Novel lignite gasification process by using fluidized bed with ash circulation and equipment of novel lignite gasification process

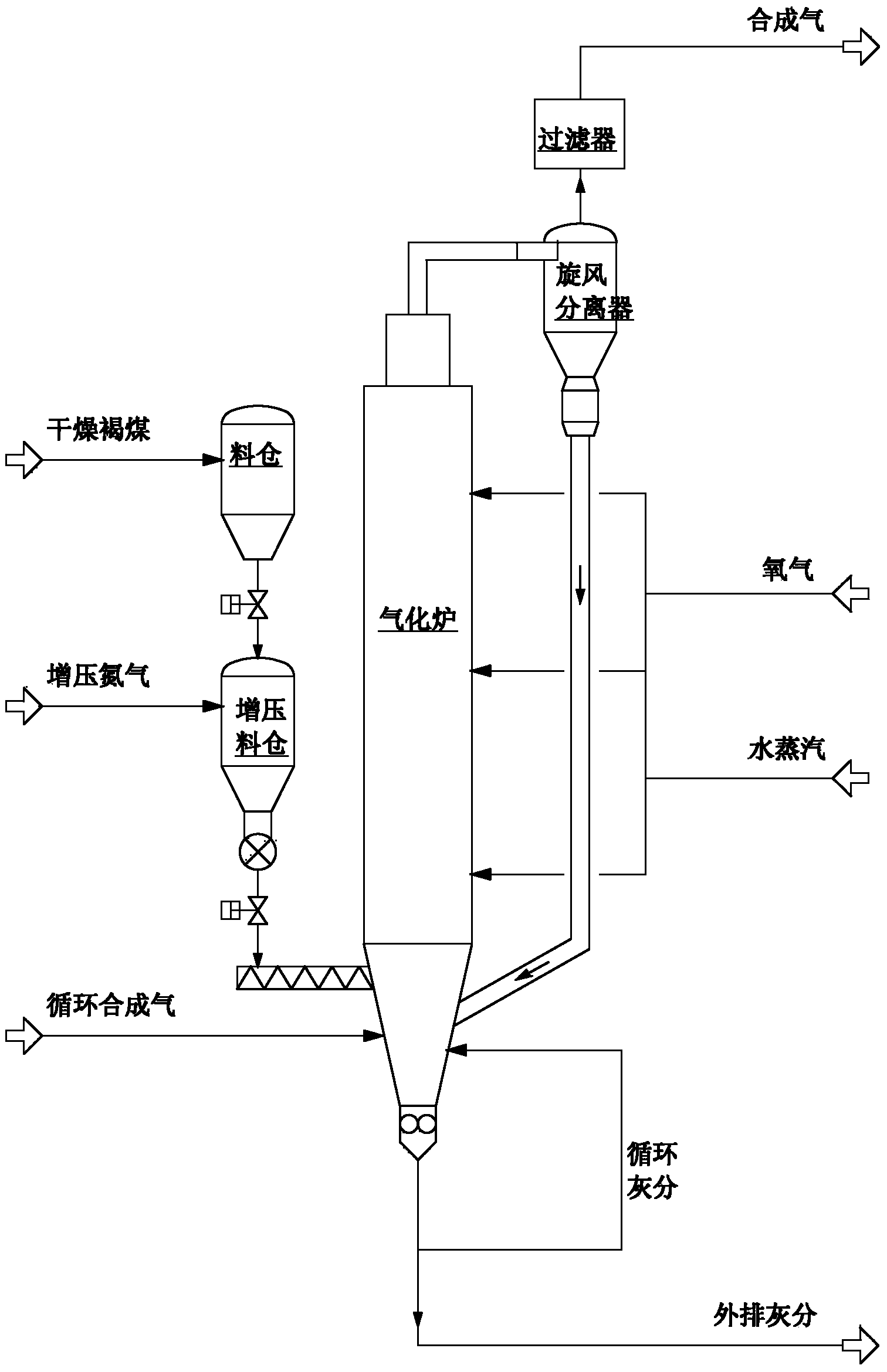

A fluidized bed gasifier and coal gasification technology, which is applied in the field of coal gasification, can solve the problems of unfavorable ash content circulation, low efficiency of synthesis gas, and difficult to circulate, and achieves the advantages of environmental friendliness, less pollutant discharge, and improved carbon utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

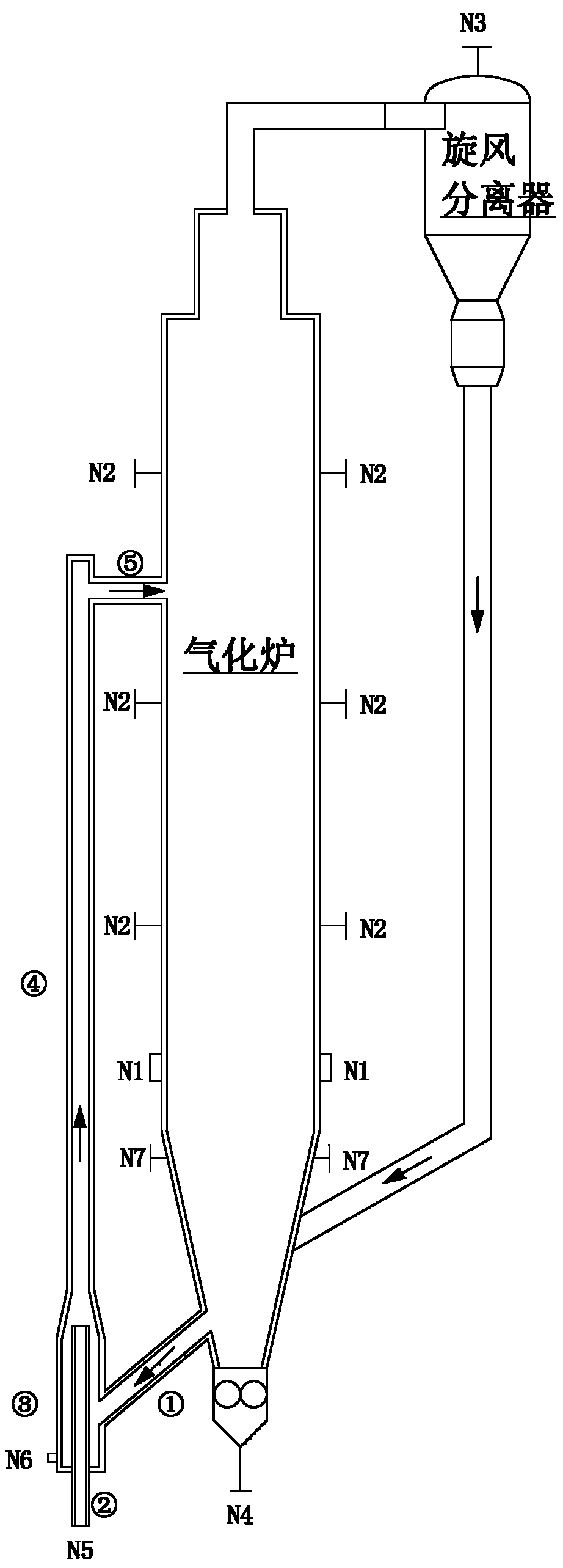

[0041] A pilot-scale lignite gasification pilot process for 2.5 kg dry basis per hour, using e.g. figure 2 Air conveyed ash circulation shown.

[0042] The temperature of the gasifier is about 1000°C, and the pressure is 0.3MPa. The dried lignite powder (the coal composition is shown in Table 1, and the particle size is less than 6mm) is sent to the gasifier through the silo, pressurized silo and screw feeder, and through the N1 port of the dry lignite raw material inlet. The cooled circulating synthesis gas enters the bottom of the gasifier through the circulating synthesis gas inlet N7, and the gas volume is adjusted so that the superficial gas velocity is about 0.1m / s. The function of the circulating syngas is to act as a loosening wind, pushing the pulverized coal upwards. The heated oxygen (about 1Nm3 / h) and water vapor (about 1kg / h) enter the gasifier through gasification agent nozzles N2 of different heights, and react with coal powder to generate synthesis gas. The...

Embodiment 2

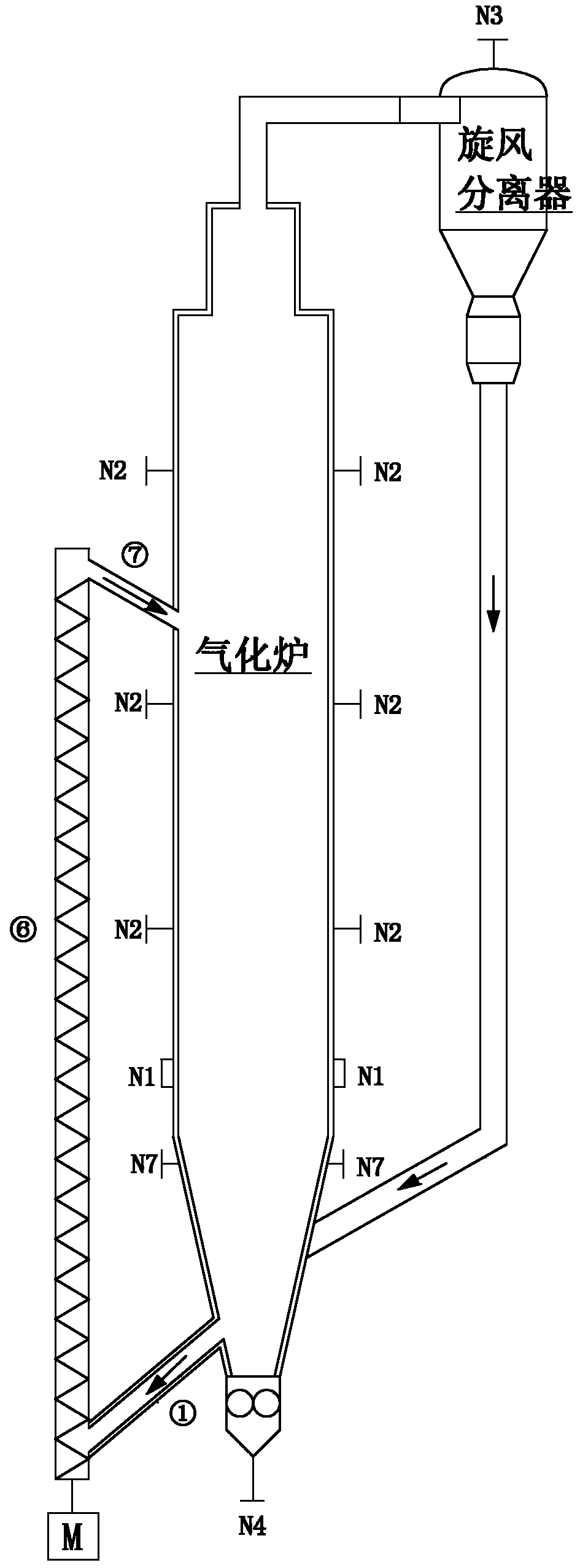

[0052] The lignite gasification test technique and equipment of the same scale as in Example 1, its main difference adopts such as image 3 Mechanically conveyed ash circulation shown. The circulating ash also flows to the vertical screw feeder ⑥ through the feeding pipe ① at the bottom of the gasifier. After the circulating ash is raised to a certain height, it returns to the gasifier through the inclined pipe ⑦ of the circulating ash returning to the gasifier. In addition, since the screw feeder is not resistant to high temperature, it is necessary to install a cooling jacket (not shown in the figure) outside the feeding inclined tube ①. The mass flow rate of the circulating ash can be controlled by the speed of the vertical screw feeder ⑥.

[0053] The ash circulation fluidized bed lignite gasification process described in the above-mentioned embodiment 1 and embodiment 2 is adopted, and the ash content can be returned to the gasifier to continue burning by using air flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com