Patents

Literature

45 results about "Carbon utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A series of processes that forms an integrated mechanism by which a cell or an organism detects the depletion of primary carbon sources and then activates genes to scavenge the last traces of the primary carbon source and to transport and metabolize alternative carbon sources such as carbon dioxide or carbonic acid. The utilization process begins when the cell or organism detects carbon levels, includes the activation of genes whose products detect, transport or metabolize carbon-containing substances, and ends when carbon is incorporated into the cell or organism's metabolism. [GOC:mah, GOC:mlg]

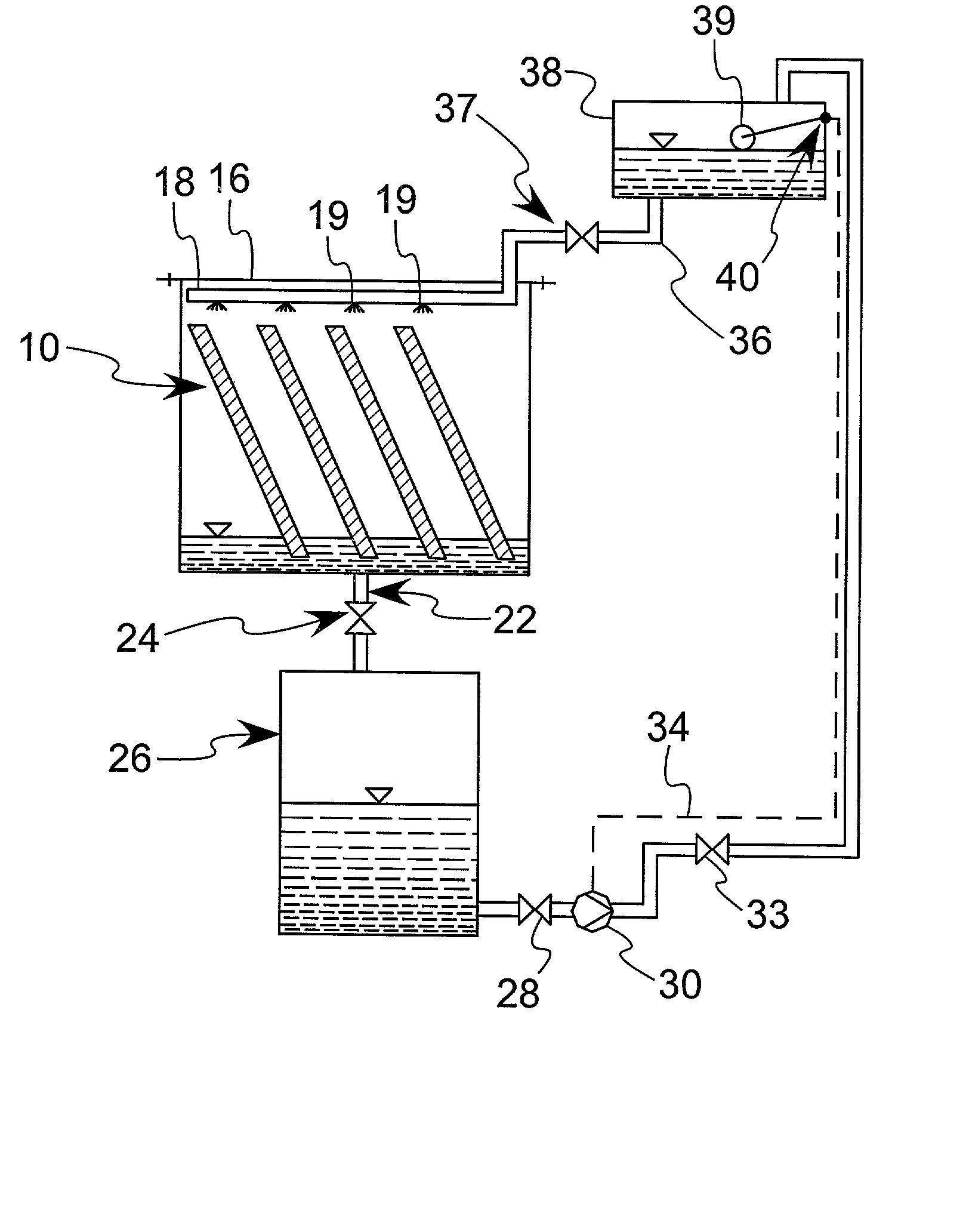

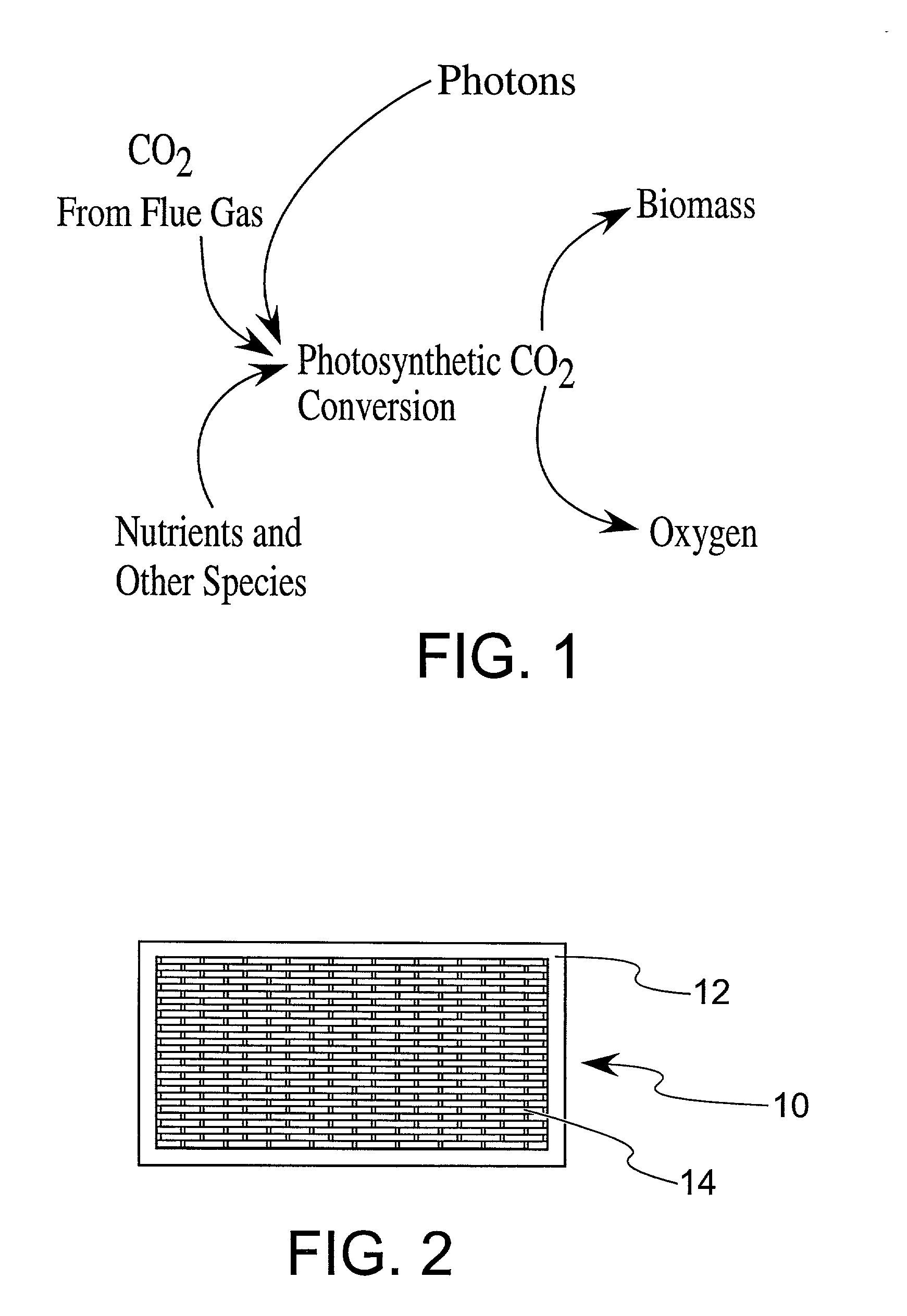

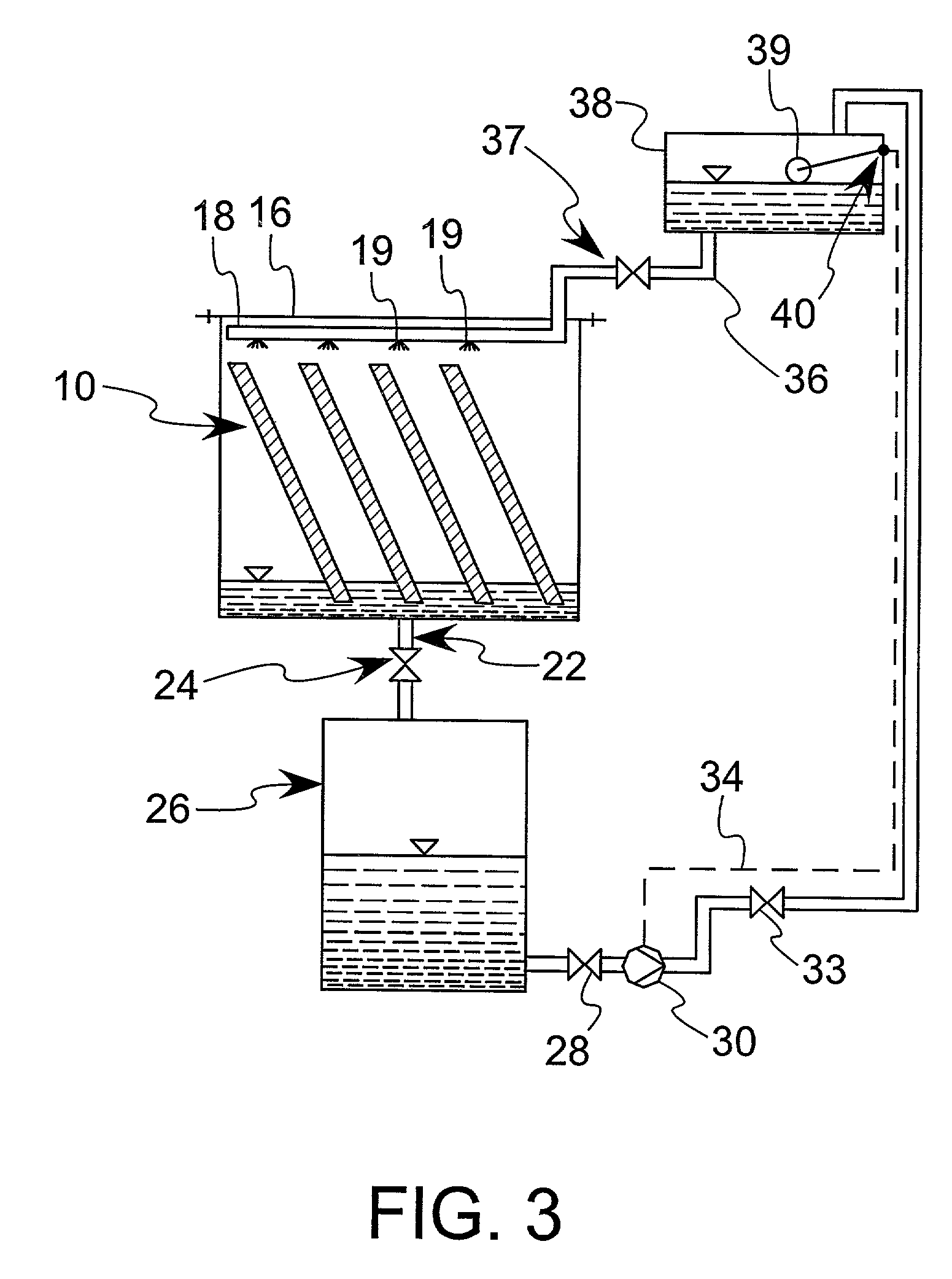

Enhanced practical photosynthetic CO2 mitigation

InactiveUS20020072109A1Increase the amount of waterBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismCyanobacteria

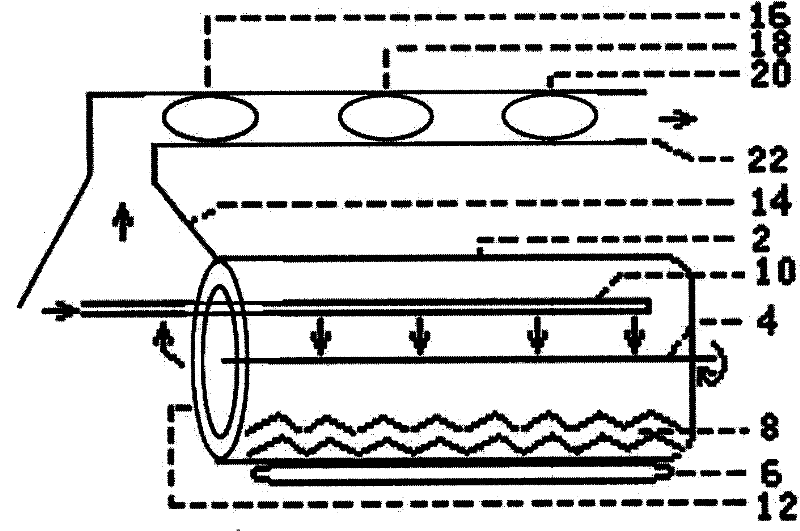

This process is unique in photosynthetic carbon sequestration. An on-site biological sequestration system directly decreases the concentration of carbon-containing compounds in the emissions of fossil generation units. In this process, photosynthetic microbes are attached to a growth surface arranged in a containment chamber that is lit by solar photons. A harvesting system ensures maximum organism growth and rate of CO2 uptake. Soluble carbon and nitrogen concentrations delivered to the cyanobacteria are enhanced, further increasing growth rate and carbon utilization.

Owner:OHIO UNIV

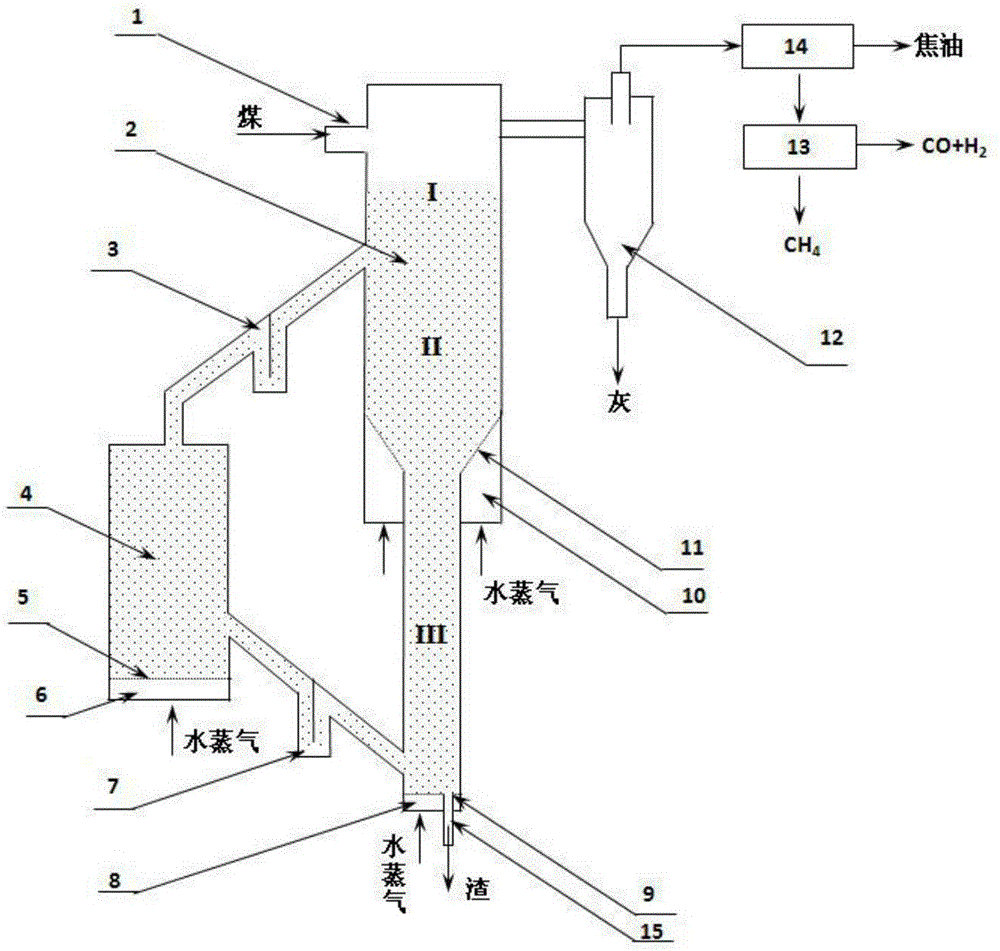

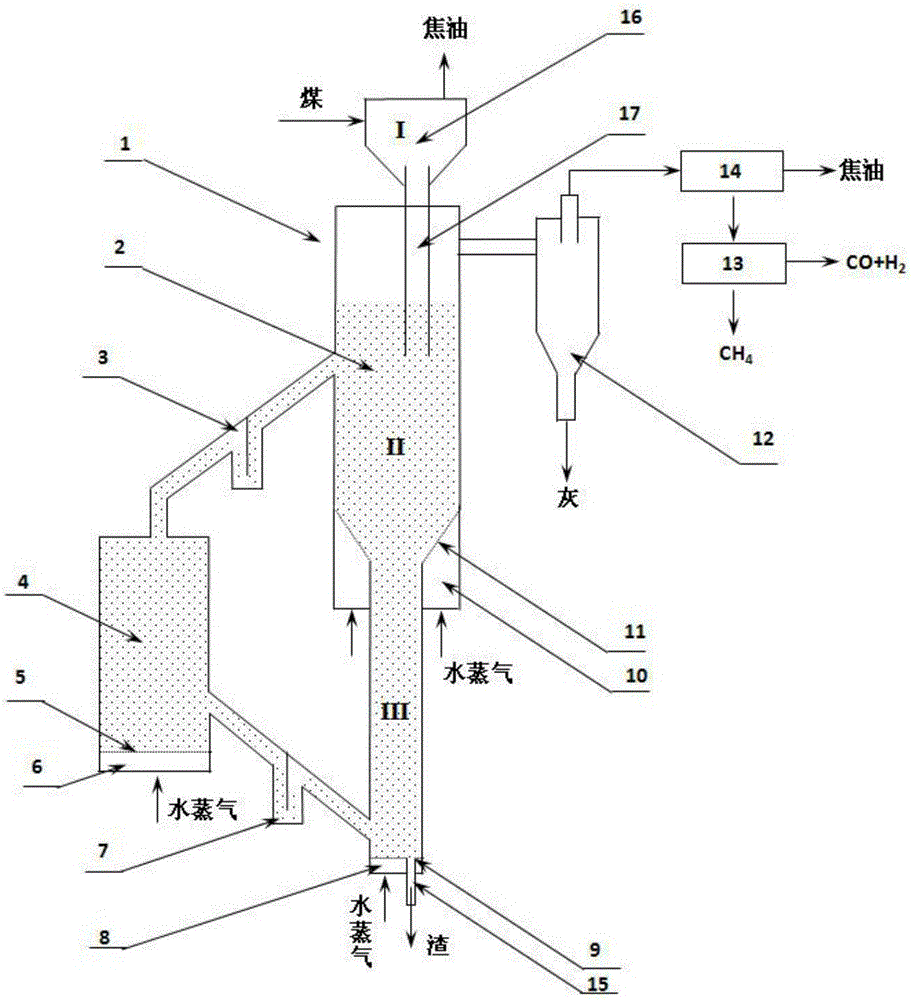

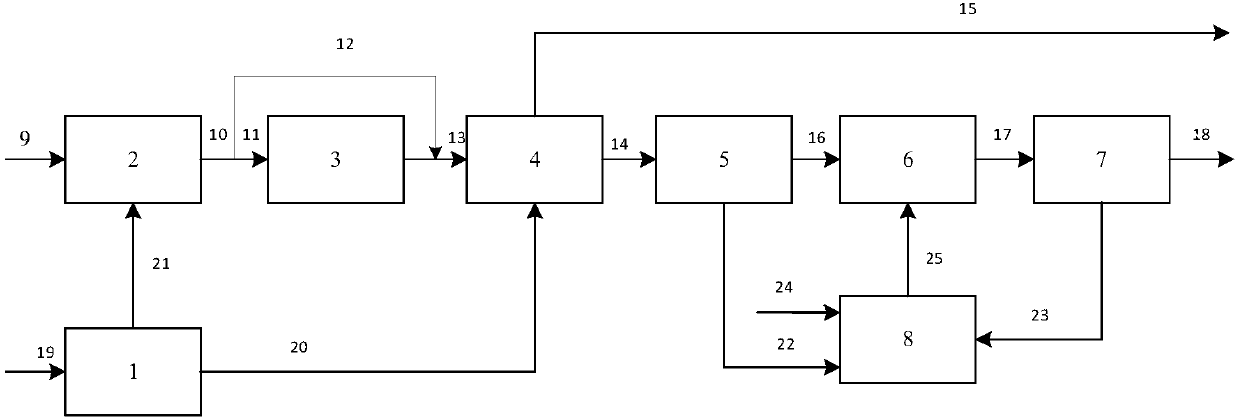

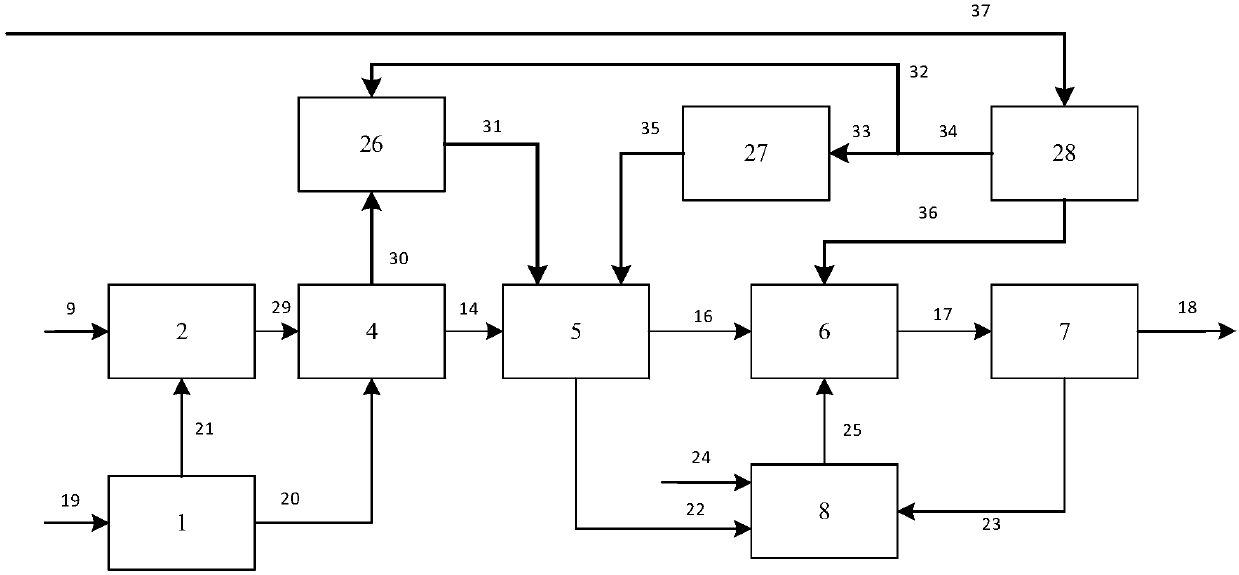

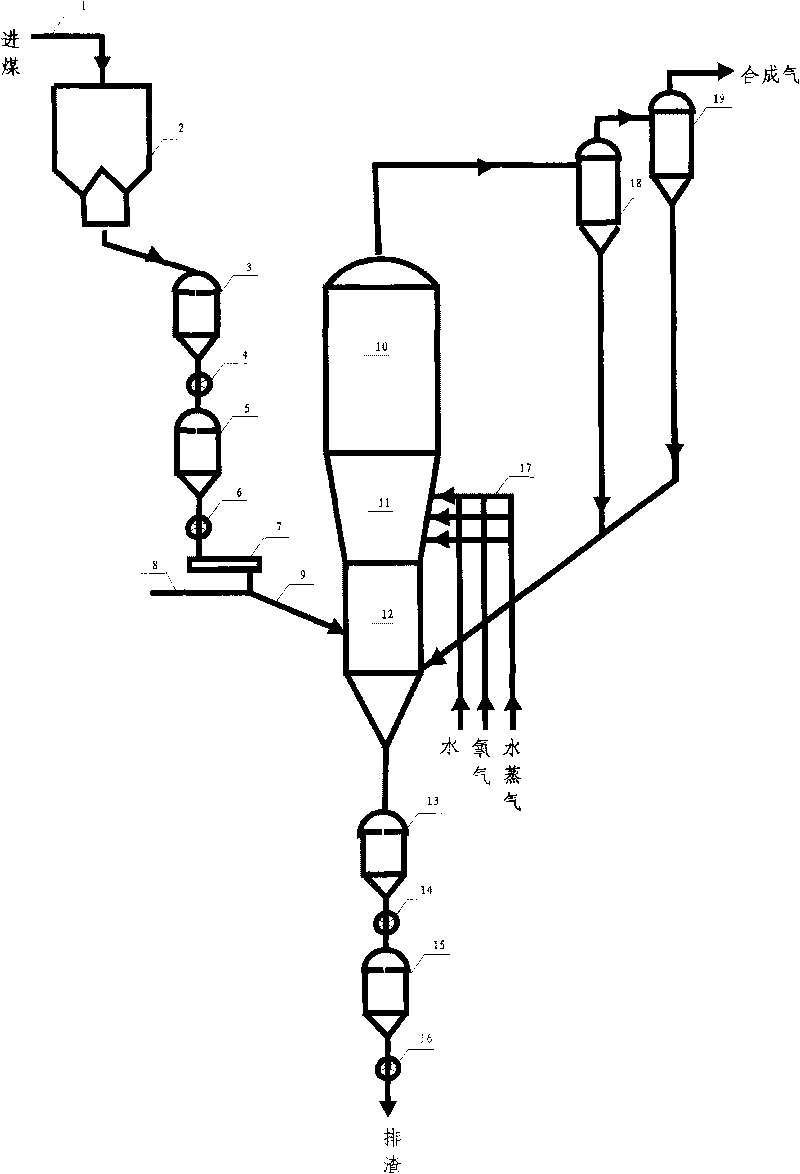

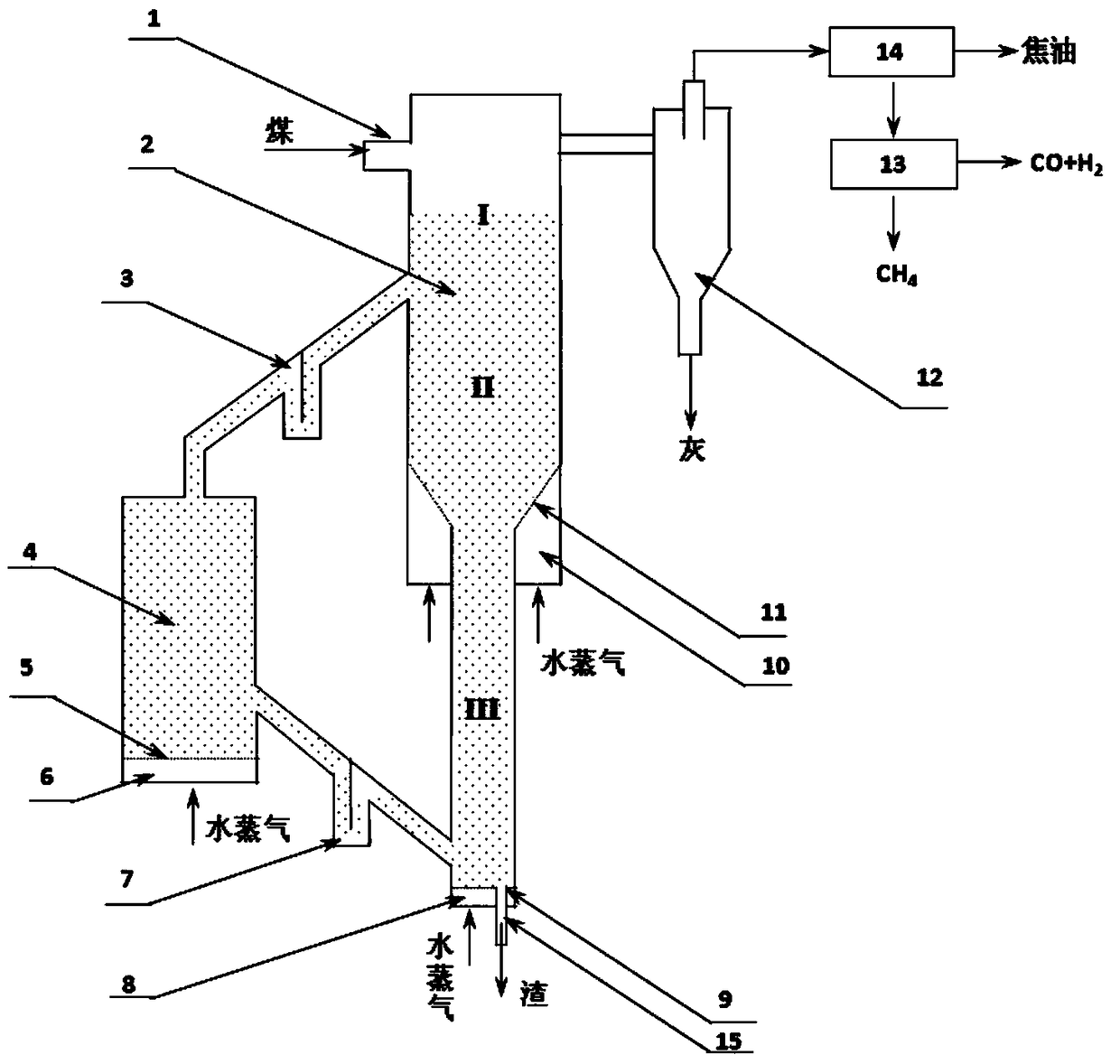

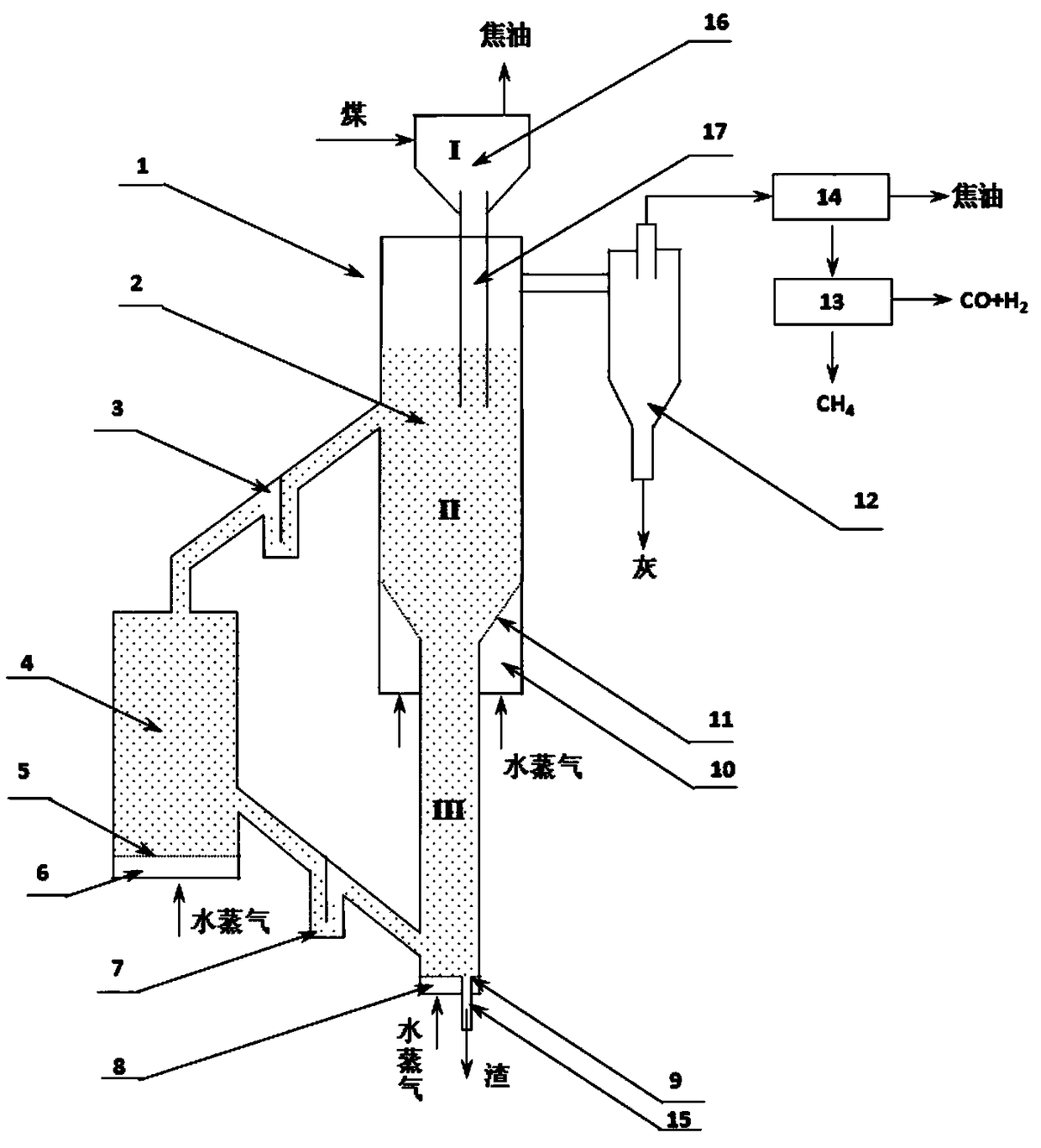

Device and method for directly preparing methane based on coal chemical chain gasification

ActiveCN106220461AReduce consumptionReduce generationHydrocarbon from carbon oxidesCatalystsMethanationSlag

The invention belongs to the technical field of preparation of substitutive natural gas from coal, and relates to a device and method for directly preparing methane based on coal chemical chain gasification. Pulverized coal particles pass through the upper portion of a chemical chain gasification reactor and enter a chemical chain gasification reactor, oxidation state multifunctional composite oxygen carrier particles and unreacted carbon in the pulverized coal particles enter a regeneration reactor on the upper portion of a coal methanation section through a first flowing control device, coal slag obtained after reacting is discharged through a slag discharging opening, gas separated by a cyclone separator sequentially passes through a gas purifying unit and a gas separation unit, methane gas is obtained, and coal ash obtained after separation of the cyclone separator, part of unreacted carbon and the oxidation state multifunctional composite oxygen carrier particles return to the chemical chain gasification reactor or the regeneration reactor again to be recycled. The device is simple in structure and convenient to operate, the process theory is scientific, the raw materials are easy to obtain, cost is low, thermal efficiency is high, the carbon utilization efficiency is high, fewer pollutants are generated, and environmental friendliness is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

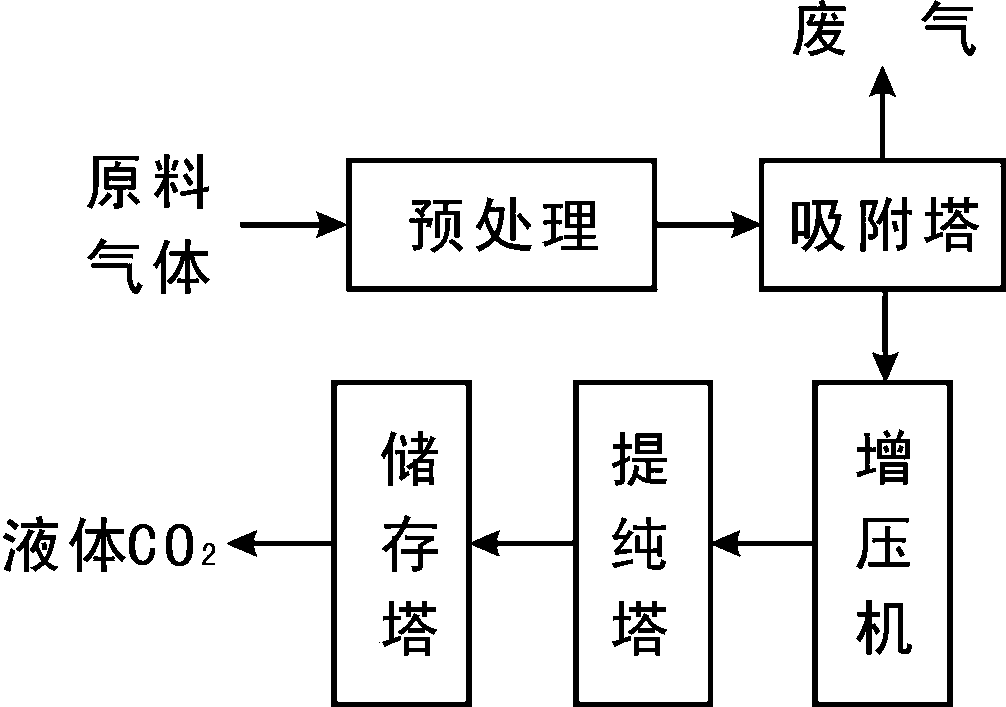

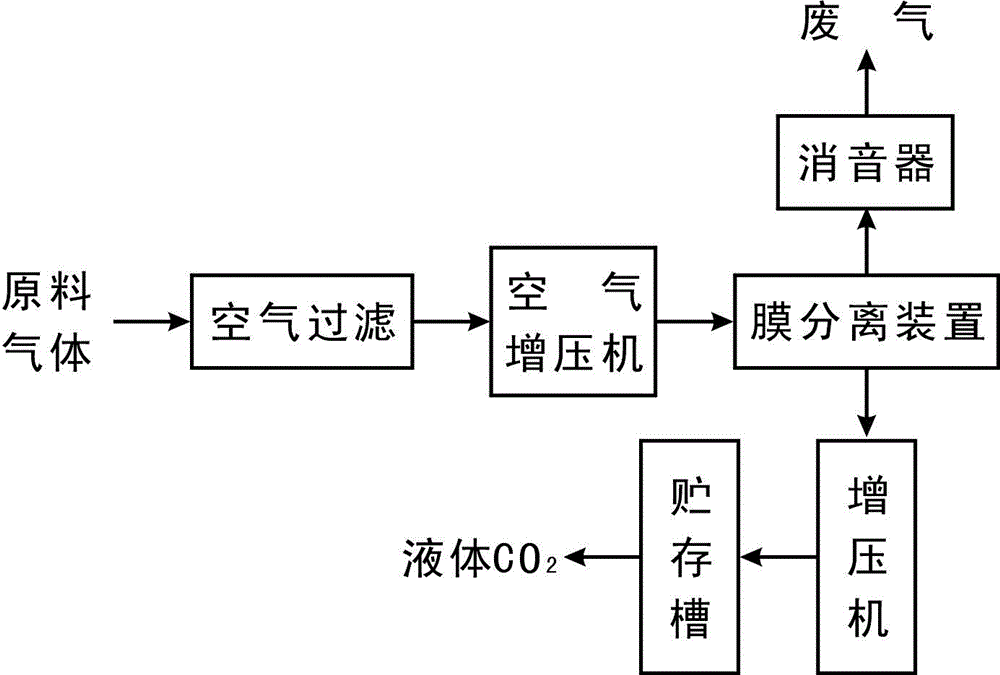

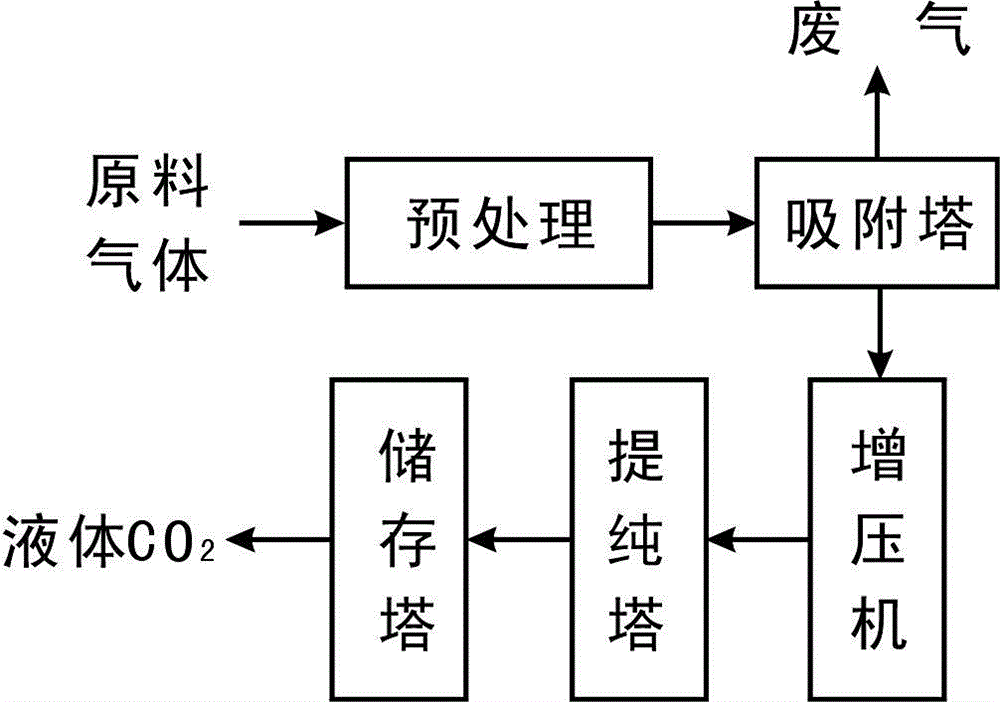

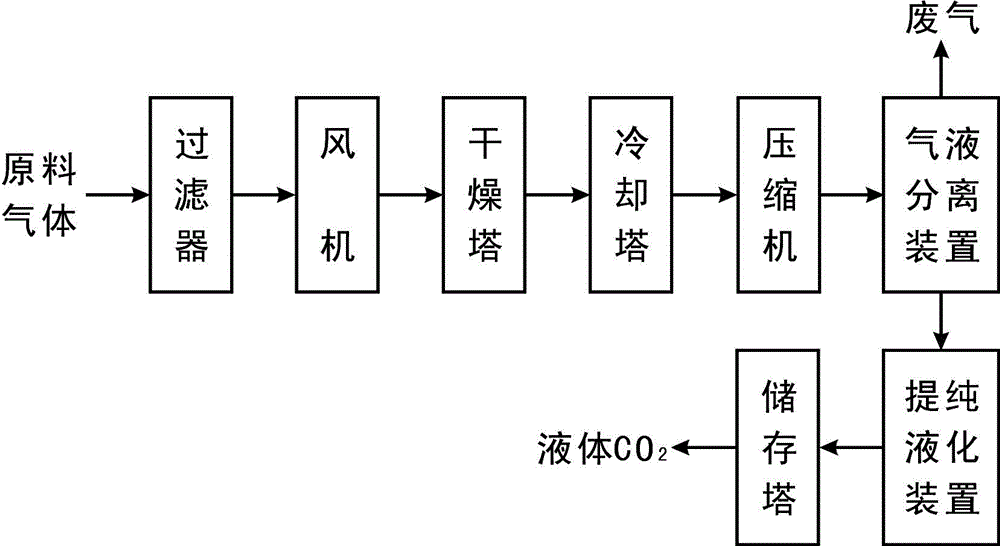

Device and method for trapping carbon resources in atmosphere

ActiveCN103418235AOffset total annual emissions growthAchieve negative growthProductsCarbon compoundsBiosphereCarbon storage

Disclosed are a device and method for trapping carbon resources in the atmosphere. The method includes the following steps: (1), transferring gaseous CO2 in the atmosphere into the biosphere to form solid organic carbon compounds through photosynthesis of rank vegetation, trapping CO2 in the atmosphere, and converting the CO2 into organic carbon compounds through microorganisms or enzyme, (2), trapping CO2 in the atmosphere in a physical method, (3), trapping CO2 in the atmosphere in a chemical method, (4), trapping CO2 in the atmosphere in a physicochemical method, and (5), carrying out carbon storage and sealing storage on the carbon resources trapped from the atmosphere to achieve negative growth of atmospheric CO2, reduce partial pressure of atmospheric CO2 gas, adjust the greenhouse effect and solve relevant environmental problems, putting the stored carbon products into global carbon trading, and carrying out technical control over the cyclic process of carbon cycle, carbon conversion, carbon storage, carbon sealing storage and carbon utilization so that people can use carbon sources fully and reasonably. Manual cultivation and planting of the rank vegetation are new power for carbon cycles on the earth.

Owner:雷学军

Low-carbon efficient system and method for combination supply of coal and coke-oven gases to produce ethylene glycol

InactiveCN108046987AReduce pollutionAchieve optimal configurationOrganic compound preparationChemical industryResource utilizationDesorption

The invention discloses a low-carbon efficient system and a method for combination supply of coal and coke-oven gases to produce ethylene glycol. The system comprises a space division unit, a coal gasification unit, an acid gas desorption unit, a hydrogen / carbon monoxide separation unit, an ethylene glycol synthesis unit, an ethylene glycol refining unit, a dimethyl oxalate synthesis unit, a methane dry reformation unit, a methane steam reformation unit and a coke-oven gas purification unit. According to the system and the method, carbon dioxide obtained through separation of the acid gas desorption unit is comprehensively utilized, a high-value synthesis gas is prepared, not only is greenhouse gas emission of the conventional coal-derived ethylene glycol process reduced, but also the carbon utilization efficiency, the energy efficiency and the economic benefits of the conventional coal-derived ethylene glycol process are improved; by adopting the system, methane dry-wet reformation techniques are integrated, an optimal hydrogen-carbon ratio of a synthesis gas is adjusted, the situation that a great deal of carbon monoxide is applied to water-gas conversion reactions is avoided, awater-gas conversion unit is avoided, the resource utilization rate of the process is remarkably increased, and the energy efficiency of the process is remarkably improved.

Owner:HEFEI UNIV OF TECH

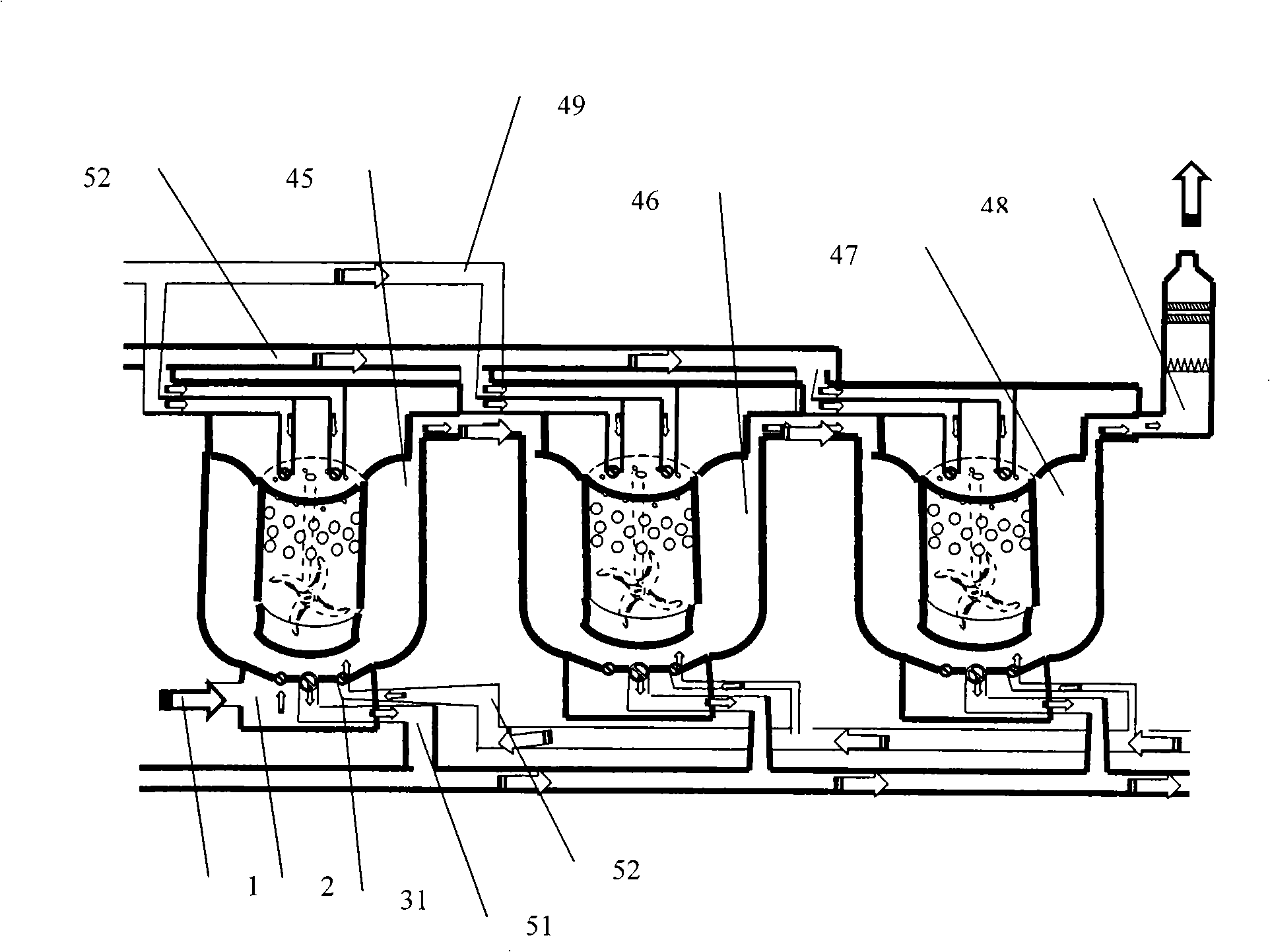

Method for fast establishing DSE and plant symbiosis cultivation system and uses thereof

InactiveCN101263778AShort build timeImprove efficiencyFungiCultivating equipmentsNutrient solutionOxygen

The invention relates to a method for the fast establishment of DSE and plant symbiotic culture system and the application of the method, in particular to a method for the fast establishment of dark septate endophytes and plant symbiotic culture system and the application of the method, belonging to the field of applied microbiology, plant nutrition and ecology. The invention is characterized in that, based on the biological characteristics of DSE of wide carbon utilization and aerobe, riversand with good air permeability is used as the solid substrate; improved MS culture medium is added as the nutrient solution, and early nutritional growth requirements for the formation of DSE-plant symbiotic system are satisfied; the invention utilizes plant seedlings and DSE as materials; by inoculating DSE and plant seedlings on an aseptic culture medium, symbiotic relationship is formed. The method of the invention has the advantages of short setup time of the DSE and plant symbiotic culture system, high efficiency and other excellences; the invention can be applied to the study of the relationship between DSE and plants, the study of DSE morphology, the initial detection of suspected DSE bacterial strains and the application of DSE inoculation.

Owner:YUNNAN UNIV

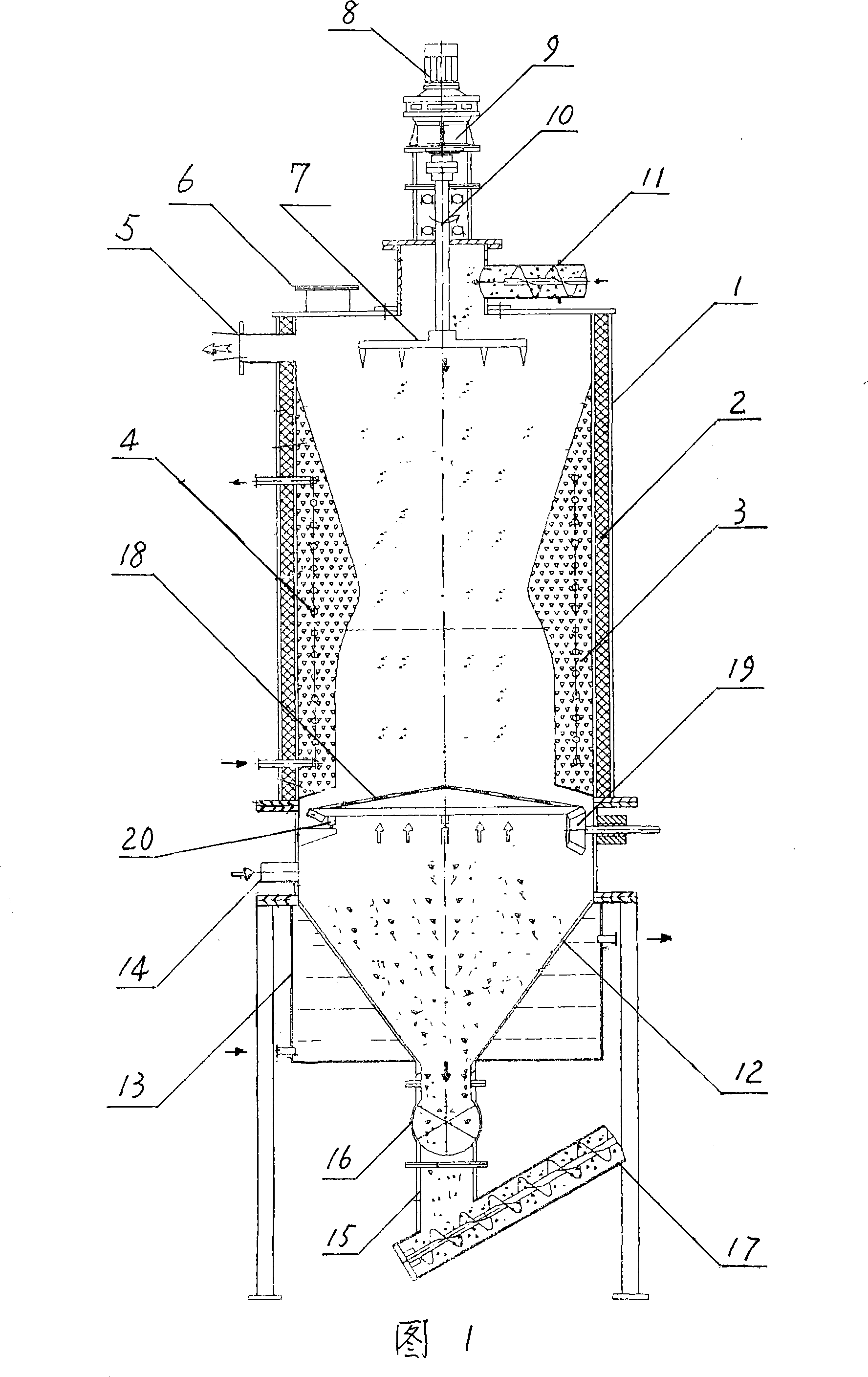

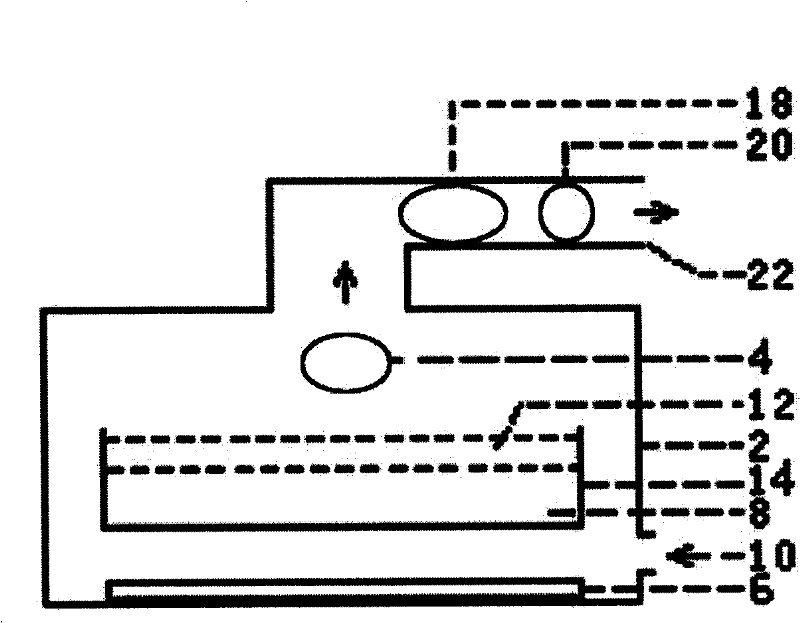

Solid biomass semi-water coal-gas producer

InactiveCN101230281AIncrease gasification rateQuality improvementSpecial form destructive distillationWater vaporCombustible gas

The invention provides a solid biomass semiwater gas generating furnace, which includes a furnace body, a transmission mechanism, a feeding mechanism and a residue discharging mechanism. A head preserving layer 2 and a fire resisting layer 3 are arranged in the furnace body, a heat exchanger pipe 4 is arranged in the fire resisting layer 3, and a material homogenizing harrow is arranged on the hearth. A clinker chamber 12 and a cooling water tank 13 are arranged on the underside of the furnace body 1, a gasification agent inlet 14 is arranged on the clinker chamber 12, and a clinker outlet 15 is arranged on the bottom of the clinker chamber which is connected with a spiral clinker discharger 17. A rotatable furnace grate is arranged on the interface of the hearth and the clinker chamber 12. The invention can feed material and discharge clinker continuously, ensures the continuous stability of the gasification process, uses the vapor generated by residual heat to participate in gasification reaction, improves the carbon utilization rate, and improves the gasification rate of the solid biomass. Compared with gasification furnace with uniform section, the gasification strength of the invention is improved by 1.5-2.0 times, and the combustible gas calorific value is doubled.

Owner:合肥天焱绿色能源开发有限公司

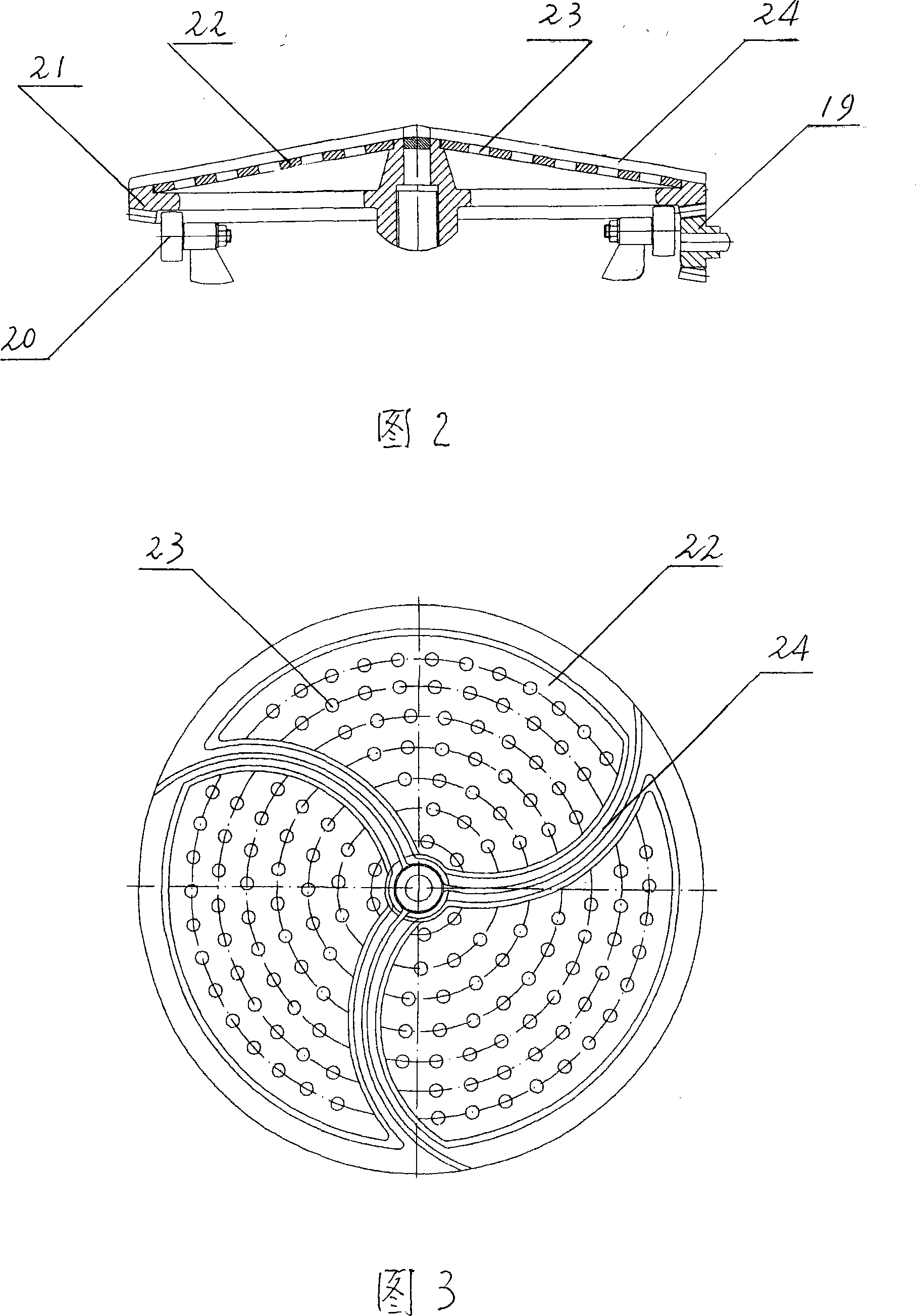

Carbon brake disc negative pressure directional flow outward thermal gradient chemical gas phase penetration process and apparatus

ActiveCN1544686AShorten the production cycleLow costChemical vapor deposition coatingFriction liningCarbon utilizationIndustrial scale

The invention is an airplane carbon brake disc's negative pressure orientation flow external thermal gradient chemical gas-phase osmosis method, its character: placing the prefabricated bodies of airplane carbon brake disc in a furnace, inserting equal-thickness graphite slices between the prefabricated bodies; under negative pressure, making the prefabricated bodies internally hot and externally cold, establishing thermal gradient in the radial direction; under negative pressure, carbon source gas directionally flows through the equidistant slots between the prefabricated bodies almost at 100%; adopting the temperature difference of 0.3 deg.C / cm-25deg.C / cm or the internal and external total temperature difference of 30 deg.C -380 deg.C; making carbon source gas enter the inside of prefabricated bodies, directionally flow through the equidistant slots, and discharged out of the furnace from the outer side; the compacting course of the prefabricated bodies gradually goes from outside high-temperature surface to inside low-temperature surface, an by gas-phase carbon deposition, preparing the finished products. It can effectively enhance carbon utilization ratio and has good friction character and high thermal efficiency, applied to various types of structures of airplane carbon brake discs and tail discs, shortens production period, reduces cost and applies to industrial scaled production.

Owner:XIAN CHAOMA SCI TECH

Method for preparing low-carbon olefin by taking biomass synthetic gas as raw material with dimethyl ether two-step method

InactiveCN102516004AHigh selectivityIncrease profitHydrocarbon from oxygen organic compoundsEthylene productionFixed bedOxygen

The invention provides a method for preparing low-carbon olefin by taking biomass synthetic gas as a raw material with a dimethyl ether two-step method, comprising the following steps of: taking the biomass synthetic gas with a low hydrogen-carbon ratio as the raw material and carrying out methanol synthesis and methanol dehydration reactions on the raw material and a dimethyl ether synthesis catalyst in a one-step fixed bed reactor to prepare an oxygen-containing hydrocarbon with higher dimethyl ether content; after dehydrating a reaction product, raising the temperature to 120 DEG C and introducing the product into a two-step fixed bed reactor to be continuously reacted with a dimethyl ether catalytic conversion catalyst under normal pressure, so as to generate the low-carbon olefin, wherein the dimethyl ether synthetic catalyst is a compound catalyst composed of a Cu / Zn / Al methanol synthesis catalyst and an HZSM-5 (Hydro Zeolite Socony Mobil-5) methanol dehydration catalyst; a carrier of the dimethyl ether catalytic conversion catalyst is an SAPO-34 (Silicoaluminophosphate-34) and HZSM-5 mechanically-mixing molecular sieve; an active component is nickel and a weight loading amount is 0.5-1.5 percent. The CO conversion rate of the method provided by the invention can reach to 39.2-77.4 percent, the selectivity of the low-carbon olefin can reach to 71.5-84.6 percent and the carbon utilization rate of the synthetic gas can reach to 10.2-32.8 percent. The invention provides a new technical route for the production of the low-carbon olefin in our country.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

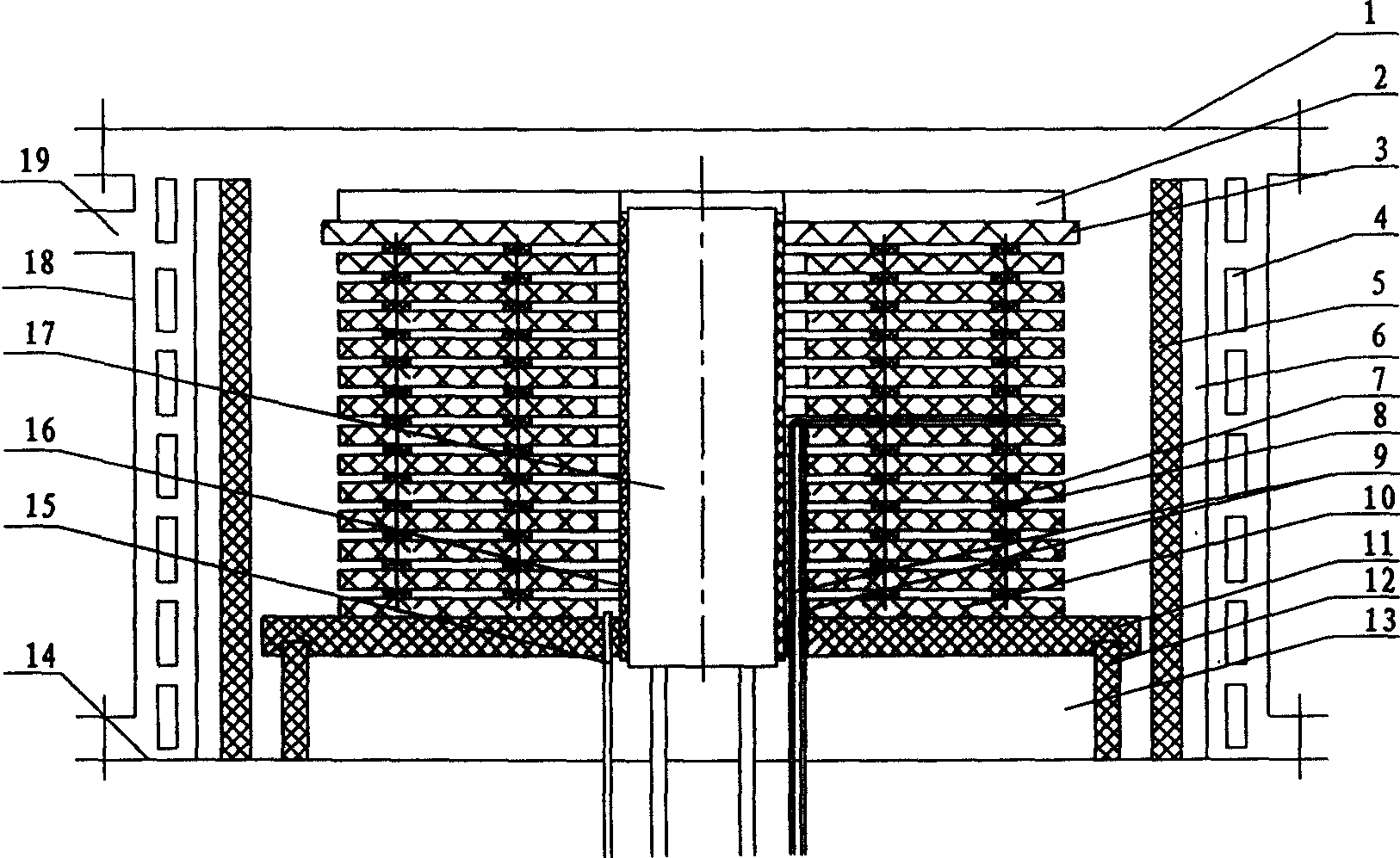

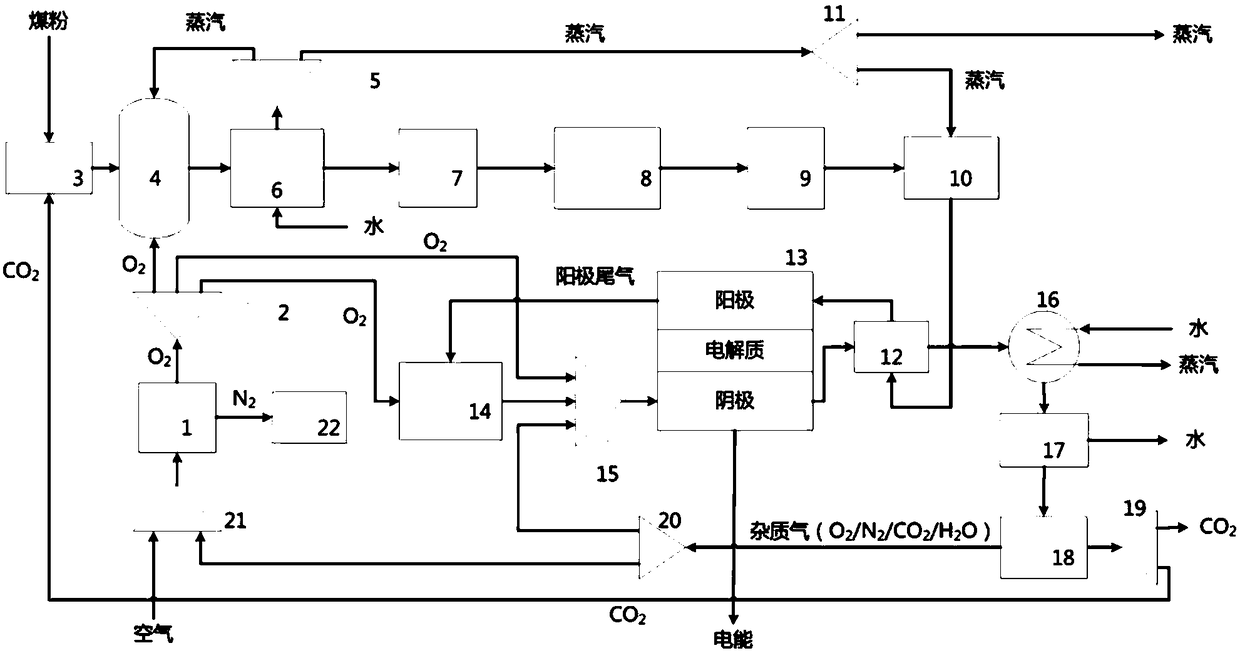

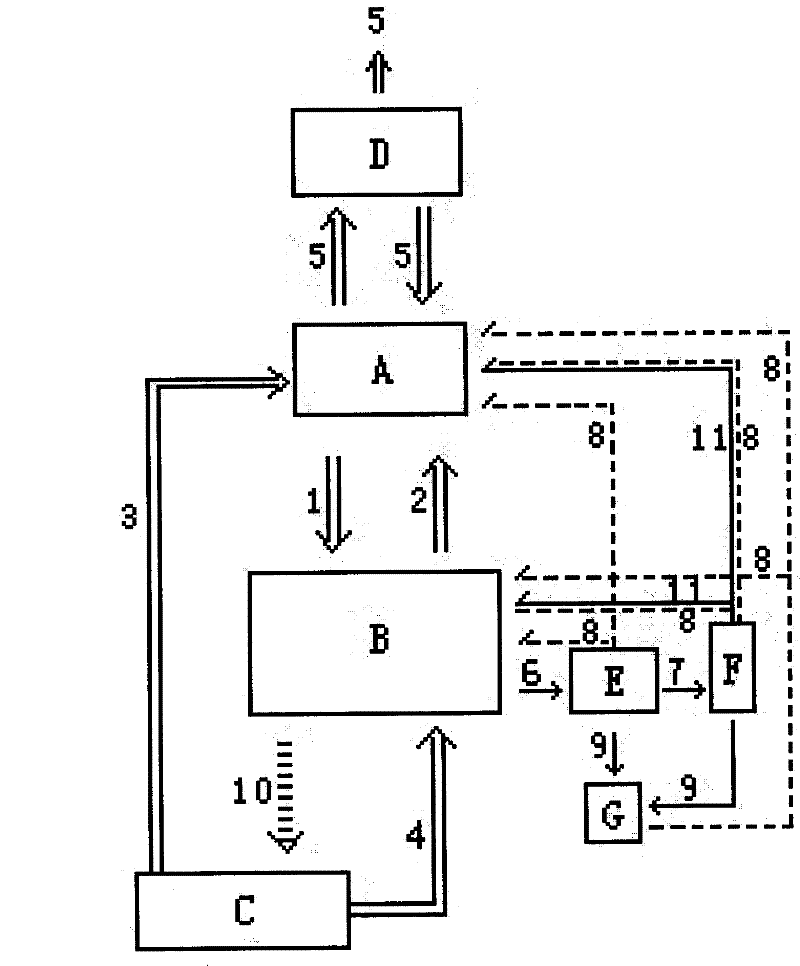

Integrated coal gasification fuel cell system with CO2 capture

PendingCN109301283AIncrease contentIncrease temperatureFuel cell heat exchangeElectrochemical responseWater vapor

The invention provides an integrated coal gasification fuel cell system with CO2 capture. A gasification furnace is used for producing synthetic gas from coal powder, O2, CO2 and steam; then the synthetic gas is subjected to dust removal and purification by using a dust removal device, a water-vapor conversion apparatus and a desulfurizing device, thus preparing synthetic gas containing H2, CO andCH4; then a fuel humidifier is used for the increasing water content of the synthetic gas; a first heat exchanger is used for increasing the temperature of the synthetic gas; then the synthetic gas is fed into the anode of a high temperature fuel cell as a fuel; meanwhile, O2 from an air separation unit and a pure oxygen combustor is fed into the cathode of the high temperature fuel cell, so thatan electrochemical reaction is carried out to the fuel and oxidant, direct current being generated and outputted. In the system, the O2 is used as the oxidant for the cathode of the fuel cell, so that the performance of the fuel cell stack is improved, energy consumption of CO2 capture after the combustion is reduced, and power generation efficiency reaches more than 50%. The system can achieve clean, high-effective and low-carbon utilization of coal resource.

Owner:HUANENG CLEAN ENERGY RES INST

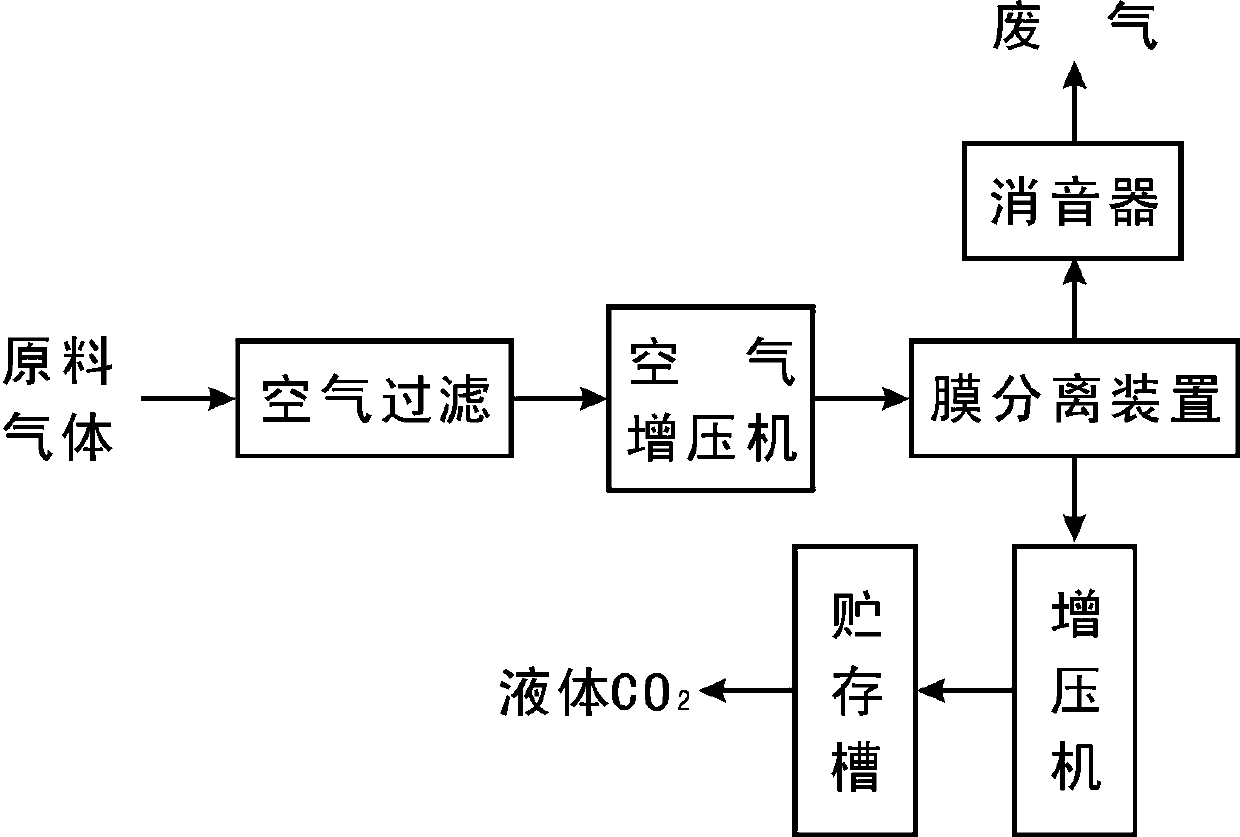

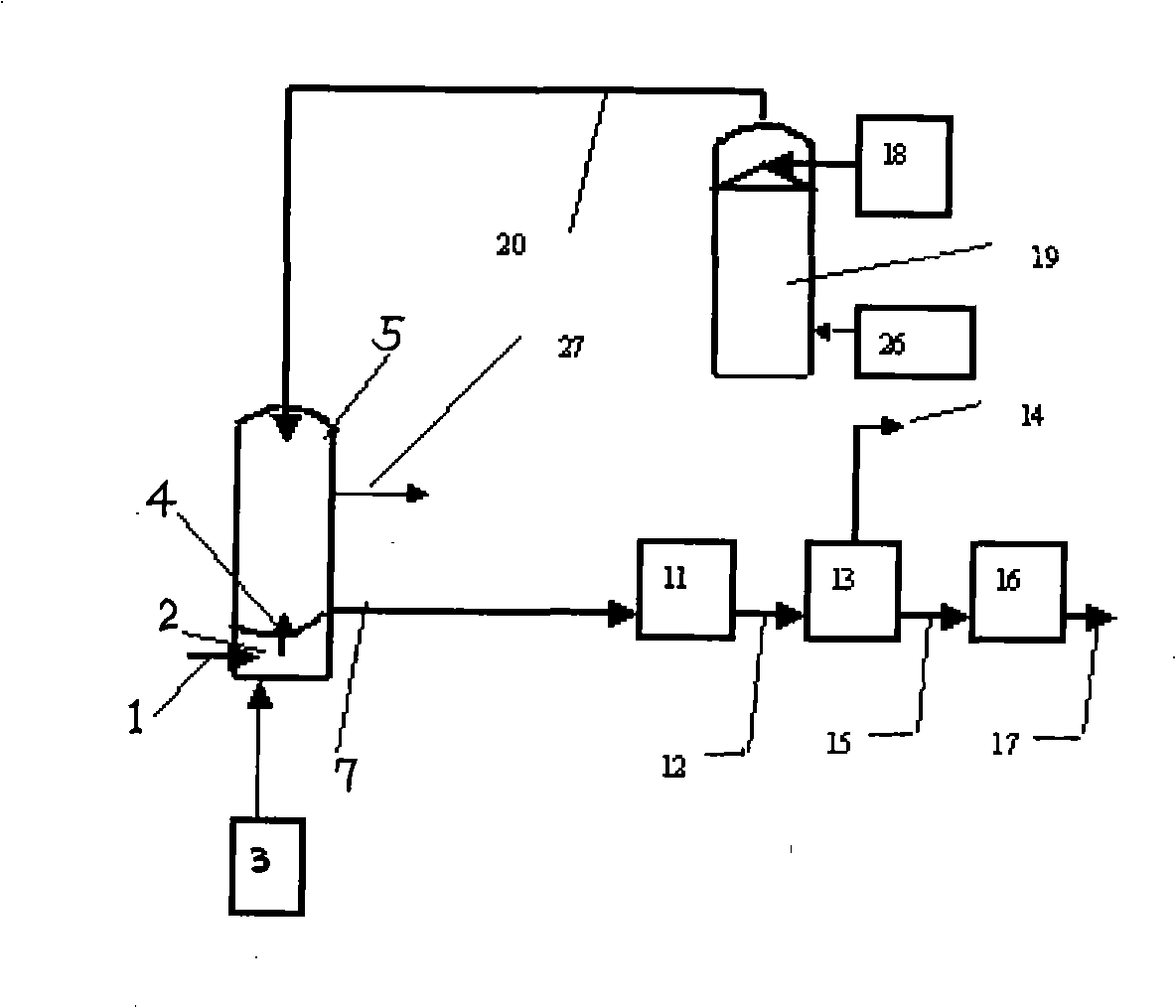

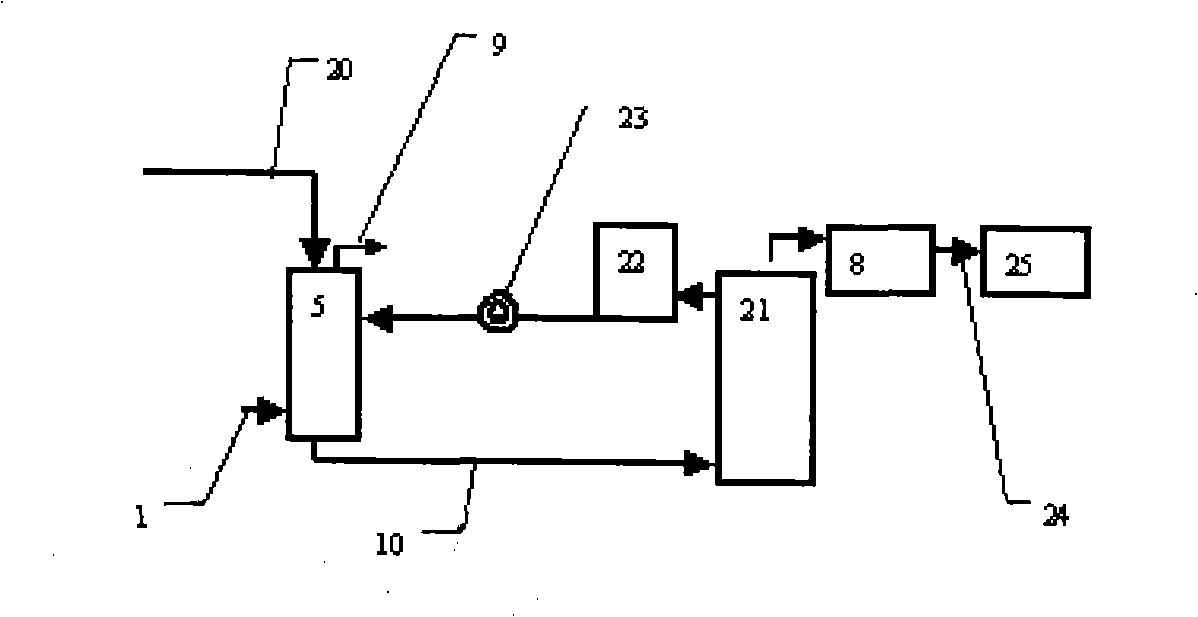

Process and equipment for preparing biological energy source

InactiveCN101307288AIncrease profitReduce consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsOperational costsAtmospheric air

The invention relates to a method for preparing a biological energy source and a device for carrying out the same. Carbon element captured through absorption / separation is used for cultivating microalgae in a form of a liquid carbon containing compound. And simultaneously components which are contained in exhaust air and pollute the atmosphere are eliminated. In the prior art for capturing carbon, after CO2 is absorbed / separated, the carbon is regenerated in a form of CO2 and is compressed and canned for storage, transportation and reconversion. The invention saves a CO2 regenerating link to a certain degree, thereby saving a CO2 micropore pipe link and a CO2 compression, canning, storage and transportation link accounting for 1 / 3 of the total microalgae cultivation cost, and consequently reducing operating cost and improving the carbon utilization ratio of microalgae when cultivating microalgae. The device comprises three parts, namely an absorption / separation device, a biological cultivation vessel and a conversion device for biological cultivation products. When CO2 is captured, dusty gases such as oxysulfide, nitric oxide, sour gas (HCl), fluoride (HF), etc. are also captured from the exhaust air.

Owner:朱洪

Solid fuel combustion and gasification device of fluidized bed or jetting bed with flying ash multiple coal gasification device

InactiveCN101712891AReduce utilizationCombined combustion mitigationGranular/pulverulent flues gasificationChemical industryOil production

The invention discloses a combustion and gasification device of a fluidized bed or a jetting bed containing hydrocarbon solid fuel, which aims at solving the problems of large flying ash amount, high carbon content and low coal utilization rate of the solid fuel combustion and gasification device of the prior fluidized bed and jetting bed. The device comprises a feeding unit, a pressurized fluidized bed and jetting bed unit, a flying ash processing unit and a flying ash circulating unit. The device is distinctly characterized in that a flying ash processing multiple coal gasification device is added in the jetting bed device of the jetting bed containing solid fuel, therefore, the flying ash amount in coal gas and carbon content of flying ash are greatly reduced, the carbon utilization rate is increased, and the effective gas components in coal gas are increased. The device can be widely applied to the chemical industries, such as combustion or gas production, oil production, ammonium production and carbon production of coal, oil shale or other organic waste materials. The device is applicable to fluidized beds or jetting bed boilers (PFBC) and coal gasifiers, and can also be applicable to the field of fuel-steam combined cycle (IGCC).

Owner:顾鸣海

Method for screening plants using bicarbonate radical ions efficiently by using photosynthetic carbon dioxide response curve

InactiveCN103125281AEfficient use ofShort timeHorticulture methodsTranspirationCarbon dioxide content

The invention discloses a method for screening plants using bicarbonate radical ions efficiently by using a photosynthetic carbon dioxide response curve. The method includes the following steps: firstly, determining photosynthetic carbon dioxide response curves of studied plants and reference plants respectively by using a conventional method of a portable photosynthetic instrument; secondly, calculating water use rate of the studied plants and the reference plants under different carbon dioxide contents according to net photosynthetic rate and transpiration rate of the studied plants and the reference plants under different carbon dioxide contents in the photosynthetic carbon dioxide response curves determined by the portable photosynthetic instrument; thirdly, fitting plant water use rate data under carbon dioxide content lower than 320 mumol-mol<-1> into a linear equation in which the plant water use rate changes along with the carbon dioxide content; and obtaining gradient of the equation, namely leaf apparent water carbon use efficiency; and fourthly, screening the plants using the bicarbonate radical ions efficiently according to ratio of leaf apparent water carbon use efficiency of the studied plants to leaf apparent water carbon use efficiency of the reference plants.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

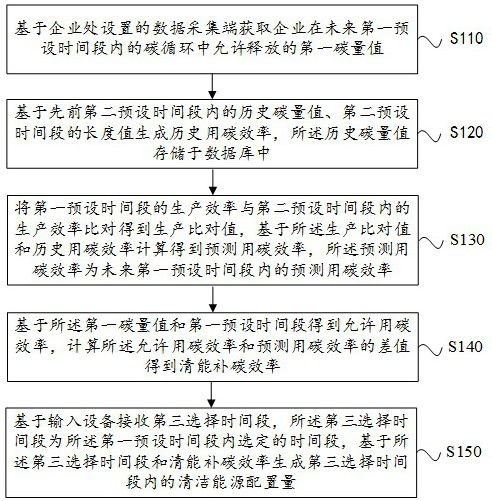

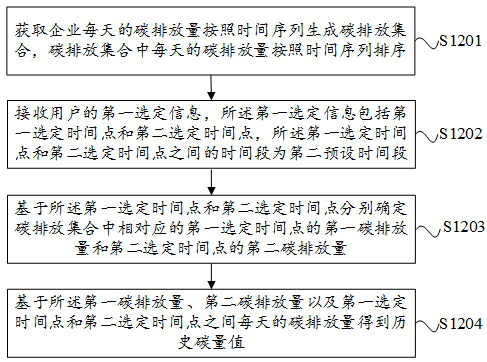

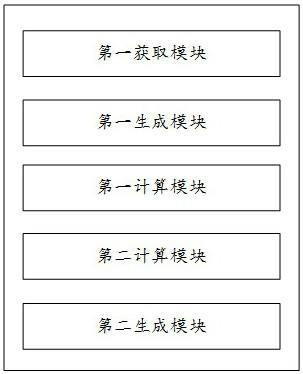

Energy configuration method and device based on carbon cycle and storage medium

ActiveCN113705936AEmission reductionThere will be no excessive emissionsEnergy industryForecastingProcess engineeringClean energy

The invention provides an energy configuration method and device based on carbon circulation and a storage medium. The method comprises the steps of obtaining a first carbon quantity value allowed to be released by an enterprise in carbon circulation in a first preset time period in the future; generating the historical carbon consumption efficiency based on a historical carbon quantity value in a previous second preset time period and a length value of the second preset time period, wherein the historical carbon quantity value is stored in a database; comparing the production efficiency in the first preset time period with the production efficiency in the second preset time period to obtain a production comparison value, and obtaining the predicted carbon efficiency through calculation, wherein the predicted carbon efficiency is the predicted carbon efficiency in the future first preset time period; on the basis of the first carbon quantity value and a first preset time period, obtaining the allowable carbon utilization efficiency, and calculating a difference value between the allowable carbon utilization efficiency and the predicted carbon utilization efficiency to obtain the energy clearing and carbon supplementing efficiency; wherein a third selection time period is a time period selected in the first preset time period, and generating a clean energy configuration amount in the third selection time period based on the third selection time period and the energy clearing and carbon supplementing efficiency.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

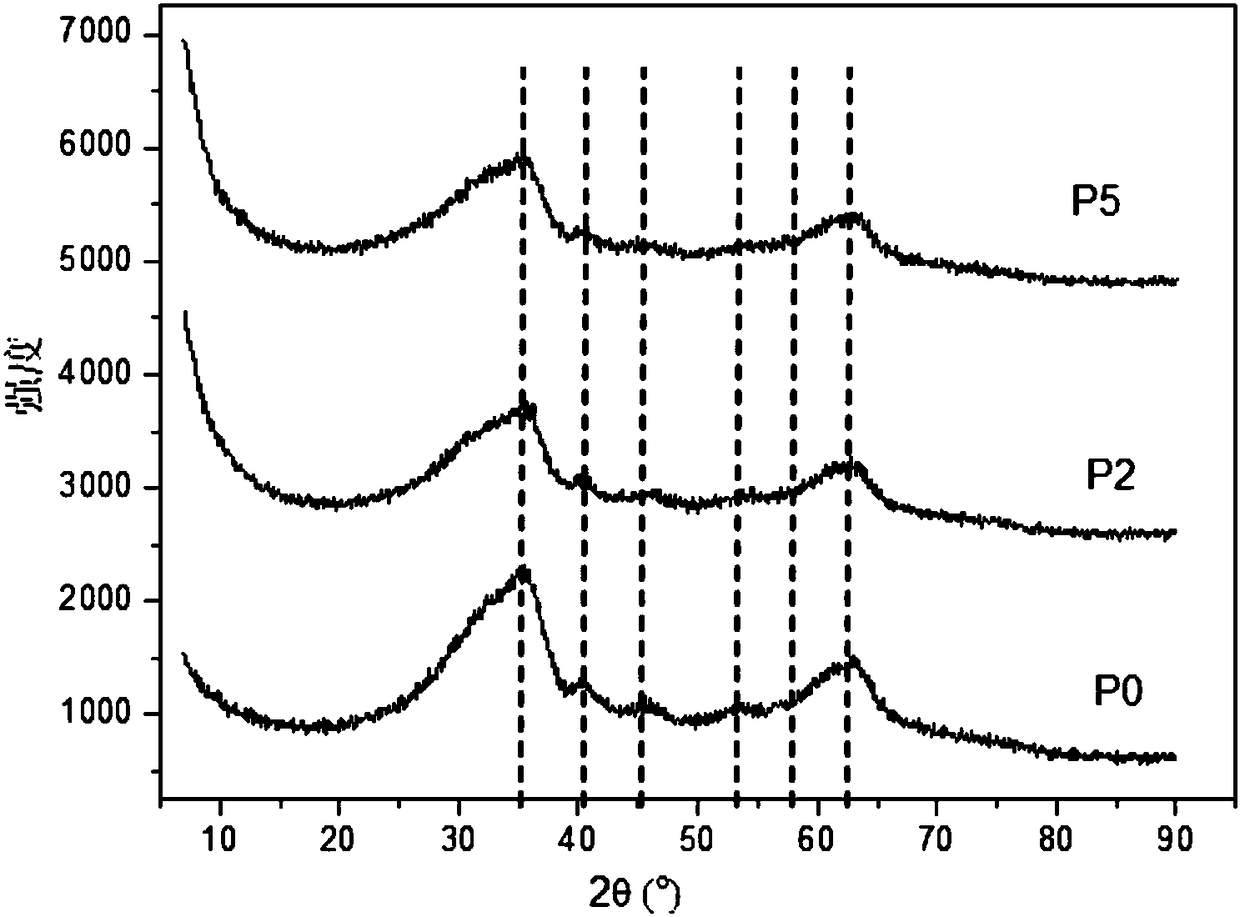

Precipitated-iron Fischer-Tropsch catalyst and preparation method and application thereof

ActiveCN108654654AHigh mechanical strengthExcellent abrasion resistancePhysical/chemical process catalystsLiquid hydrocarbon mixture productionUltimate tensile strengthOrganic chemistry

The invention relates to the field of precipitated-iron Fischer-Tropsch catalysts, and discloses a precipitated-iron Fischer-Tropsch catalyst and a preparation method and application thereof. The catalyst comprises, by parts in weight, 100 parts of Fe, 1-5 parts of Cu, 0.5-5 parts of K, 5-40 parts of Si and 0.01-15 parts of P. Since the precipitated-iron Fischer-Tropsch catalyst contains P, the mechanical strength and abrasion resistance of the catalyst are improved, the Fischer-Tropsch synthesis reactivity of the catalyst is improved, and the carbon utilization rate is increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Hydrogen and carbon utilization in synthetic fuels production plants

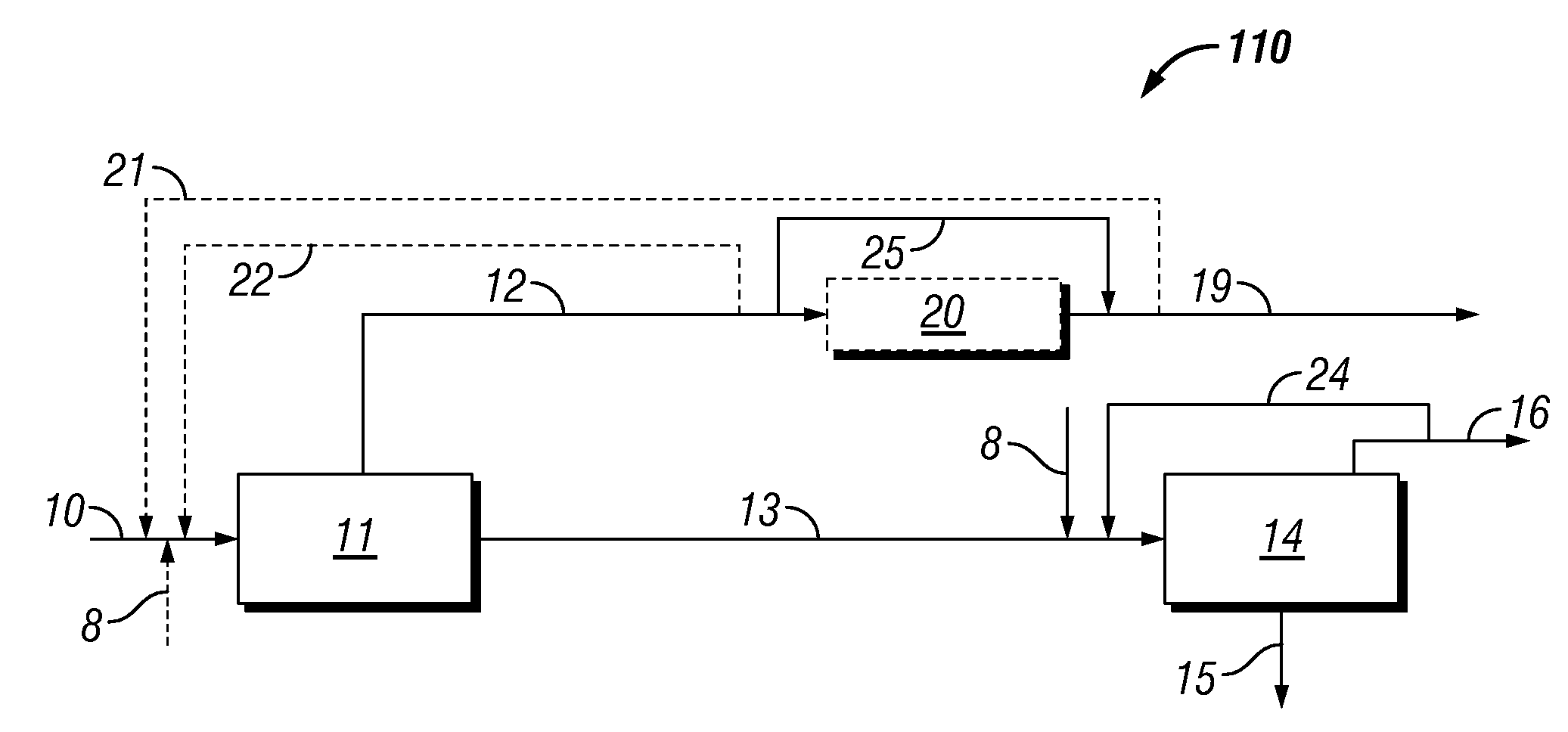

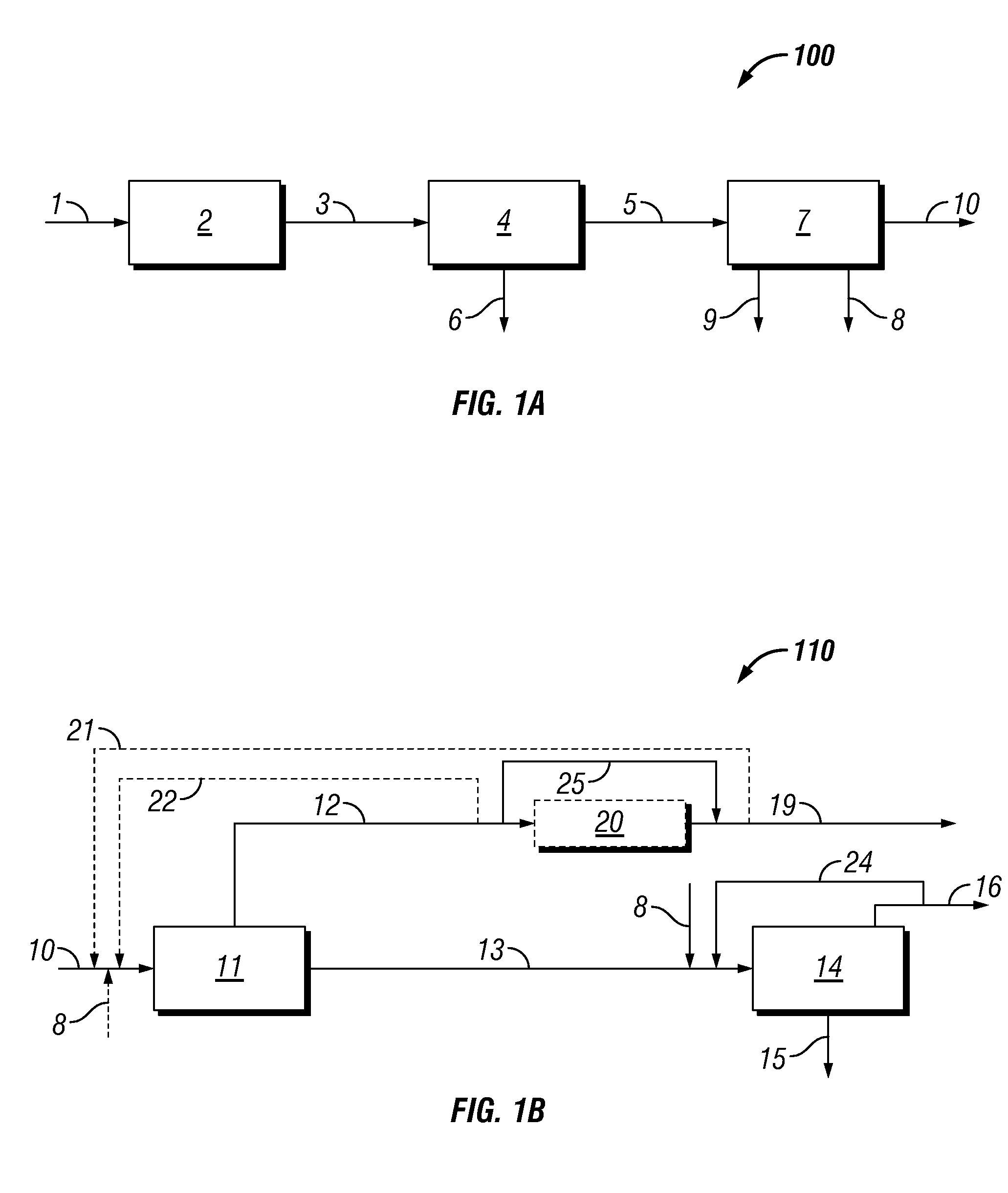

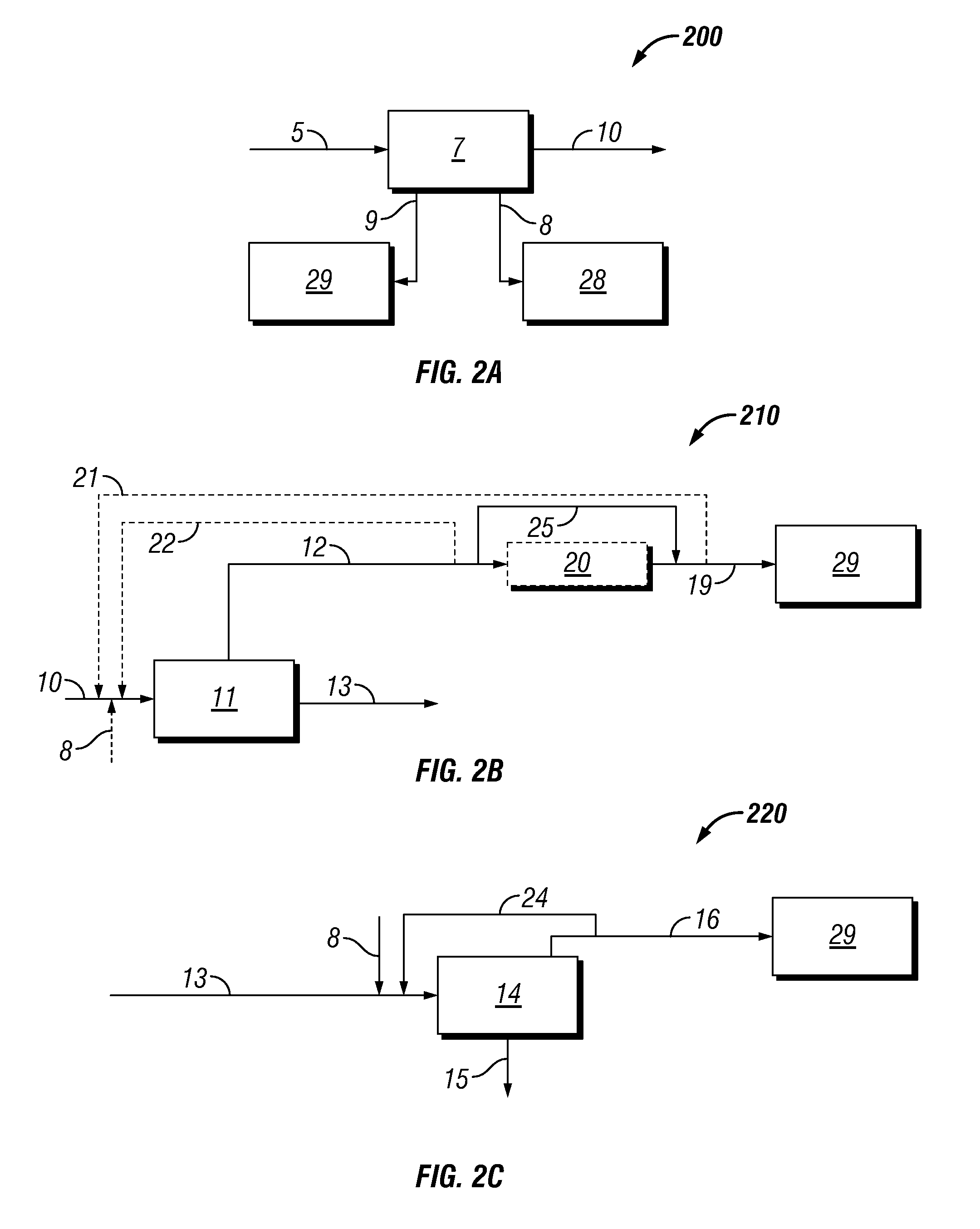

InactiveUS8088187B2Easy to useLiquid hydrocarbon mixture productionHydrogen productionForming gasHydrogen

A method of utilizing hydrogen in synthesis gas production by forming synthesis gas from one or more carbonaceous materials, the synthesis gas comprising hydrogen and carbon monoxide; separating a hydrogen-rich product and a hydrogen-lean product from the synthesis gas to yield an adjusted synthesis gas product; and activating a hydrocarbon synthesis catalyst with at least a portion of the hydrogen-lean product. A system for carrying out the method is also provided, the system including at least one hydrogen extraction unit and an activation reactor operable to activate hydrocarbon synthesis catalyst, wherein the activation reactor comprises an inlet fluidly connected with the at least one hydrogen extraction unit whereby at least a portion of a hydrogen-lean gas stream, at least a portion of a hydrogen-rich gas stream, or at least a portion of both may be introduced into the activation reactor.

Owner:RES USA LLC

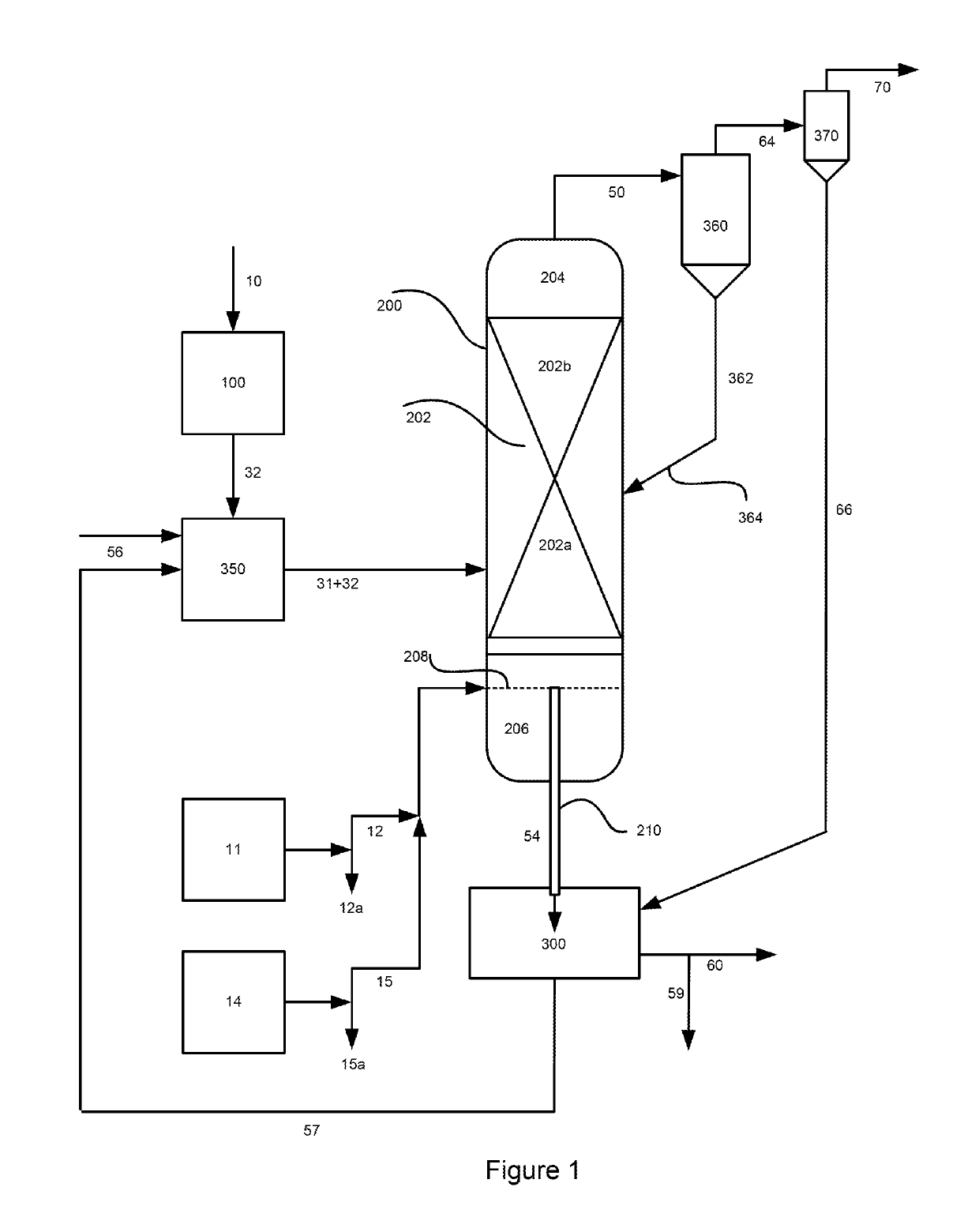

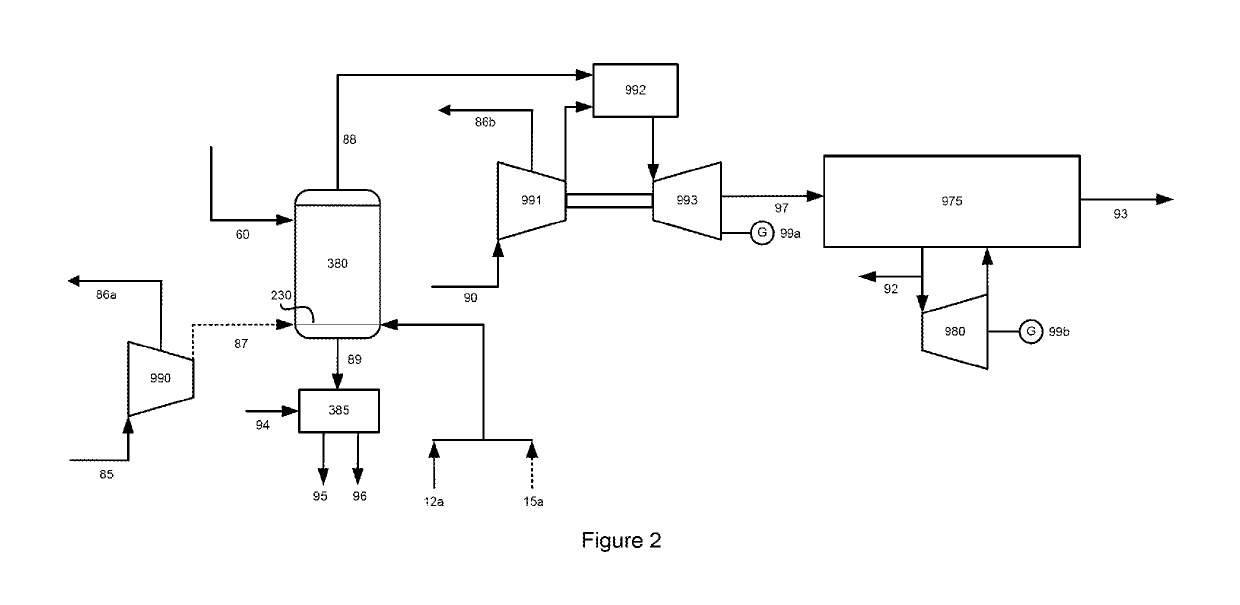

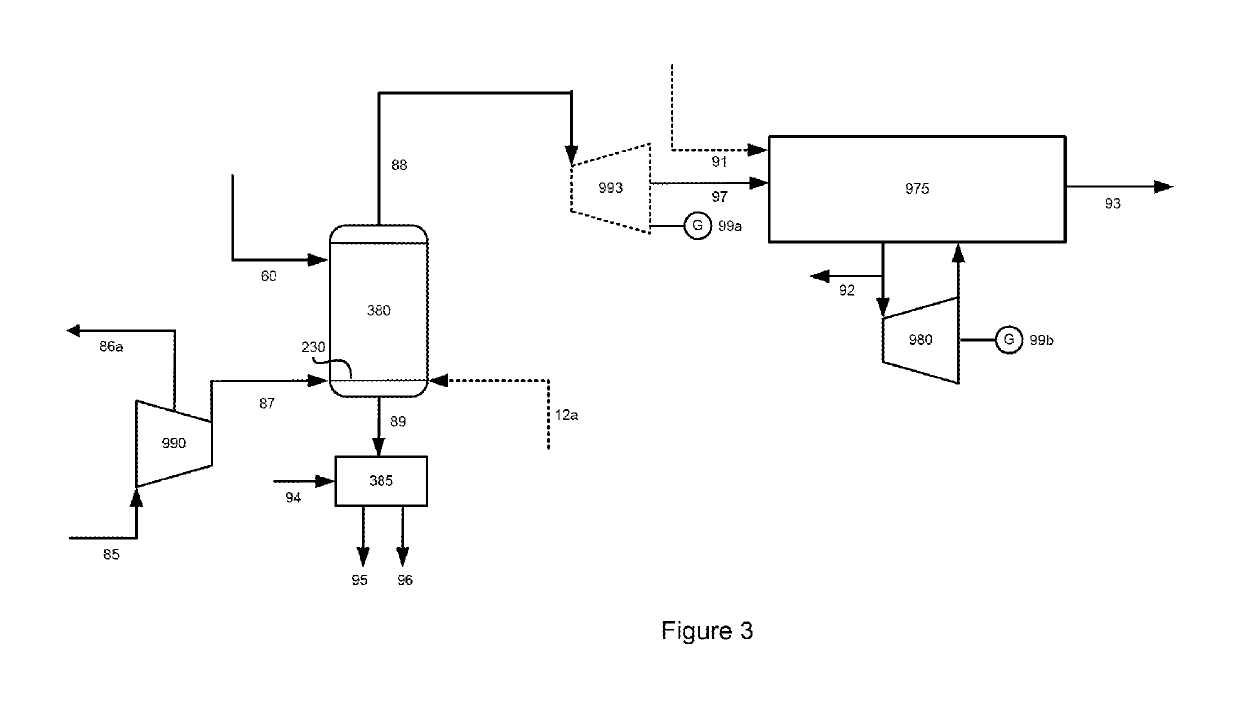

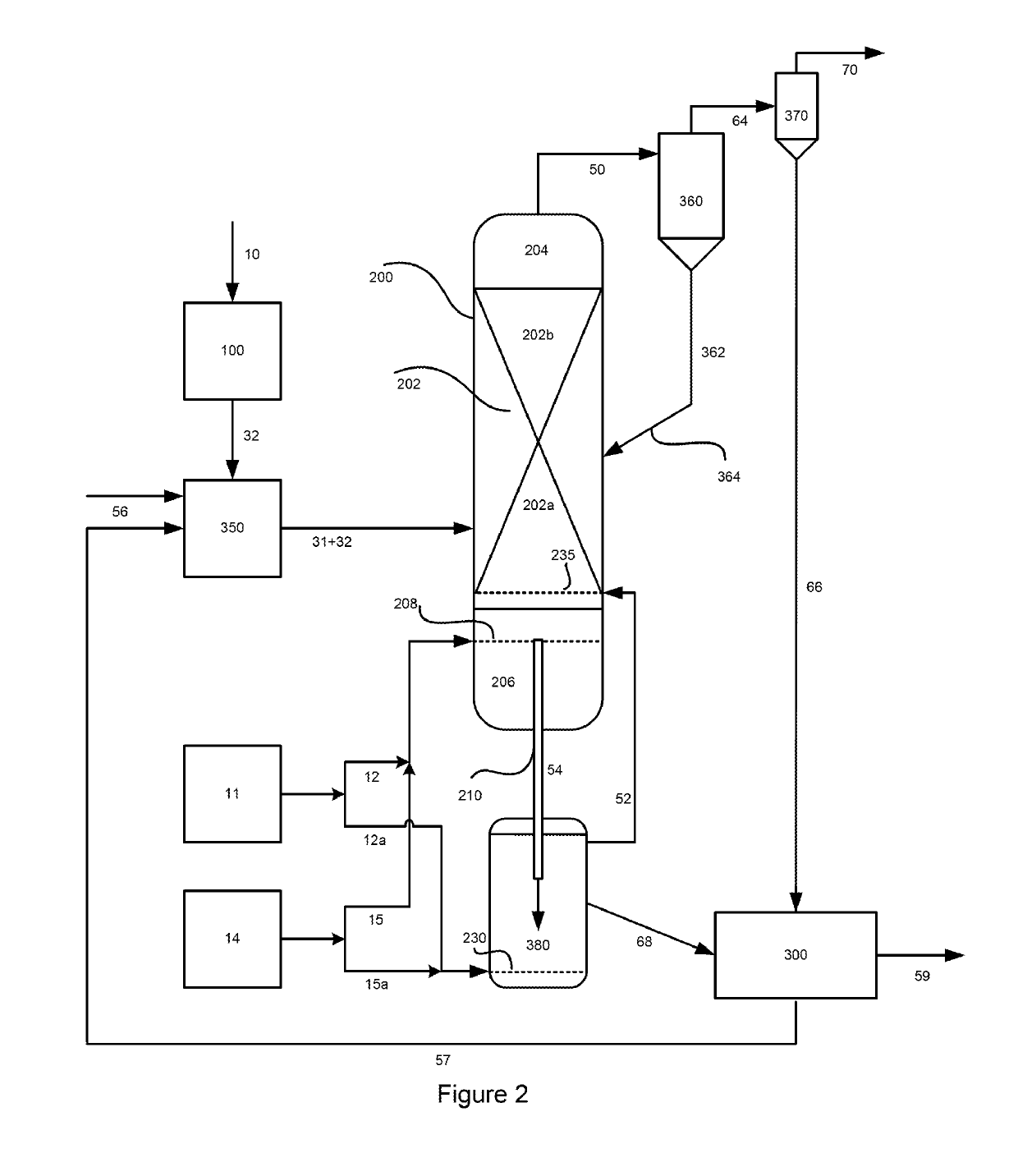

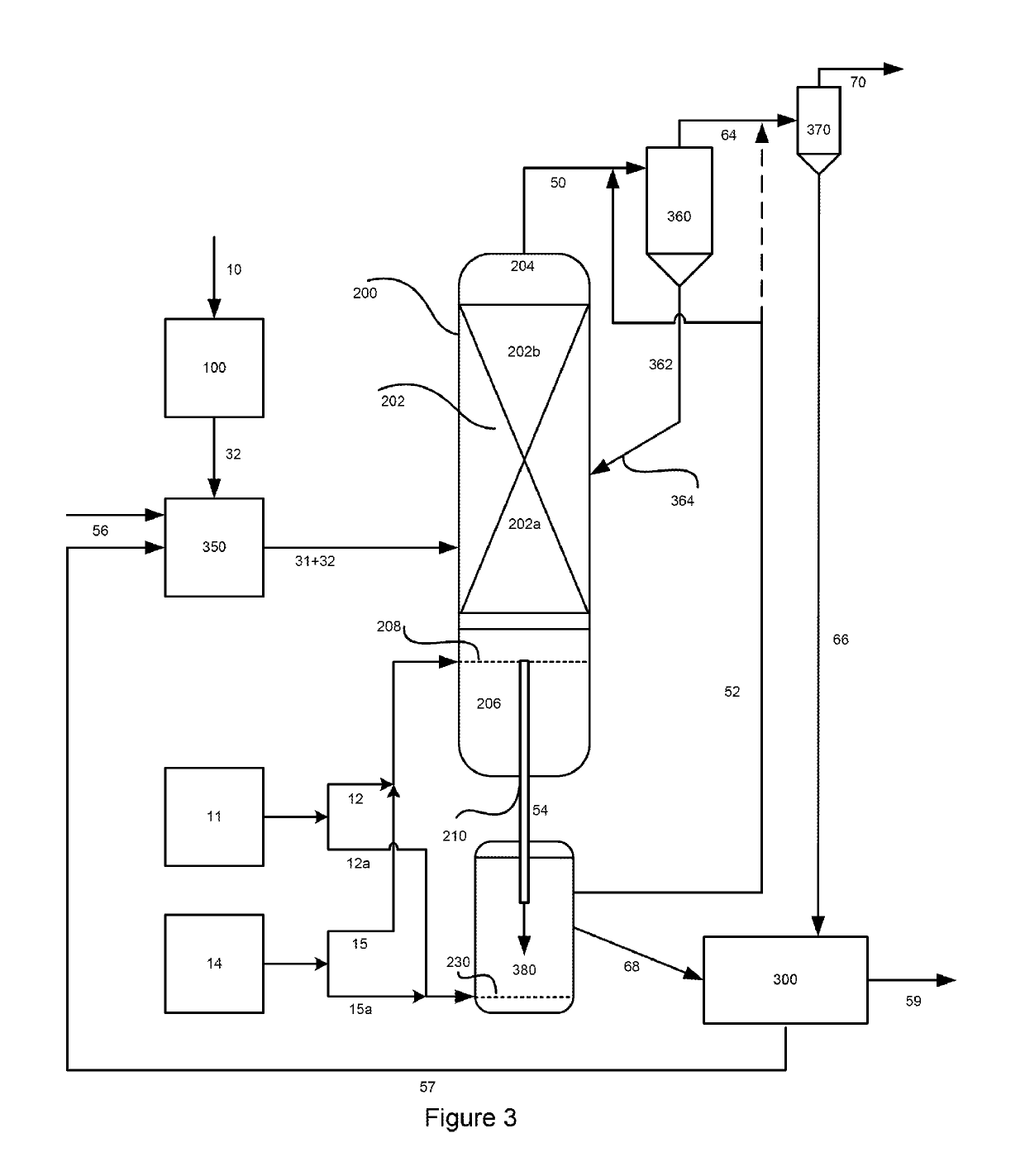

Hydromethanation of a carbonaceous feedstock with improved carbon utilization and power generation

ActiveUS10435637B1Improve efficiencyLower total carbon conversionCombustible gas catalytic treatmentEnergy inputProcess engineeringSubstitute natural gas

The present invention relates generally to processes for hydromethanating a carbonaceous feedstock in a hydromethanation reactor to a methane-enriched raw product stream, and more specifically to processing of solid char by-product removed from the hydromethanation reactor to improve the carbon utilization and thermal efficiency and economics of the overall process by co-producing electric power and steam from the by-product char in addition to the end-product pipeline quality substitute natural gas.

Owner:SURE CHAMPION INVESTMENT LTD

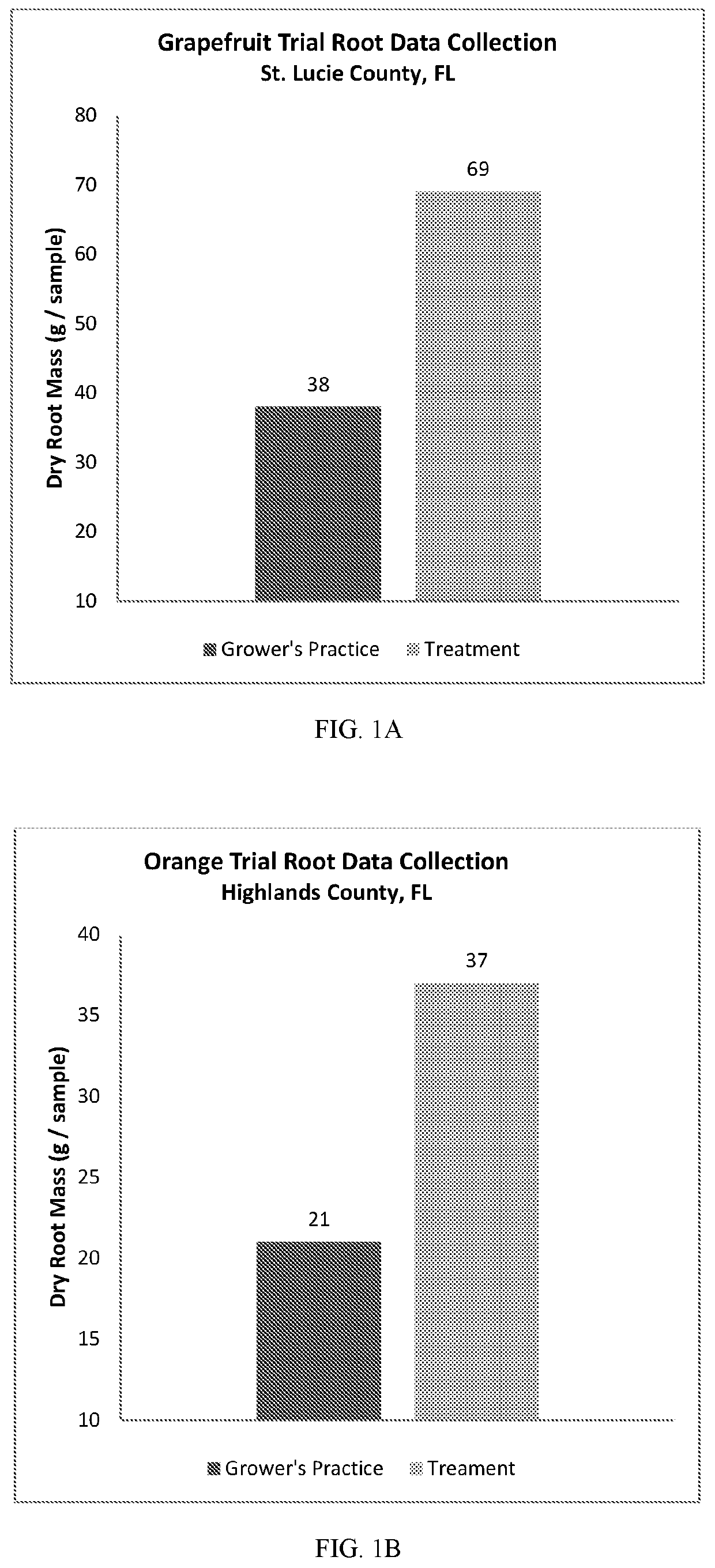

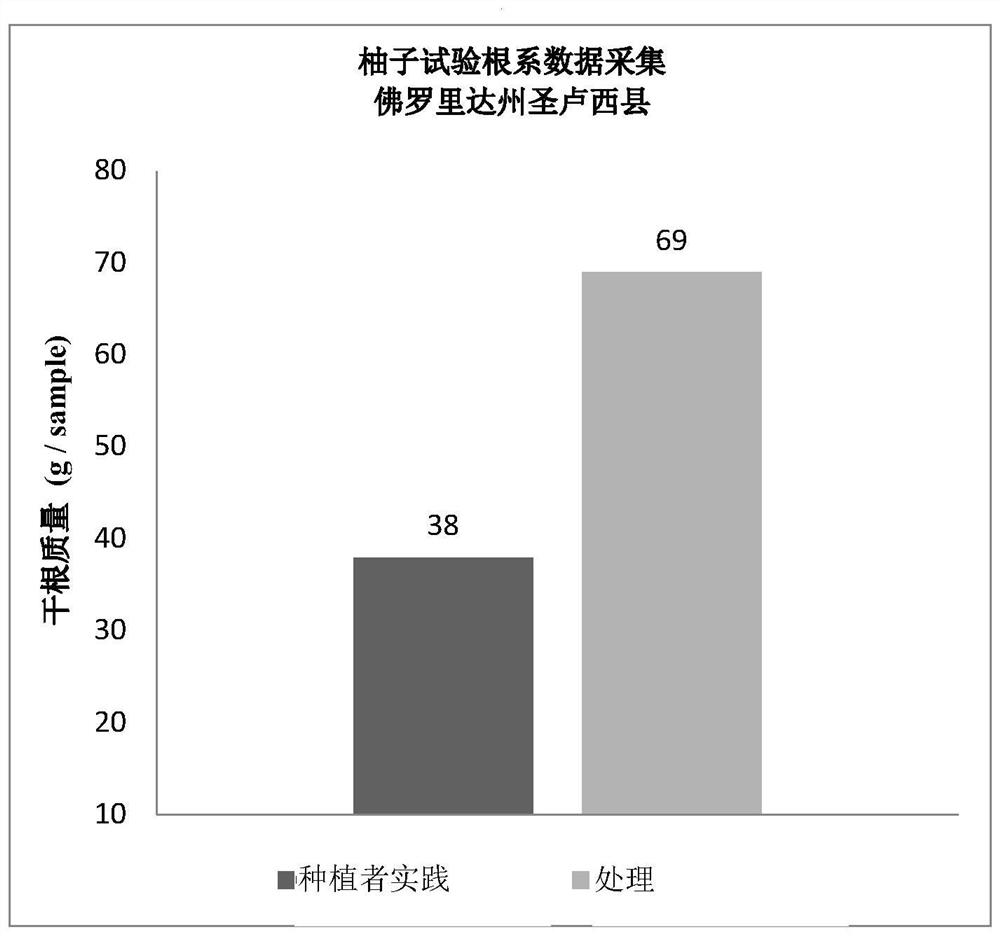

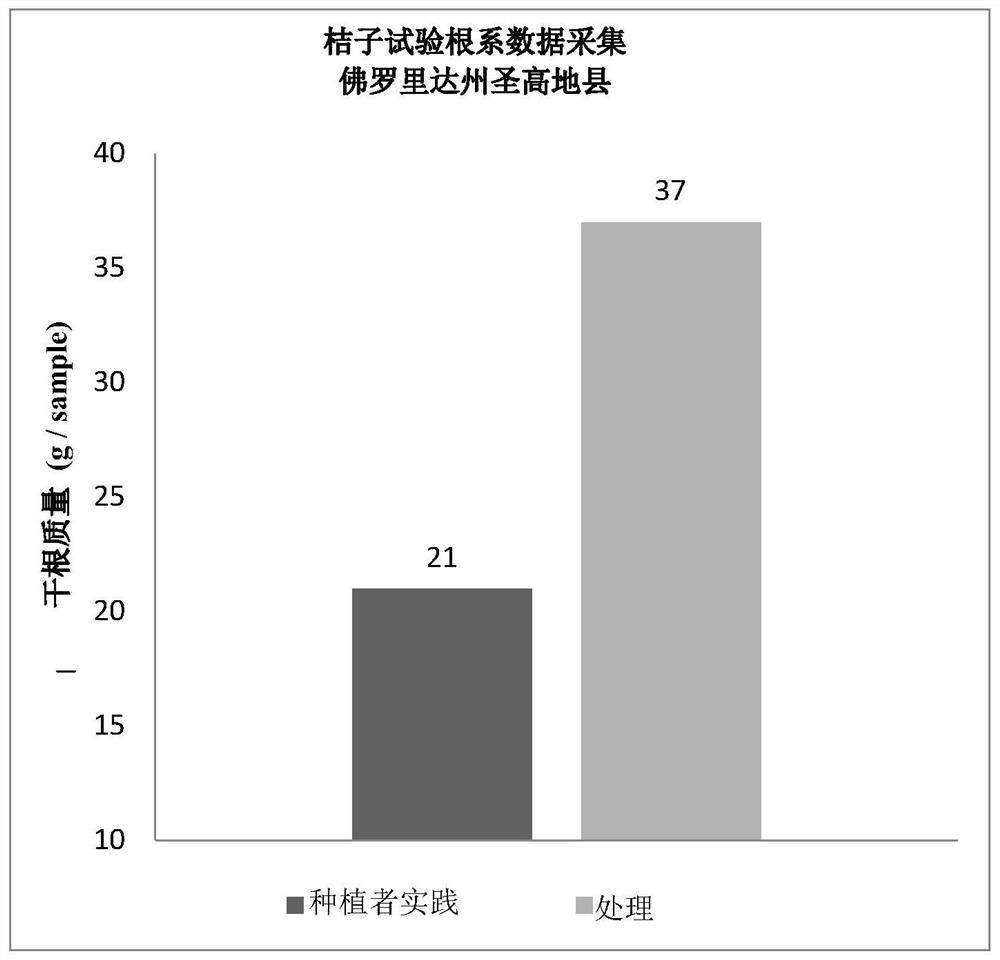

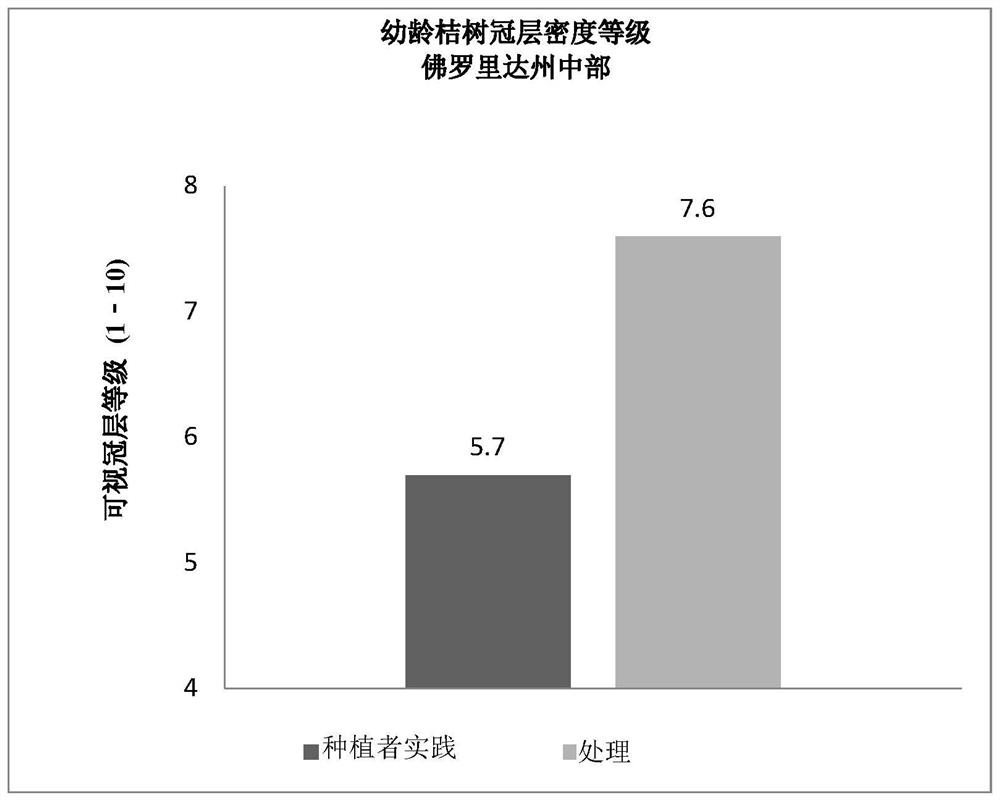

Materials and Methods for Enhanced Carbon Utilization and/or Sequestration as well as Reducing Deleterious Atmospheric Gases

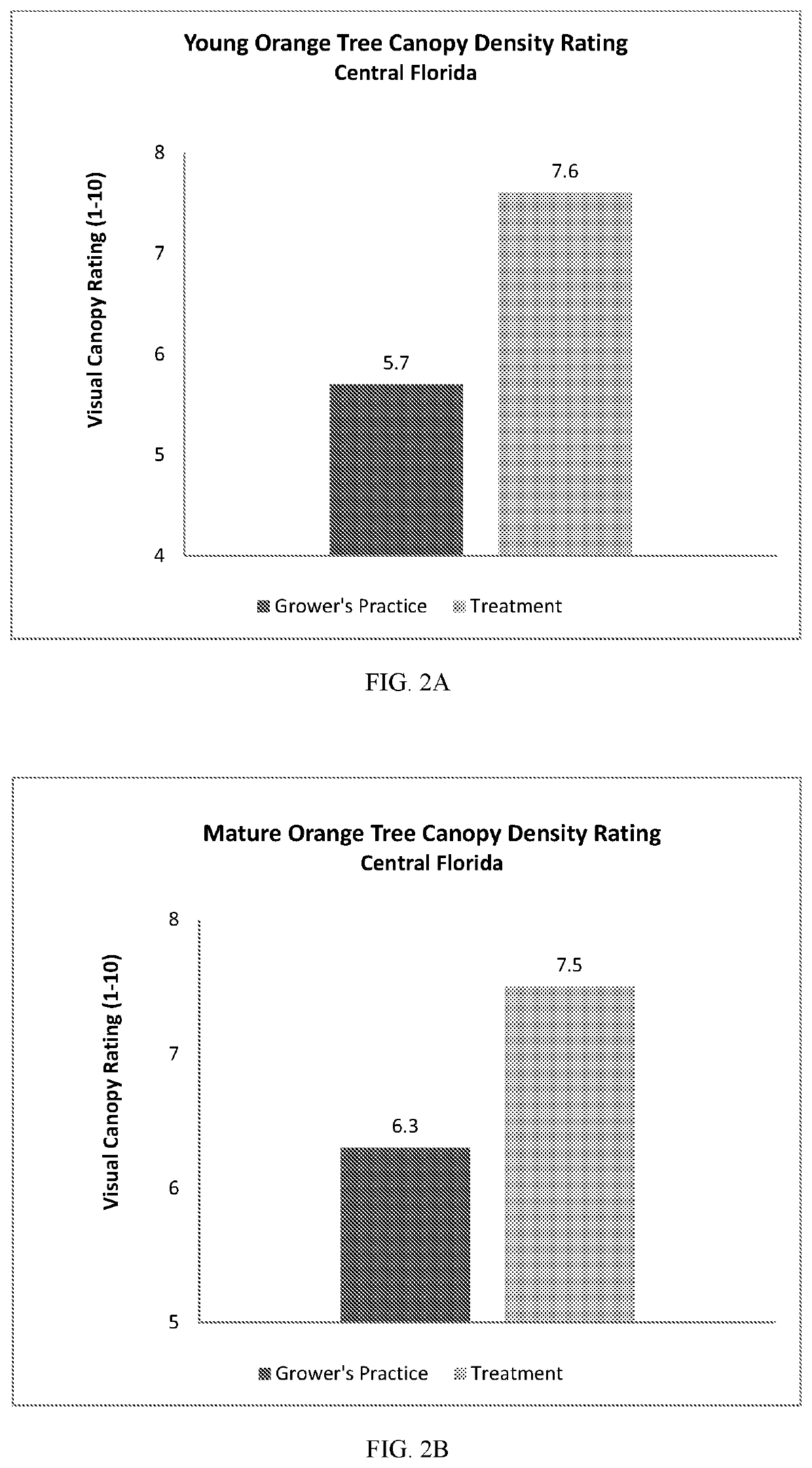

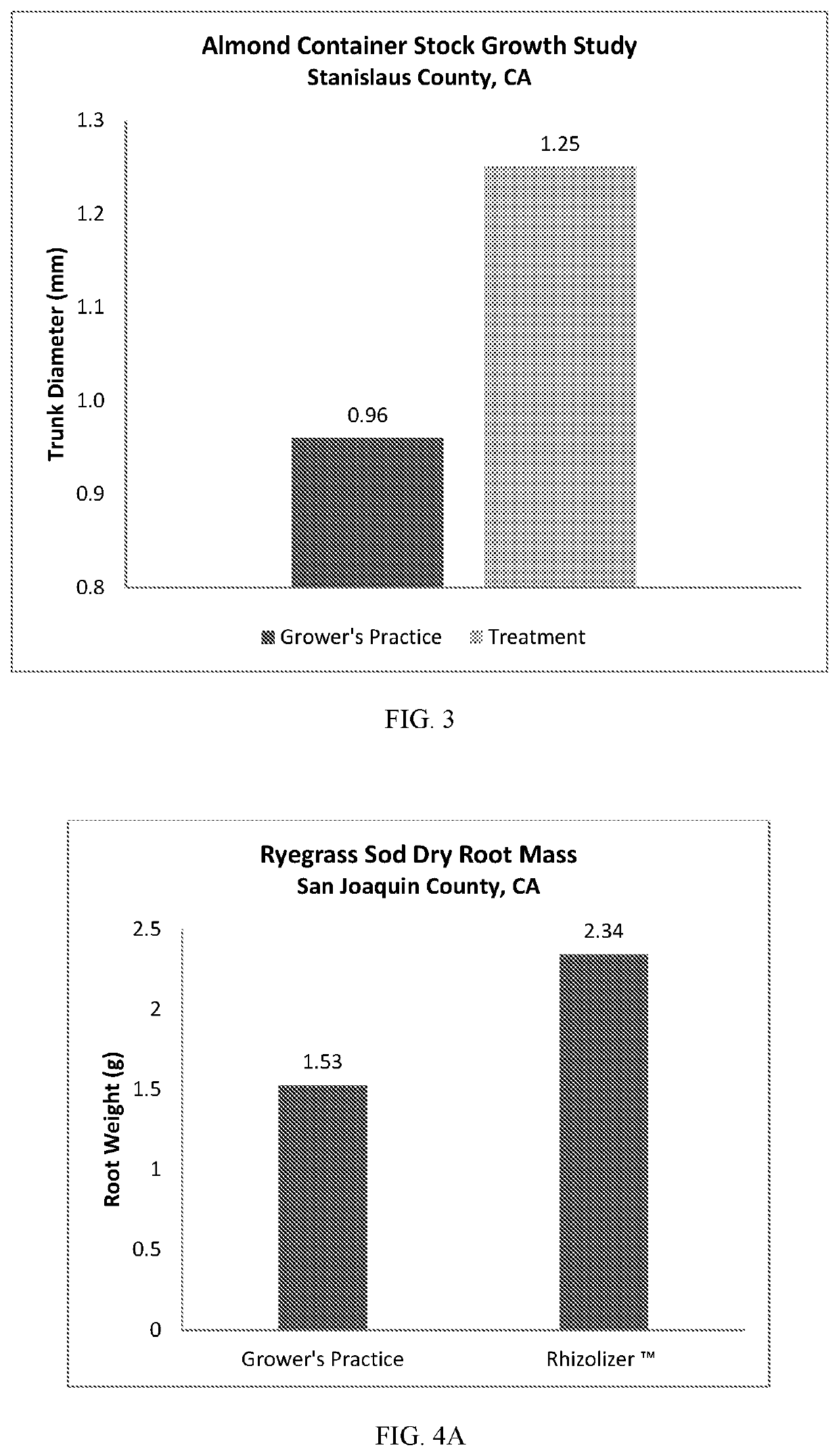

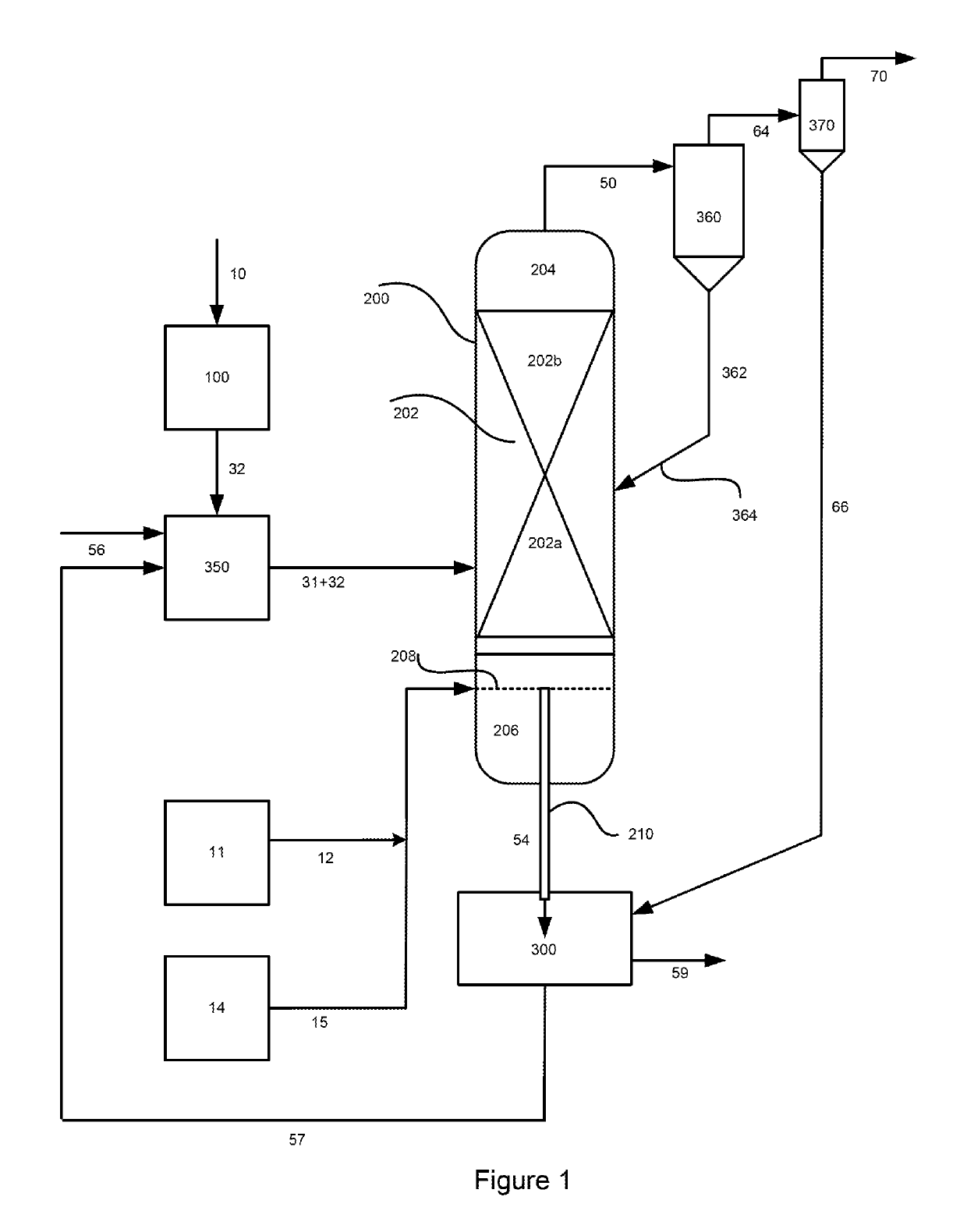

PendingUS20210267214A1Reduce in quantityReduction of atmospheric greenhouse gasBiocideBio-organic fraction processingCrop livestockDisposal waste

The subject invention provides materials and methods for reducing deleterious atmospheric gases, such as greenhouse gases. In specific embodiments, the reduction in deleterious atmospheric gases is achieved via enhanced vegetative carbon utilization and storage, as well as increased carbon sequestration in soil. In some embodiments, the subject invention can be used for reducing the number of carbon credits used by an operator involved in, e.g., agriculture, livestock production, waste management or other industries. In certain embodiments, the subject invention provides customizable microbe-based products, as well as methods of using these microbe-based products for reduction of greenhouse gases and / or enhanced sequestration of carbon.

Owner:LOCUS SOLUTIONS IPCO LLC

Hydromethanation of a carbonaceous feedstock with improved carbon utilization

ActiveUS10344231B1Improve efficiencyLower total carbon conversionGaseous fuelsCatalystsProcess engineeringEnvironmental engineering

The present invention relates generally to processes for hydromethanating a carbonaceous feedstock in a hydromethanation reactor to a methane-enriched raw product stream, and more specifically to processing of solid char by-product removed from the hydromethanation reactor to improve the carbon utilization and thermal efficiency of the overall process and thereby lower the net costs of the end-product pipeline quality substitute natural gas.

Owner:SURE CHAMPION INVESTMENT LTD

Materials and methods for enhanced carbon utilization and/or sequestration as well as reducing deleterious atmospheric gases

PendingCN112839516AReduce credit limitImprove utilizationBiocideBio-organic fraction processingSoil scienceDisposal waste

The subject invention provides materials and methods for reducing deleterious atmospheric gases, such as greenhouse gases. In specific embodiments, the reduction in deleterious atmospheric gases is achieved via enhanced vegetative carbon utilization and storage, as well as increased carbon sequestration in soil. In some embodiments, the subject invention can be used for reducing the number of carbon credits used by an operator involved in, e.g., agriculture, livestock production, waste management or other industries. In certain embodiments, the subject invention provides customizable microbe-based products, as well as methods of using these microbe-based products for reduction of greenhouse gases and / or enhanced sequestration of carbon.

Owner:LOCUS IP CO LLC

Apparatus and method for capturing carbon resources in the atmosphere

ActiveCN103418235BOffset total annual emissions growthAchieve negative growthProductsCarbon compoundsBiosphereCarbon storage

A device and method for capturing carbon resources in the atmosphere, the method comprising: (1) using the photosynthesis of fast-growing plants to transfer gaseous CO2 in the atmosphere into the biosphere to form solid organic carbon compounds. Use microorganisms or enzymes to capture CO2 in the atmosphere and convert it into organic compounds. (2) Use physical methods to capture CO2 in the atmosphere. (3) Use chemical methods to capture CO2 in the atmosphere. (4) Use physical and chemical methods to capture CO2 in the atmosphere; (5) Sequester carbon resources captured in the atmosphere to achieve negative growth of atmospheric CO2, reduce the partial pressure of CO2 in the atmosphere, adjust the greenhouse effect, and solve related environmental problems; Sequestered carbon products participate in global carbon trading, and implement technical control over the carbon cycle, carbon conversion, carbon storage, carbon sequestration, and carbon utilization cycles, so that human beings can make full and reasonable use of carbon resources. Artificially cultivating and planting fast-growing plants is a new driving force for the earth's carbon cycle.

Owner:雷学军

Production method of lithium battery high-performance electrode material

InactiveCN104733727ASmall specific surface areaEasy to processCell electrodesCapacitanceCarbonization

The invention discloses a production method of a lithium battery high-performance electrode material. The production method is characterized by comprising the following steps: (1) preparing a multi-element precursor; (2) manufacturing pore-forming agent sol; (3) carrying out carbonization; (4) washing the electrode preparation material. The raw materials used in the method are relatively low in price; by adding boric acid, the specific capacitance of the electrode material is improved, the repeatability is good, the uniformity of a carbon cladding layer in a lithium iron phosphate material can be improved, the conductivity is guaranteed, the carbon amount is reduced, the carbon utilization rate in the lithium iron phosphate material is increased, the specific surface area of the material is reduced, the machining performance of the material is improved, the method is simple, the cycle life of the electrode is relatively long, and easiness in industrialization can be realized.

Owner:于桂菊

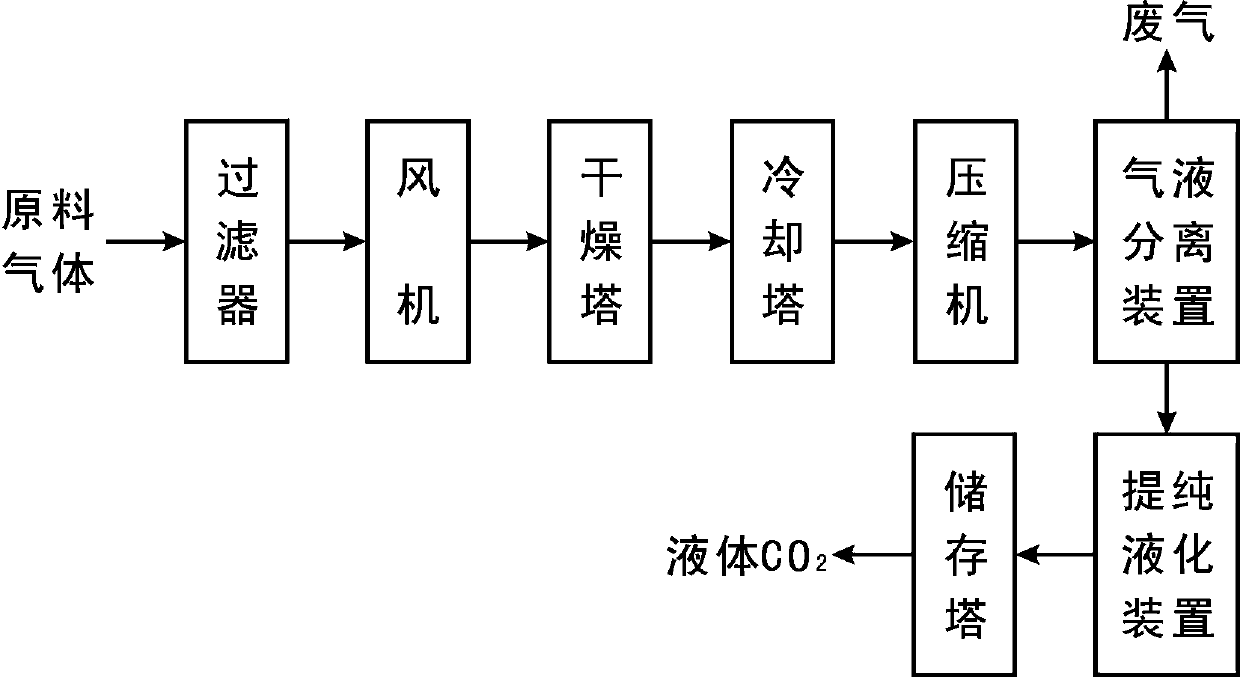

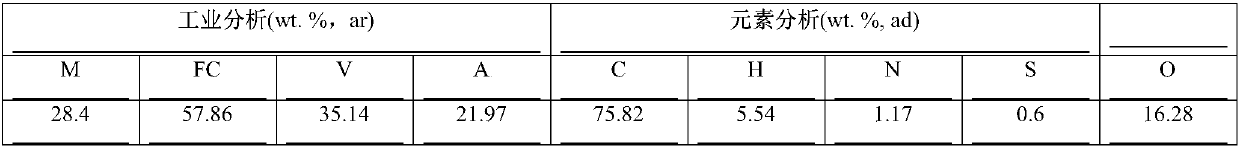

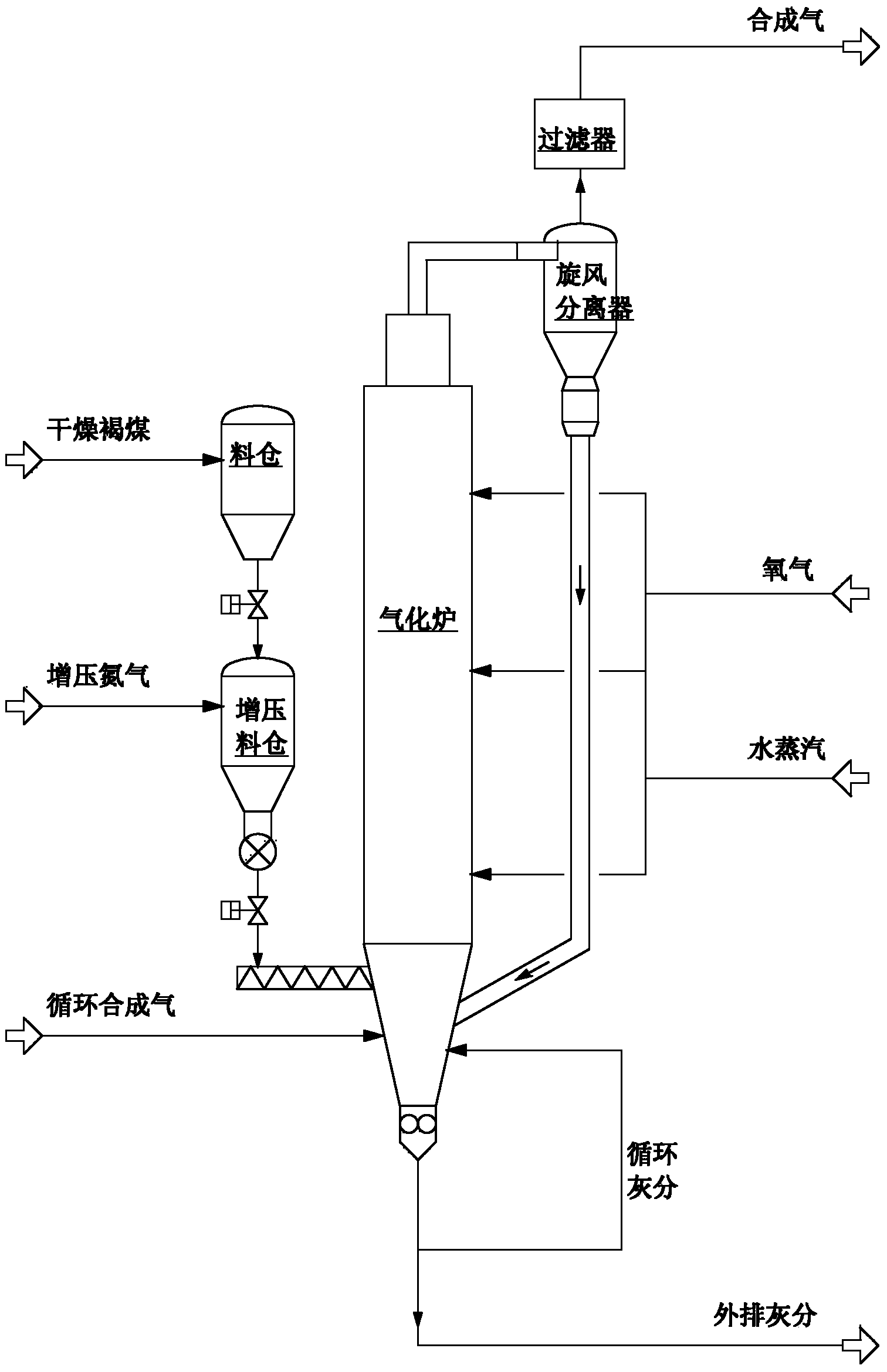

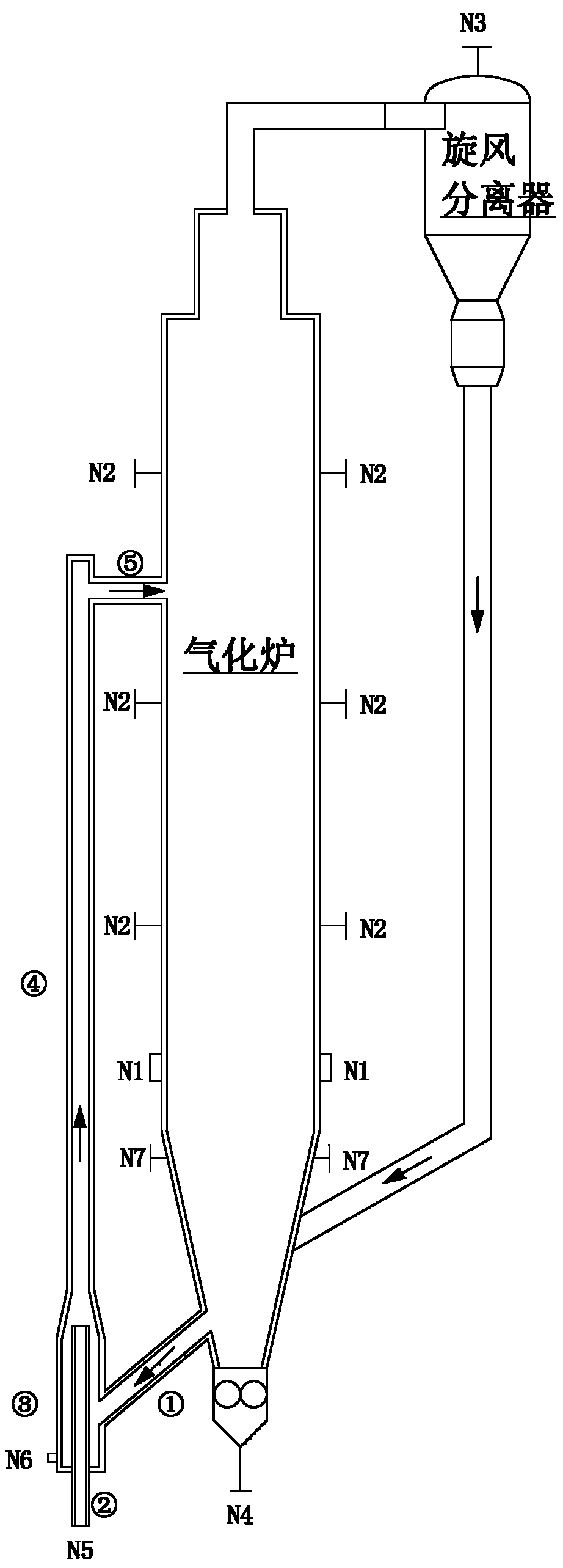

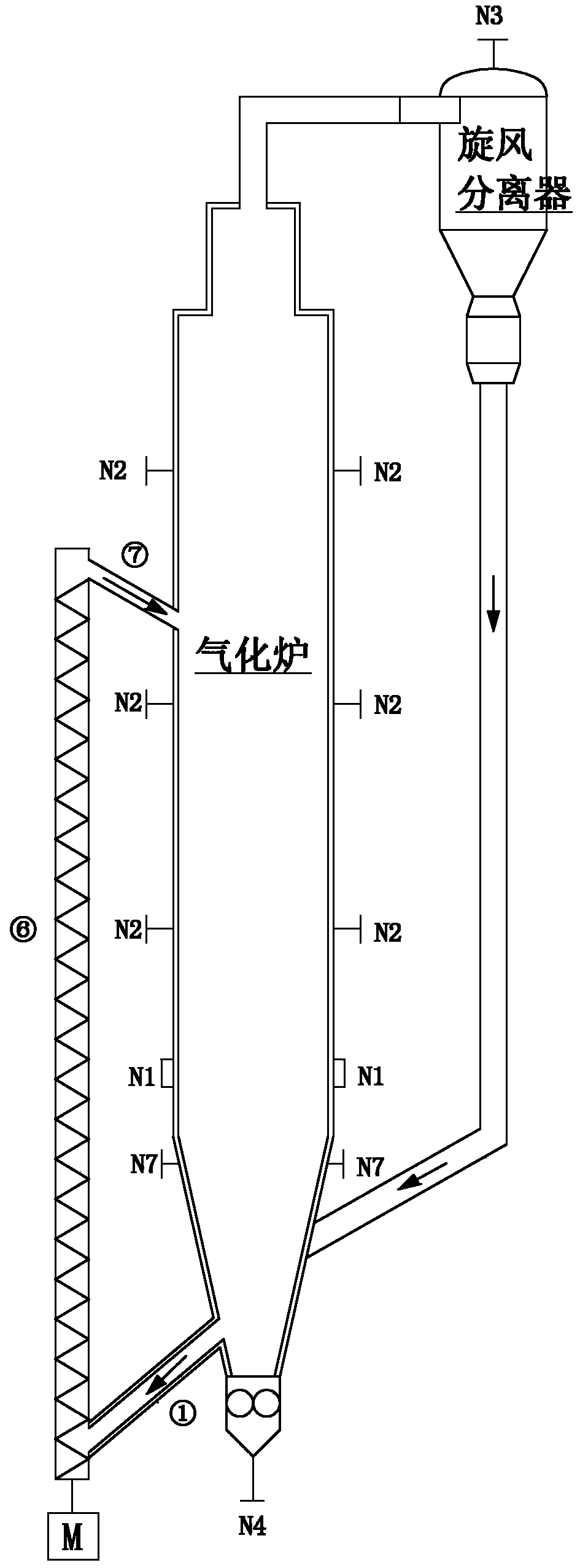

Novel lignite gasification process by using fluidized bed with ash circulation and equipment of novel lignite gasification process

ActiveCN103450947AImprove conversion rateReduce carbon residueCombined combustion mitigationGranular/pulverulent flues gasificationSyngasFluidized bed gasifier

The invention discloses a novel lignite gasification process by using a fluidized bed with ash circulation and equipment of the novel lignite gasification process. According to the novel lignite gasification process, a dried lignite raw material is put into a fluidized bed gasification furnace, a gasifying agent is put into the gasification furnace to perform mixed reaction with the lignite, a synthetic gas generated by the reaction between the lignite and the gasifying agent leaves the gasification furnace and flows to a downstream section after being separated and filtered, and separated fine powder returns to the gasification furnace through a pipeline; one part of the ash generated by lignite combustion is returned to the gasification furnace to perform further burning, and the other part of the ash is discharged from the bottom of the gasification furnace; the ash returned to the gasification furnace can be further burnt in two modes including a gas flow conveying mode and a mechanical conveying mode. According to the process disclosed by the invention, two ash circulating modes including the gas flow conveying mode and the mechanical conveying mode are used to ensure that the ash can be returned to the gasification furnace for continuous burning so as to reduce carbon residues on the ash and improve the carbon utilization ratio when the lignite raw material is converted into the synthetic gas. The process and the equipment are simple and reliable, can effectively reduce investment and increase the running reliability, and have environment-friendly effect and less in pollutant discharge.

Owner:CHINA TIANCHEN ENG +1

A kind of method that takes biomass as raw material to prepare biogasoline

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

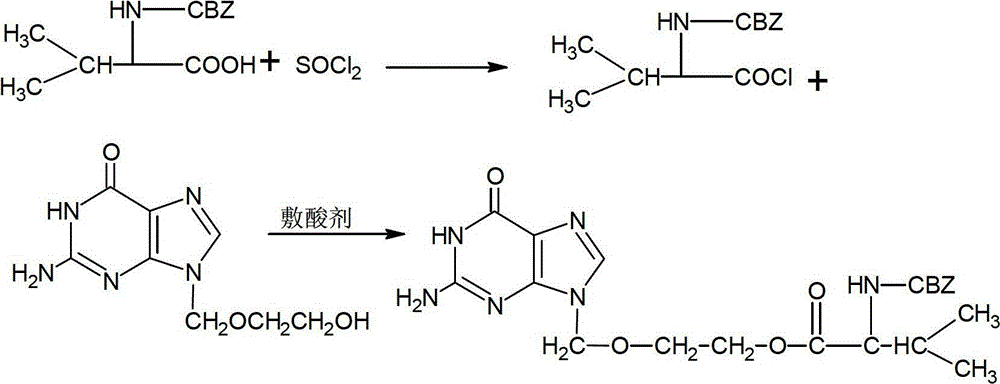

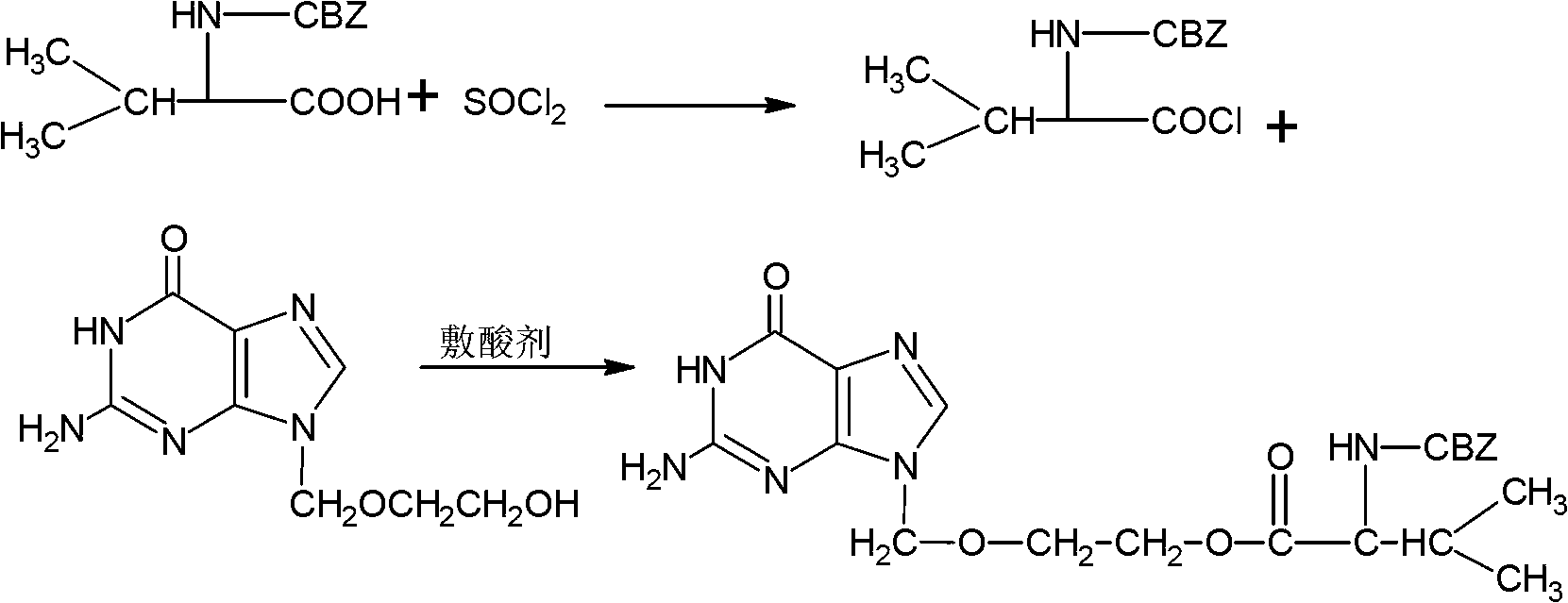

Preparation method of carbamazepine (CBZ)-valaciclovir

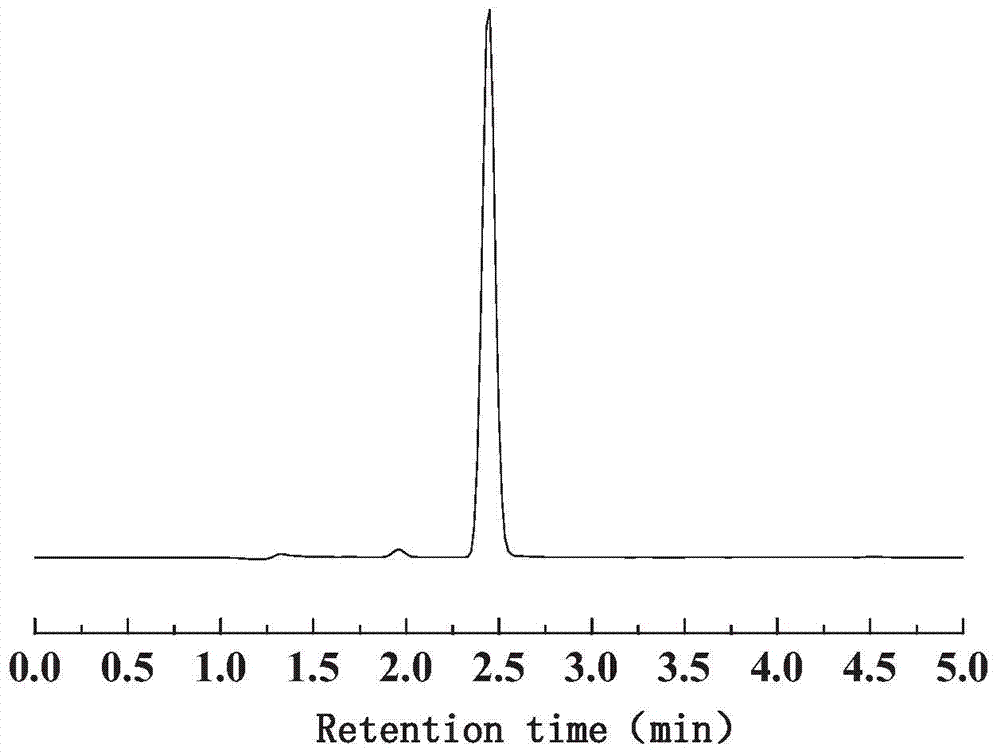

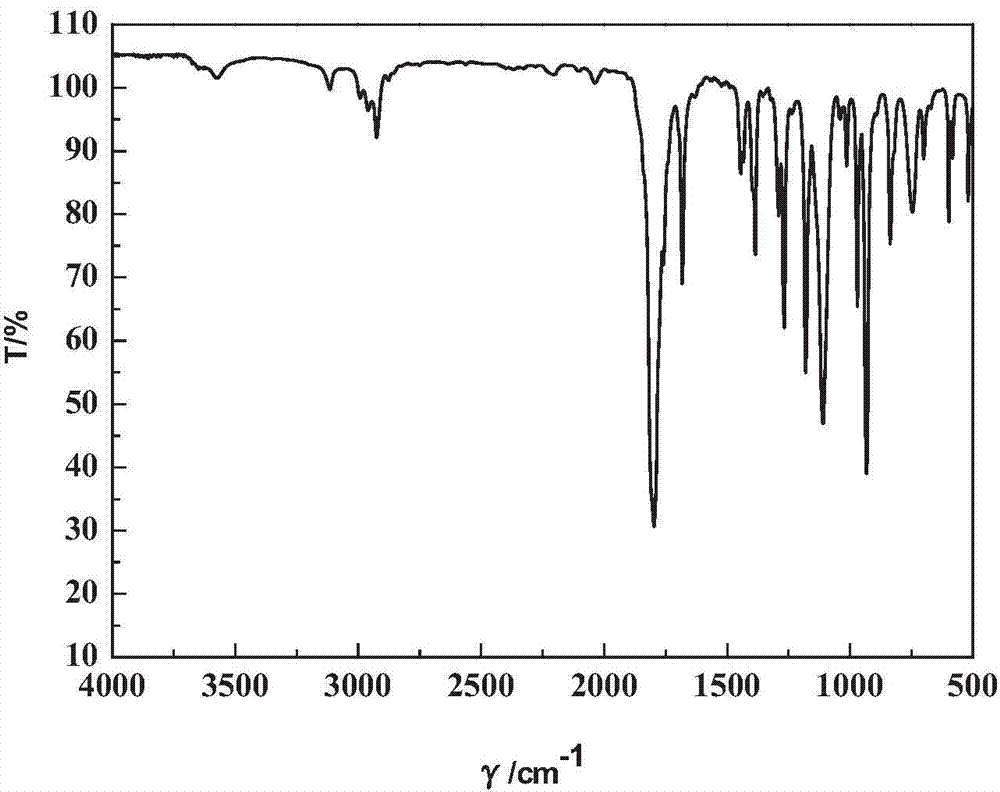

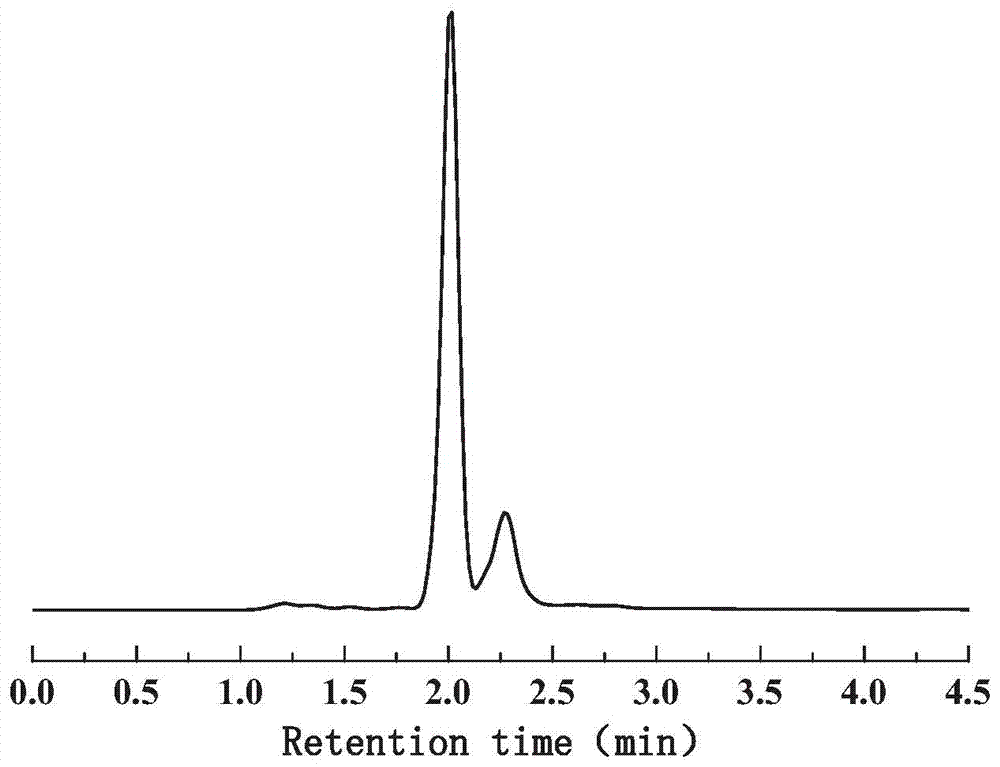

ActiveCN102850353BImprove overall utilizationHigh purityOrganic chemistryDicyclohexylureaCarbamazepine

The invention relates to the field of a medicine synthesis technology, and in particular relates to a preparation method of carbamazepine (CBZ)-valaciclovir. The preparation method comprises the steps of: reacting CBZ-L-valine with an acyl chlorination reagent to obtain acyl chloride; then, reacting acyl chloride with a mixed system of acyclovir and an acid-binding agent; and finally, filtering and refining to obtain the CBZ-valaciclovir. According to the method, acyl chloride is utilized to prepare ester, dicyclohexylcarbodiimide (DCC) is not used in the reaction process and does not generate dicyclohexylurea (DCU) is not remianed in the product, thus being beneficial to improvement of the palladium-carbon utilization rate; and the preparation method disclosed by the invention is an effective method for preparing the high-purity CBZ-valaciclovir.

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

Preparation method of carbamazepine (CBZ)-valaciclovir

ActiveCN102850353AImprove overall utilizationHigh purityOrganic chemistryDicyclohexylureaCarbamazepine

The invention relates to the field of a medicine synthesis technology, and in particular relates to a preparation method of carbamazepine (CBZ)-valaciclovir. The preparation method comprises the steps of: reacting CBZ-L-valine with an acyl chlorination reagent to obtain acyl chloride; then, reacting acyl chloride with a mixed system of acyclovir and an acid-binding agent; and finally, filtering and refining to obtain the CBZ-valaciclovir. According to the method, acyl chloride is utilized to prepare ester, dicyclohexylcarbodiimide (DCC) is not used in the reaction process and does not generate dicyclohexylurea (DCU) is not remianed in the product, thus being beneficial to improvement of the palladium-carbon utilization rate; and the preparation method disclosed by the invention is an effective method for preparing the high-purity CBZ-valaciclovir.

Owner:SHANDONG JINCHENG PHARMACEUTICAL GROUP CO LTD

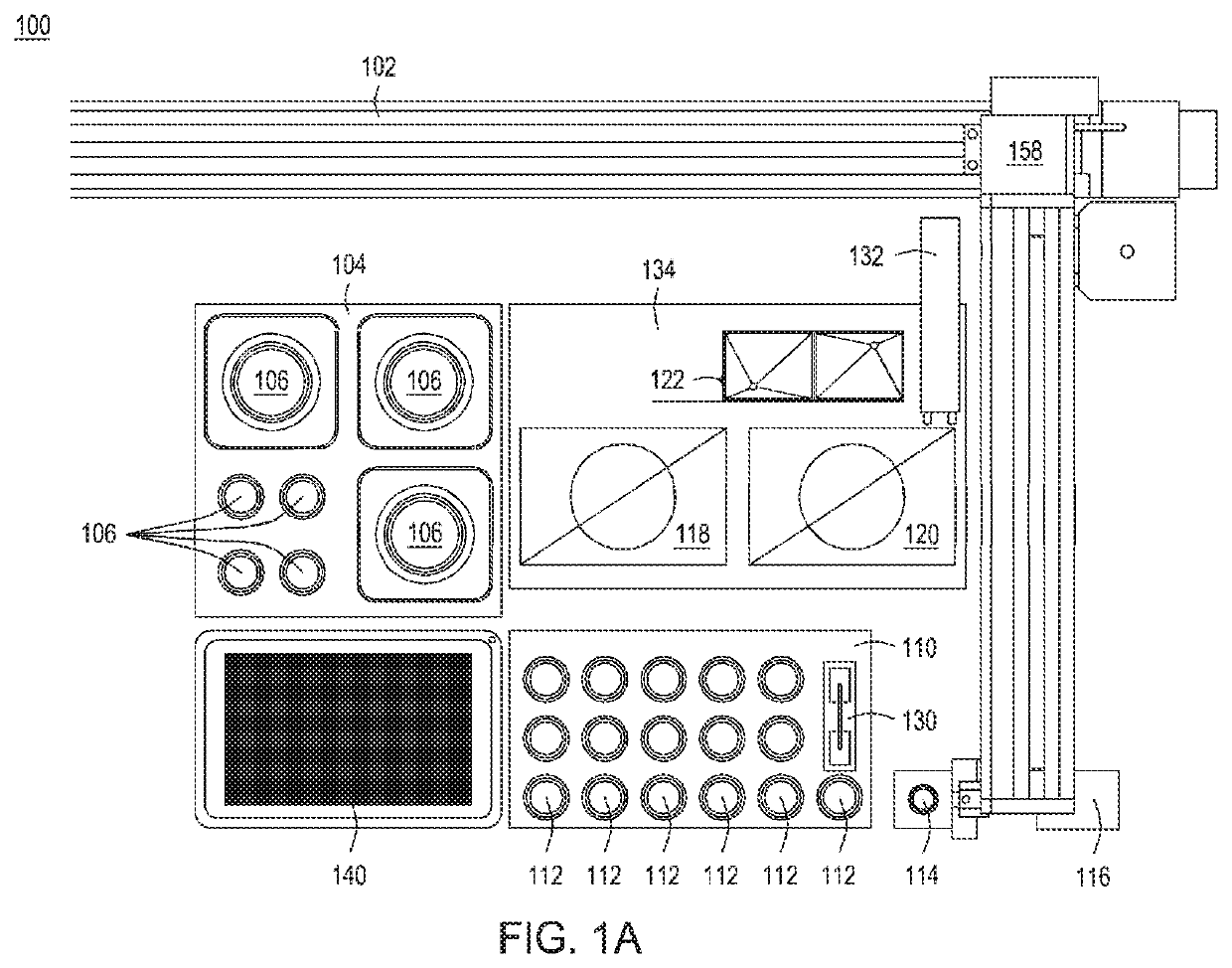

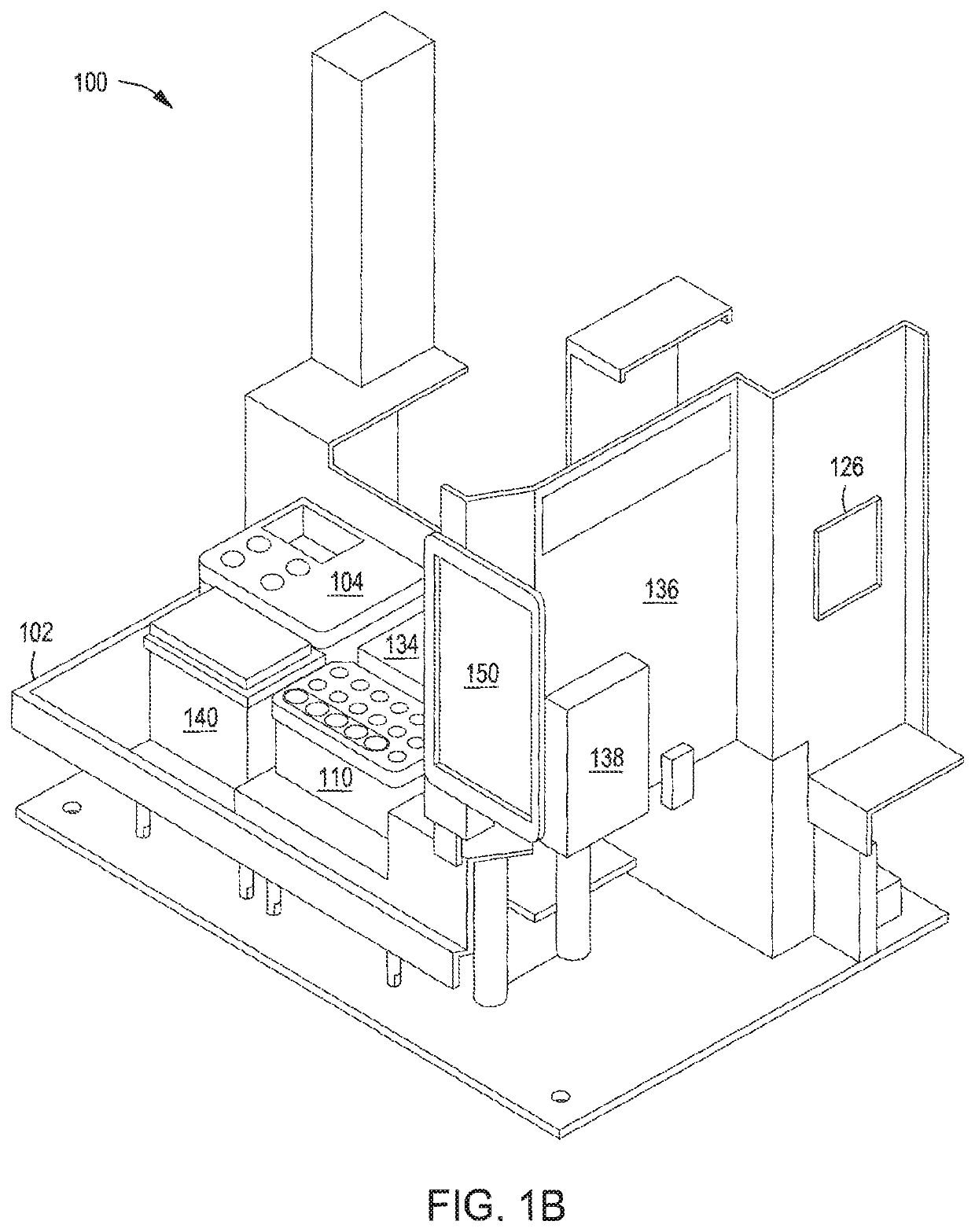

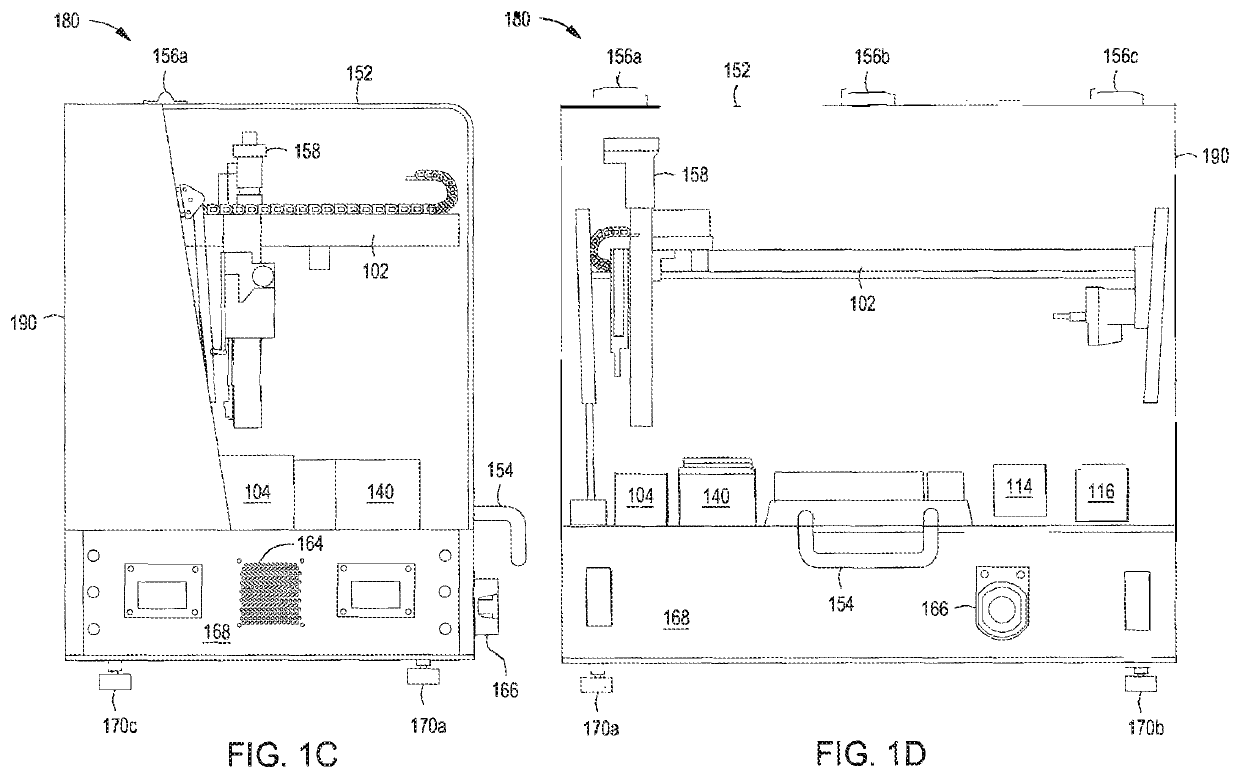

Multiplexed engineered cells and systems for biofuel production

PendingUS20220267812A1Increase productionImprove heat resistanceBacteriaHydrolasesBiotechnologyHeterologous

The present disclosure provides multiplexed engineered cells, automated multi-module instruments and methods of producing biofuel producing cells for enhanced production of biofuels. This platform empowers users to design genetic variant libraries of insertions, swaps, and / or deletions, that can be intentionally or randomly positioned across the entire genome to generate engineered cell populations with improved properties for several common biofuel applications including, but not limited to, improved tolerance to biomass inhibitors, increased thermo-tolerance, increased ethanol production and / or tolerance, expanded carbon utilization abilities, and increased utilization of heterologous proteins or pathways.

Owner:INSCRIPTA INC

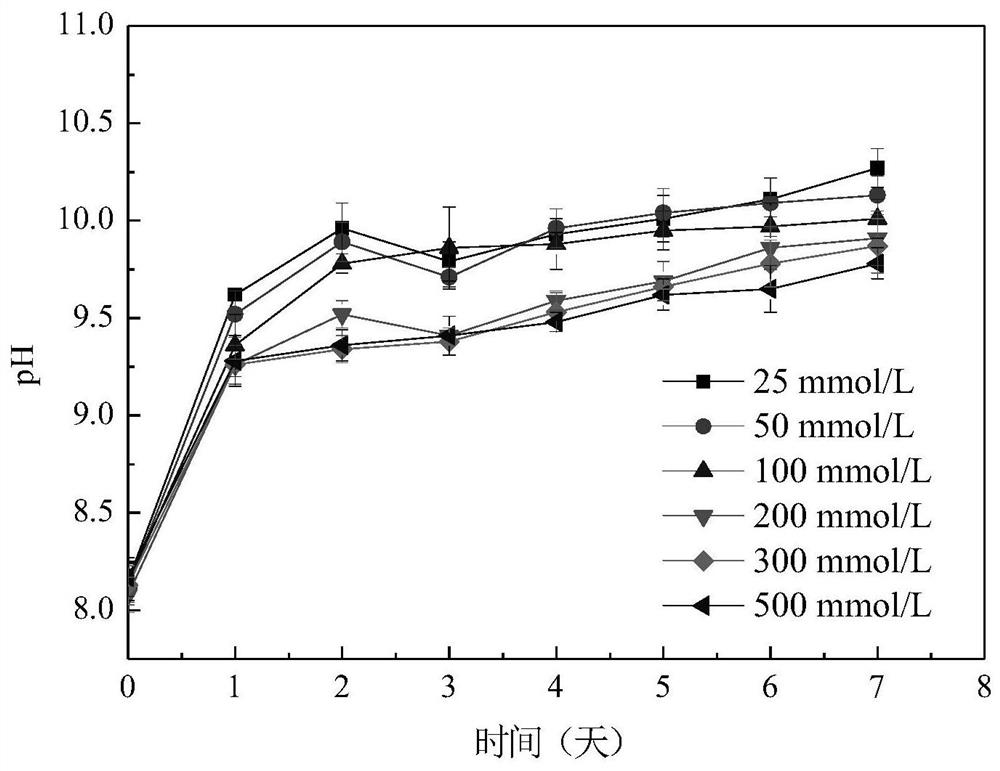

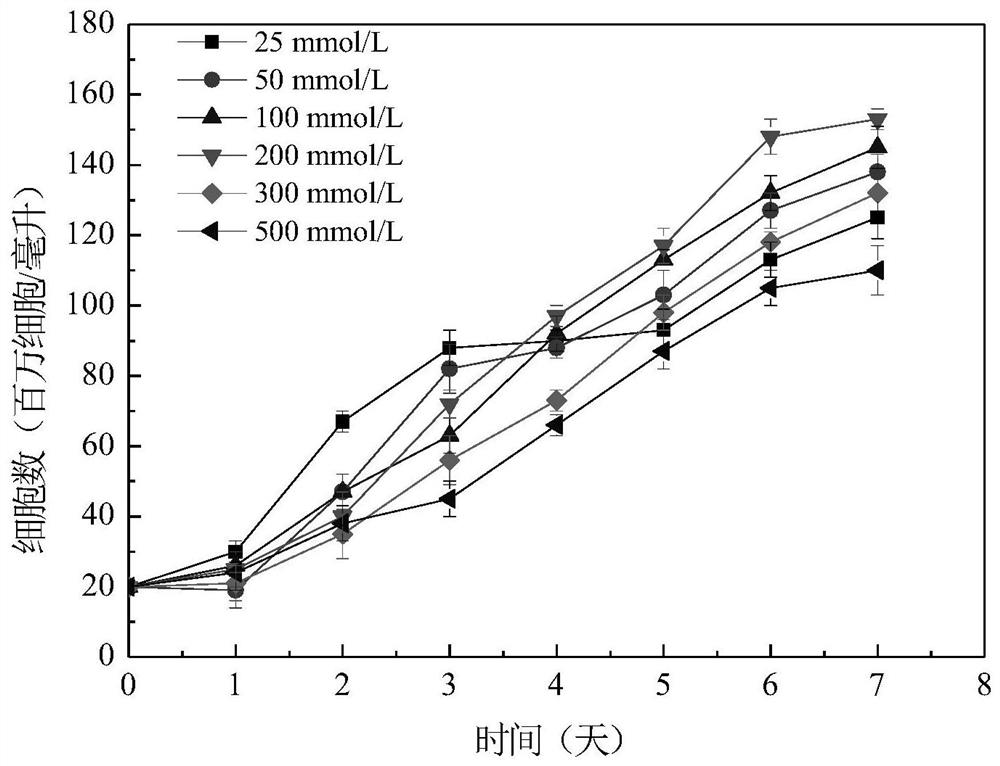

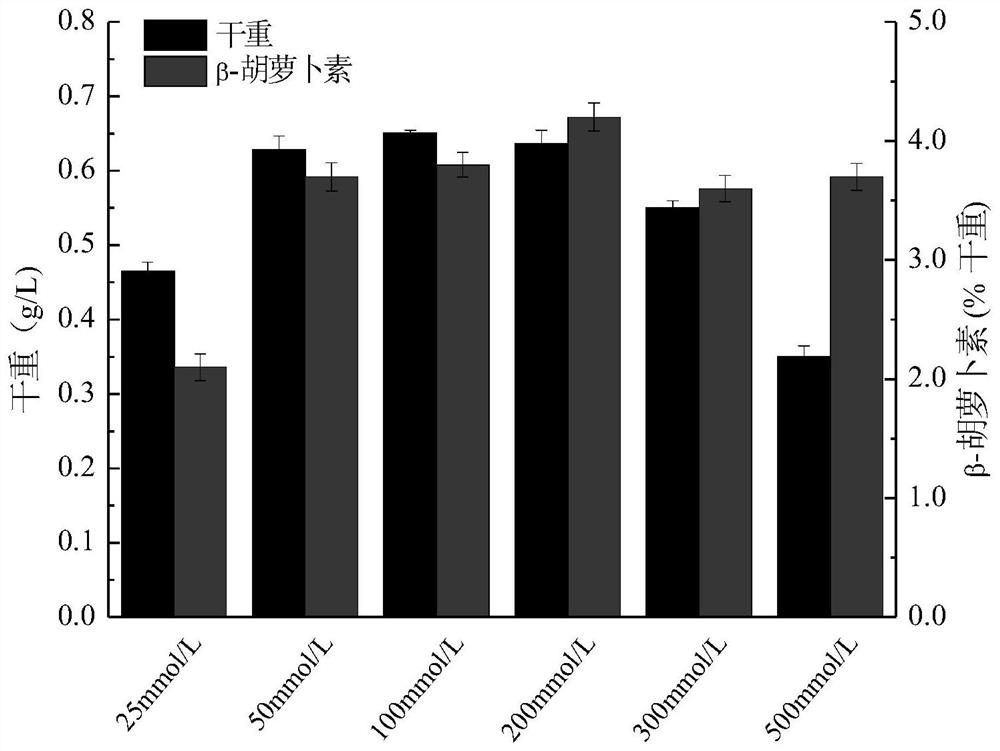

A Dunaliella culture medium utilizing sodium bicarbonate as a carbon source and its application

ActiveCN108342323BAvoid deathGood pH buffering effectUnicellular algaeMicroorganism based processesBiotechnologyDunaliella salina

The invention discloses a Dunaliella culture medium using sodium bicarbonate as a carbon source and its application, specifically a Dunaliella culture medium using bicarbonate as the sole carbon source, a method for cultivating Dunaliella using it, and optimization of the culture medium Including calcium and magnesium ion optimization, trace element optimization. Adopting the Dunaliella culture medium of the present invention can well provide the carbon source source used in Dunaliella, thereby ensuring the growth of Dunaliella. At the same time, using sodium bicarbonate as a carbon source can also increase the concentration of β-carrot in Dunaliella salina. More importantly, the use of bicarbonate as a carbon source can also maintain the pH in the culture system in a range that is conducive to the growth of Dunaliella salina, so as to improve the growth rate of Dunaliella salina, but not As for the death of the cultivated Dunaliella salina caused by the high pH, the cultivation method is simple, low in cost and high in carbon utilization efficiency, and is suitable for industrial application.

Owner:DALIAN UNIV OF TECH

A device and method for directly producing methane based on coal chemical looping gasification

ActiveCN106220461BReduce consumptionReduce generationHydrocarbon from carbon oxidesCatalystsMethanationSlag

The invention belongs to the technical field of preparation of substitutive natural gas from coal, and relates to a device and method for directly preparing methane based on coal chemical chain gasification. Pulverized coal particles pass through the upper portion of a chemical chain gasification reactor and enter a chemical chain gasification reactor, oxidation state multifunctional composite oxygen carrier particles and unreacted carbon in the pulverized coal particles enter a regeneration reactor on the upper portion of a coal methanation section through a first flowing control device, coal slag obtained after reacting is discharged through a slag discharging opening, gas separated by a cyclone separator sequentially passes through a gas purifying unit and a gas separation unit, methane gas is obtained, and coal ash obtained after separation of the cyclone separator, part of unreacted carbon and the oxidation state multifunctional composite oxygen carrier particles return to the chemical chain gasification reactor or the regeneration reactor again to be recycled. The device is simple in structure and convenient to operate, the process theory is scientific, the raw materials are easy to obtain, cost is low, thermal efficiency is high, the carbon utilization efficiency is high, fewer pollutants are generated, and environmental friendliness is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

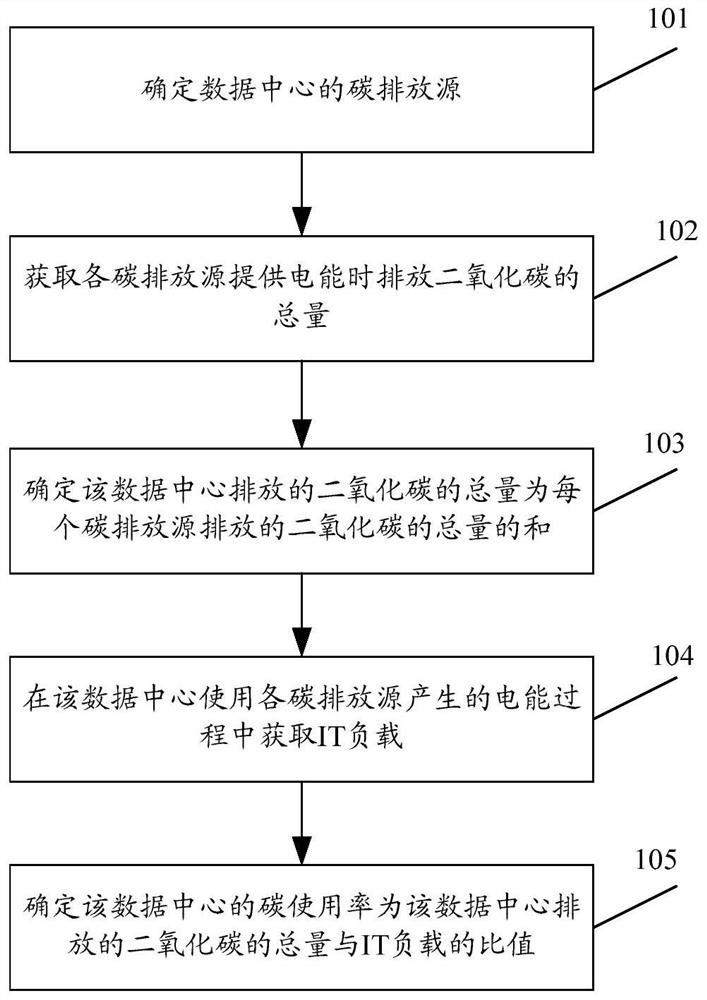

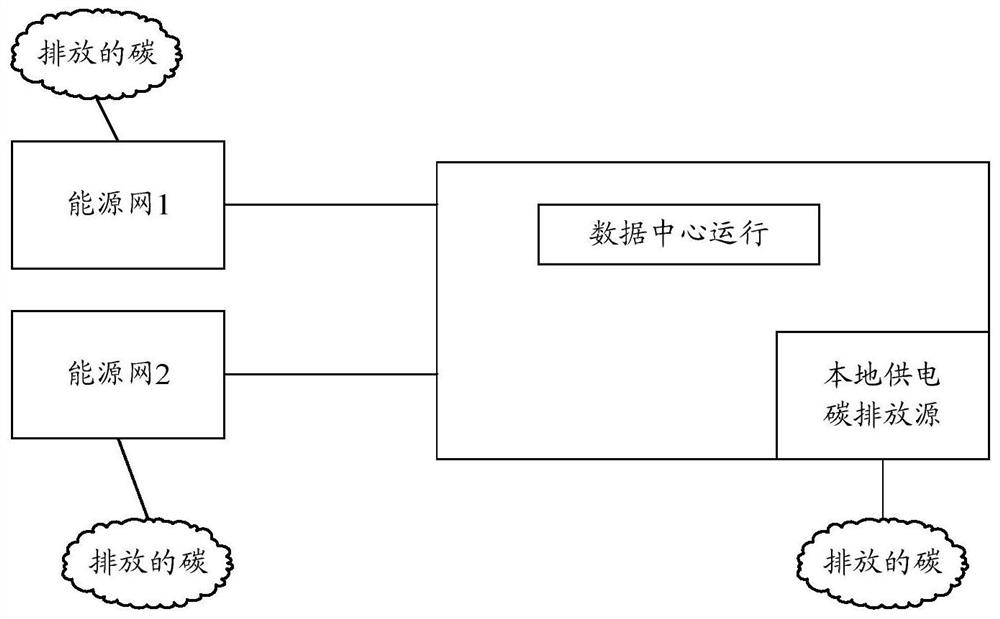

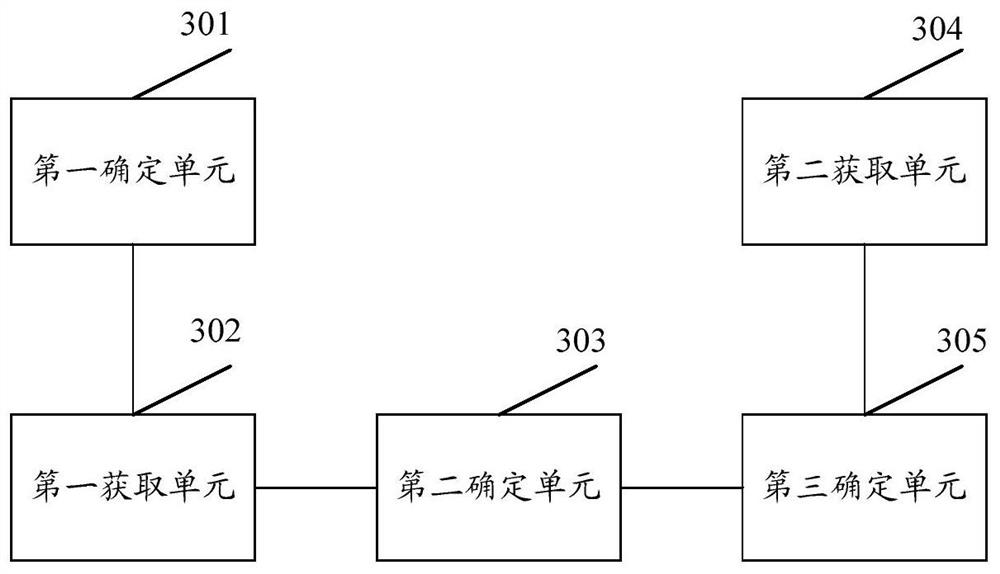

Method and device for determining carbon utilization rate of data center

The invention provides a method and device for determining the carbon utilization rate of a data center. The method comprises the steps: determining a carbon emission source of the data center; obtaining the total amount of carbon dioxide discharged when each carbon emission source provides electric energy; determining that the total amount of carbon dioxide emitted by the data center is the sum of the total amount of carbon dioxide emitted by each carbon emission source; obtaining an IT load in the process that the data center uses the electric energy generated by each carbon emission source;determining that the carbon utilization rate of the data center is the ratio of the total amount of carbon dioxide discharged by the data center to the IT load. The method can accurately determine the carbon usage rate of the data center.

Owner:CHINA ACADEMY OF INFORMATION & COMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com