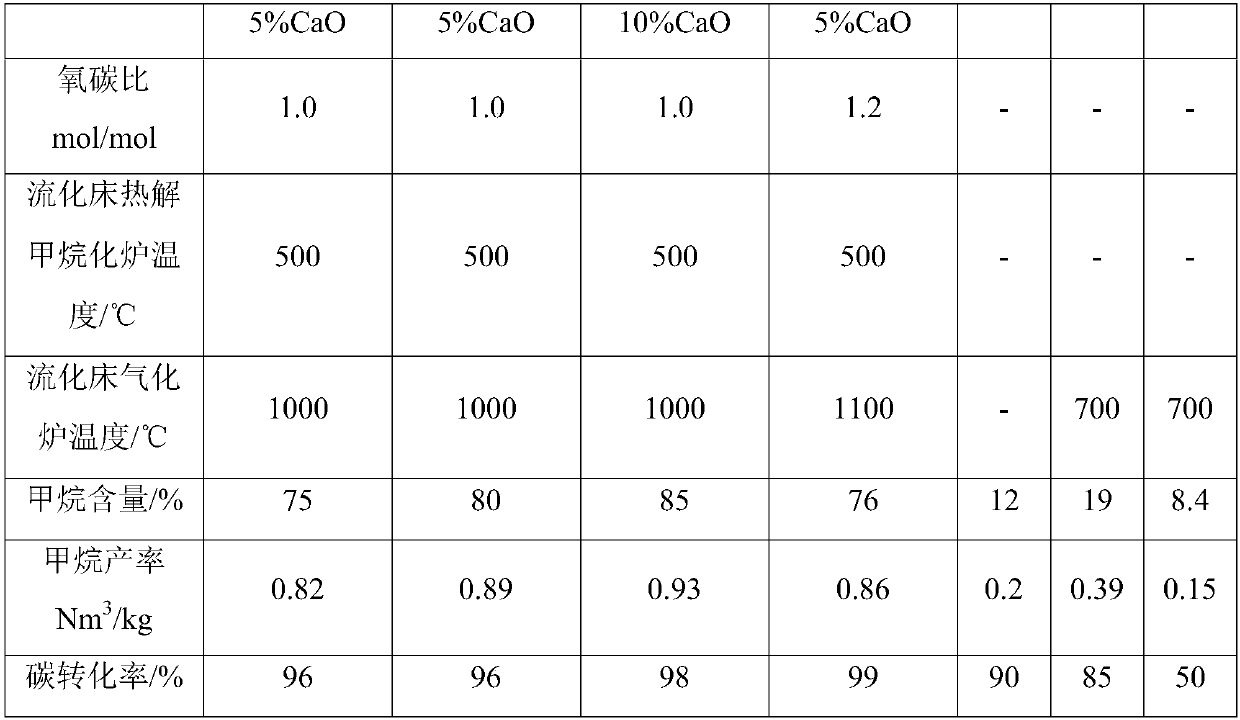

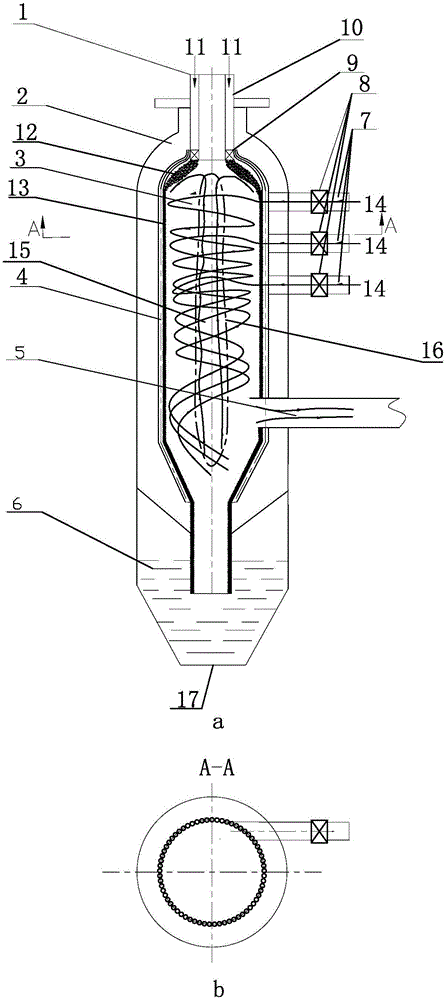

Apparatus and method for producing methane-rich synthesis gas through efficient coal catalytic gasification

ActiveCN107760384AHigh equilibrium concentrationTake advantage ofGasification processes detailsBulk chemical productionCatalytic pyrolysisSyngas

The invention relates to an apparatus and a method for producing methane-rich synthesis gas through efficient coal catalytic gasification. A purpose of the present invention is to solve the problems of low carbon conversion rate, low gasification intensity, low methane yield, high energy consumption and poor gasification furnace operation stability in the prior art. The apparatus comprises a fluidized bed gasification furnace and a fluidized bed pyrolysis methanation furnace, wherein a raw material inlet is positioned on the upper portion of the fluidized bed pyrolysis methanation furnace, thebottom portion of the fluidized bed pyrolysis methanation furnace is connected to the bottom portion of the fluidized bed gasification furnace, and a synthesis gas conduction pipe connected to the outlet above the fluidized bed gasification furnace extends into the bottom portion of the pyrolysis methanation furnace. The method mainly comprises that a catalyst-loading coal sample and high-temperature synthesis gas are subjected to a catalytic pyrolysis and methanation reaction in the fluidized bed pyrolysis methanation furnace, the semi-coke particles obtained after the pyrolysis and fly ashparticles enter the fluidized bed gasification furnace, and a combustion gasification reaction is performed. With the technical scheme of the present invention, the problems in the prior art are wellsolved. The apparatus and the method of the present invention can be used for the coal-to-methane-rich synthesis gas field.

Owner:CHINA PETROLEUM & CHEM CORP +1

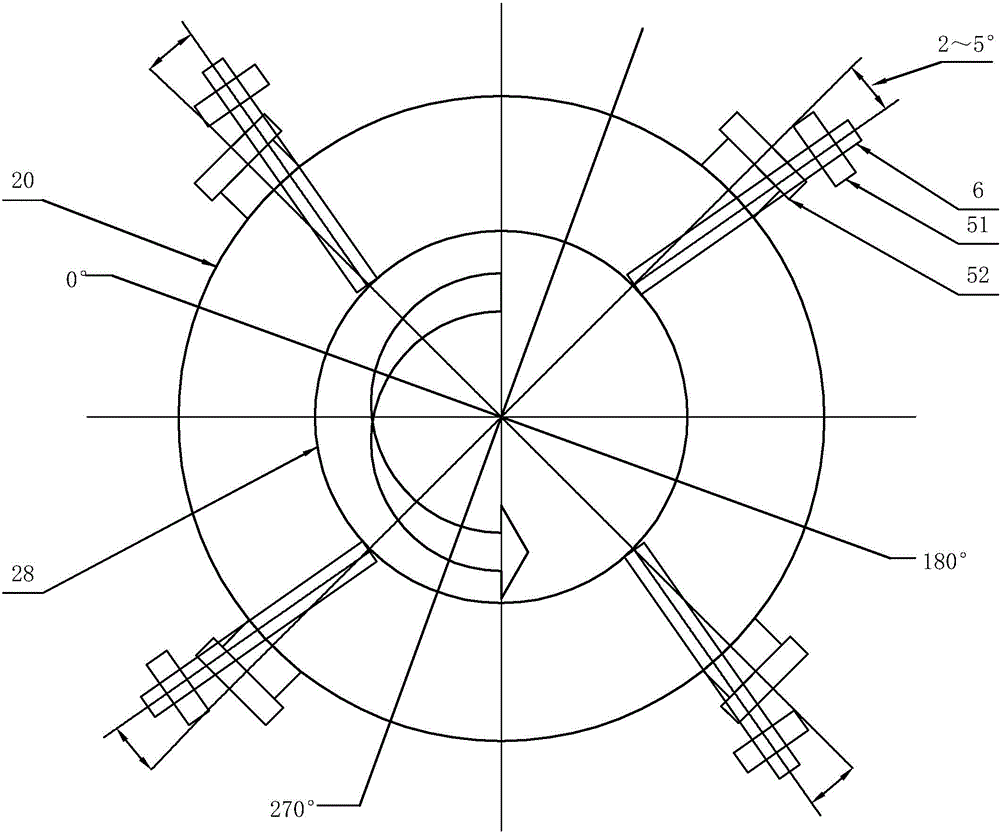

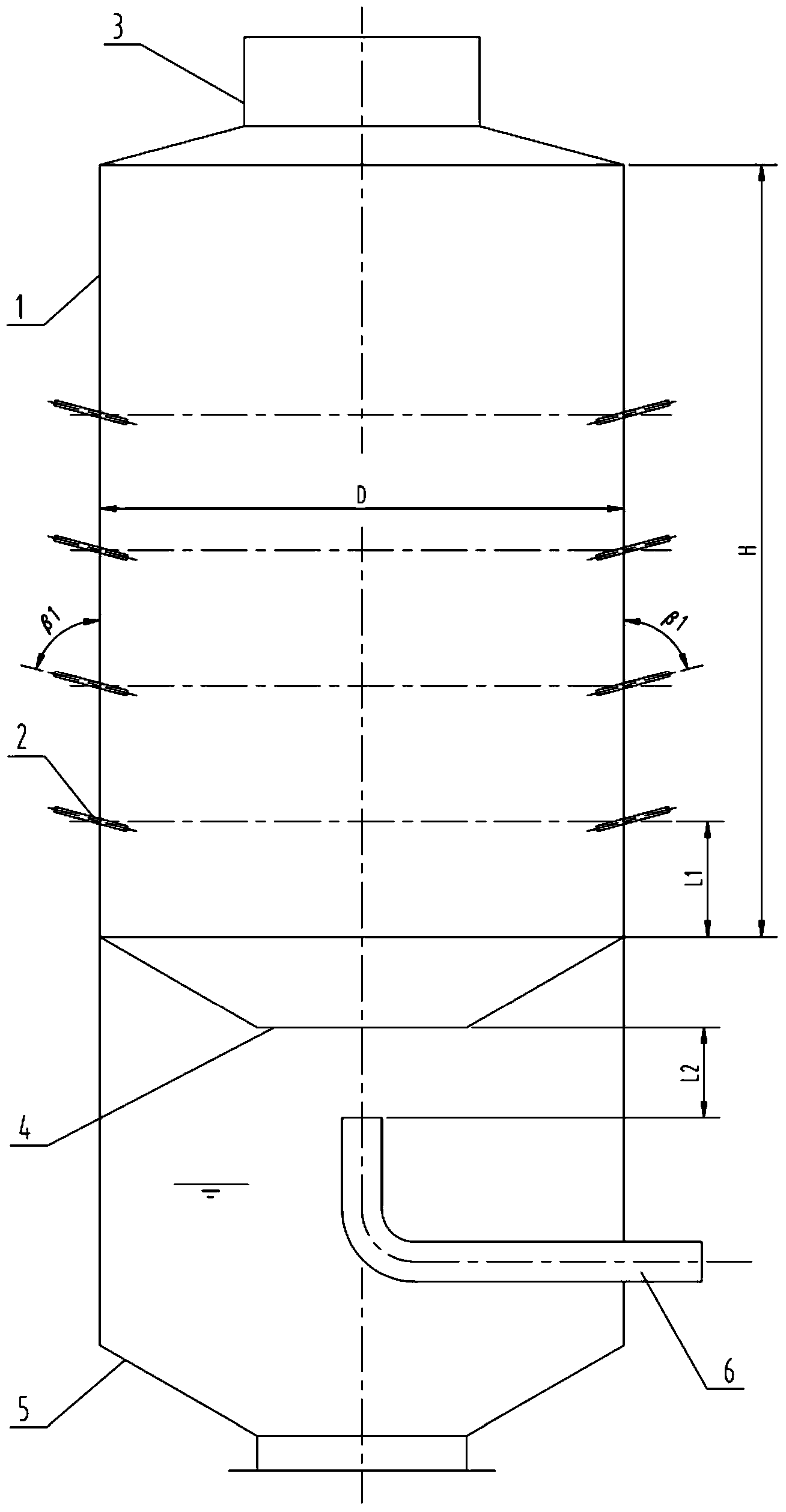

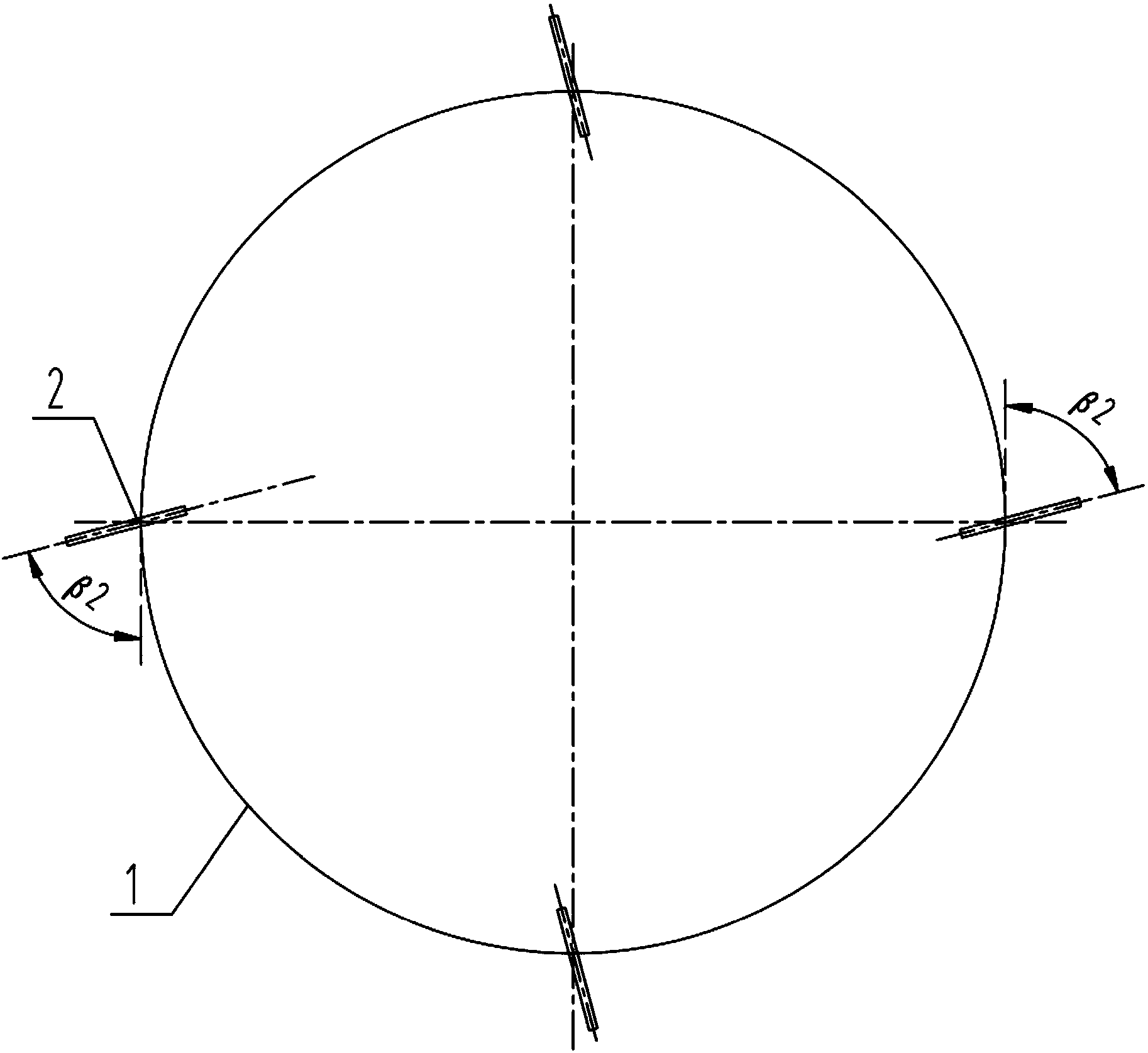

Device and method for gasifying pulverized coal through stratified strong rotation of gasifying agents along furnace height

InactiveCN105087075AUniform thicknessWell mixedGranular/pulverulent flues gasificationVertical planeSlag

The invention relates to a device and method for gasifying pulverized coal through strong rotation of gasifying agents and in particular relates to a device and method for gasifying pulverized coal through stratified strong rotation of gasifying agents along the furnace height, aiming to solve the problems in the prior art that slag adheres to the walls of gasifiers non-uniformly and temperature distribution along the directions of the furnace heights is non-uniform. The device is characterized in that a water wall is installed in a gasifier body and is formed by a plurality of vertical circular tubes; the water wall forms a rotator gasifier hearth by enclosing; a slag bath is arranged at the bottom of the gasifier body; a synthesis gas channel is inserted in the lower part of the gasifier body; a plurality of gasifying agent nozzles are uniformly formed in the upper outer side wall of the gasifier body from top to bottom in sequence and are in a same vertical plane; each gasifying agent nozzle is inserted in the gasifier hearth along the tangential direction of the gasifier hearth; a pulverized coal burner is installed at the top of the gasifier body; the axis of the pulverized coal burner coincides with that of the gasifier hearth; and a pulverized coal channel with a ring-shaped cross section is arranged in the pulverized coal burner. The device and the method are used in the field of coal gasification.

Owner:HARBIN INST OF TECH

Coal gasification system and method using supercritical carbon dioxide as gasifying agent

PendingCN107177383AImprove heat transfer effectRealize comprehensive utilizationGasification processes detailsGas purification by liquid washingGas compressorProcess engineering

The invention discloses a coal gasification system and a coal gasification method using supercritical carbon dioxide as a gasifying agent. The coal gasification system comprises a gasification furnace system, a coal gas purification system and a carbon dioxide storage and utilization system, wherein the gasification furnace system comprises a pulverized coal pressurization device, a burner nozzle and a gasification surface; the coal gas purification system comprises a coal gas cooler, a gas purification system, a chilling gas compressor, a carbon dioxide separation system, a carbon dioxide compressor and a chilling heat exchanger. By using the system and the method, the supercritical carbon dioxide can be used as the gasifying agent for the gasification of coal.

Owner:XIAN THERMAL POWER RES INST CO LTD

Novel gas generator

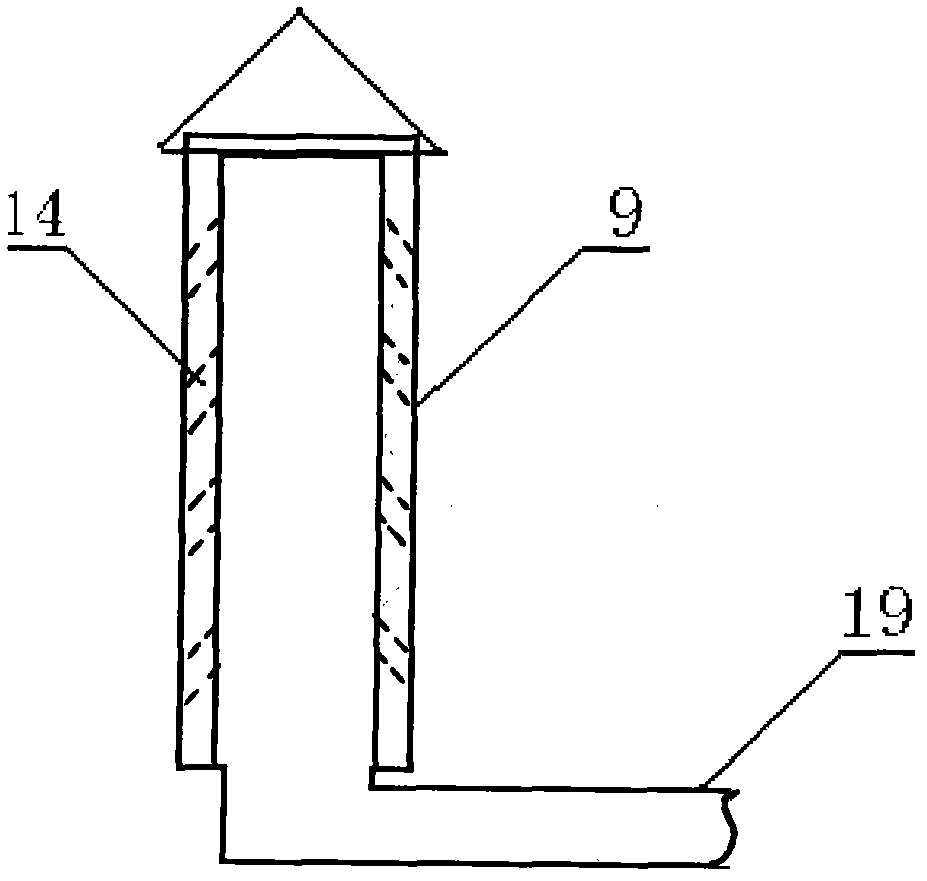

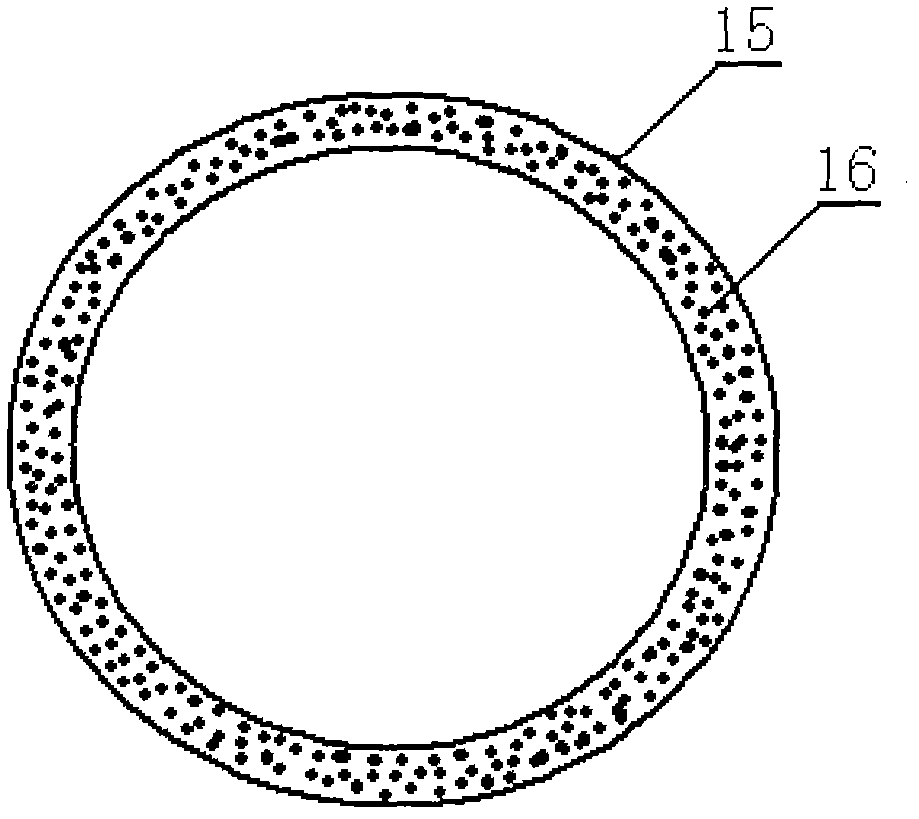

InactiveCN101275088AUniform temperatureIncrease gasification strengthCombustible gas productionWear resistantSlag

The present invention provides a new type gas producer, including a furnace body and a disintegrating slag strip, characterized in that the middle wall of the furnace body is poured by a high temperature resistant, heat insulating non-metal material brick masonry or high temperature resistant, heat insulating castable, the inner wall of the furnace wall is covered with a high temperature resistant, wear resistant porcelain plate or coated with high temperature and wear resistant coating layer; the lower of the furnace body is a metal ring cylinder which inner is ring steam channel, the disintegrating slag strip is mounted on the inside of the ring cylinder, the inner wall of the ring cylinder is provided with a steam pylome, the outer wall is provided with an air inlet joint. The invention has no water line jacket, having no water wall effect, the temperature of the furnace inside is evenly, having gasification intensity, adequate coal carbon burn, lower quantity of slag discharge and carbon residue, having high utilization ratio of gasified coal; the invention also has a simple structure, lower investment, convenient operation, lower safety evaluation grade standard, gasified raw material coal having high quality is saved at the same time.

Owner:彭思尧

Pulse downdraft type high-temperature fixed bed gasification furnace

InactiveCN103756729ASatisfy the poking requirementsHarmlessCombustible gas productionFixed bedPower engineering

The invention relates to a pulse downdraft type high-temperature fixed bed gasification furnace, and belongs to the field of thermal power engineering. Pulse gas inlet channels, high-temperature steam inlet channels and a product gas outlet channel are formed in a gasification furnace body; the high-temperature steam inlet channels are symmetrically formed in the throat part of the gasification furnace body; the pulse gas inlet channels are formed above the high-temperature steam inlet channels; the product gas outlet channel is formed in the lower part of the gasification furnace body. According to the high-temperature fixed bed gasification furnace, high-heat-value solid fuels such as biomass, urban wastes and medical wastes can be gasified, the gasification efficiency, the gasification intensity and the fuel gas quality are high, the wastes can be harmlessly treated, reduced and recycled, the environmental protection effect is remarkable, the economic benefit is huge, and the market prospect is wide.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Gasification reduction device and method for co-production of yellow phosphorus and synthesis gas

PendingCN111394133AGuarantee continuous and stable operationConducive to environmental protection and green emissionsHydrogen separationChemical industrySlagProcess engineering

The invention provides a gasification reduction device for co-production of yellow phosphorus and synthesis gas. The gasification reduction device comprises a phosphocoal gasification reduction unit and a chilling unit. The phosphocoal gasification reduction unit is communicated with the chilling unit vertically, and the phosphocoal gasification reduction unit is used for realizing gasification reduction reaction of all materials in the phosphocoal gasification reduction unit to obtain phosphorus-containing furnace gas; and the chilling unit is used for cooling slag formed in the phosphocoal gasification reduction reaction process into a solid state and discharging the solid state. The invention also provides a method for implementing co-production of yellow phosphorus and synthesis gas byusing the gasification reduction device. The gasification reduction device is a technology which is high in energy utilization rate, optimized in process, energy-saving, environment-friendly and lower in cost.

Owner:贵州航天迈未科技有限公司

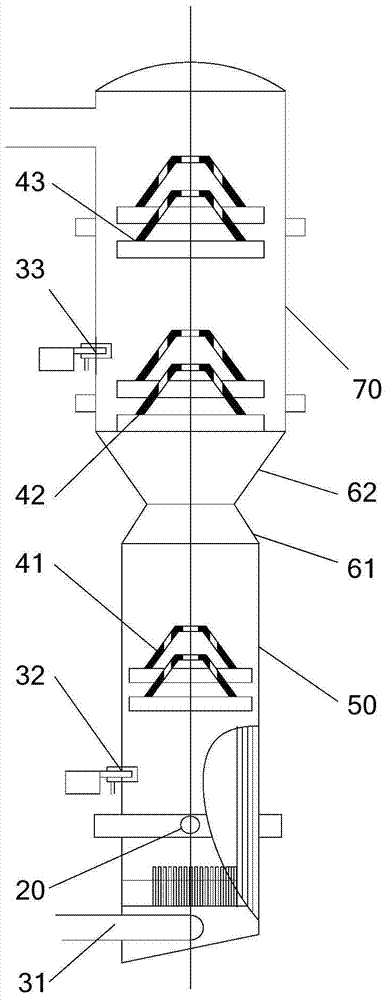

Three-layer gas supply heating self-conversion tar gasifier

InactiveCN108949234ASimple structureSolve the tar problemGasification processes detailsCombustible gas productionTarEngineering

The invention discloses a three-layer gas supply heating self-conversion tar gasifier. The gasifier is composed of a double bell coal feeder, a gasifier body, a three-layer of gas supply heating gasifier distributor, an ash residue discharging structure and a gas supply system; the three-layer of gas supply heating gasifier distributor is provided with a coal gas delivery line in the center in themiddle of the interlayer gasifier body, and the coal inlet at the bottom of the three-layer of gas supply heating gasifier distributor is arranged between a second gas supply heating gasifier distributor and a third gas supply heating gasifier distributor; a first gas supply heating gasifier distributor is located at the upper part of the gasifier body; the second gas supply heating gasifier distributor is located on the inner side of the middle gasifier wall and the outer side of the coal gas delivery line; and the third gas supply heating gasifier distributor is located in the center at thebottom of the gasifier body. Through the structural improvement of the gasifier, a high-temperature region can be formed, so that tar can be cracked and gasified in the high-temperature region, the performance of the gasifier can be greatly enhanced, efficient cleaning conversion of coal can be realized, and powerful support can be provided for development of coal gasification technologies.

Owner:TAIYUAN UNIV OF TECH

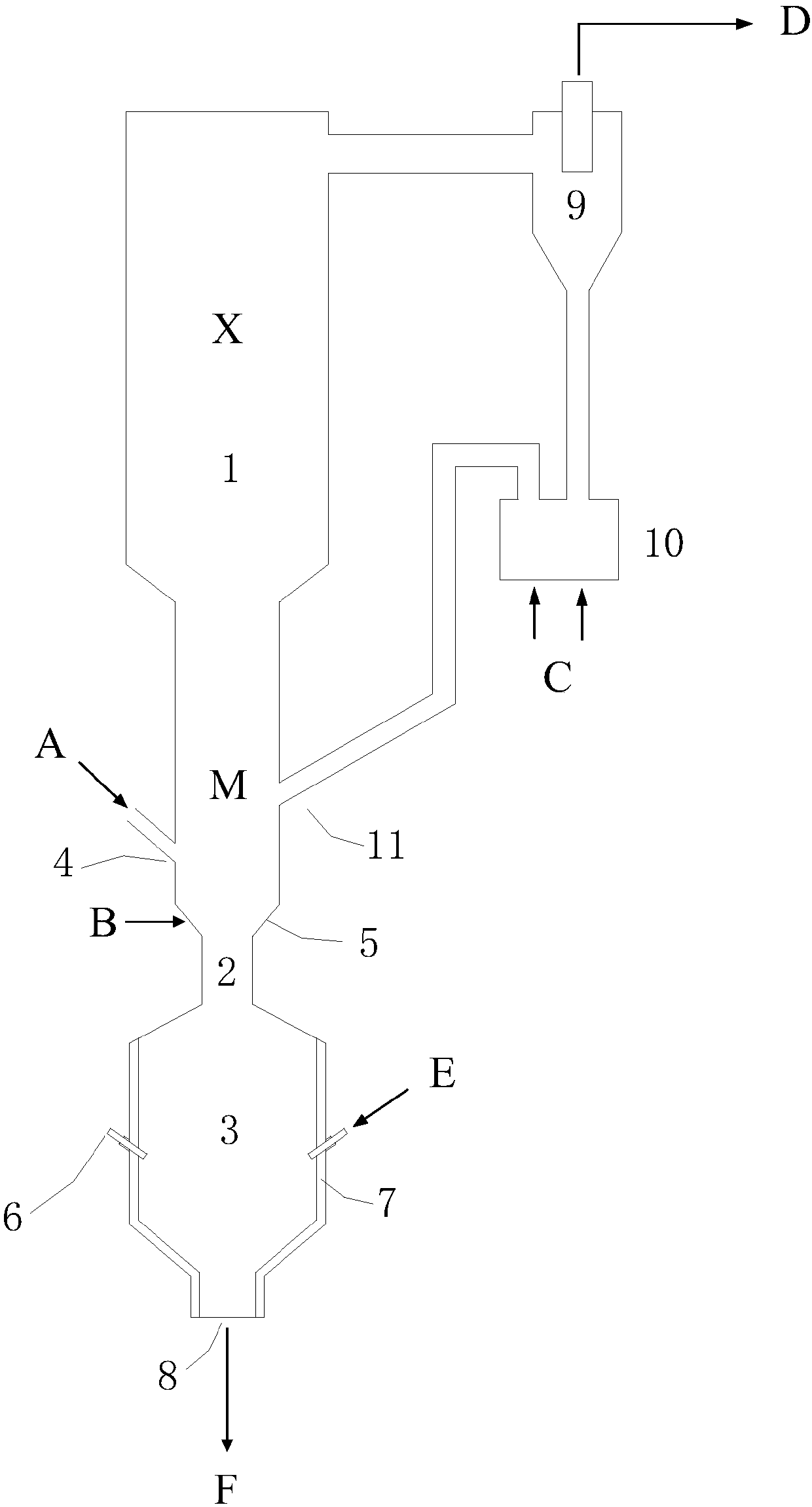

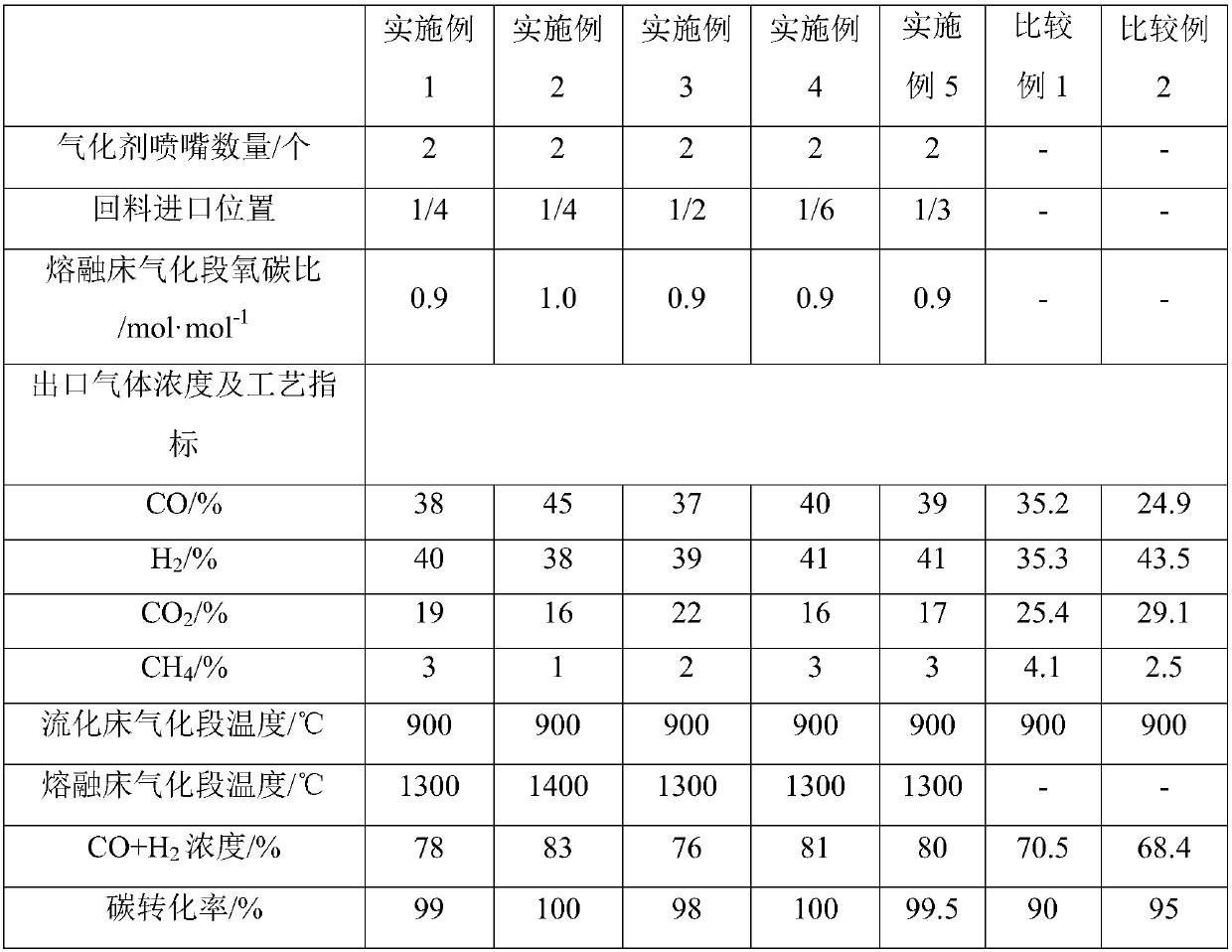

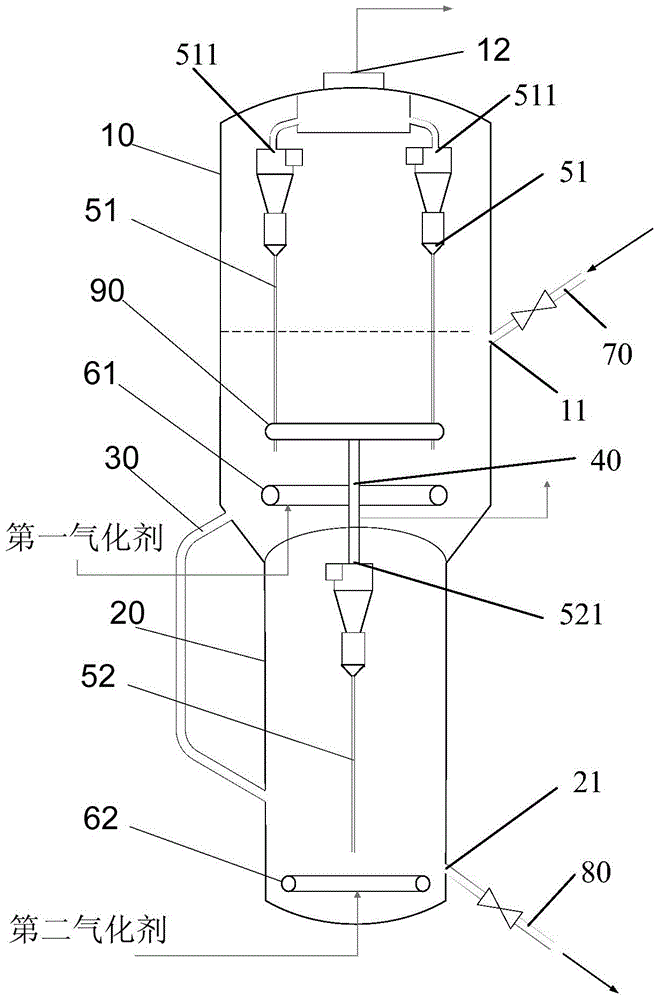

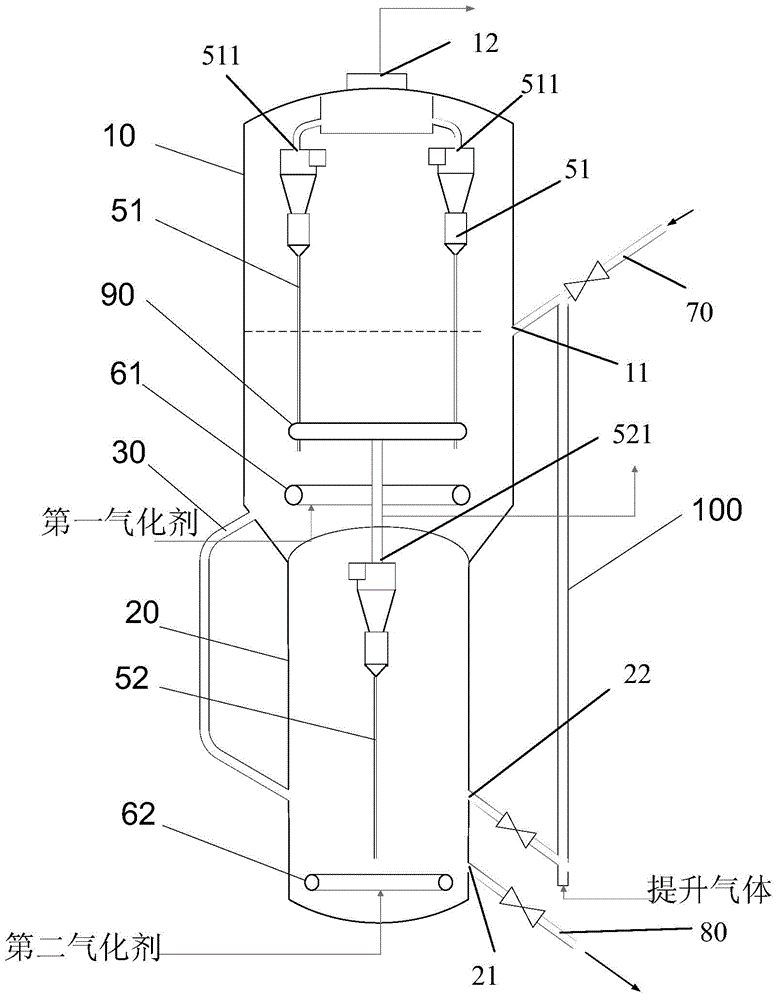

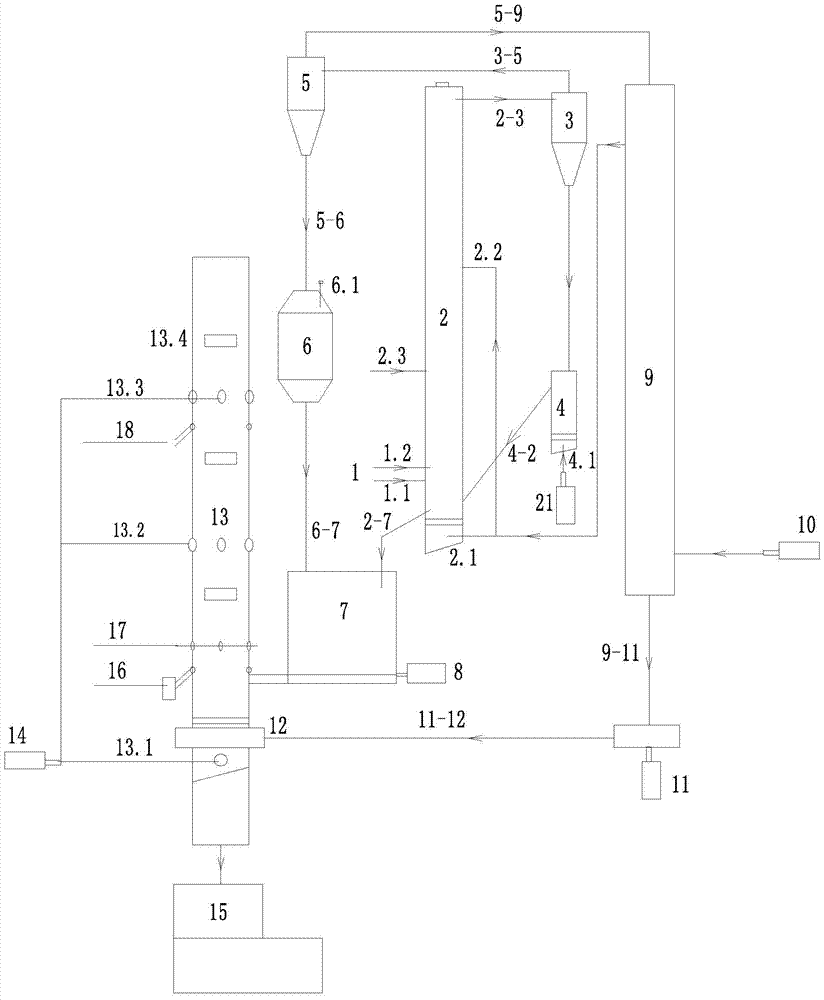

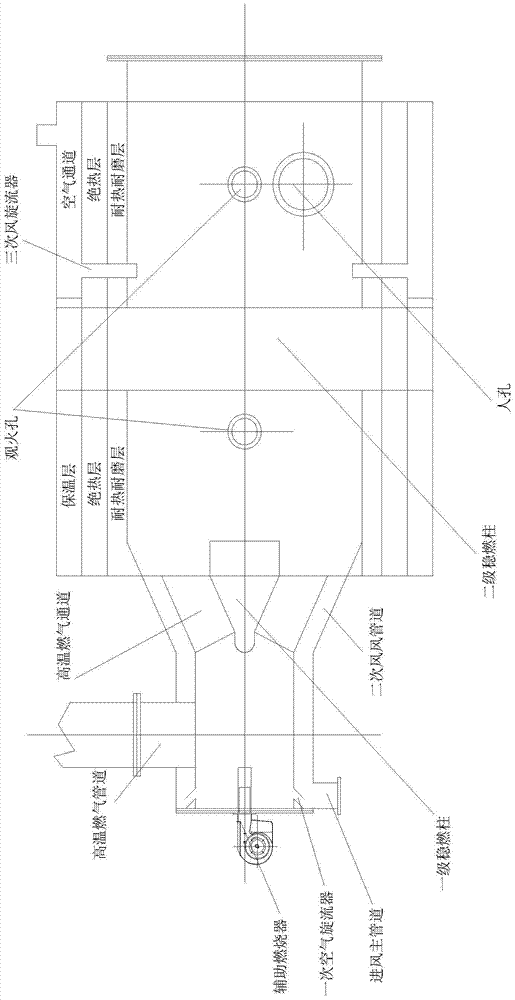

Fluidized bed and molten bed combined gasification apparatus and fluidized bed and molten bed combined gasification method

ActiveCN107760385AImprove carbon conversionImprove gasification efficiencyGasification processes detailsGasification apparatus detailsFluidized bedSpray nozzle

The invention relates to a fluidized bed and molten bed combined gasification apparatus and a fluidized bed and molten bed combined gasification method. A purpose of the present invention is to solvethe problems of low carbon conversion rate, low gasification intensity, low effective gas concentration, and poor operation stability and poor reliability of the gasification furnace in the prior art.The technical scheme of the present invention comprises that the fluidized bed and molten bed combined gasification apparatus comprises a fluidized bed gasification section on the upper portion and amolten bed gasification section on the lower portion, the two gasification sections are connected by using a throat, the lower portion of the fluidized bed gasification section is provided with a rawmaterial inlet and a return material inlet, and the side surface of the molten bed gasification section is provided with gasification agent spraying nozzles. The fluidized bed and molten bed combinedgasification method mainly comprises that a carbon-containing raw material and a gasification agent are subjected to a gasification reaction in the fluidized bed gasification section, the incompletely-reacted flying ash is collected by a cyclone separator and a return material device, and is cyclically introduced into the fluidized bed gasification section, and the generated coarse residue is further combusted in the molten bed gasification section. With the technical scheme of the present invention, the problem in the prior art is well solved. The apparatus and the method of the present invention can be used in the coal gasification field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasification entrained-flow bed coal powder gasification furnace and gasification method of micro-positive pressure air

ActiveCN103725327AFully contactedAdequate responseGranular/pulverulent flues gasificationPositive pressureSlag

The invention discloses a gasification entrained-flow bed coal powder gasification furnace and a gasification method of micro-positive pressure air. At present, a normal-pressure fixed bed gasification furnace is commonly applied in an industrial fuel gas preparation industry and an efficient powdered coal entrained-flow bed gasification technology has some difficulties on preparing industrial fuel gas under the condition that the micro-positive pressure air is used as a gasifying agent. The gasification entrained-flow bed coal powder gasification furnace is characterized in that a gasification furnace body is provided with at least one row of wall surface burners; each row of the wall surface burners comprise a plurality of wall surface burners which are arranged along the peripheral direction of the gasification furnace body at intervals; the gasification agent which is sprayed into the gasification furnace by all the wall surface burners accounts for 80%-97% of the use amount of all the gasification agent; a furnace bottom nozzle is arranged below the bottom face of a gasification furnace slag opening; the gasification agent which is sprayed into the gasification furnace by the furnace bottom nozzle accounts for 3%-20% of the use amount of all the gasification agent. According to the gasification furnace, the gasification intensity of a unit volume is high; the quantity of in-furnace coal powder falling into a dreg tank is effectively reduced; the gasification entrained-flow bed coal powder gasification furnace is very suitable for producing the industrial fuel gas by taking the micro-positive pressure air as the gasification agent.

Owner:ZHEJIANG ASROAD HIGHWAY CONSTR & MAINTENANCE MACHINERY

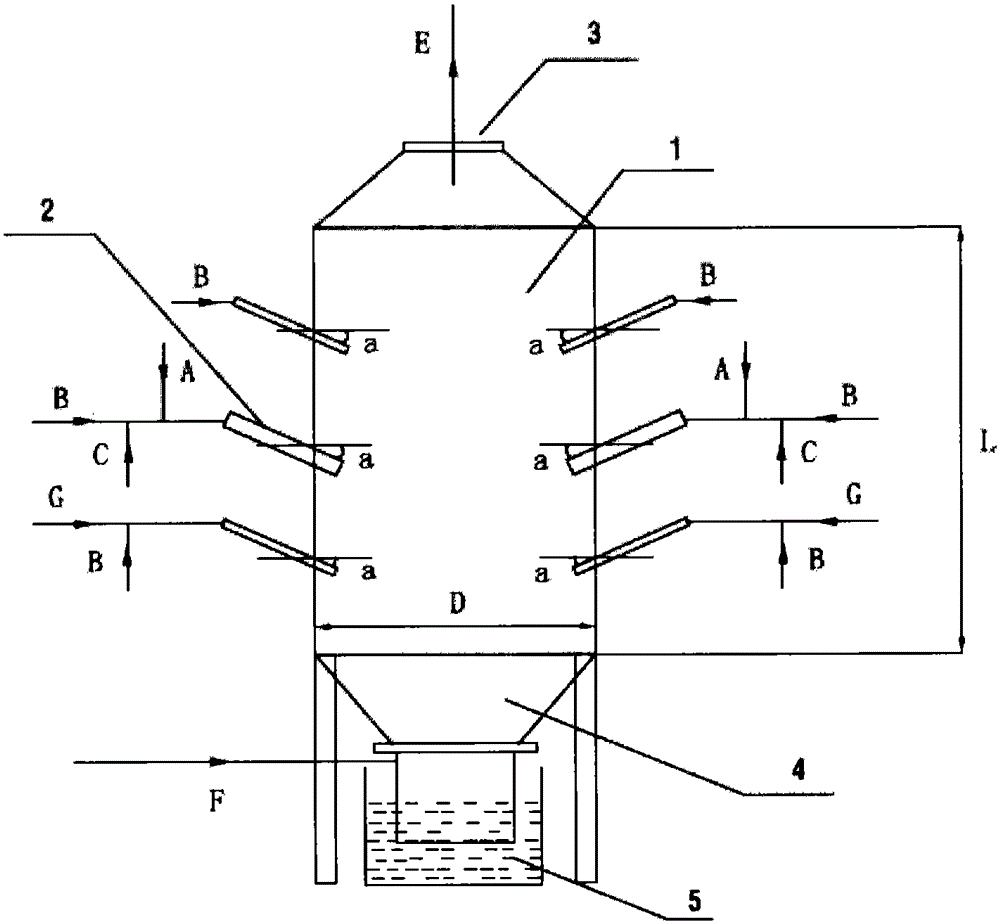

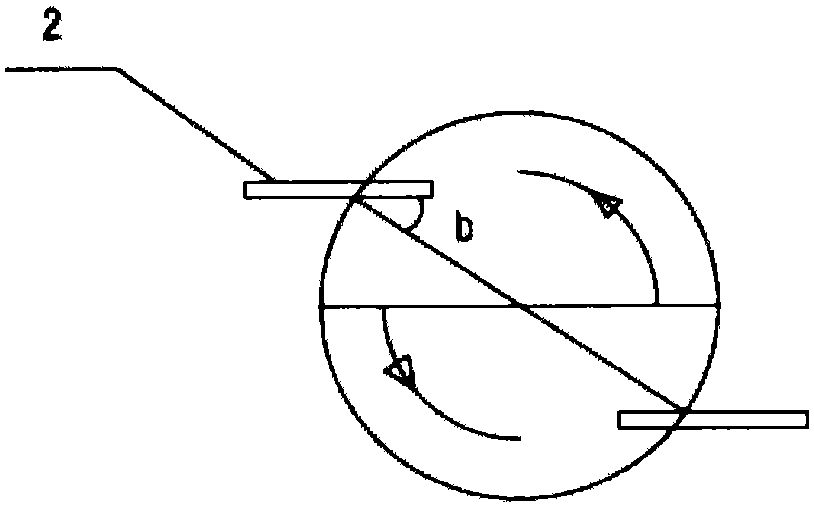

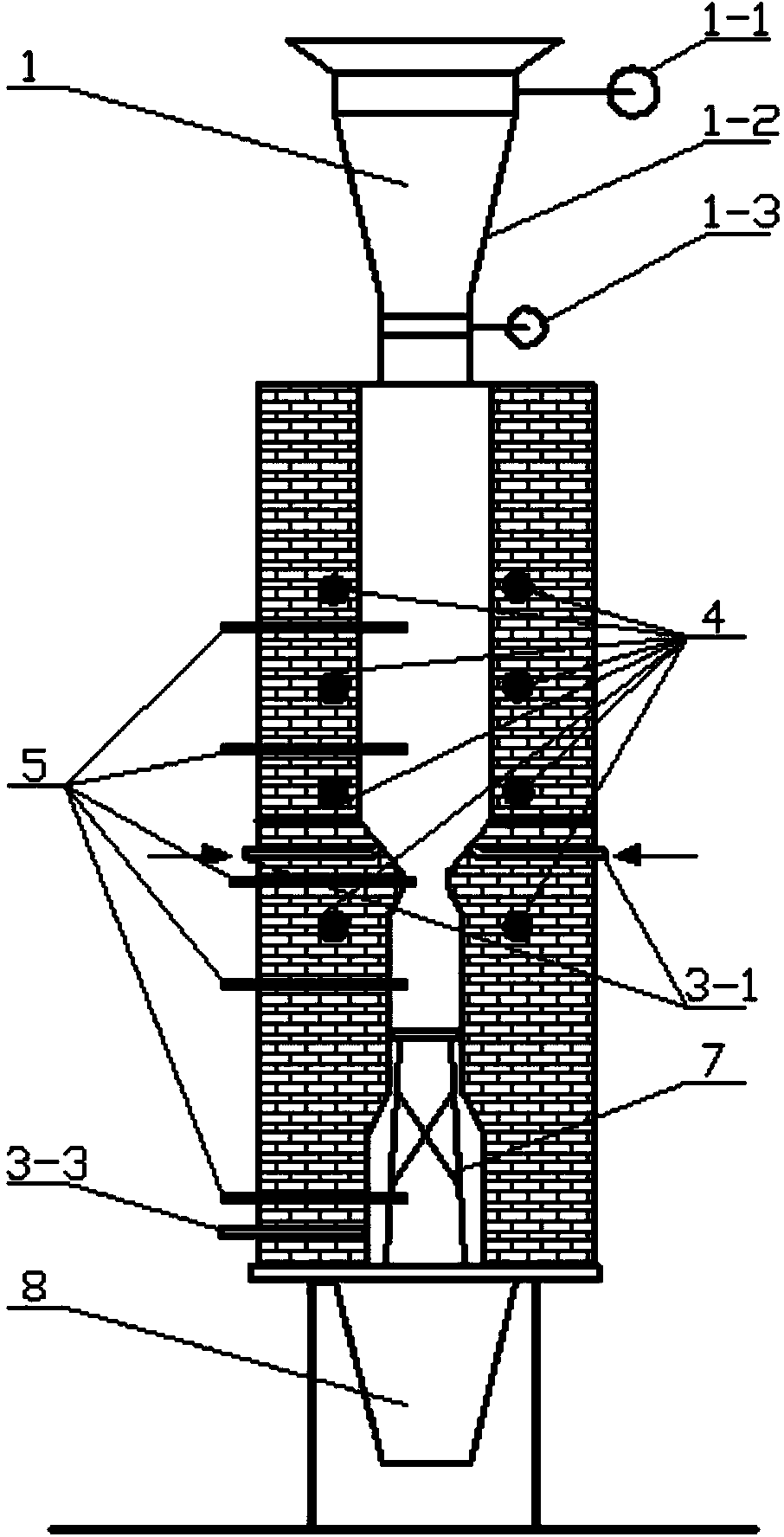

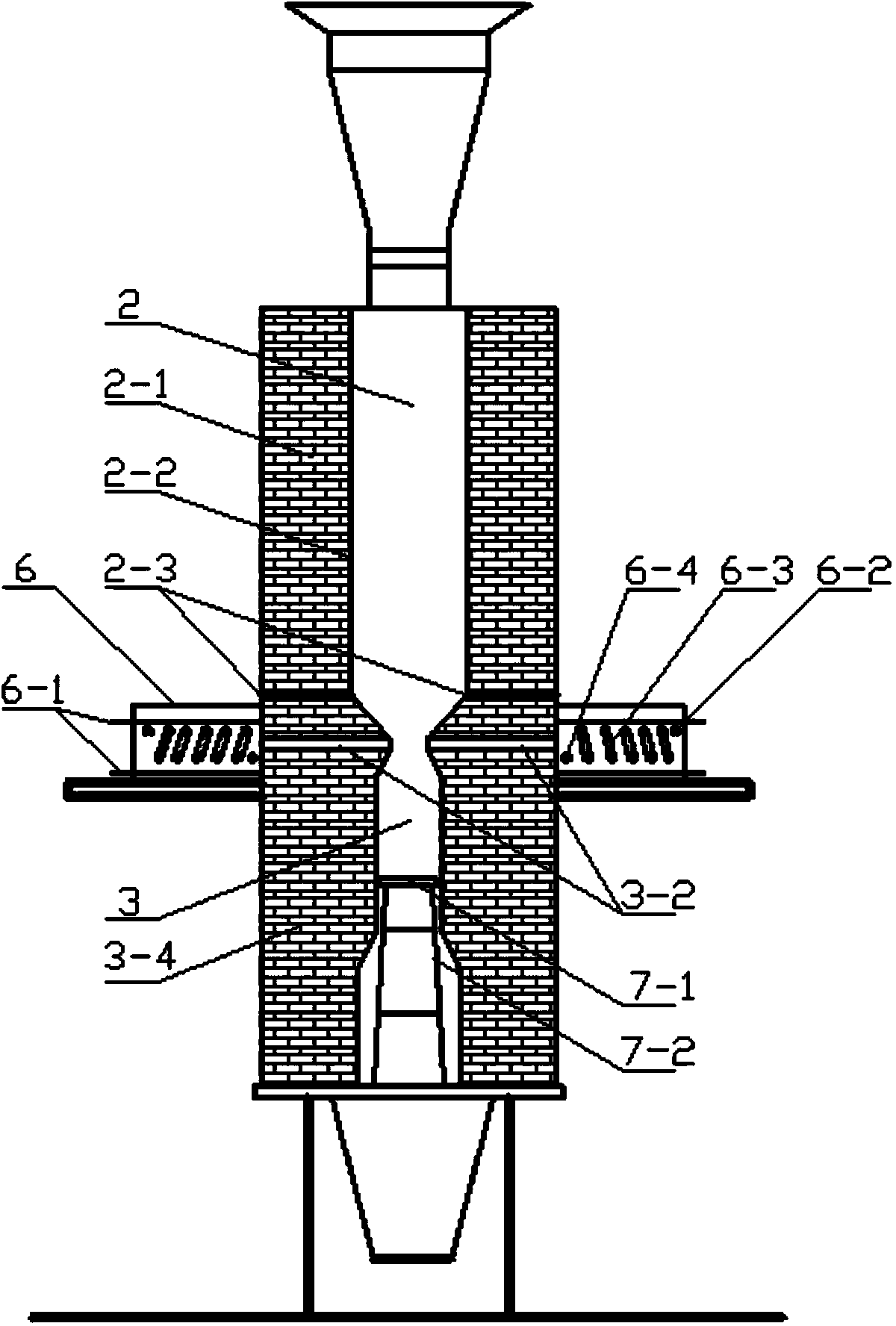

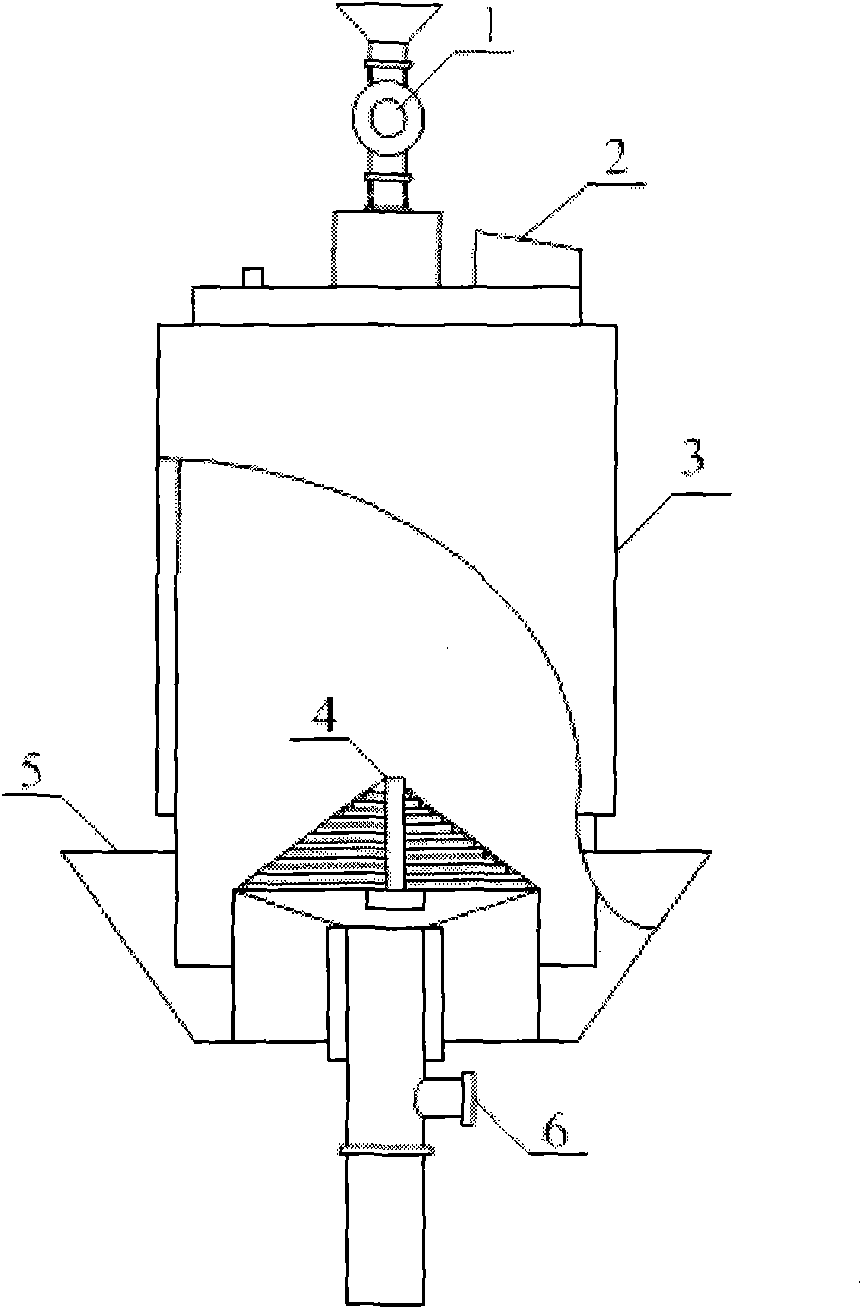

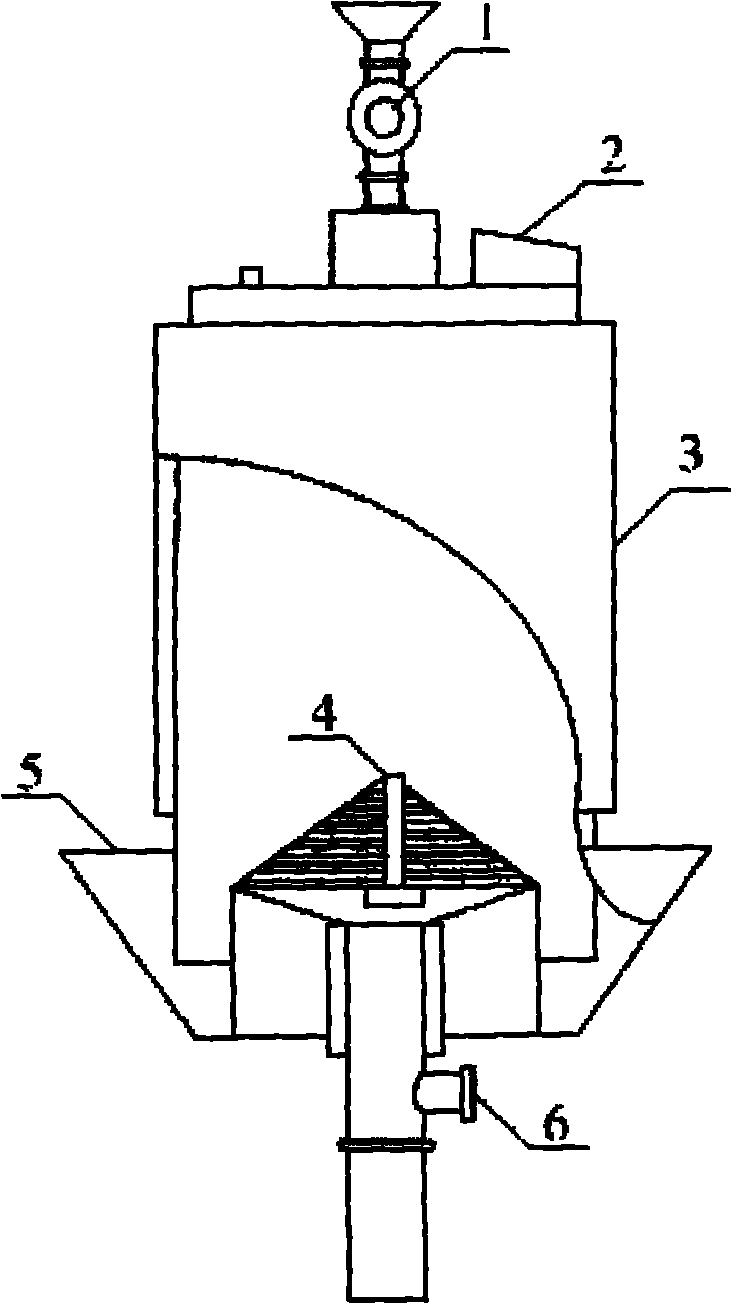

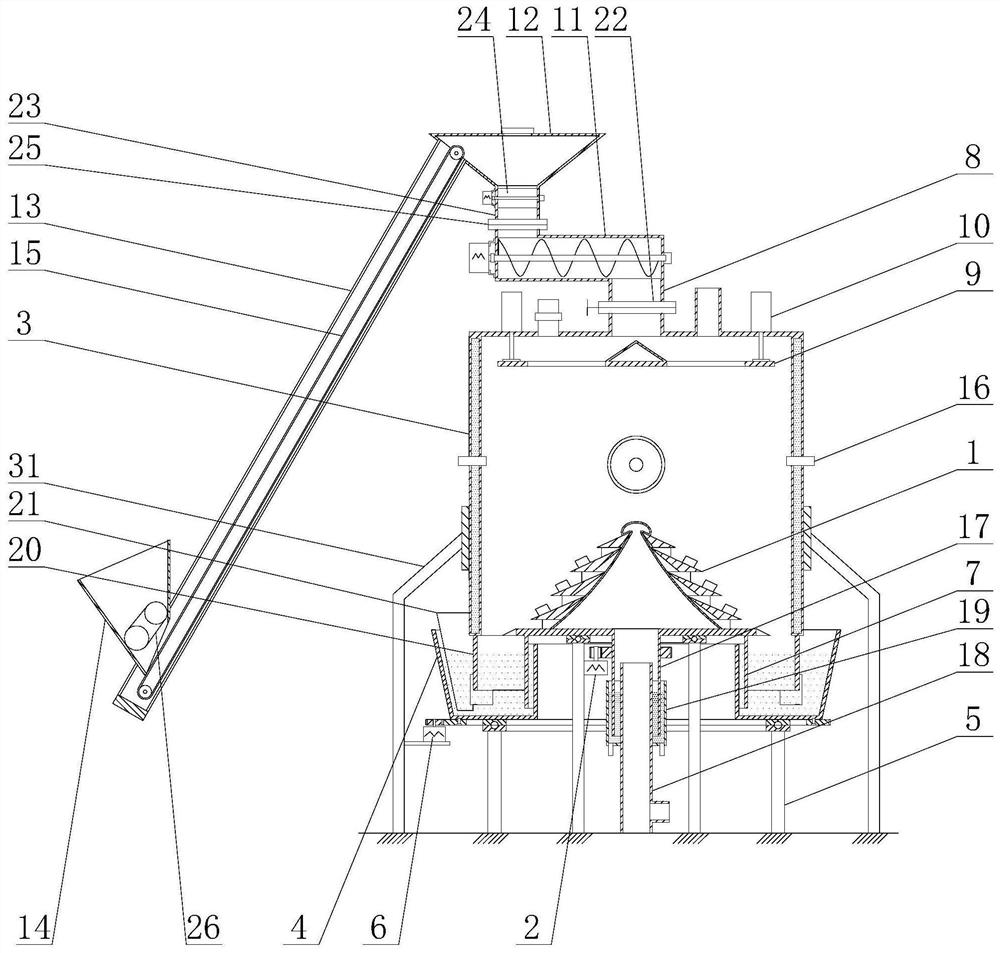

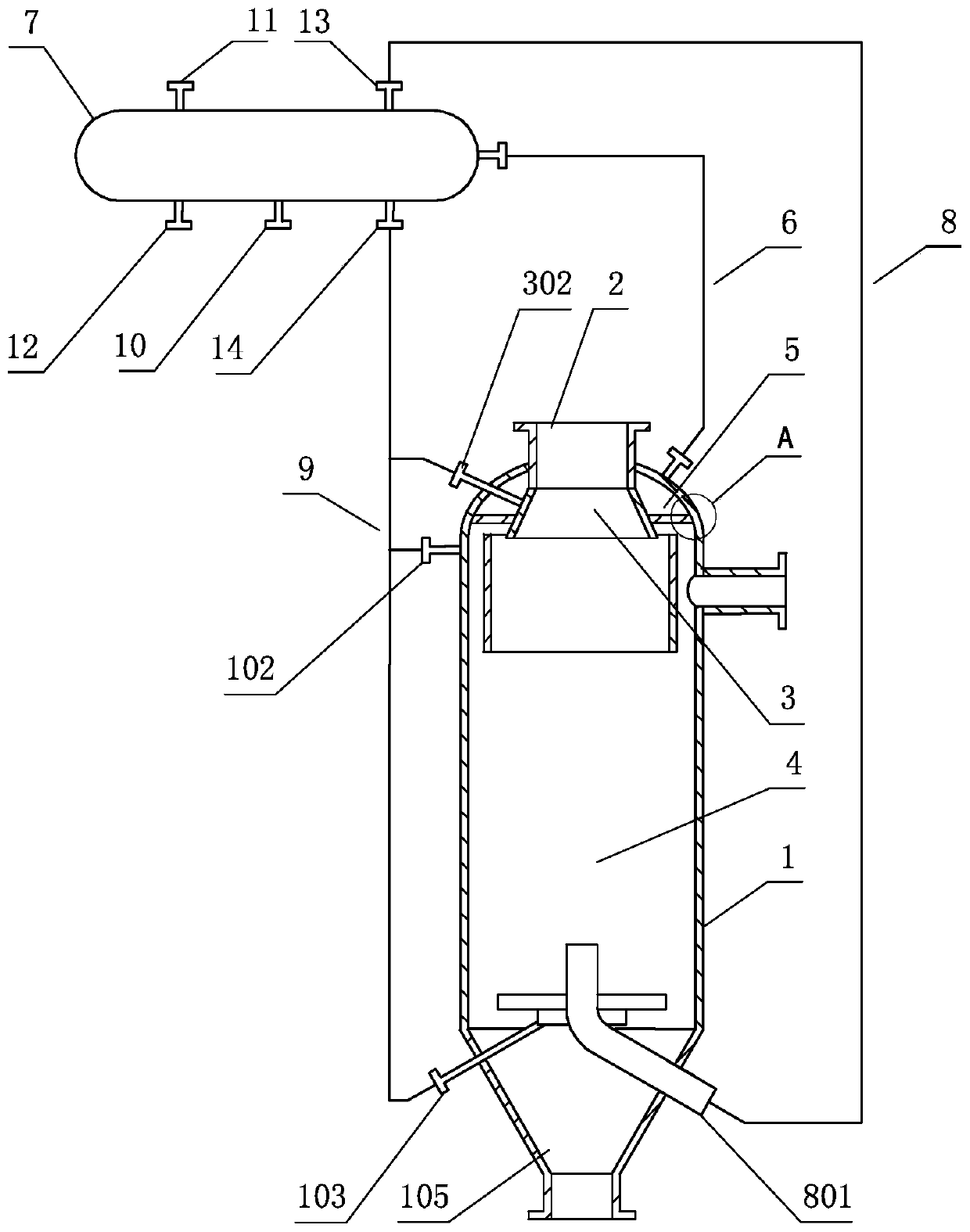

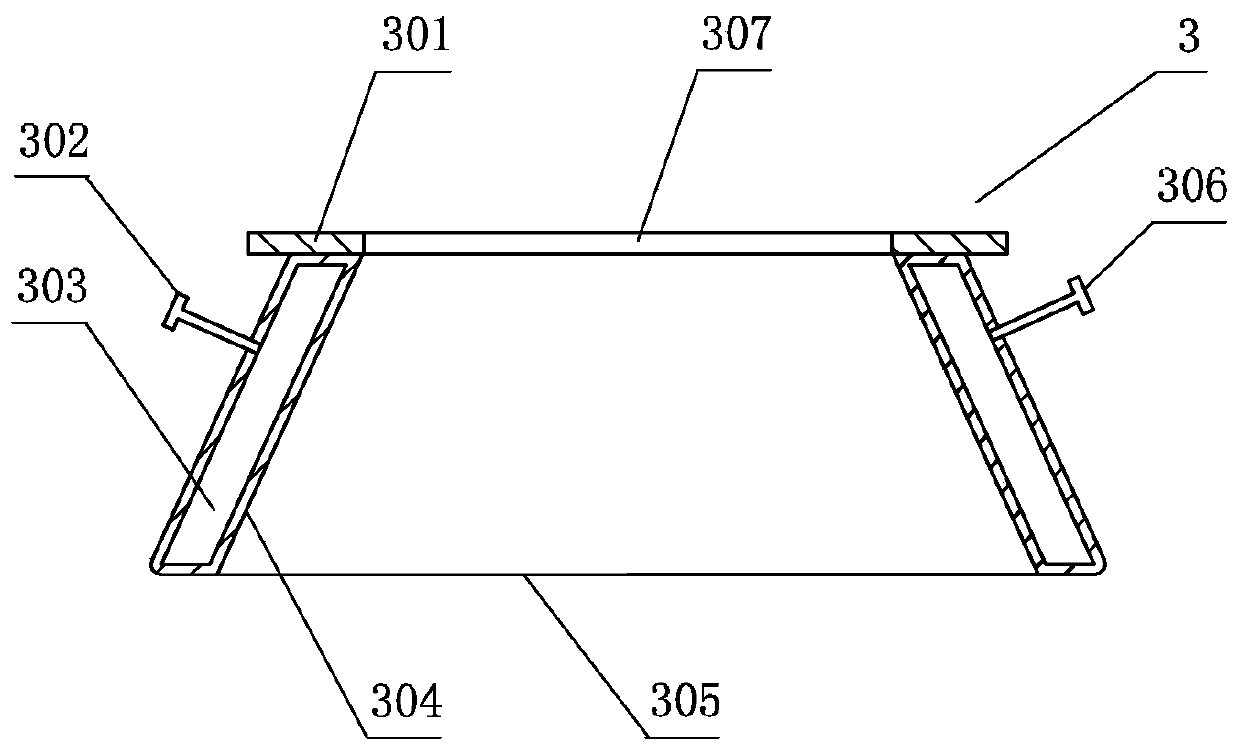

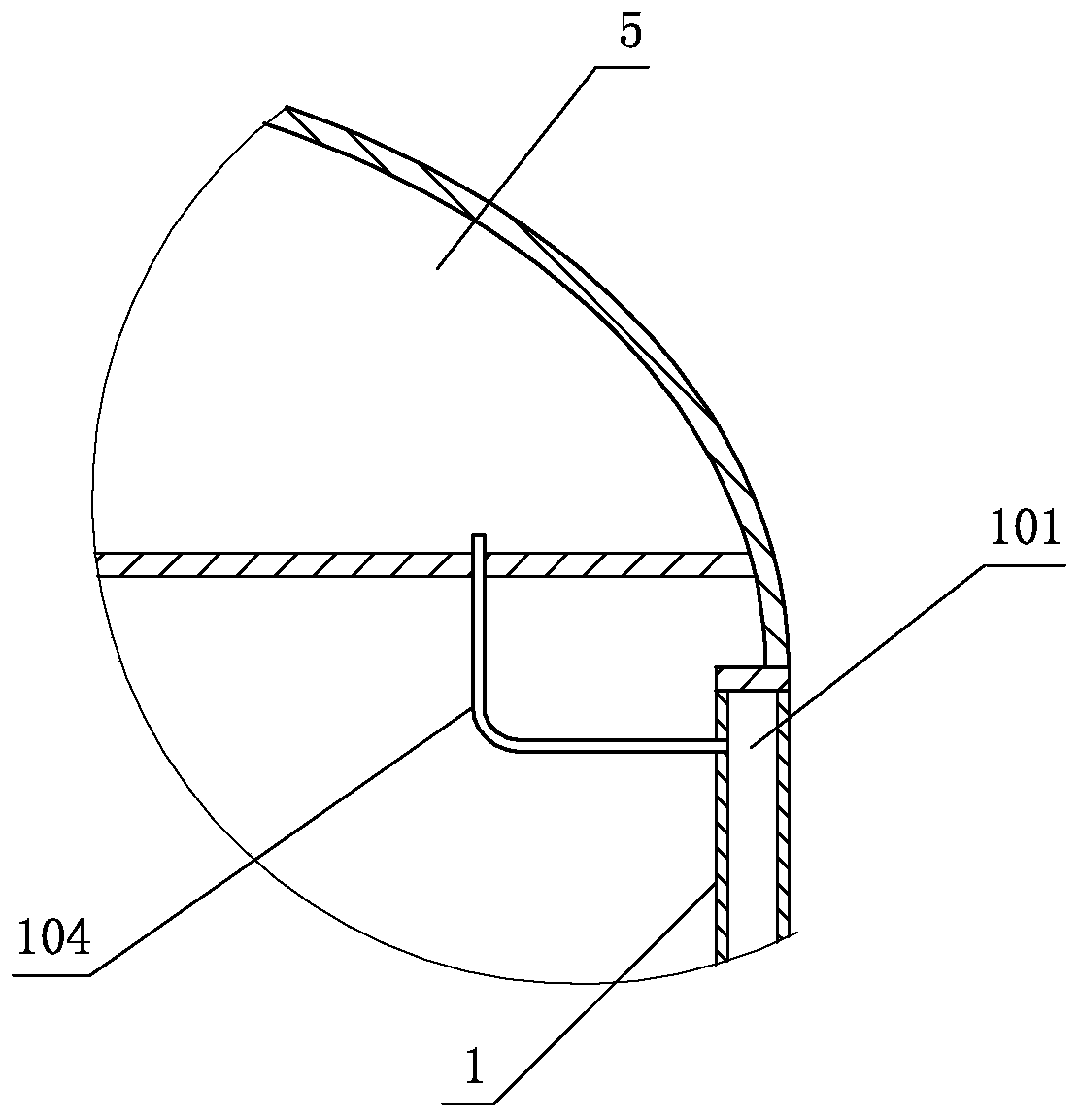

Large-scale fixed bed biomass gasification furnace and production process of gas with low oxygen content

InactiveCN101892084AOverall high thermal efficiencyImprove gasification efficiencyFixed-bed gasificationBriquetteCorrosion

The invention discloses a biomass (especially briquette straw) gasification furnace, in particular a fixed bed gasification furnace with an anticorrosion liner which can effectively prevent corrosion of alkali metals on the furnace wall. The gasification furnace comprises a charging device (1), a gas discharge port (2), a furnace body (3), a grate (4), a dust discharge port (5), an air inlet (6) and the like. The raw material is continuously added from the upper part and moves downwards under the action of gravitation to form a stable reduction layer (completely reacts with oxygen in air), and slag is discharged from the bottom; and air enters from the lower part, and gas is discharged from the upper part. The inner diameter of the gasification furnace is 3 m, the height is more than 3 m, and the gasification intensity is at least 100 m<3> / (m<2>h). The carbon conversion rate of the gasification furnace can reach 95%, and the oxygen content of gas can be below 0.6%. The invention has the advantages of high production capacity, long operating cycle and good gas quality, and can be used for combustion or power generation.

Owner:EAST CHINA UNIV OF SCI & TECH +2

Low-tar double-bed gasifying method and device

InactiveCN108085063AFlexible operationWide adaptabilityCombustible gas catalytic treatmentGasification processes detailsCycloneFixed bed

The invention discloses a low-tar double-bed gasifying method and a low-tar double-bed gasifying device. The low-tar double-bed gasifying device comprises a fluidized bed, a fixed bed, a primary cyclone separator, a secondary cyclone separator and a material returning device, wherein oxidant inlets and catalyst jetting orifices are formed in the upper space of a lean-phase zone of the fluidized bed. After biomass enters a fluidized bed gasifier and is gasified, a gasified product sequentially passes through a catalytic cracking section and an oxygen-enriched combustion section, so that the tarcontent of the gasified product can be effectively reduced and the fuel gas quality can be improved. Gas-solid separation is performed on reacted gas through the primary cyclone separator and the secondary cyclone separator, a solid product returns to the fixed bed through two returns to form a fixed catalytic bed layer, a gas product enters the upper space of the fixed bed and passes through thecatalytic bed layer, a tar component in the gas product is catalytically cracked, and finally combustible gas is produced after a secondary gasification reaction. The produced gas product is low in tar content and high in quality after multiple reactions; the low-tar double-bed gasifying device is strong in adaptability to raw materials, small in floor area and compact in structure, and the raw material utilization rate is high.

Owner:SOUTHEAST UNIV

Differential rotating bed continuous feeding biomass gasification furnace

InactiveCN112126468AAdjustable speedNot easy to slaggingProductsGasifier feeding meansProcess engineeringBiomass gasifier

The invention discloses a differential rotating bed continuous feeding biomass gasification furnace, and mainly relates to the technical field of energy science. The furnace comprises a furnace body,an air distribution disc and an air disc driving device for driving the air distribution disc to rotate are arranged in the furnace body, the furnace body comprises a cylinder body and a cylinder bodysupport located on the outer side of the cylinder body and used for supporting the cylinder body, an ash bin is arranged on the lower side of the cylinder body, and an ash bin driving device for driving the ash bin to rotate is arranged on the cylinder body support. A blanking pipe is arranged at the top of the furnace body, a conical distributor is arranged on the lower side of the blanking pipe, a spiral sealing feeder is arranged at the top of the blanking pipe, a buffer bin is arranged at the top of the end, away from the blanking pipe, of the spiral sealing feeder, and a feeding barrel with the closed bottom end is obliquely arranged on one side of the buffer bin. The biomass gasification furnace can realize continuous sealed feeding in the gasification process, can effectively prevent partial burning deviation and burning through, is easy to control the thickness of an ash layer, can enhance the disturbance of biomass in the furnace, and improves the gasification strength.

Owner:山东信科环境科学研究院有限公司

A pressurized gasification process for simultaneously gasifying pulverized coal and coal-water slurry

ActiveCN104531219BSimple structureHigh failure rateGasification apparatus detailsGranular/pulverulent flues gasificationFire brickProcess engineering

The invention relates to a pressure gasification process for simultaneously gasifying powdered coal and coal water slurry. The pressure gasification process is characterized in that a purpose-made gasification furnace is used, the gasification furnace is provided with a purpose-made powdered coal burner and a start-up burner and capable of simultaneously processing the coal water slurry and the powdered coal; gasification comprises the following steps of carrying out ignition start-up, igniting the powdered coal burner, increasing the temperature and pressure of the gasification furnace and a carbon washing tower, igniting a coal water slurry burner, increasing the pressure inside a gasification chamber, and controlling continuous gasification under a specific reaction condition. The pressure gasification process disclosed by the invention can be used for solving the problems of low effective component, high requirement on the quality of coal fed into the furnace, short life of the coal water slurry burner, short operation time of a single furnace, short life of a refractory brick, low coal slurry concentration and the like of a synthetic gas obtained through the traditional coal water slurry and solving the problems of large investment, complex equipment, high comprehensive energy consumption and the like of the traditional powdered coal gasification process.

Owner:SINOPEC NINGBO ENG +2

Coke-containing solid particle two-stage gasification method and device

InactiveCN105713675AFast gasification rateContinuous gasificationGranular/pulverulent flues gasificationSyngasProcess engineering

Owner:PETROCHINA CO LTD

A biomass solid waste and hazardous waste treatment system

ActiveCN104819470BEasy to handleEmission reductionEmission preventionIncinerator apparatusFixed bedEngineering

The invention discloses a biomass solid waste and hazardous waste treatment system. The biomass solid waste and hazardous waste treatment system sequentially performs pretreatment, feeding, pyrolysis gasification and combustion gas production on materials and performs flue gas treatment on the produced exhaust gas. The combustion temperature of a pyrolysis gasification furnace is controlled at 700 DEG C-900 DEG C to avoid the problem of coking proneness of a fixed bed. The overall operating environment is a reducing atmosphere for effectively suppressing the production of NOx, overall materials in the bed is high in disturbance, and the overall gas production amount and the overall gas production rate are stable. The gas produced by a pyrolysis gasification bed can fully burn and burn out waste liquid and ash produced by the pyrolysis gasification bed to further reduce carbon residue values of the ash and complete eliminate the waste liquid. A bubbling fluidized bed combustion column uses the pyrolysis gasification bed ash as a bed material, and the air entering the combustion column prompts the fluidization of materials in the furnace.

Owner:山东知周环境科技有限公司

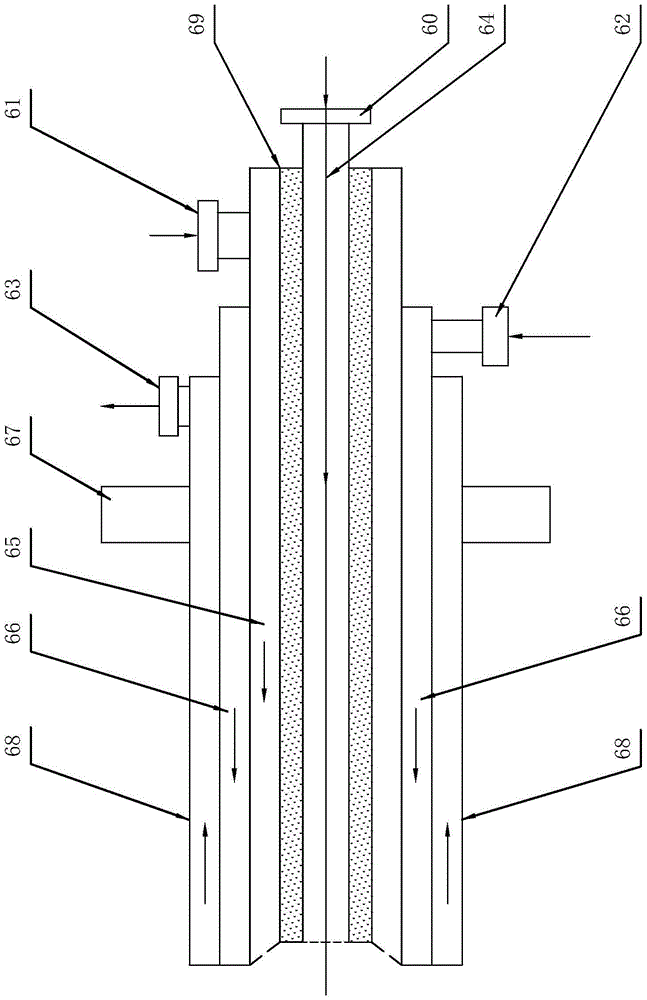

Furnace body cooling device of coal gasifier

PendingCN111321014AIncrease the heating areaIncrease productionCombustible gas productionThermodynamicsCoal gasifier

The invention relates to a furnace body cooling device of coal gasifier, a feed coal inlet pipe section is arranged at the top of a furnace body, and a gasification reaction hearth is arranged in themiddle of the furnace body; a coal distribution section cooling water jacket device is arranged on the taper-pipe-shaped coal distribution section, a first water supply pipe connector is arranged on one side of the coal distribution section cooling water jacket device, and a coal distribution section steam outlet pipe is arranged on the other side; a furnace body cooling water jacket device is arranged on the outer wall of the furnace body, a second water supply pipe connector is arranged on one side of the furnace body cooling water jacket device, and a furnace body steam outlet pipe is arranged on the other side of the furnace body cooling water jacket device; the steam supply pipeline is communicated with an input port of a gasifying agent pipe at the bottom of the furnace body, and acooling water outlet pipe joint and a make-up water pipe joint are arranged at the bottom of the steam collector and respectively communicated with a first water supply pipe joint and a second water supply pipe joint through cooling water distribution pipelines.

Owner:INNER MONGOLIA HUAXING NEW ENERGY

Hydrogen-assisted combustion coal gasification boiler

InactiveCN103244948AIncrease gasification strengthDispersed particle separationHydrogen productionBrickGamma ray

The invention discloses a hydrogen-assisted combustion coal gasification boiler. The boiler comprises a coal feeding device and a cylindrical coal gas combustion heat accumulation device which is encircled by refractory bricks. The coal feeding device on the upper portion of a boiler body is provided with a primary automatic seal, a secondary automatic seal and a vacuum pipe. One to twelve antimatter gamma ray emitters are arranged at the front section of the periphery of the heat accumulation device and enable matters and antimatters of coal gas to annihilating, so that energy is produced, and the combustion value is improved. One to twelve iron oxide plates and one to twelve steam spray nozzles are arranged on the inner circumference at the tail end of the heat accumulation device, steam interval pulses are sprayed to impact on the high-temperature iron oxide plates, and accordingly, water decomposes into hydrogen and oxygen to assist combustion, and heat is transferred through a cylindrical inclined cellular boiler. A discharge flue heat transfer device is arranged at the front section of a discharge flue, and a plasma discharger is composed of an air blower and one to twenty four tubular high-frequency pulse dischargers, so that hot gas after heat transfer and a part of processed humid and hot gas are sucked by a backflow gas pipe to be mixed and heated with a small part of coal gas through a pipeline to serve as a compound gasification agent, and the compound gasification agent is supplied to a gas producer, and steam and carbon molecules are subjected to oxidizing reaction to generate CO and H2, accordingly, compared with a conventional gas producer, the gasification strength of the gas producer is improved by more than 4 times.

Owner:金大盛

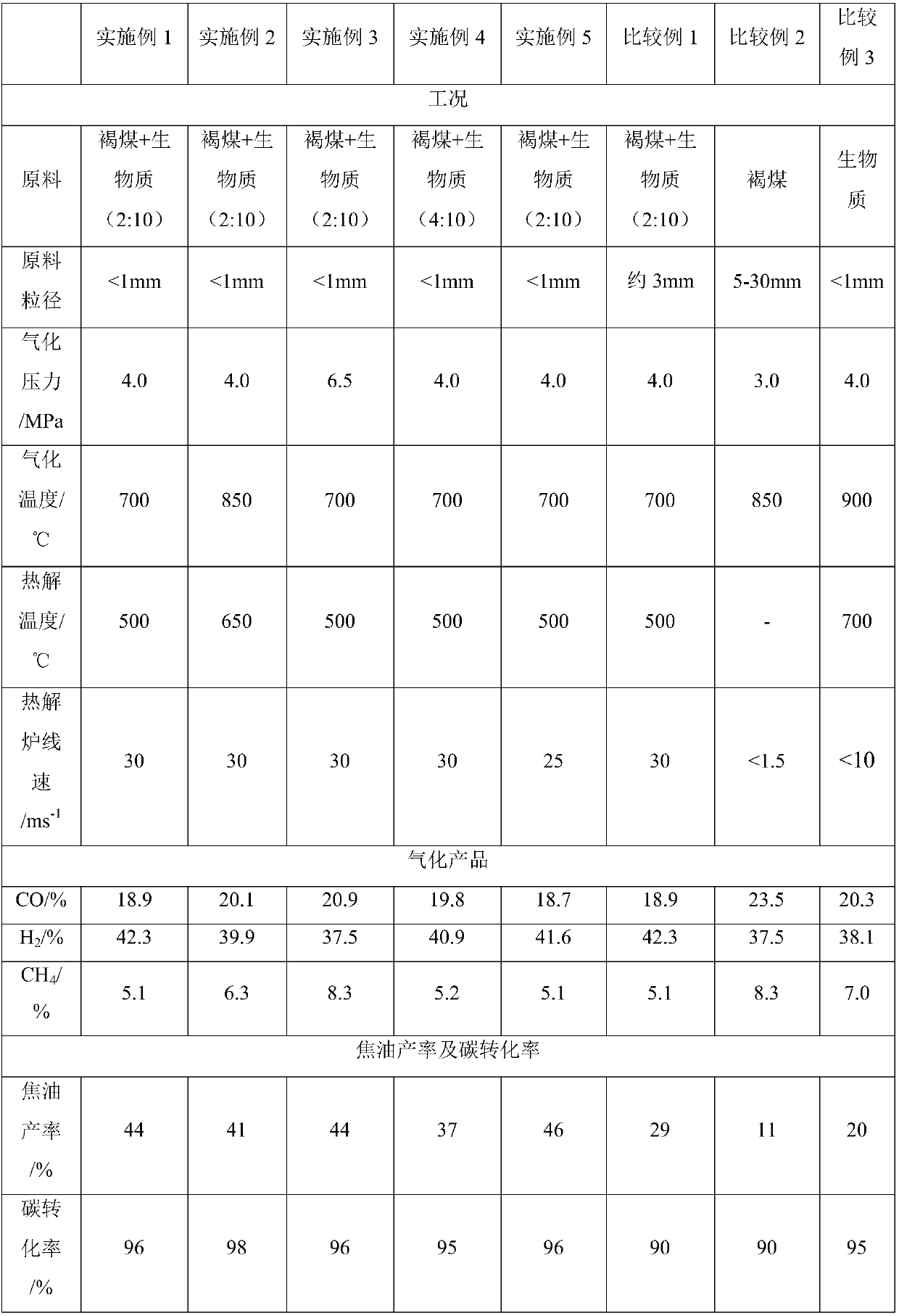

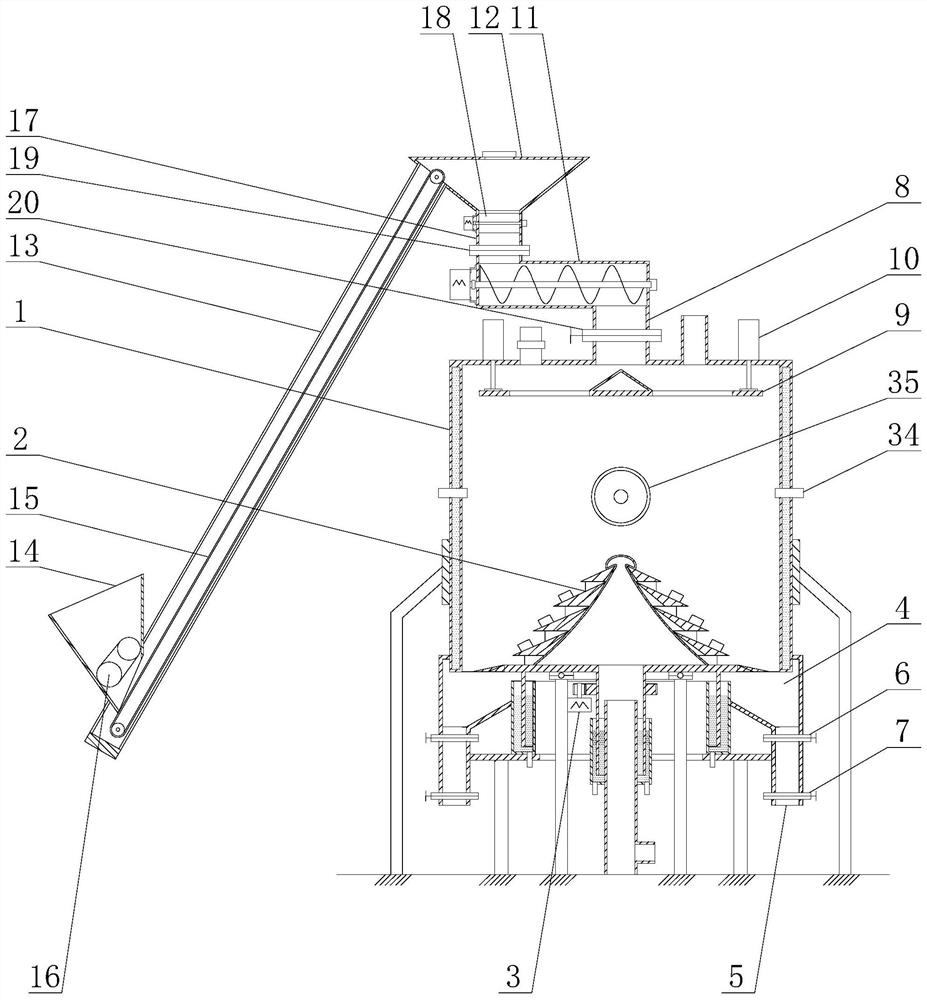

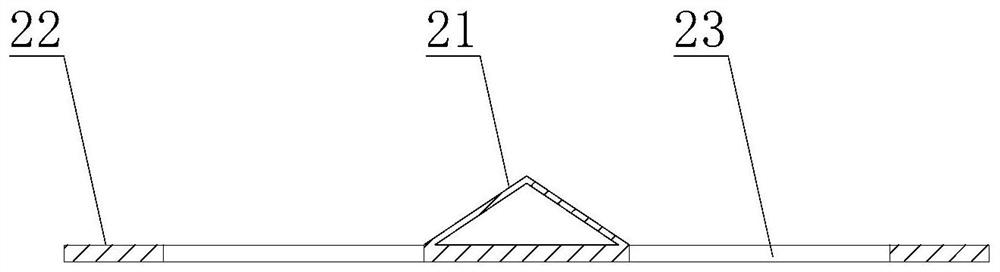

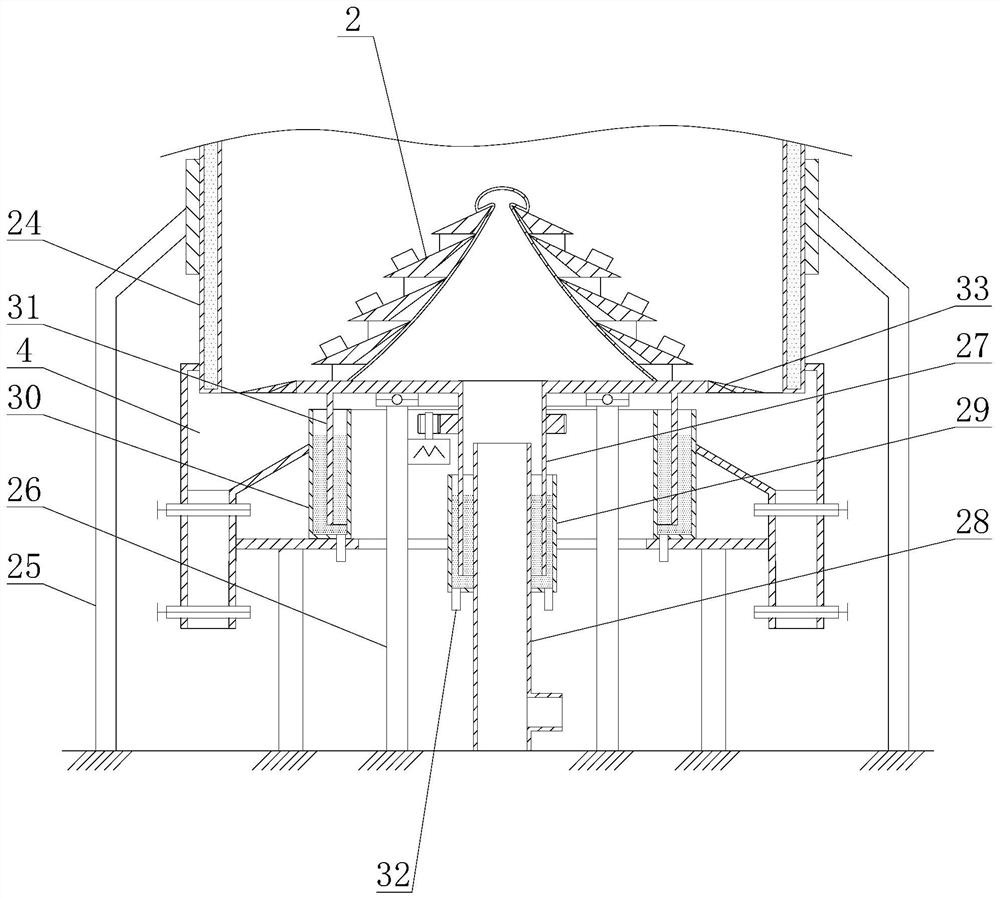

Gasification-flash pyrolysis graded utilization method for biomass and low-rank coal

ActiveCN107916141AReduce energy consumptionEnsure synergyGasification processes detailsCombustible gas productionHeat carrierTar

The invention relates to a gasification-flash pyrolysis graded utilization method for biomass and low-rank coal and mainly solves the problems that the tar yield is low, the low-rank coal is difficultto use and excessively depends on heat carriers and the like in the prior art. The method adopts combination of technologies for preparing synthesis gas through gasification and preparing tar throughflash pyrolysis and mainly comprises steps as follows: a mixture of biomass and the low-rank coal enters a pyrolysis furnace through a feeding device, is heated by high-temperature circulating semi-coke from a gasifier and is subjected to flash pyrolysis at a high linear speed, volatile components are separated out, and semi-coke is obtained; the volatile components are fed into a condenser by agas-solid separation device and is condensed, a tar product with biomass oil as a main component is obtained, the semi-coke is fed into the gasifier and reacts with a gasifying agent, and the synthesis gas and the high-temperature circulating coke are produced; after separation, the synthesis gas is purified by a purification device and processed into a chemical raw material, and the high-temperature circulating semi-coke is fed into a pyrolysis furnace and supplies heat continuously to the raw materials for pyrolysis. The method can be applied to the technical field of the coal chemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

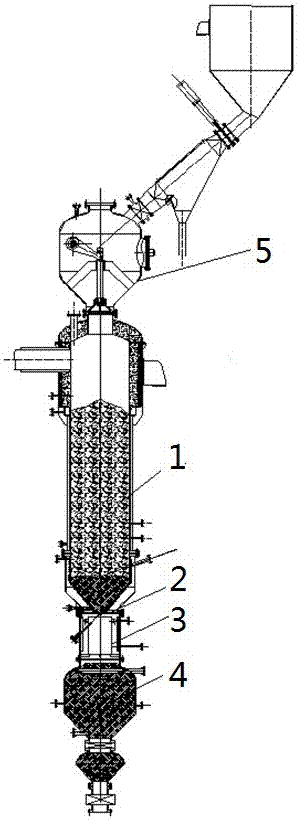

Dry deslagging continuous feeding biomass gasification furnace

The invention discloses a dry deslagging continuous feeding biomass gasification furnace, and mainly relates to the technical field of energy science. The dry deslagging continuous feeding biomass gasification furnace comprises a furnace body, an air distribution disc is arranged in the furnace body, a slag storage chamber is arranged on the outer side of the bottom of the air distribution disc and fixedly connected with the furnace body, a plurality of slag discharging pipes are arranged at the bottom of the slag storage chamber, upper inserting plates used for sealing the slag discharging pipes are arranged on the upper portions of the slag discharging pipes, and lower inserting plates used for sealing the slag discharging pipes are arranged on the lower portions of the slag dischargingpipes. Wherein a blanking pipe is arranged at the top of the furnace body, a conical distributor is arranged on the lower side of the blanking pipe, a spiral sealing feeder is arranged at the top of the blanking pipe, and a buffer bin is arranged at the top of one end, far away from the blanking pipe, of the spiral sealing feeder; continuous sealed feeding in the gasification process can be achieved, a material layer in the furnace body can be prevented from being fluffy, local partial burning deviation and burning through can be effectively prevented, the gasification strength can be improved, water consumption can be reduced, the ash utilization range can be enlarged, and overheating burning loss of the air distribution disc can be prevented.

Owner:山东信科环境科学研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com