Low-carbon efficient system and method for combination supply of coal and coke-oven gases to produce ethylene glycol

A technology of ethylene glycol and coke oven gas, which is applied in the direction of chemical instruments and methods, carbon monoxide or formate reaction preparation, organic compound preparation, etc., can solve the problems of environmental pollution and waste of resources, and reduce environmental pollution and Greenhouse gas emission and the effect of increasing commercial utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

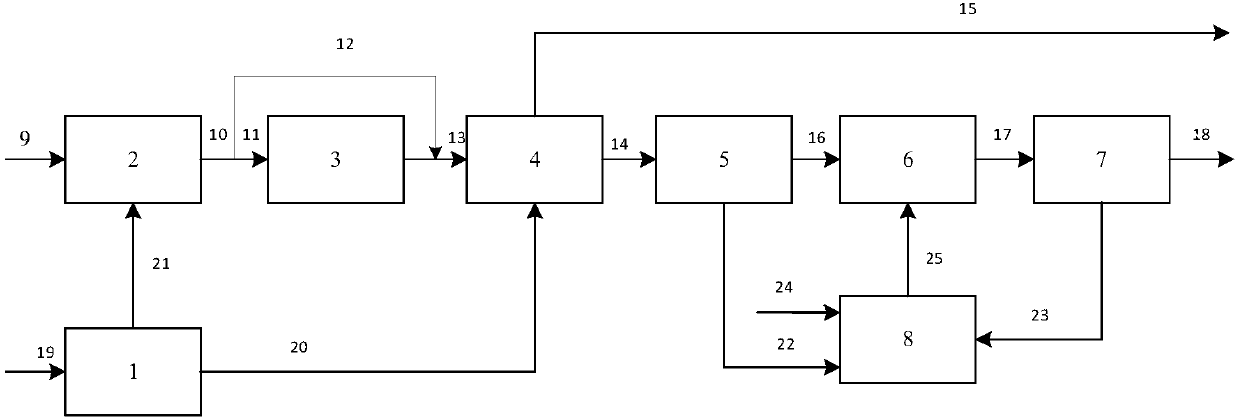

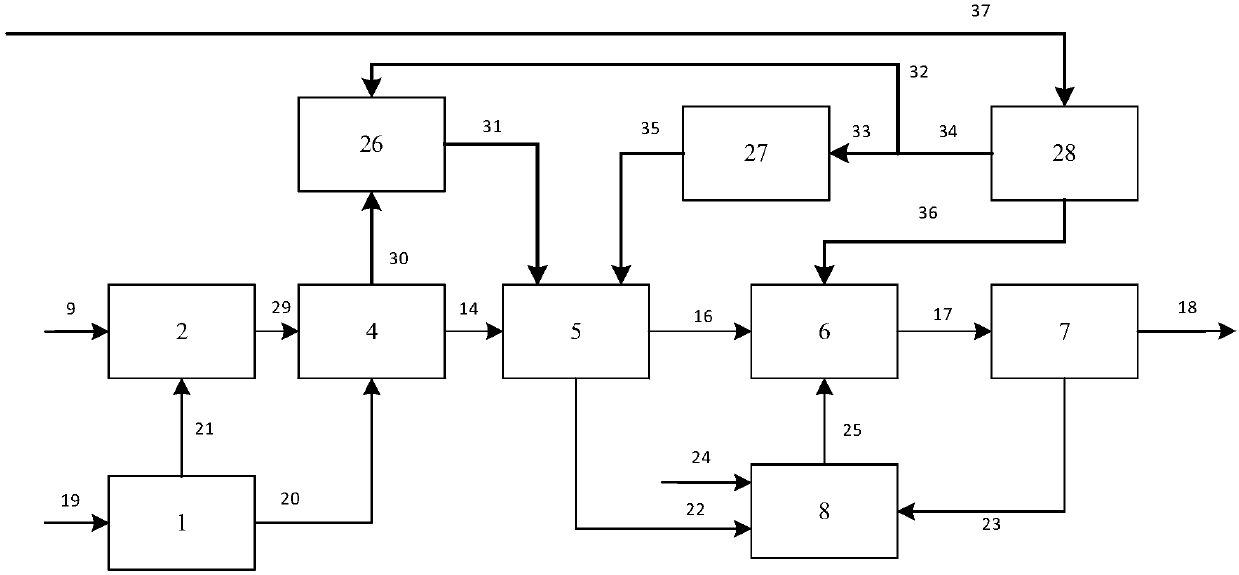

[0043] A low-carbon and high-efficiency coal and coke oven gas combined supply system for producing ethylene glycol of the present invention such as figure 2 As shown, it mainly includes: air separation unit 1, coal gasification unit 2, acid gas removal unit 4, hydrogen / carbon monoxide separation unit 5, ethylene glycol synthesis unit 6, ethylene glycol refining unit 7, dimethyl oxalate synthesis unit 8. Methane dry reforming unit 26 , methane steam reforming unit 27 and coke oven gas purification unit 28 .

[0044] Wherein: the air separation unit 1 is provided with an air inlet, a nitrogen outlet and an oxygen outlet; the coal gasification unit 2 is provided with a raw coal inlet, an oxygen inlet and a gasification synthesis gas outlet; the acid gas removal unit 4 is provided with a gasification synthesis gas inlet, Nitrogen gas inlet, carbon dioxide outlet and purified synthesis gas outlet; hydrogen / carbon monoxide separation unit 5 is provided with purified synthesis gas ...

Embodiment 2

[0063] This embodiment utilizes the system and method in embodiment 1 to carry out ethylene glycol production, wherein:

[0064] The flow rate of raw coal entering the system is 100t / h, and the feed flow rate of coke oven gas is 68t / h; the ratio of the amount of hydrogen to carbon monoxide separated by the hydrogen / carbon monoxide separation unit is 1.86:1; in the ethylene glycol synthesis unit , the feed molar ratio of hydrogen to dimethyl oxalate is 45.8; the temperature of the methane dry reforming unit is 850°C, the feed molar ratio of carbon dioxide and methane is 1:1; the temperature of the methane steam reforming unit is 900°C, and the steam The feed molar ratio to methane is 3.5.

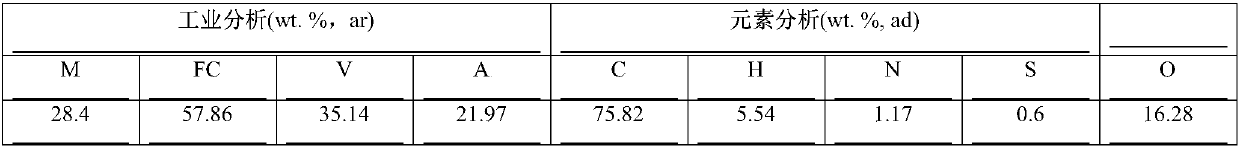

[0065] The industrial analysis and elemental analysis of raw coal are shown in Table 1, and the process flow chart is as follows figure 2 .

[0066] Table 1 Industrial analysis and elemental analysis of raw coal

[0067]

[0068] Note: M, FC, V and A in the table represent the content...

Embodiment 3

[0071] This embodiment utilizes the system and method in embodiment 1 to carry out ethylene glycol production, wherein:

[0072] The flow rate of raw coal entering the system is 150t / h, and the feed flow rate of coke oven gas is 165t / h; the ratio of the amount of hydrogen to carbon monoxide separated by the hydrogen / carbon monoxide separation unit is 2.0:1; in the ethylene glycol synthesis unit In the process, the feed molar ratio of hydrogen to dimethyl oxalate is 50:1; the temperature of the methane dry reforming unit is 900°C, the feed molar ratio of carbon dioxide and methane is 1.1:1.0; the temperature of the methane steam reforming unit is 850°C , the water vapor and methane feed molar ratio is 4.

[0073] The industrial analysis and elemental analysis of raw coal are shown in Table 2, and the process flow chart is as follows figure 2 .

[0074] Table 2 Industrial analysis and elemental analysis of raw coal

[0075]

[0076] Note: M, FC, V and A in the table represe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com