Precipitated-iron Fischer-Tropsch catalyst and preparation method and application thereof

A technology of catalyst and iron fee, which is applied in the field of precipitated iron Fischer-Tropsch catalyst and its preparation, to achieve the effect of improving corrosion resistance, improving mechanical strength, and improving the reaction performance of Fischer-Tropsch synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

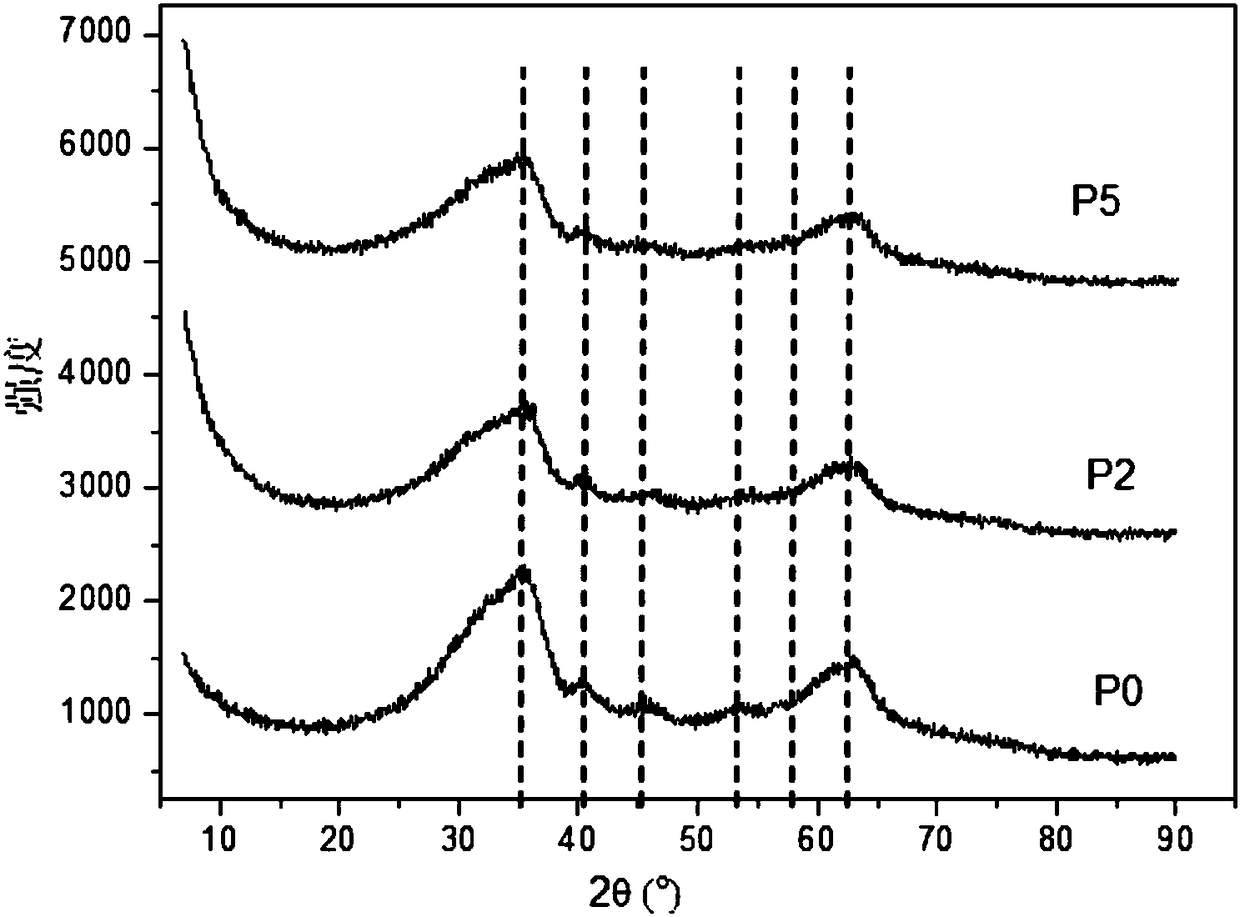

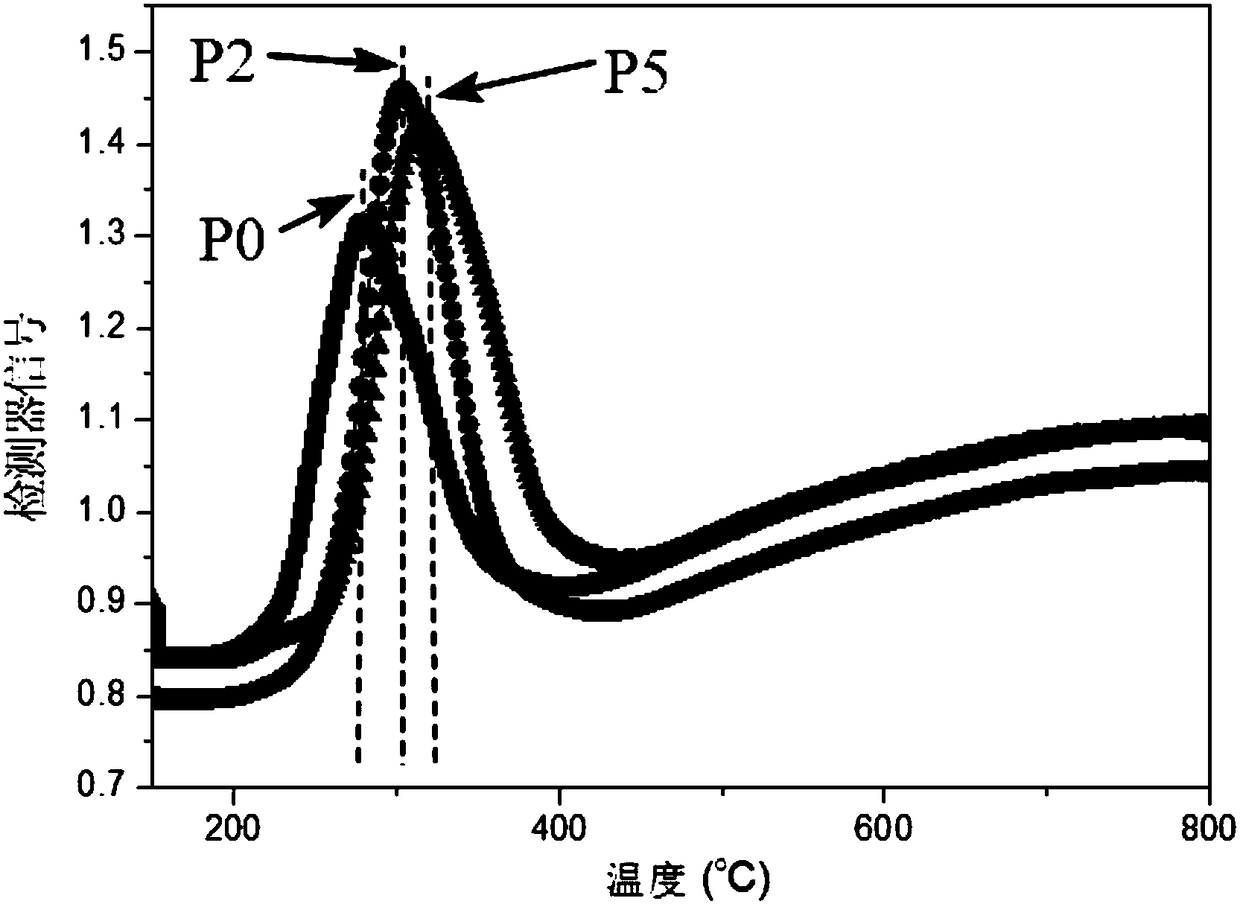

Examples

preparation example Construction

[0027] The preparation method provided by the invention is used to realize the addition of P element into the catalyst. Wherein, the iron source may be selected from various water-soluble compounds containing Fe, preferably at least one selected from ferric nitrate, ferric sulfate, and ferric chloride.

[0028] The copper source may be selected from various water-soluble compounds containing Cu, preferably at least one selected from copper nitrate, copper sulfate and copper chloride.

[0029] The phosphorus source may be selected from various water-soluble compounds containing P element, preferably at least one selected from phosphoric acid, ammonium phosphate, ammonium hydrogen phosphate and aluminum dihydrogen phosphate.

[0030] The silicon source may be selected from various water-soluble compounds containing Si element, preferably at least one selected from silica sol, potassium water glass, sodium water glass and soluble silicates.

[0031] The potassium source may be s...

Embodiment 1

[0061] 60.5g of Fe(NO 3 ) 3 , 1.49g of Cu(NO 3 ) 2 Mix with 0.88g of phosphoric acid, and add sodium carbonate to adjust the pH value to 7.5, then stir vigorously at 70°C until a coprecipitate is formed; after aging the coprecipitate for 60min, filter and wash the coprecipitate until sodium ions Remove (conductivity of filtrate is lower than 500 μ S / cm), obtain filter cake;

[0062] Add deionized water to the filter cake for beating, the solid content is 12.5% by weight; then add 30g of silica sol (concentration is 20% by weight, average particle size 10nm) and mix well, and add an appropriate amount of deionized water for beating, then add 0.62g of K 2 CO 3 Stir evenly, further disperse evenly, and obtain slurry;

[0063]The slurry was spray-dried, and the inlet temperature was controlled to be 270° C., and the outlet temperature was 120° C.; the dried product was then calcined at 500° C. for 6 hours to obtain a precipitated iron Fischer-Tropsch catalyst.

[0064] The...

Embodiment 2

[0068] 60.5g of Fe(NO 3 ) 3 and 1.49g of Cu(NO 3 ) 2 Mix with 2.22g of phosphoric acid, and add sodium carbonate to adjust the pH value to 7.0, then stir vigorously at 70°C until a coprecipitate is produced; after aging the coprecipitate for 60min, filter and wash the coprecipitate until sodium Ions are removed, the conductivity of the filtrate is lower than 500μs / cm, and a filter cake is obtained;

[0069] Add deionized water to the filter cake for beating, the solid content is 10% by weight; then add 30g of silica sol (concentration is 20% by weight, average particle size 10nm) and mix well, and add an appropriate amount of deionized water for beating, then add 0.62g of K 2 CO 3 Stir well to further disperse evenly.

[0070] The slurry is spray-dried, the inlet temperature is controlled at 270°C, and the outlet temperature is 120°C; the dried product is then calcined at 500°C for 6 hours to obtain a precipitated iron Fischer-Tropsch catalyst.

[0071] The composition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com