Solid biomass semi-water coal-gas producer

A technology of solid biomass and semi-water gas, which is applied in the field of energy conversion equipment and generators, can solve the problems of limiting the application range of gasifiers, low density of solid biomass energy, and low gasification intensity of gasifiers, so as to reduce specific gravity, The effect of strengthening gasification intensity, improving gasification rate and gas quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

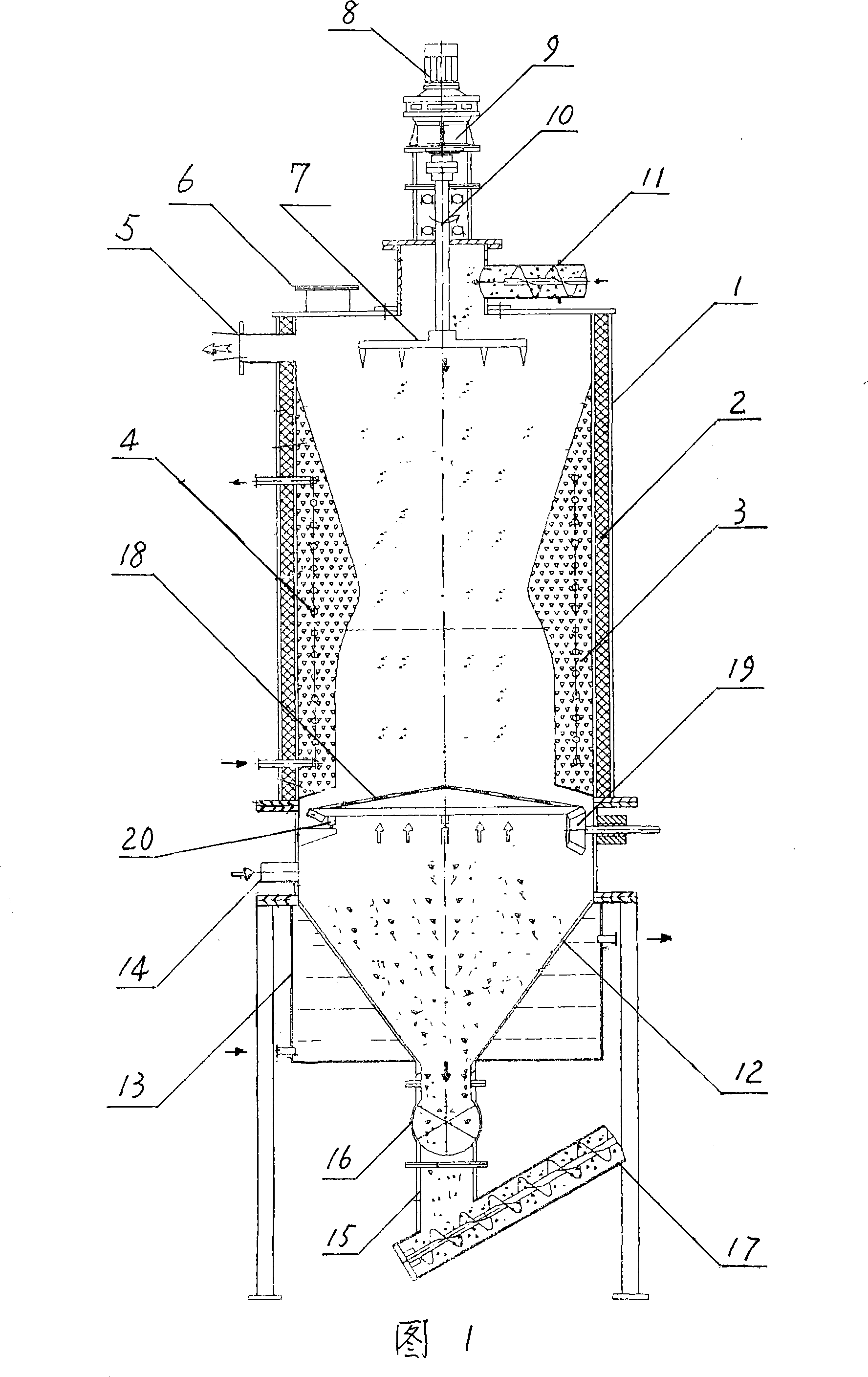

[0015] 1. Take the steel plate and process the cylindrical furnace body 1 with the gas outlet 5 and the inspection port 6, fix the insulation layer 2 in the furnace body 1, fix the refractory layer 3 on the insulation layer 2, and the inner surface of the refractory layer 3 is an arc surface, The curved surface makes the middle of the furnace a "waist" shape, and the spiral heat exchange tube 4 is preset in the refractory layer 3.

[0016] 2. Set a screw feeder 11 above the furnace body 1, set a reducer 9 and a motor 8 at the same time, process the toothed rake 7 with heat-resistant steel, and connect it to the reducer 9 through the shaft 10, and the rake 7 Located in the upper part of the furnace.

[0017] 3. Process the cone bucket-shaped ash bin 12 with a steel plate, on which there is a gasification agent inlet 14, and the cone bucket part is connected with a cooling water tank 13. Ash bin 12 bottom has ash outlet 15, and cooperates with valve 16.

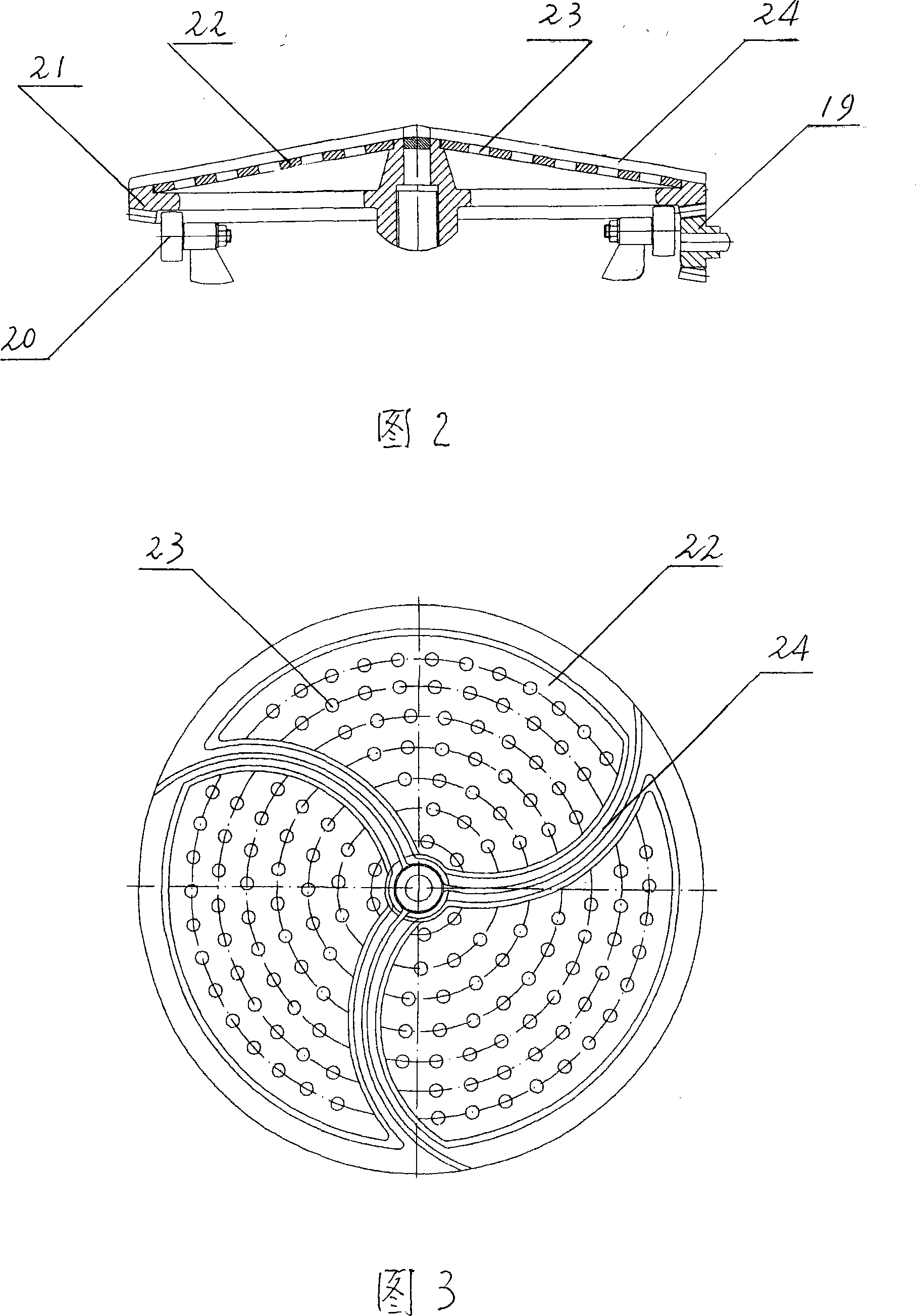

[0018] 4. The rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com