Process and equipment for preparing biological energy source

A technology of bio-energy and equipment, which is applied in the fields of bio-energy manufacturing equipment, cultivation of photosynthetic organisms and waste gas treatment, to achieve the effect of reducing regeneration links, improving utilization rate, reducing energy consumption and equipment investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

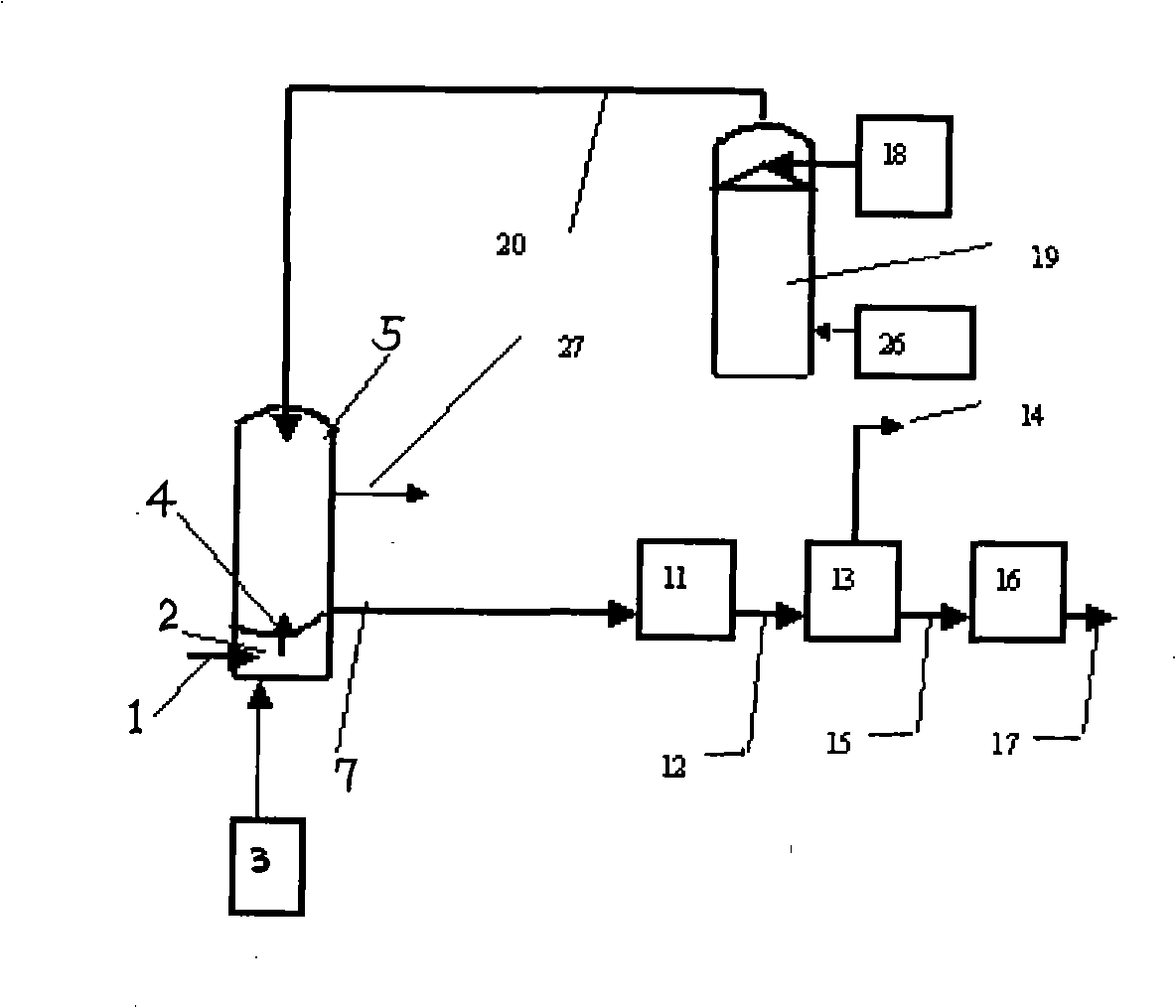

[0064] Embodiment 1 The patented technology is illustrated by taking the absorption of liquid ammonia as an example below:

[0065] The absorption separation agent or absorption separation agent precursor storage tower 18 sends the absorption separation agent or absorption separation agent precursor such as urea to the spray tower 19 after heating 26 to produce absorption separation agent 30 such as liquid ammonia. The absorption separation agent 30 such as liquid ammonia enters the absorption / separation device through the absorption separation agent supply pipe 20 .

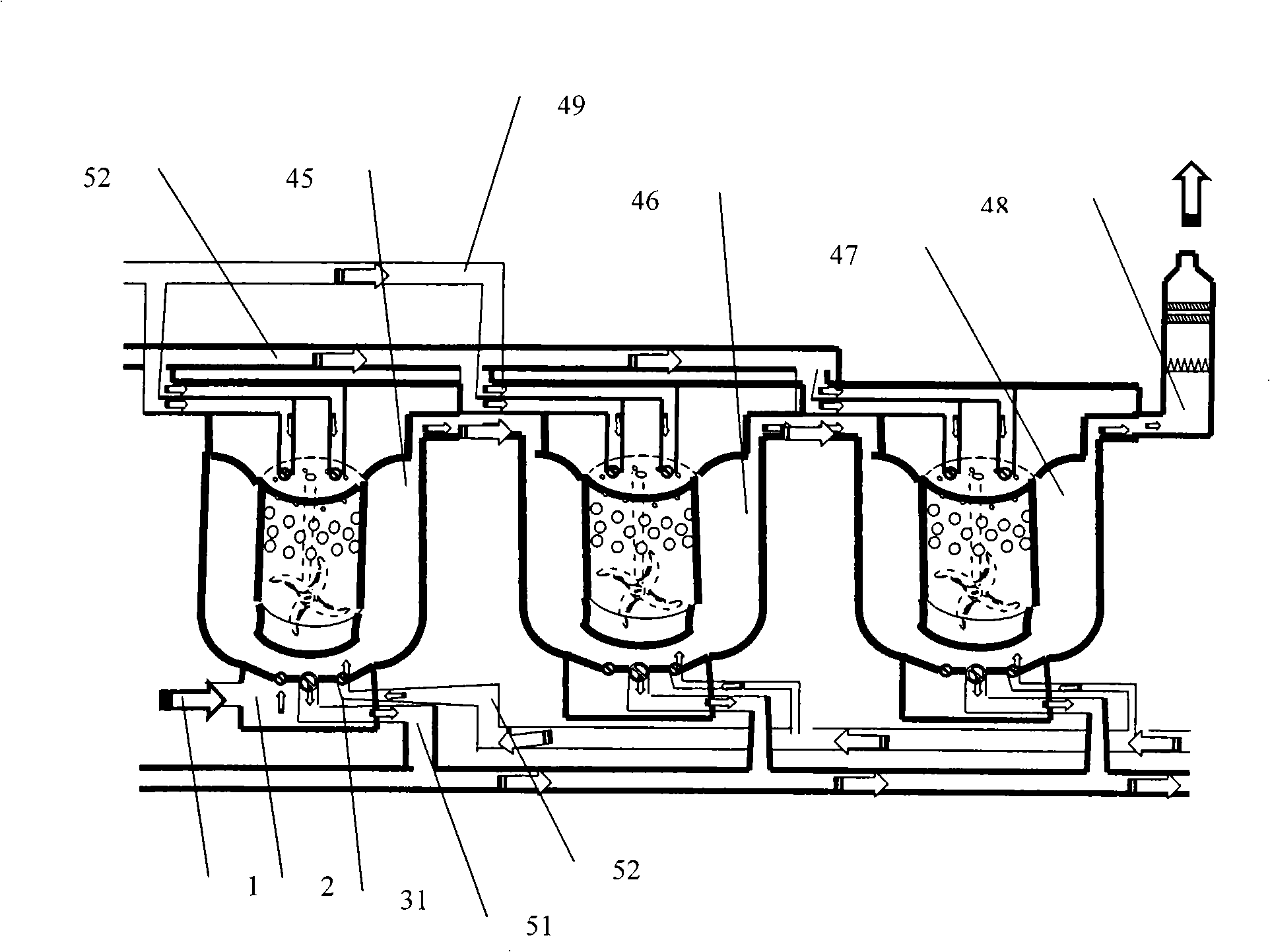

[0066] due to CO 2 Reacting with liquid ammonia can form solid sediment, which is easy to block the absorption pipe. This patent provides absorption / separation equipment designed with multi-blade radial impellers (the shaded part represents the blade part), which rotates at a speed of 1400rpm, and there is a thick hole with a large wall outside. The net (33) is detachably fixed on the upper wall of the absorber...

Embodiment 2

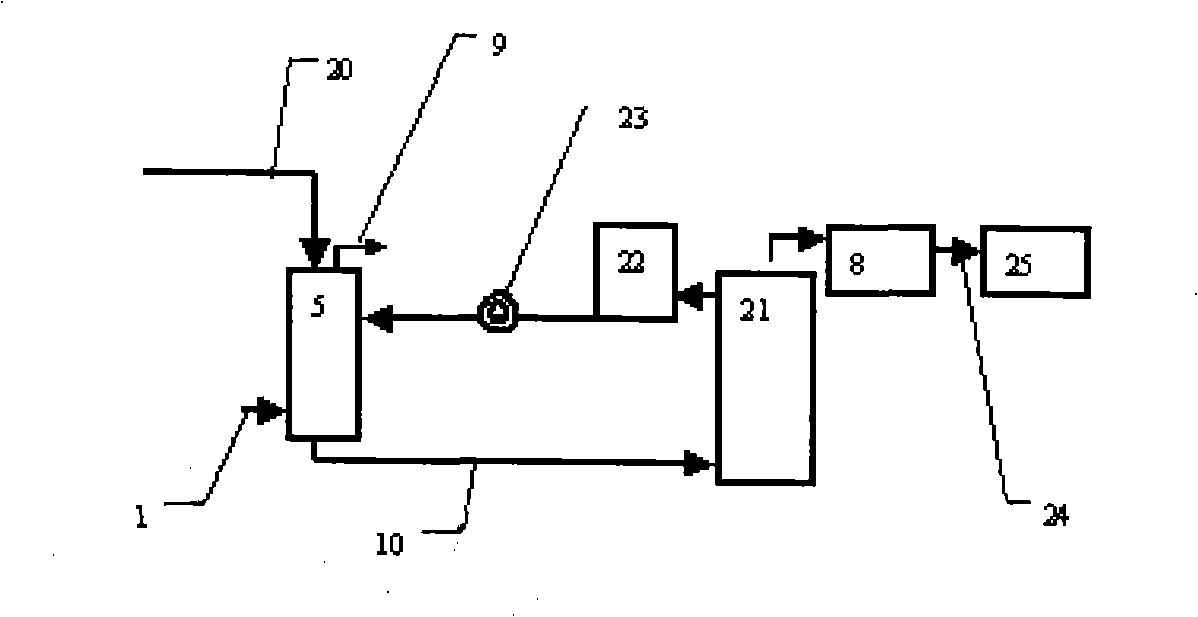

[0070] Hereinafter, the present invention will be further described by taking the combination of absorption separation agent liquid ammonia absorption and gas separation membrane as an example.

[0071] The absorption separation agent or absorption separation agent precursor storage tower 18 sends the absorption separation agent or absorption separation agent precursor such as urea to the spray tower 19 after heating 26 to produce absorption separation agent 30 such as liquid ammonia. The absorption separation agent 30 such as liquid ammonia enters the absorption / separation device through the absorption separation agent supply pipe 20 .

[0072] due to CO 2 Reacting with liquid ammonia can form solid sediment, which is easy to block the absorption pipe. This patent provides absorption / separation equipment designed with multi-blade radial impellers (the shaded part represents the blade part), which rotates at a speed of 1400rpm, and there is a thick hole with a large wall outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com