Patents

Literature

39results about How to "Improve carbon utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment of wastewater containing phosphorous and nitrogen

InactiveUS20060249449A1Great extent of P releaseHigh P uptakeTreatment using aerobic processesSeparation devicesOxygenClarifier

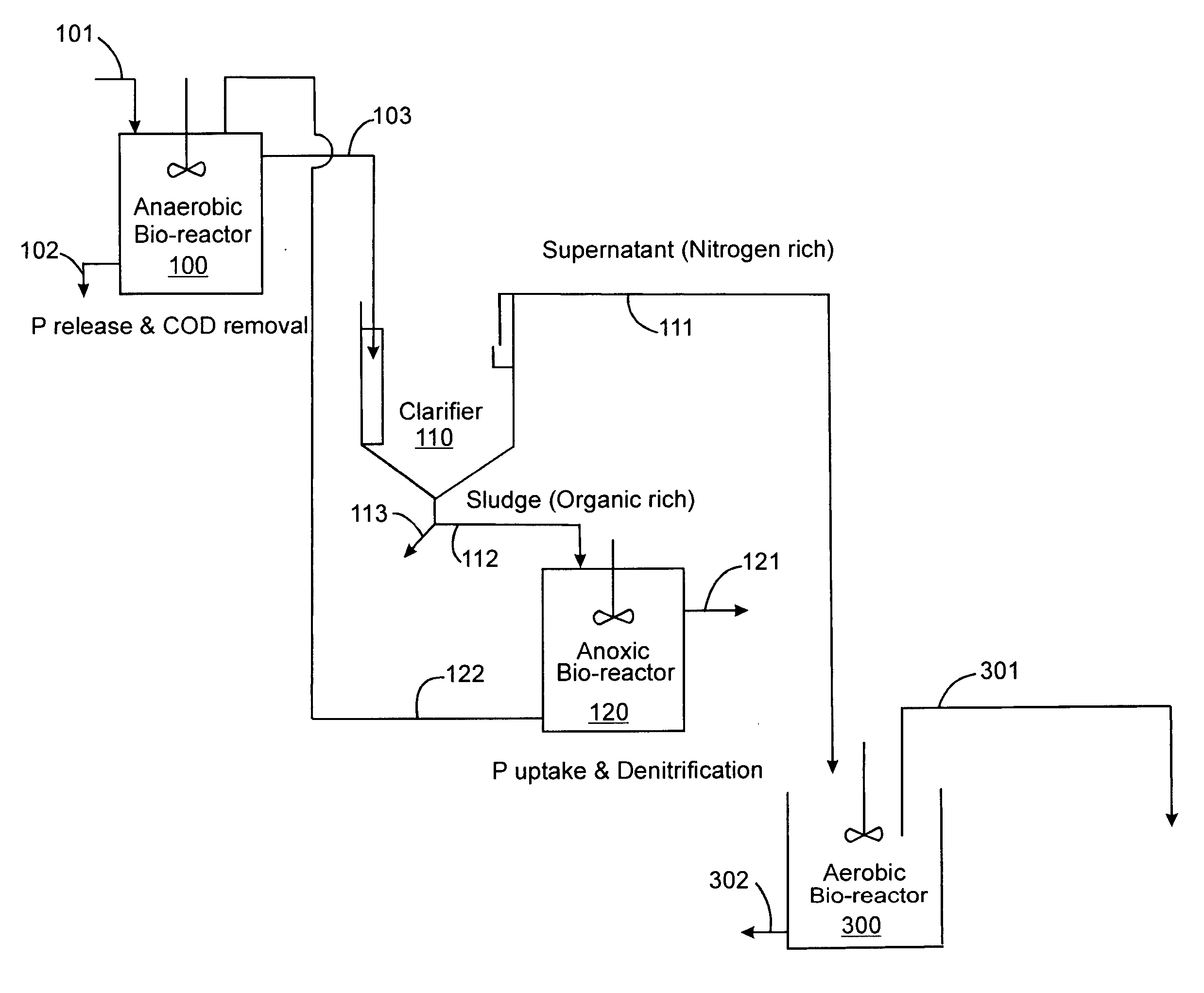

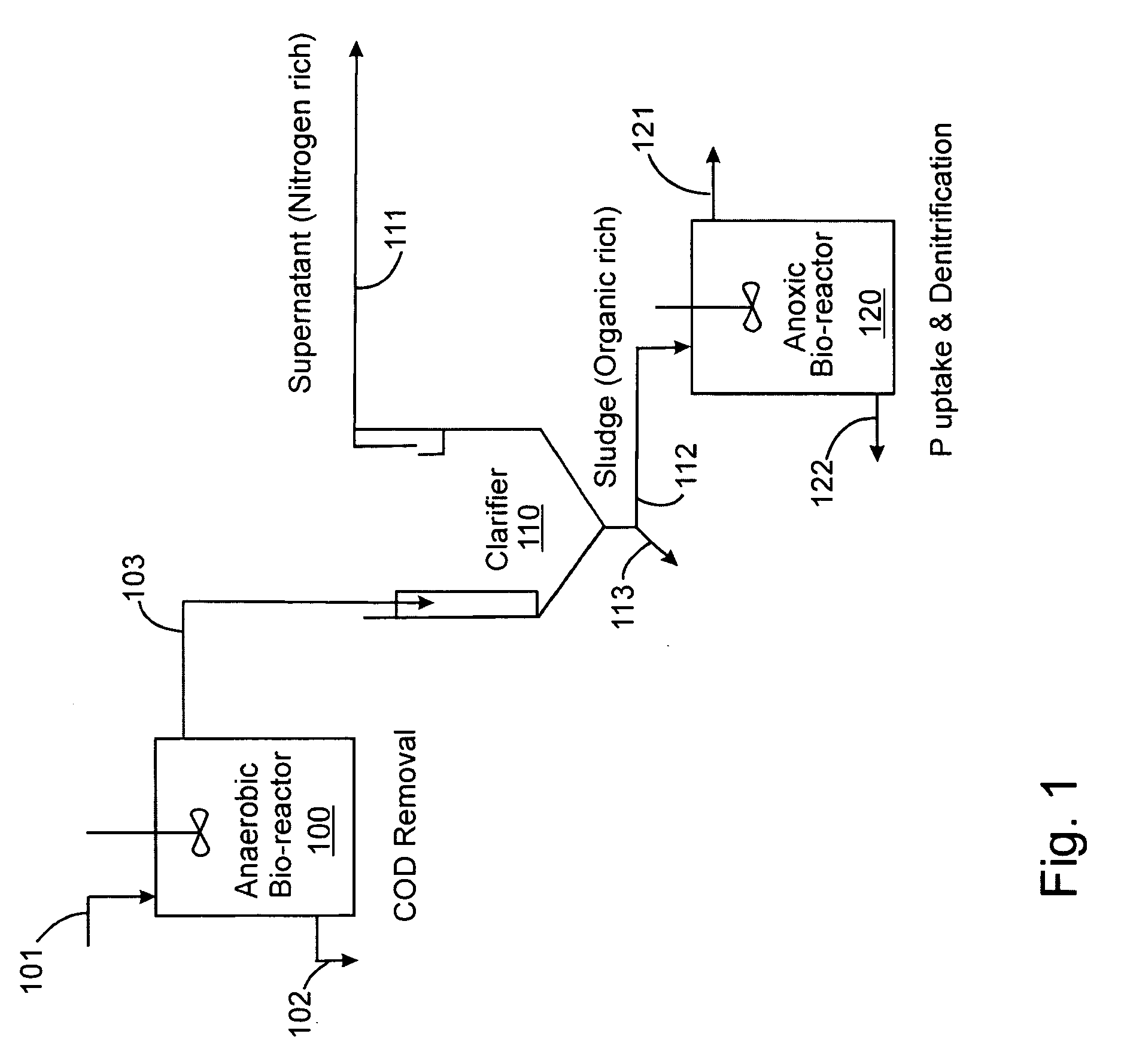

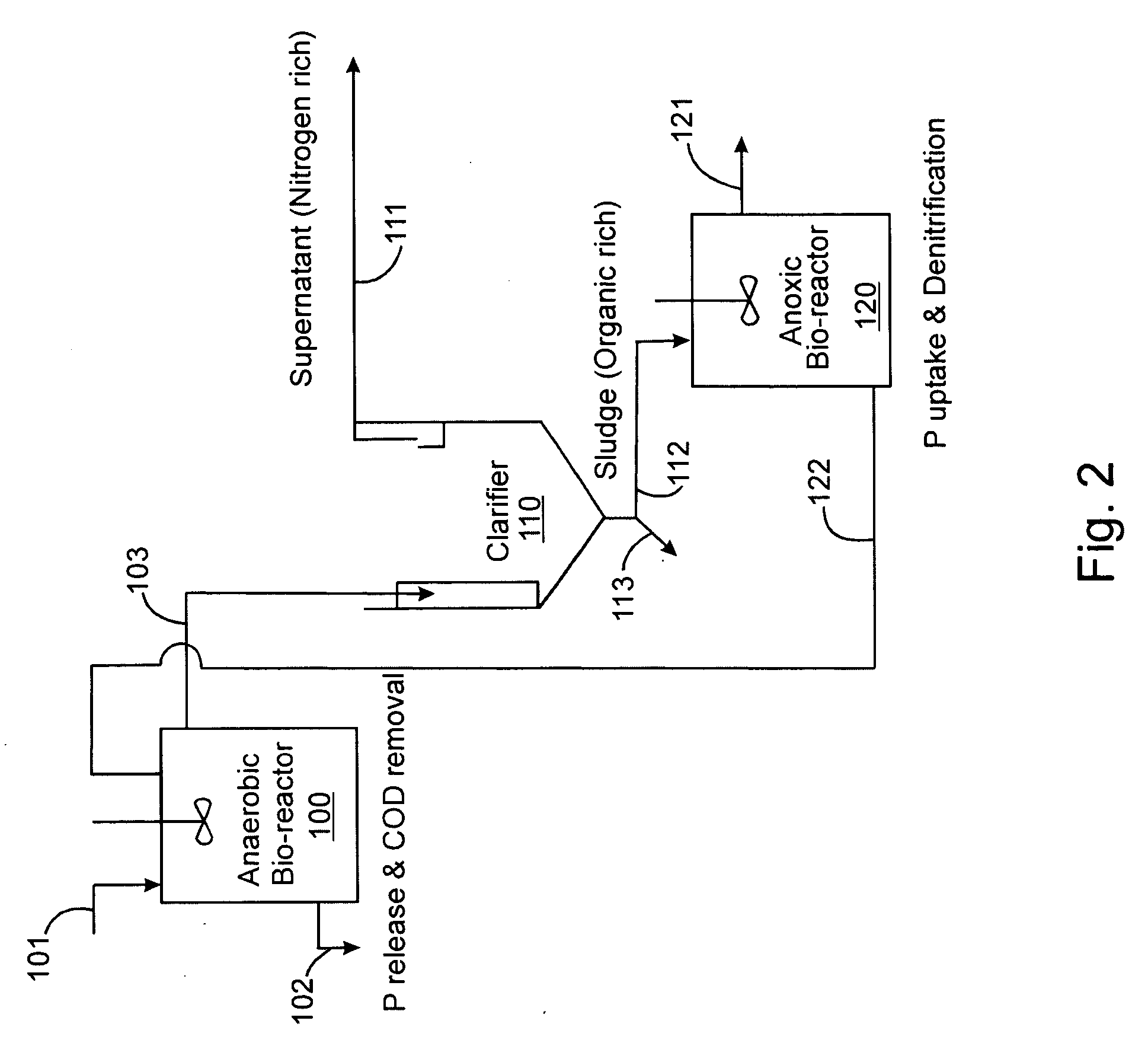

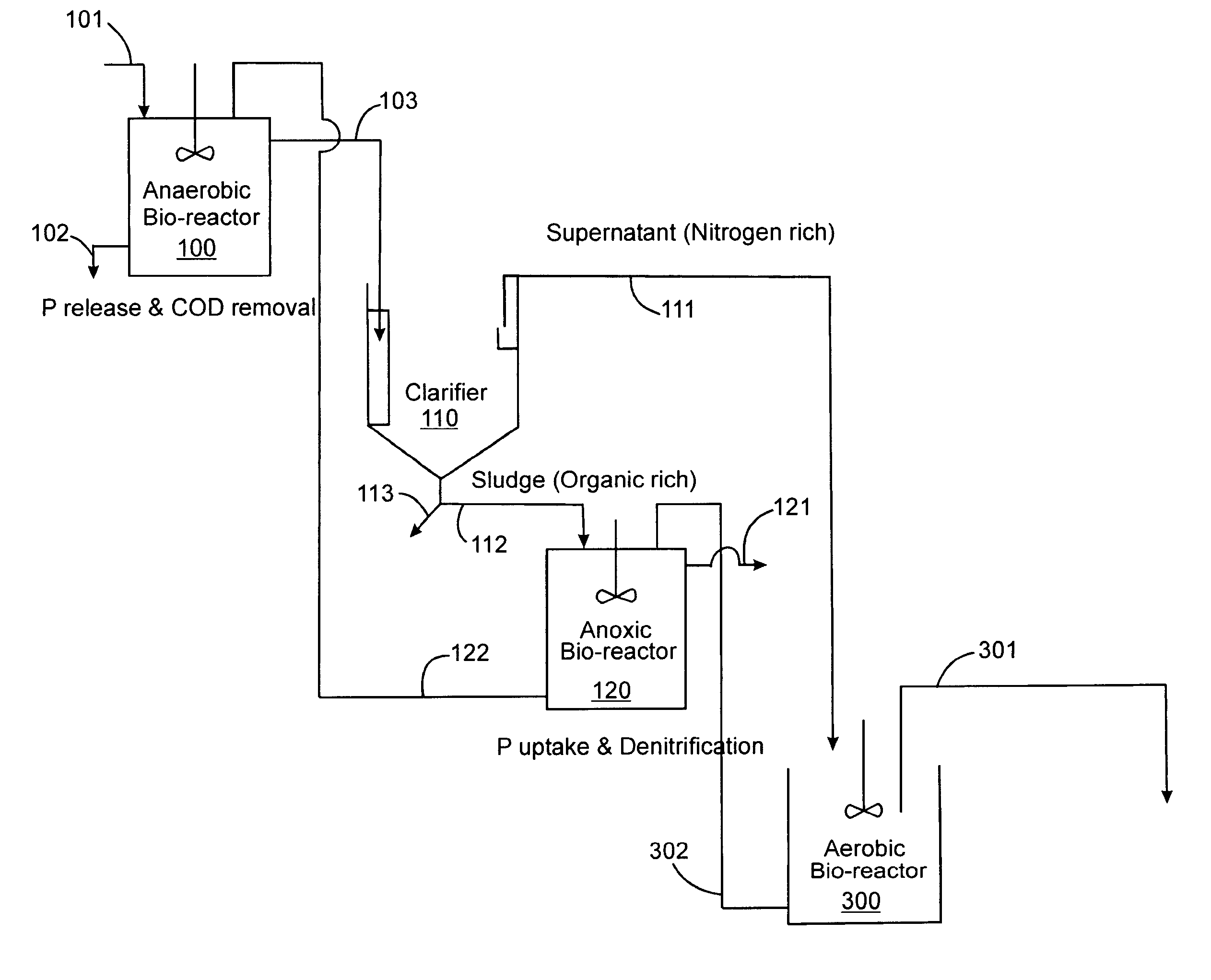

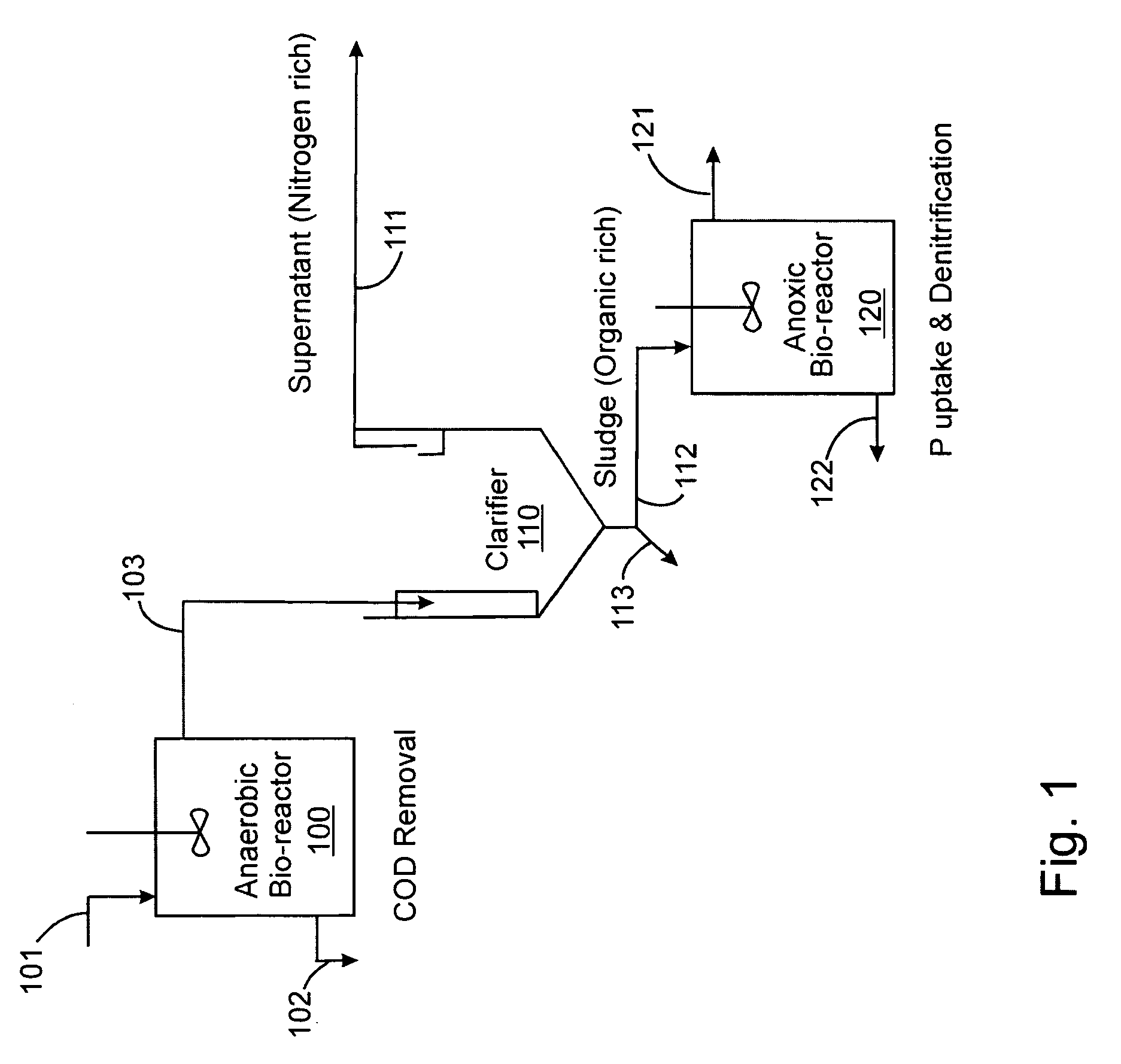

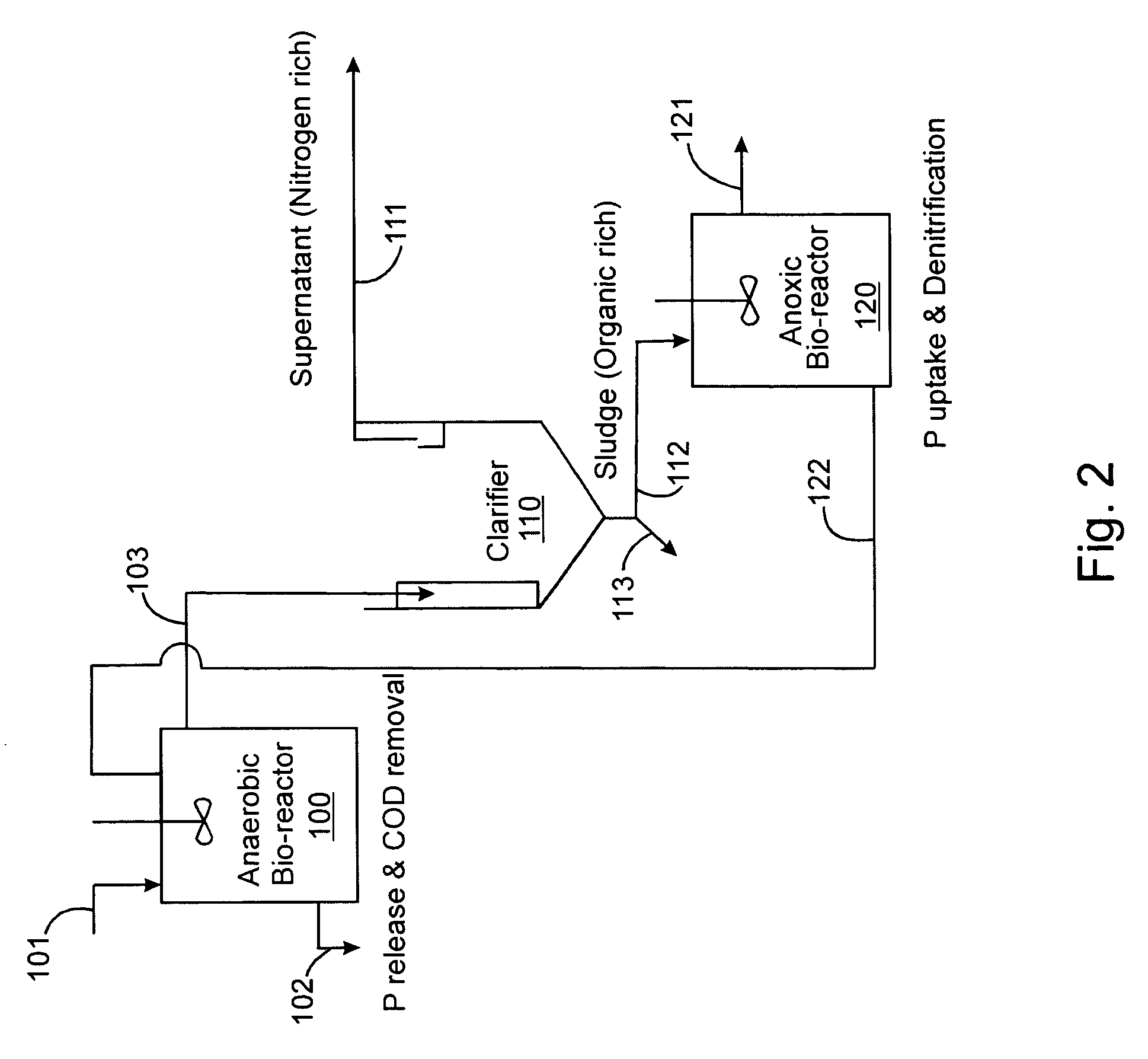

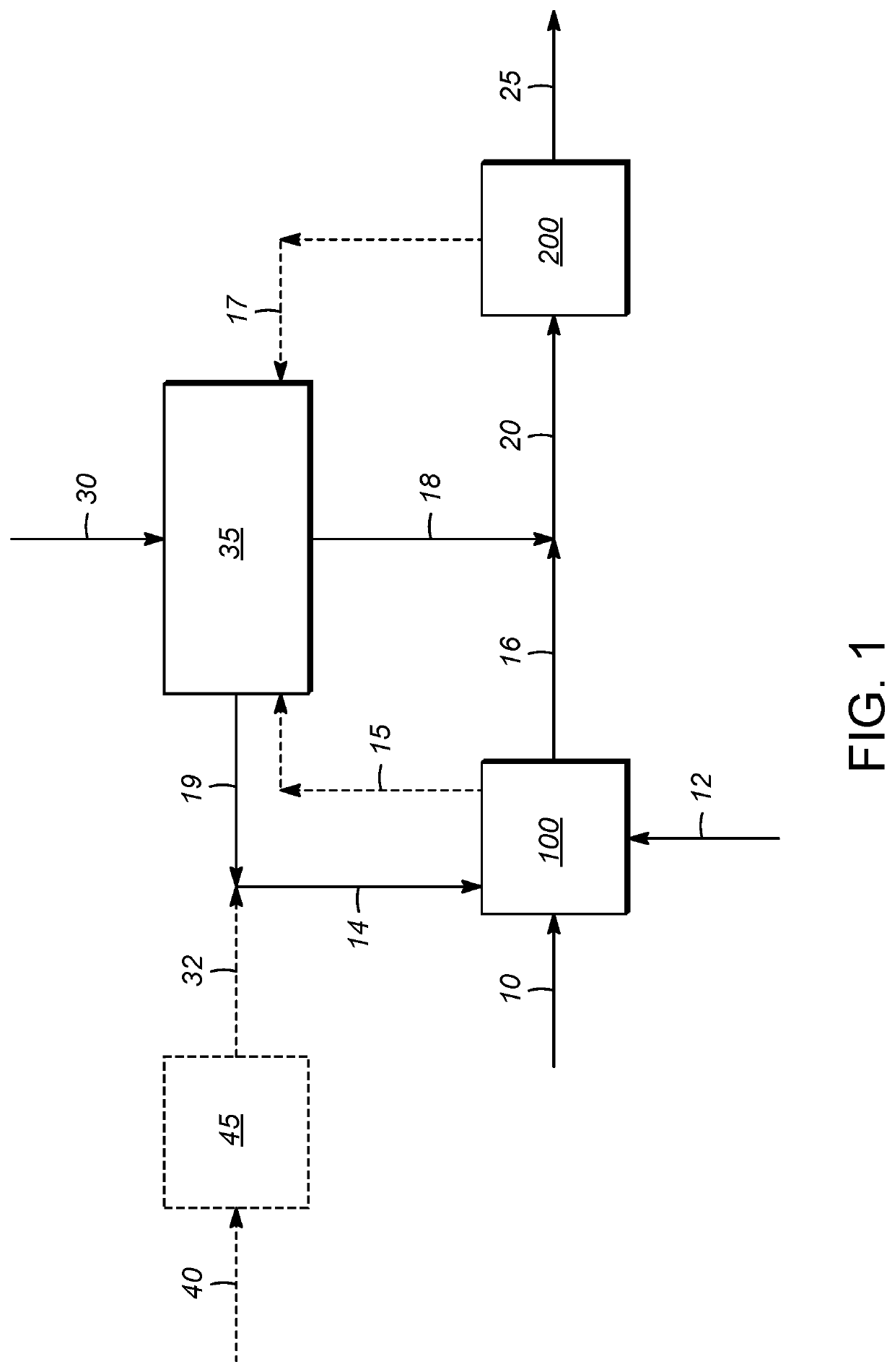

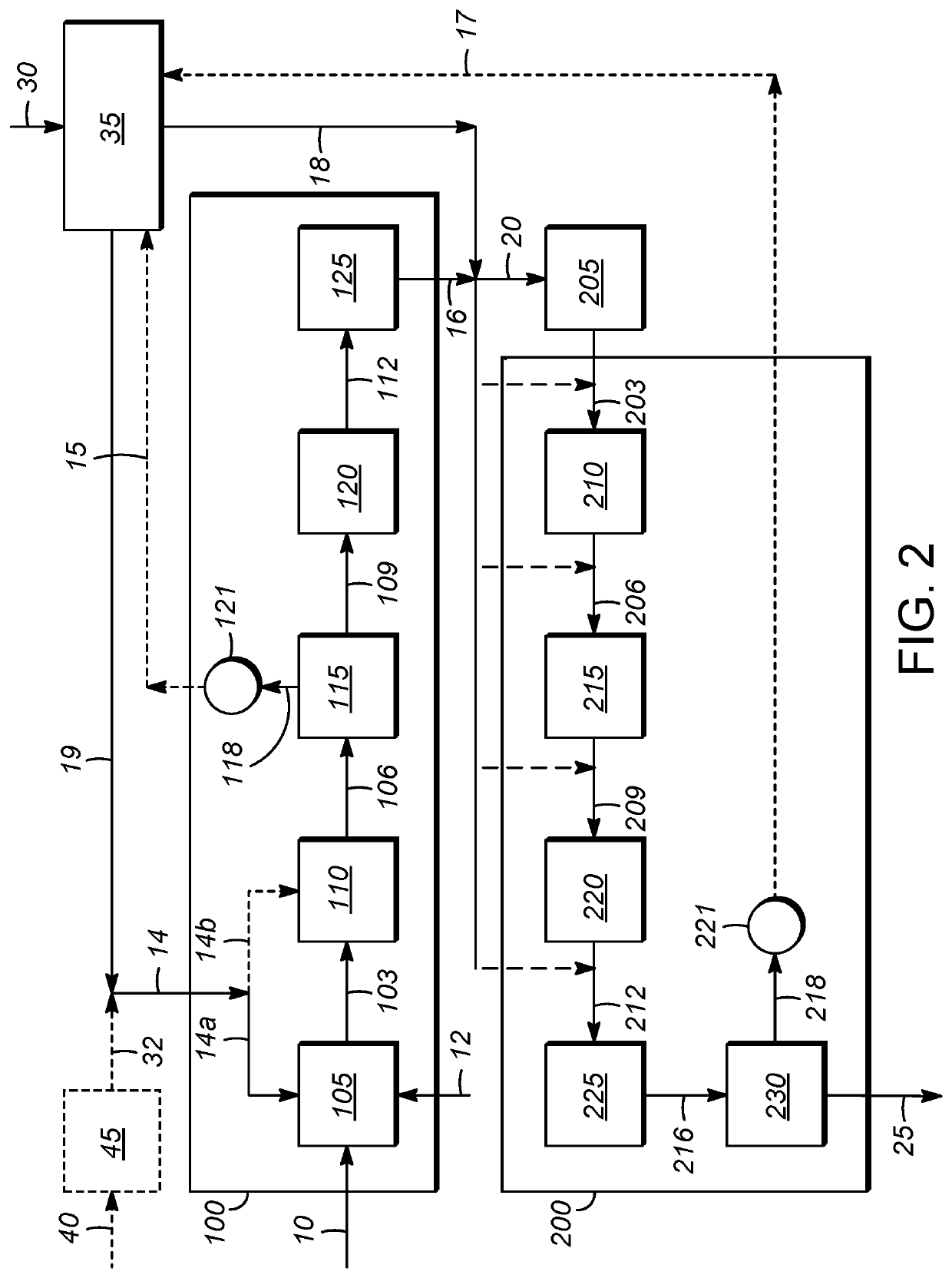

A method and process for the treatment of wastewater containing phosphorous and nitrogen. The wastewater is first anaerobically treated to produce an anaerobic effluent from which insoluble organic carbon is separated to form a sludge rich in organic carbon that is used as a substrate during anoxic treatment of the wastewater by de-nitrifying phosphorous accumulating organisms (DPAO's) and ordinary de-nitrifying organisms. The separation of insoluble organic carbon is normally conducted using a clarifier located intermediate the anaerobic and anoxic bio-reactors. In one embodiment, the ammonia rich clarifier supernatant is directed to an aerobic reactor for nitrification and the nitrate produced is recycled to the anoxic bio-reactor. The final effluent may be membrane filtered to retain nitrifying biomass within the aerobic bio-reactor. The invention reduces overall hydraulic residence time and sludge volume, which results in a smaller, less expensive wastewater treatment system.

Owner:UNIV OF WESTERN ONTARIO

Treatment of wastewater containing phosphorous and nitrogen

InactiveUS7326343B2Lower competition for carbonLower the volumeTreatment using aerobic processesSeparation devicesOxygenClarifier

A method and process for the treatment of wastewater containing phosphorous and nitrogen. The wastewater is first anaerobically treated to produce an anaerobic effluent from which insoluble organic carbon is separated to form a sludge rich in organic carbon that is used as a substrate during anoxic treatment of the wastewater by de-nitrifying phosphorous accumulating organisms (DPAO's) and ordinary de-nitrifying organisms. The separation of insoluble organic carbon is normally conducted using a clarifier located intermediate the anaerobic and anoxic bio-reactors. In one embodiment, the ammonia rich clarifier supernatant is directed to an aerobic reactor for nitrification and the nitrate produced is recycled to the anoxic bio-reactor. The final effluent may be membrane filtered to retain nitrifying biomass within the aerobic bio-reactor. The invention reduces overall hydraulic residence time and sludge volume, which results in a smaller, less expensive wastewater treatment system.

Owner:UNIV OF WESTERN ONTARIO

Method for producing aromatic hydrocarbon from biomass and composition product thereof

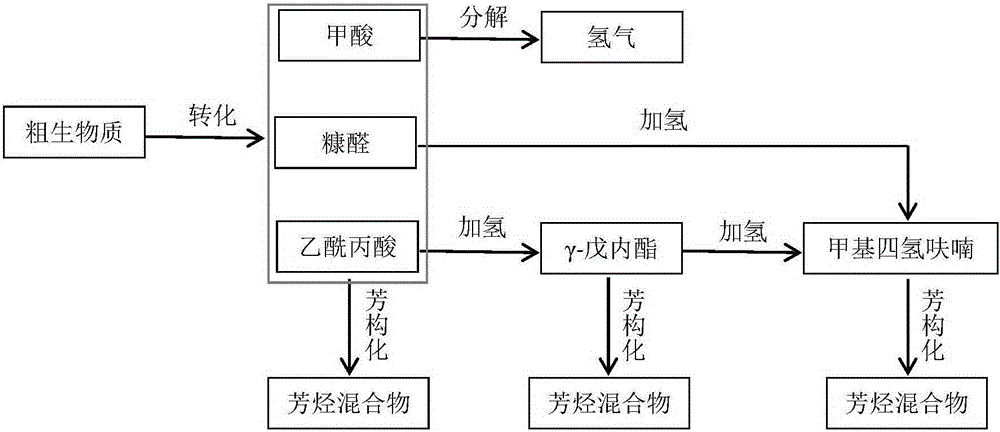

ActiveCN106256809ALow costImprove carbon utilizationHydrocarbon from oxygen organic compoundsAromatizationFurfural

The invention relates to a method for producing aromatics from biomass and a composition obtained by the method. The method comprises the following steps: a) catalytic conversion of biomass raw materials and separation of products to obtain levulinic acid, furfural and formic acid; b) contacting the levulinic acid obtained in step a) with an aromatization catalyst to obtain Aromatic stream I of toluene; c) optionally, levulinic acid obtained in step a) is contacted with a hydrogenation catalyst to obtain gamma-valerolactone and / or methyltetrahydrofuran; d) optionally, furfural obtained in step a) Contacting with a hydrogenation catalyst to obtain methyl tetrahydrofuran; e) Optionally, the γ-valerolactone obtained in step c) is contacted with an aromatization catalyst to obtain an aromatic hydrocarbon stream II containing benzene, toluene and xylene; f) optionally , the methyl tetrahydrofuran obtained in step c) and / or step d) is contacted with an aromatization catalyst to obtain an aromatic hydrocarbon stream III containing benzene, toluene and xylene. The method can be used in the industrial production of aromatics such as benzene, toluene and xylene from biomass containing cellulose and hemicellulose.

Owner:CHINA PETROLEUM & CHEM CORP +1

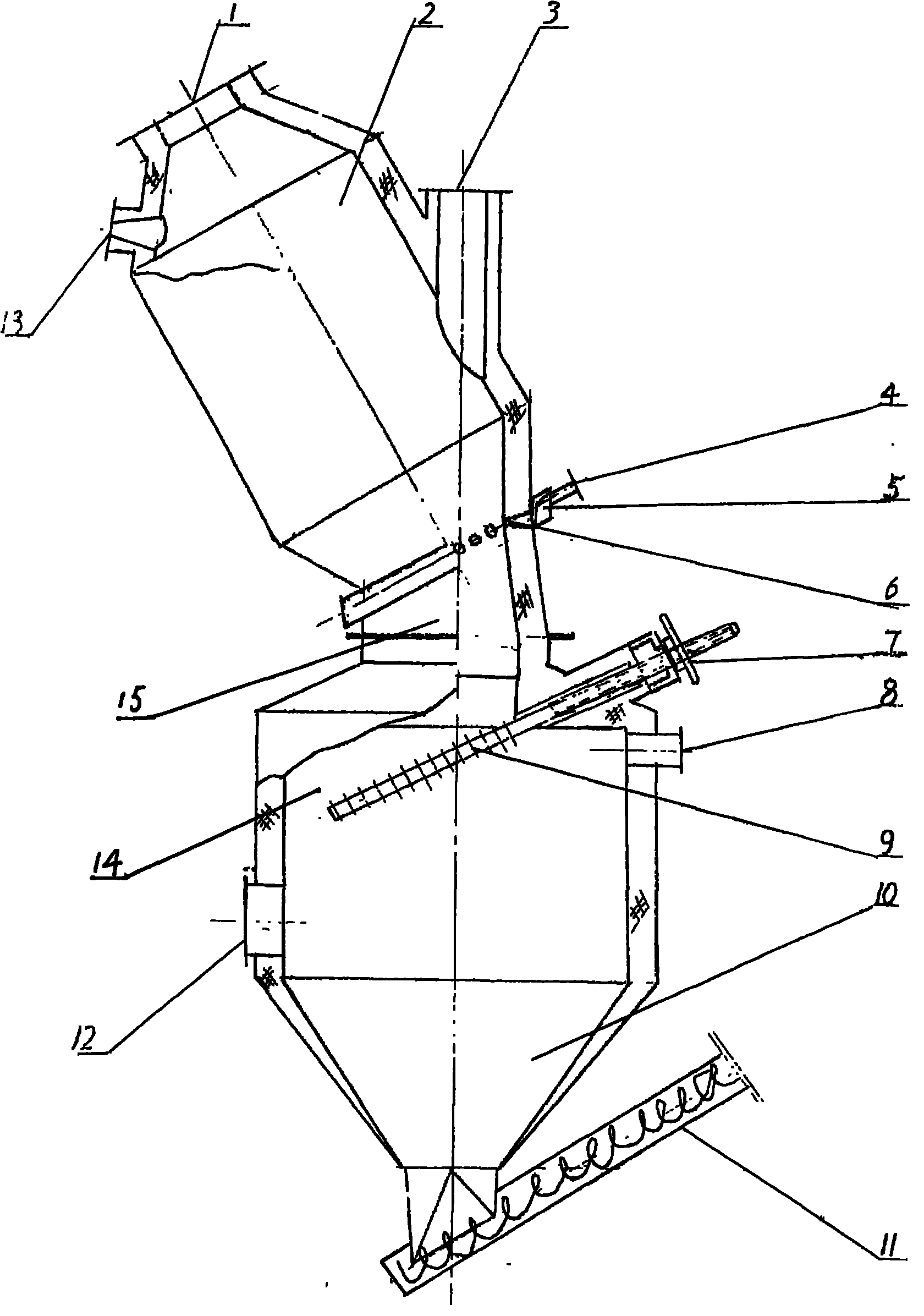

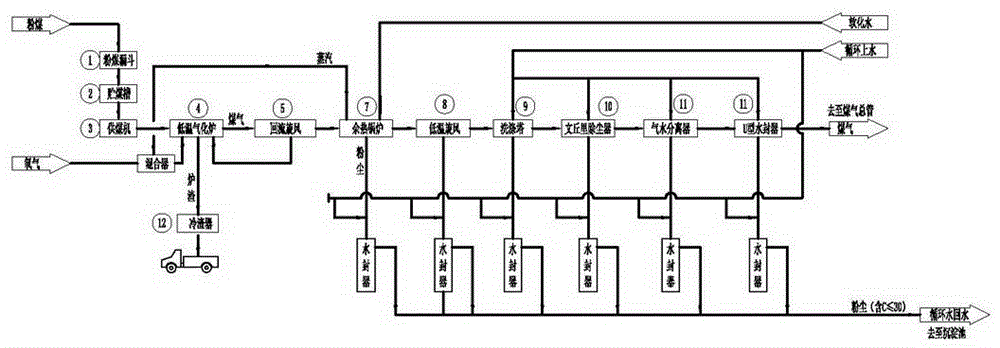

Pyrolysis and gasification cracking furnace for solid biomass

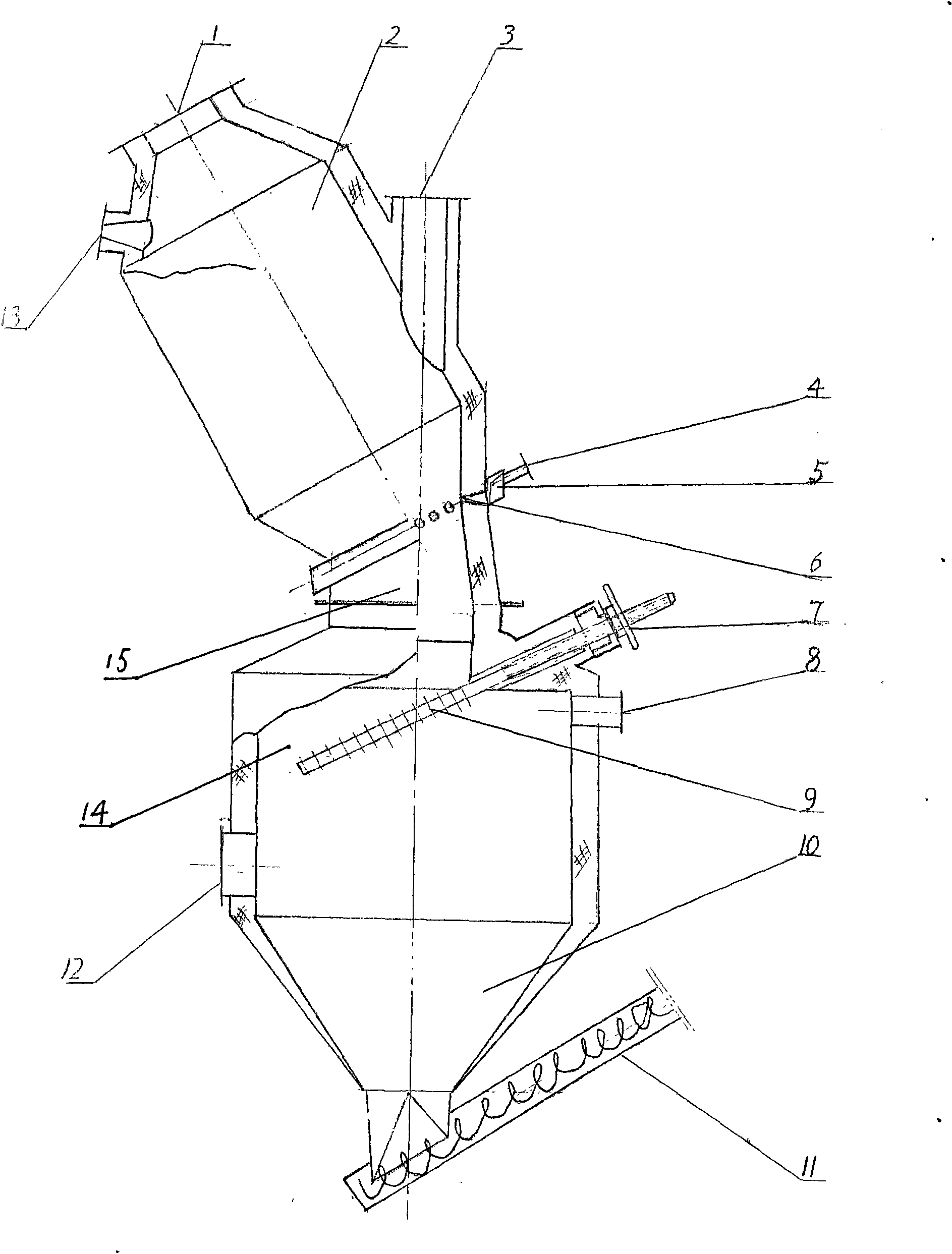

InactiveCN101955802AIncrease productionImprove resource utilizationGranular/pulverulent flues gasificationCatalytic pyrolysisSludge

The invention discloses a pyrolysis and gasification cracking furnace for solid biomass, comprising an upper boiling gasification furnace, a middle catalytic pyrolysis section and a lower fuel gas primary purifying chamber, wherein the boiling gasification furnace is obliquely arranged above the fuel gas primary purifying chamber; a spile fire grate capable of adjusting the inserting depth is arranged at the upper part of the fuel gas primary purifying chamber; a gasification agent inlet and a gasification agent spraying nozzle are arranged at the bottom of the boiling gasification furnace; afuel gas outlet is arranged below the spile fire grate; and a material inlet and an ignition hole are arranged at the upper part of the boiling gasification furnace. The invention can be used for pyrolyzing and gasifying straws and solid wastes of agriculture and forestry and can be also used for incinerating solid domestic wastes in cities and towns and sludge which is dehydrated and dried by sewage treatment plants and acquiring energy sources; tar particles generated by gasification are cracked, large part of carbon dioxide is reduced and the yield of combustible gas can be increased; the fuel gas has high quality and no tar so as to be beneficial to purification; and the gasification temperature is high, so that harmful gases such as dioxin and the like can be avoided.

Owner:合肥天焱生物质能科技有限公司

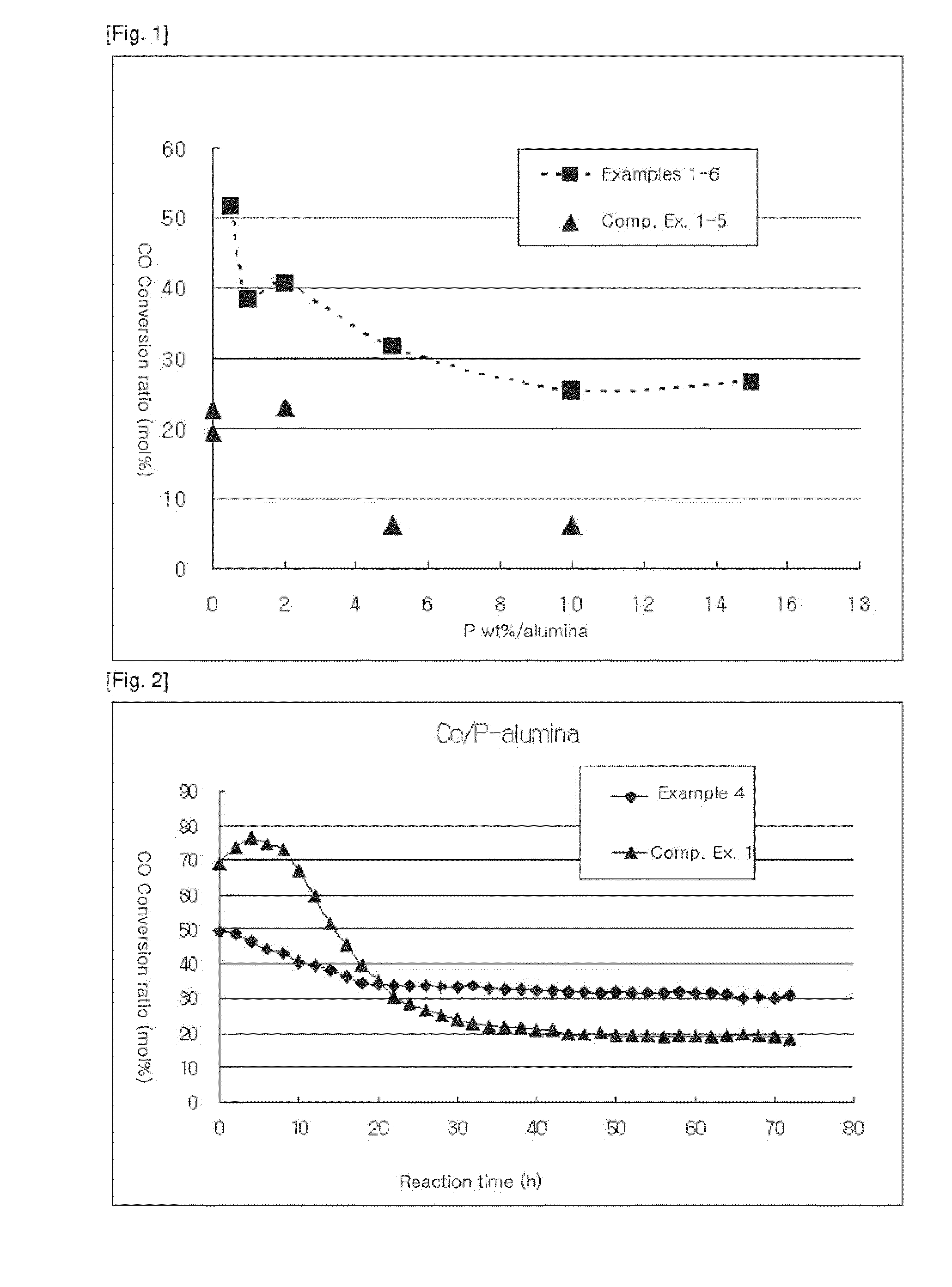

Catalysts for fischer-tropsch synthesis on cobalt/phosphorus-aluminum oxide and preparation methods thereof

ActiveUS20100093523A1Optimize F-T reactionLow selectivityOrganic compound preparationOxygen compounds preparation by reductionActive componentLiquid hydrocarbons

The present invention relates to a cobalt / phosphorus-alumina catalyst in which cobalt is supported as an active component on a phosphorus-alumina support wherein phosphorus is supported on alumina surface. With a bimodal pore structure of pores of relatively different pore sizes, the catalyst provides superior heat- and matter-transfer performance and excellent catalytic reactivity. Especially, when Fischer-Tropsch (F-T) reaction is performed using the catalyst, deactivation by the water produced during the F-T reaction is inhibited and, at the same time, the dispersion and reducing property of cobalt and other active component are improved. Therefore, the cobalt / phosphorus-alumina catalyst for F-T reaction in accordance with the present invention provides good carbon monoxide conversion and stable selectivity for liquid hydrocarbons.

Owner:SK INNOVATION CO LTD +2

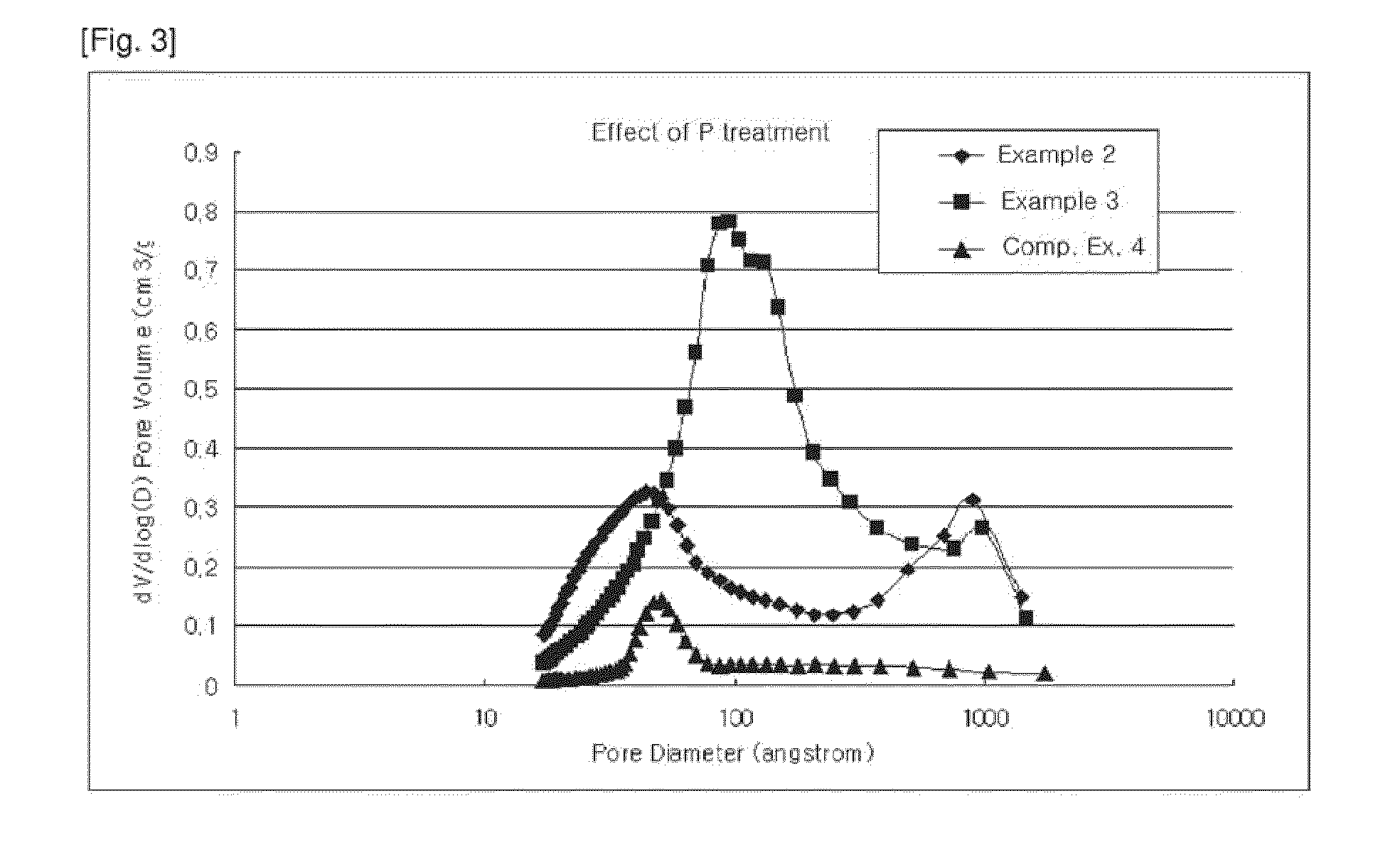

System for producing natural gas by electrolytic hydrogen production and gas synthesis from coal

InactiveCN104531246ALow investment costAddressing the need for high-purity hydrogenGaseous fuelsElectrolysisMethanation

The invention relates to a system for producing natural gas by electrolytic hydrogen production and gas synthesis from coal. The system comprises a coal preparation unit, wherein the coal preparation unit is connected with a gasification furnace, a crude coal gas outlet of the gasification furnace is connected with an inlet of a first absorption tower, a main circuit of a first absorption tower outlet is connected with a low temperature methanol washing unit through a conversion unit, an auxiliary circuit of the first absorption tower outlet is connected with a power plant, and the electric energy is directly supplied to an electrolytic water hydrogen production unit; a circulating sewage outlet of the gasification furnace is connected with the electrolytic water hydrogen production unit through a second absorption tower, a hydrogen outlet of the electrolytic water hydrogenation unit is connected with a methanation unit after being combined with a low temperature methanol washing unit outlet, and an oxygen outlet of the electrolytic water hydrogen production unit is connected with a corresponding device. By adopting the system, not only can the requirement of high-purity hydrogen for the reduction of methanation catalyst be met, but also the hydrogen-carbon ratio in the synthesis gas of a conversion working section can be supplemented by adopting the hydrogen with relative high purity, the load produced by the conversion working section in the conventional coal natural gas process can be reduced, and the utilization rate of carbon can be increased.

Owner:HUANENG CLEAN ENERGY RES INST +1

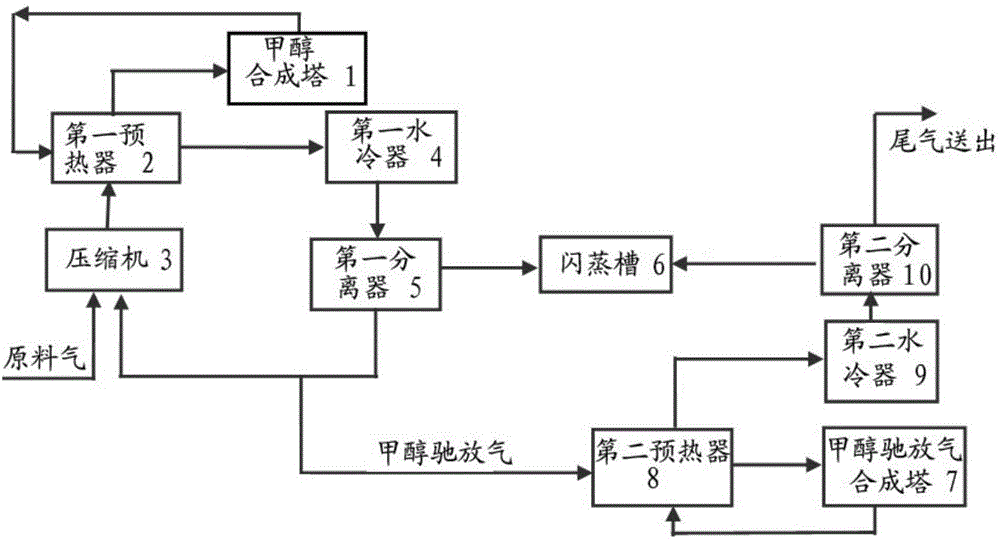

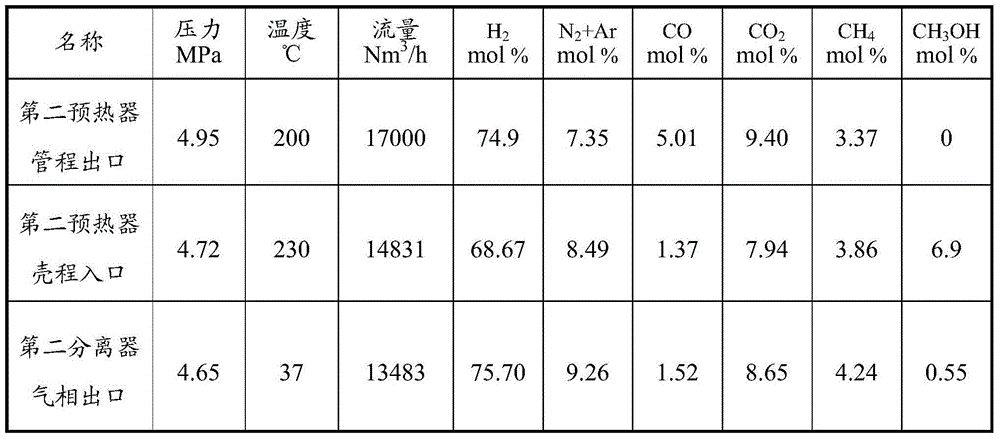

System for producing methanol by using coke oven gas

ActiveCN103980091AFully digestedEmission reductionOrganic compound preparationHydroxy compound preparationCombustionEconomic benefits

The invention discloses a system for producing methanol by using coke oven gas. The system comprises a methanol synthesis unit and a methanol purge gas utilization unit, wherein the methanol purge gas utilization unit is used for synthesizing methanol by taking methanol purge gas from the methanol synthesis unit as a raw material. The invention also discloses a methanol purge gas utilization method. The traditional simple combustion utilization constraint is broken on the aspect of methanol purge gas utilization, and the methanol purge gas is further deeply synthesized to produce methanol, so that carbon in the methanol purge gas is more sufficiently digested, the extremely low carbon content of tail gas is difficult to reach by a conventional synthesis tower, the utilization ratio of carbon is increased, the discharged greenhouse gas is reduced, and meanwhile, the considerable economic benefit is further brought.

Owner:CHINA KINGHO ENERGY GRP +1

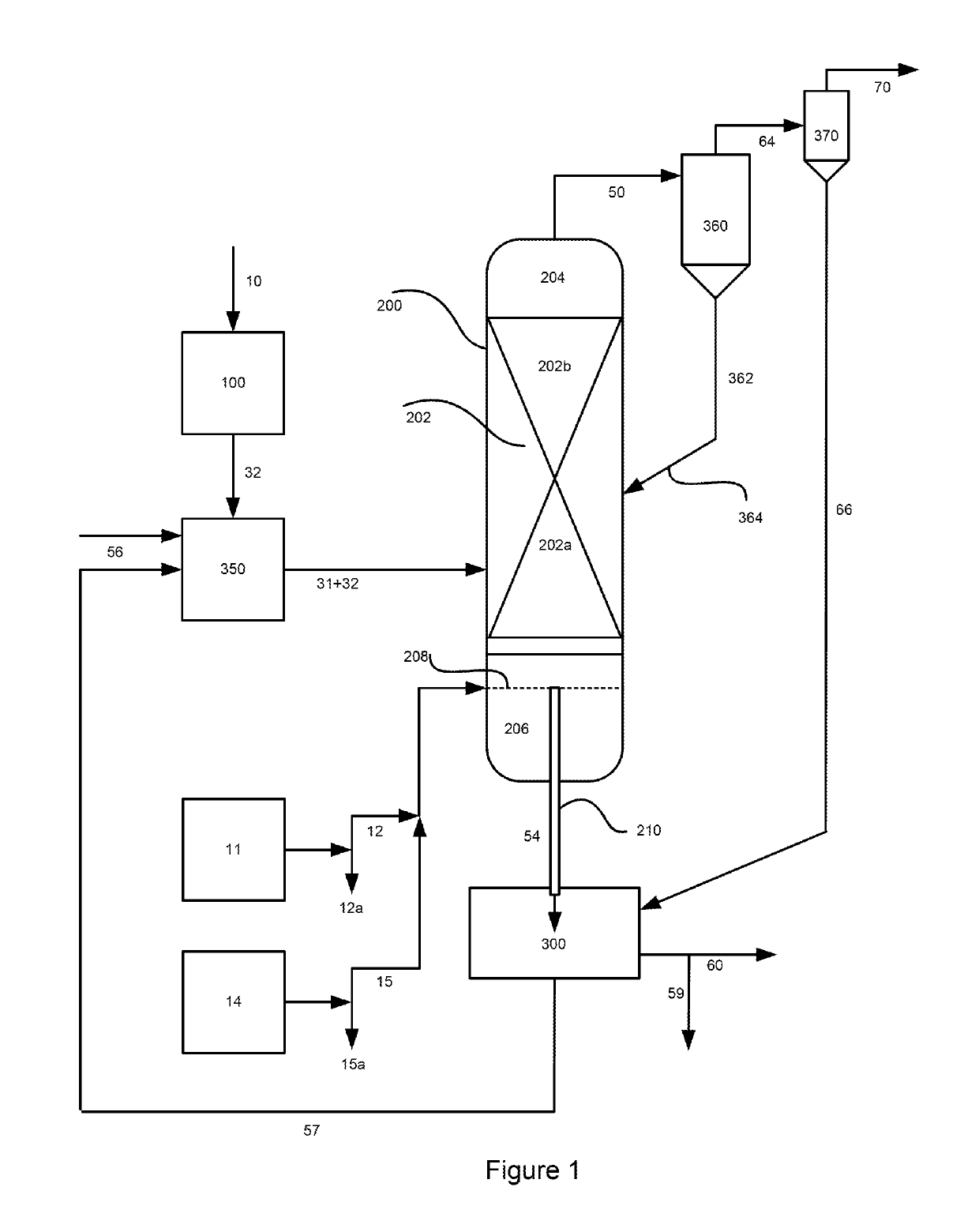

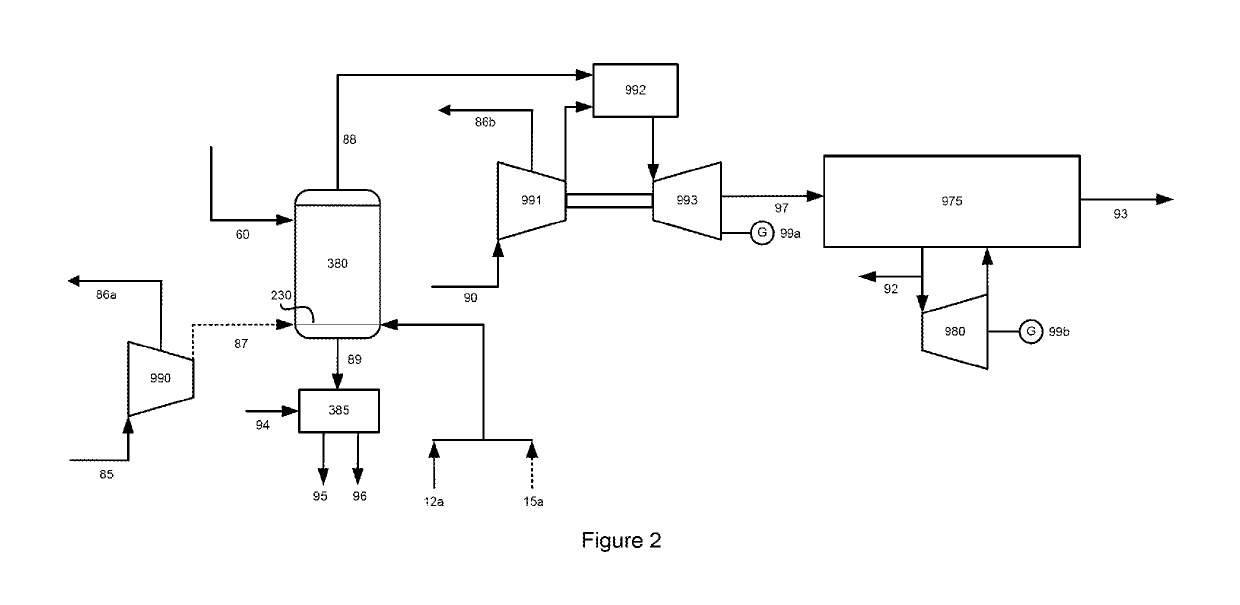

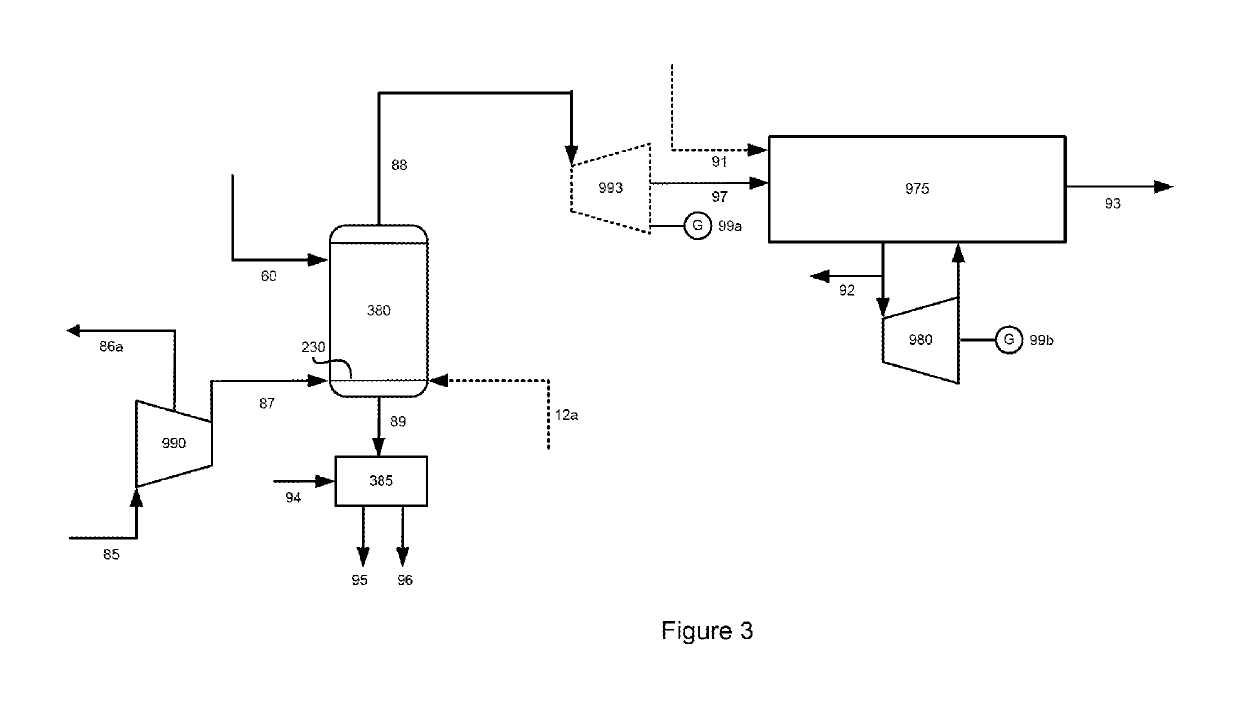

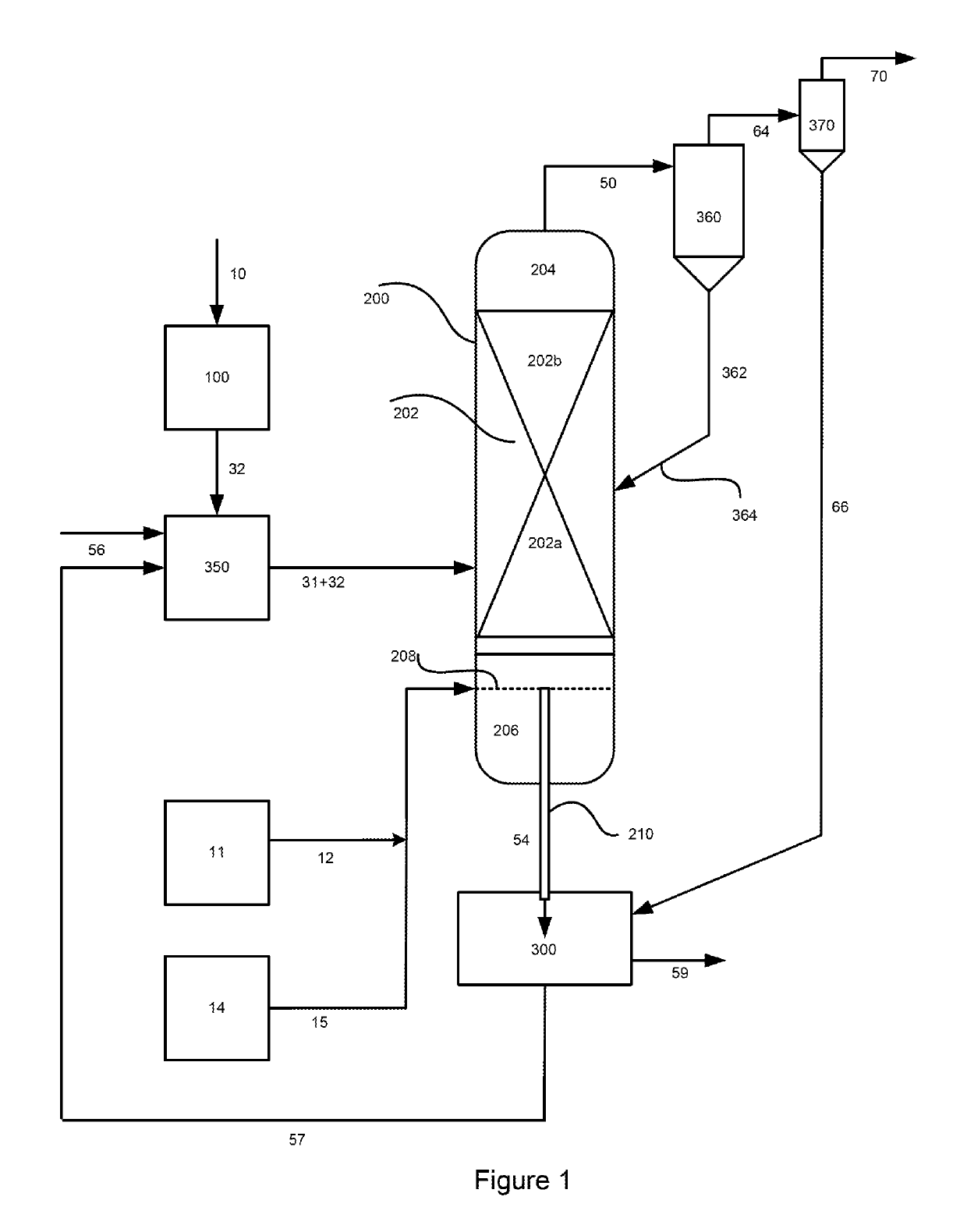

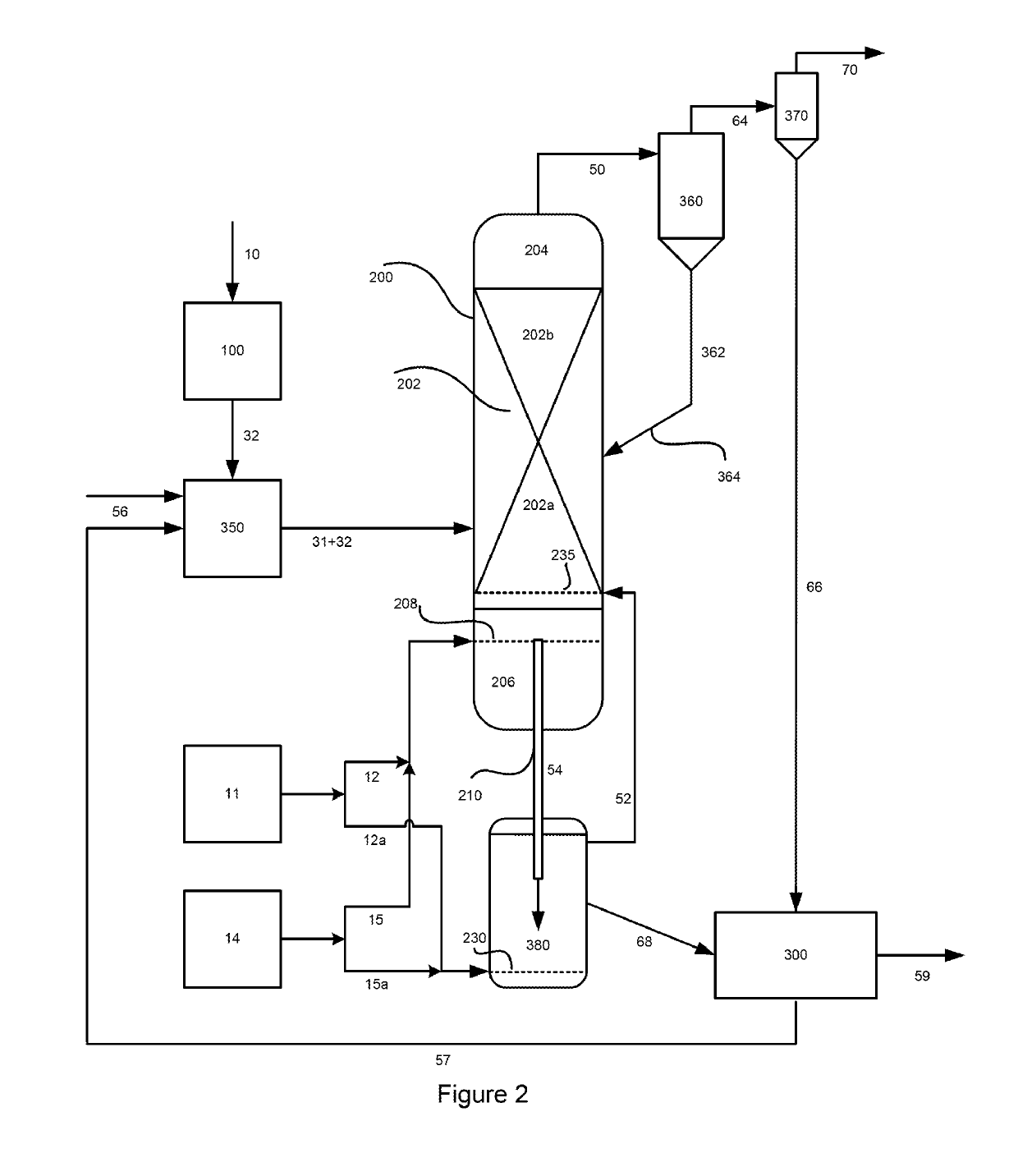

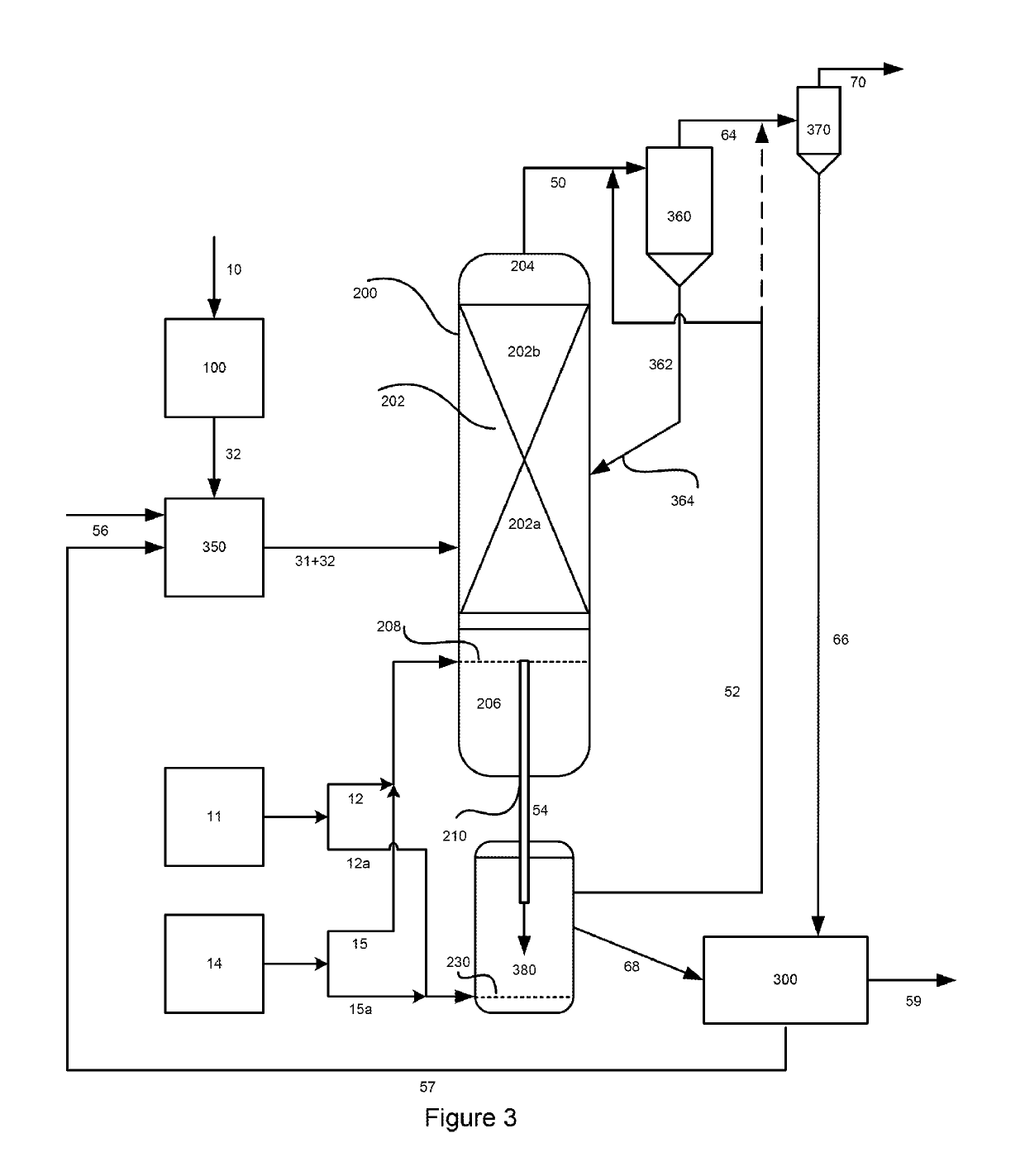

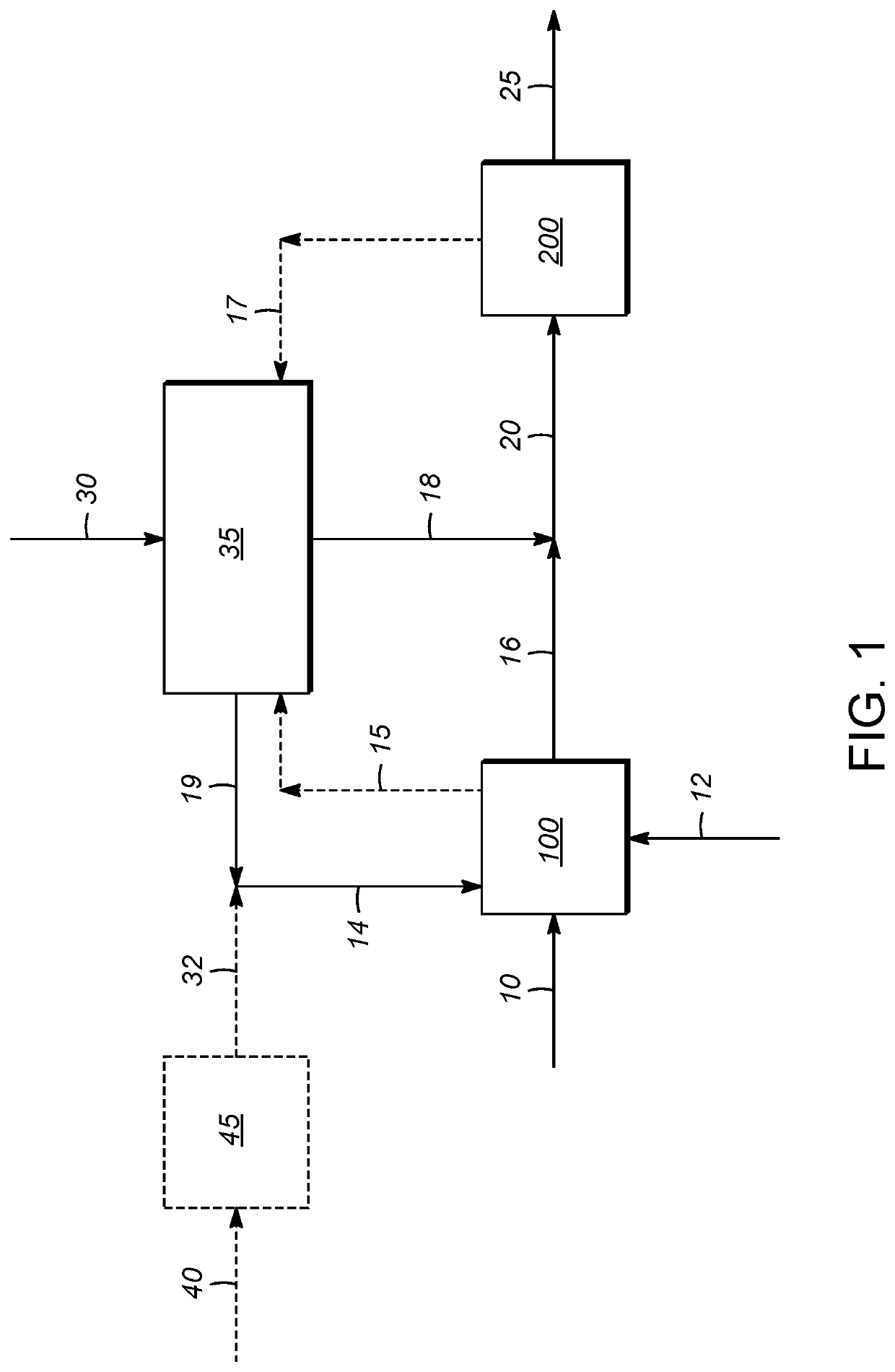

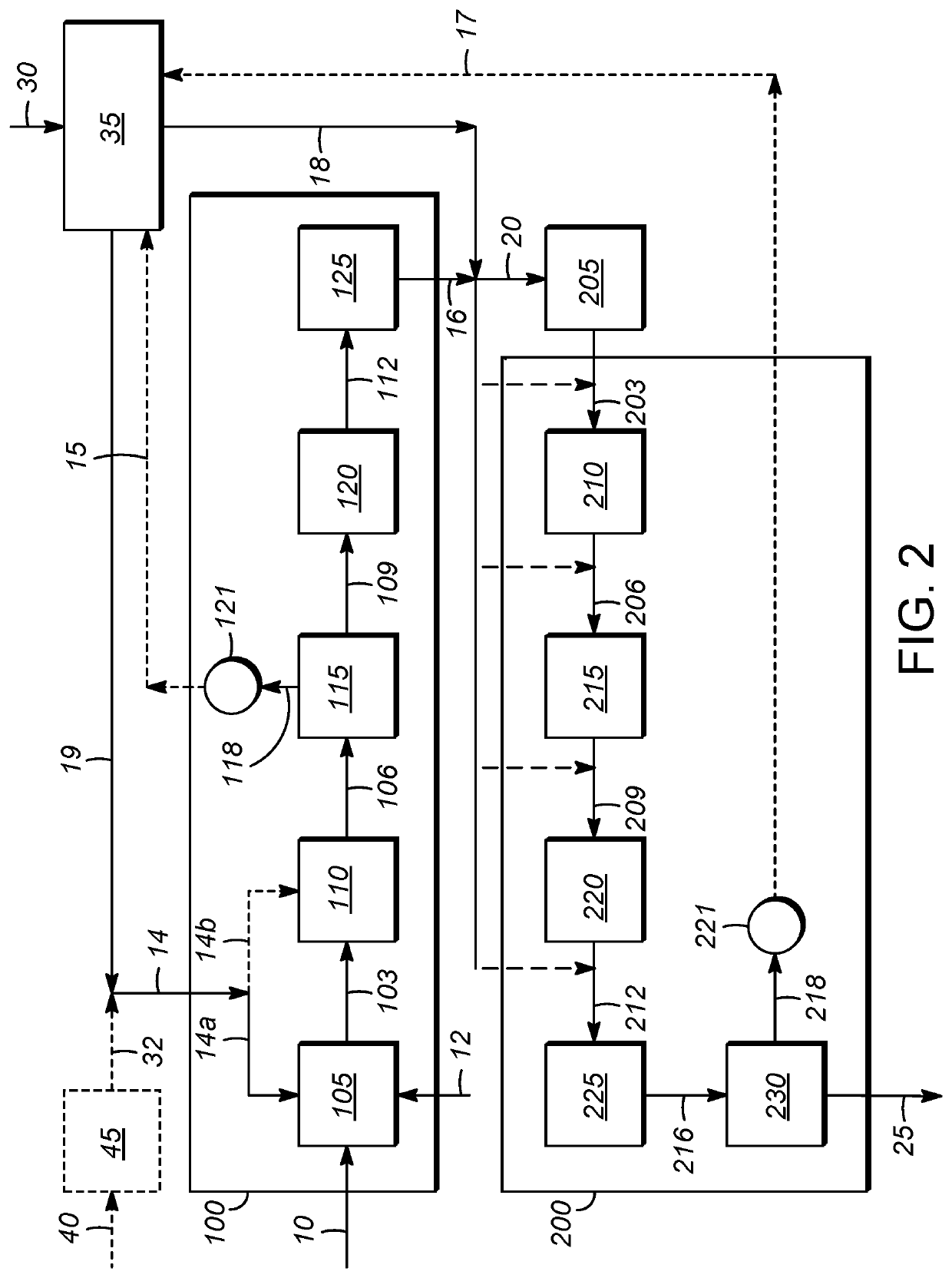

Hydromethanation of a carbonaceous feedstock with improved carbon utilization and power generation

ActiveUS10435637B1Improve efficiencyLower total carbon conversionCombustible gas catalytic treatmentEnergy inputProcess engineeringSubstitute natural gas

The present invention relates generally to processes for hydromethanating a carbonaceous feedstock in a hydromethanation reactor to a methane-enriched raw product stream, and more specifically to processing of solid char by-product removed from the hydromethanation reactor to improve the carbon utilization and thermal efficiency and economics of the overall process by co-producing electric power and steam from the by-product char in addition to the end-product pipeline quality substitute natural gas.

Owner:SURE CHAMPION INVESTMENT LTD

Hydromethanation of a carbonaceous feedstock with improved carbon utilization

ActiveUS10344231B1Improve efficiencyLower total carbon conversionGaseous fuelsCatalystsProcess engineeringEnvironmental engineering

The present invention relates generally to processes for hydromethanating a carbonaceous feedstock in a hydromethanation reactor to a methane-enriched raw product stream, and more specifically to processing of solid char by-product removed from the hydromethanation reactor to improve the carbon utilization and thermal efficiency of the overall process and thereby lower the net costs of the end-product pipeline quality substitute natural gas.

Owner:SURE CHAMPION INVESTMENT LTD

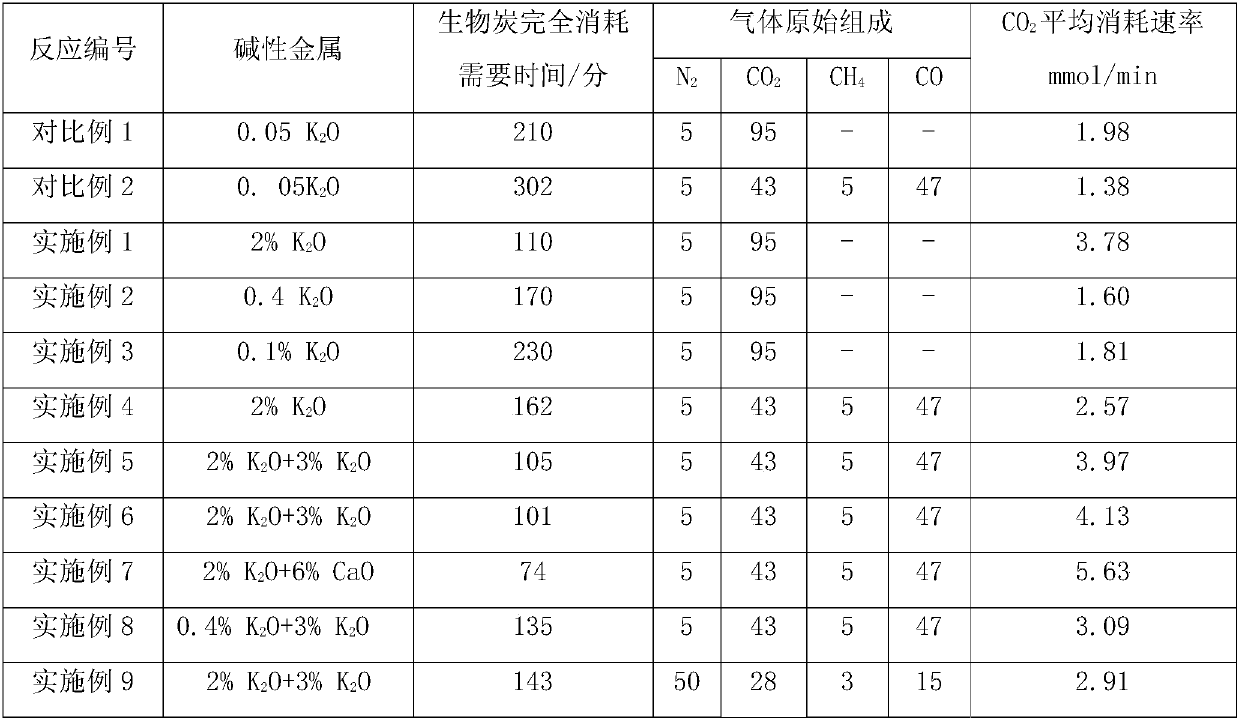

Utilization method for CO2 in biomass pyrolysis tail gas

PendingCN109809407AImprove carbon resource utilizationEmission reductionBiofuelsCarbon monoxideExhaust gasBiomass

The invention provides a utilization method for CO2 in biomass pyrolysis tail gas. The method comprises the following steps that biological carbon produced in the biomass pyrolysis process is adoptedas a reducing agent, the CO2 with relatively high content in pyrolysis tail gas is reduced to CO through catalytic reaction, and preferably, an alkaline metal catalyst can be added in a reaction system to accelerate a reduction speed of the CO2, wherein the alkaline metal catalyst is one or more of alkali metal, alkaline earth metal or rare earth metal. By adopting the method provided by the invention, the greenhouse gas CO2 produced by biomass pyrolysis can be converted to high-added-value CO, and the biological carbon produced in the pyrolysis process is converted to the CO at the same time,so that the utilization rate of carbon resources in the biomass pyrolysis process is increased, emission of the greenhouse gas is reduced, and the utilization method has a good industrial applicationprospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparation of methanol, dimethyl ether and low-carbon olefin with synthetic gas

ActiveCN101745397BHigh selectivityHigh conversion rate of COHydrocarbon from carbon oxidesMolecular sieve catalystsPtru catalystAlkene

The invention provides a method for preparation of methanol, dimethyl ether and low-carbon olefin with synthetic gas, which comprises contacting synthetic gas with a catalyst under the condition that the synthetic gas can be converted into methanol, dimethyl ether and low-carbon olefin. The catalyst contains amorphous alloy and a carrier, the amorphous alloy is a cladding material applied on the carrier and is composed of M and X, wherein X is B and / or P, and M is selected from one or more of IB, IVB, VIIB, VIII and lanthanide elements in the periodic table of elements. The method provided in the invention has the advantages of high CO conversion rate, high selectivity for target products and high carbon utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

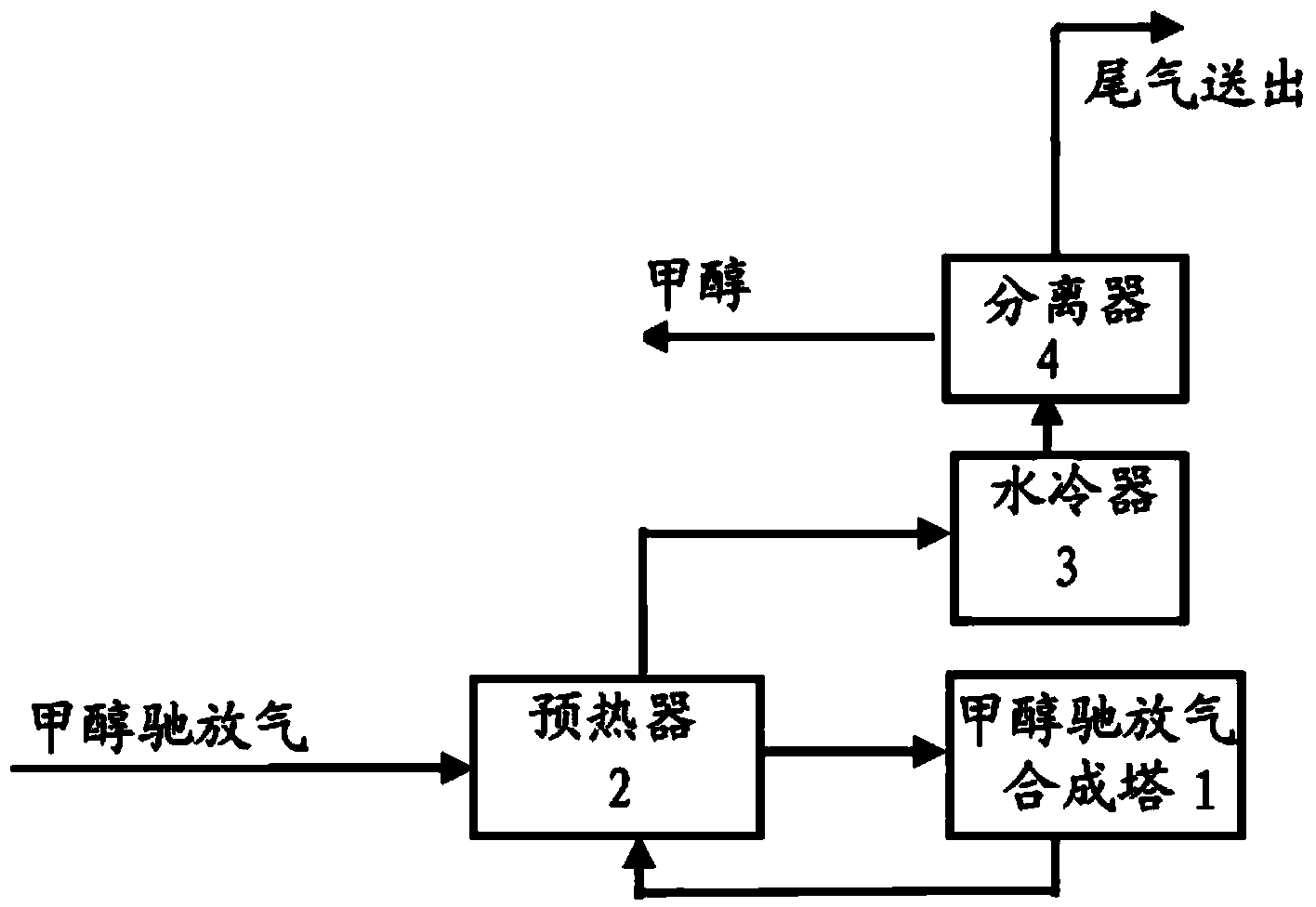

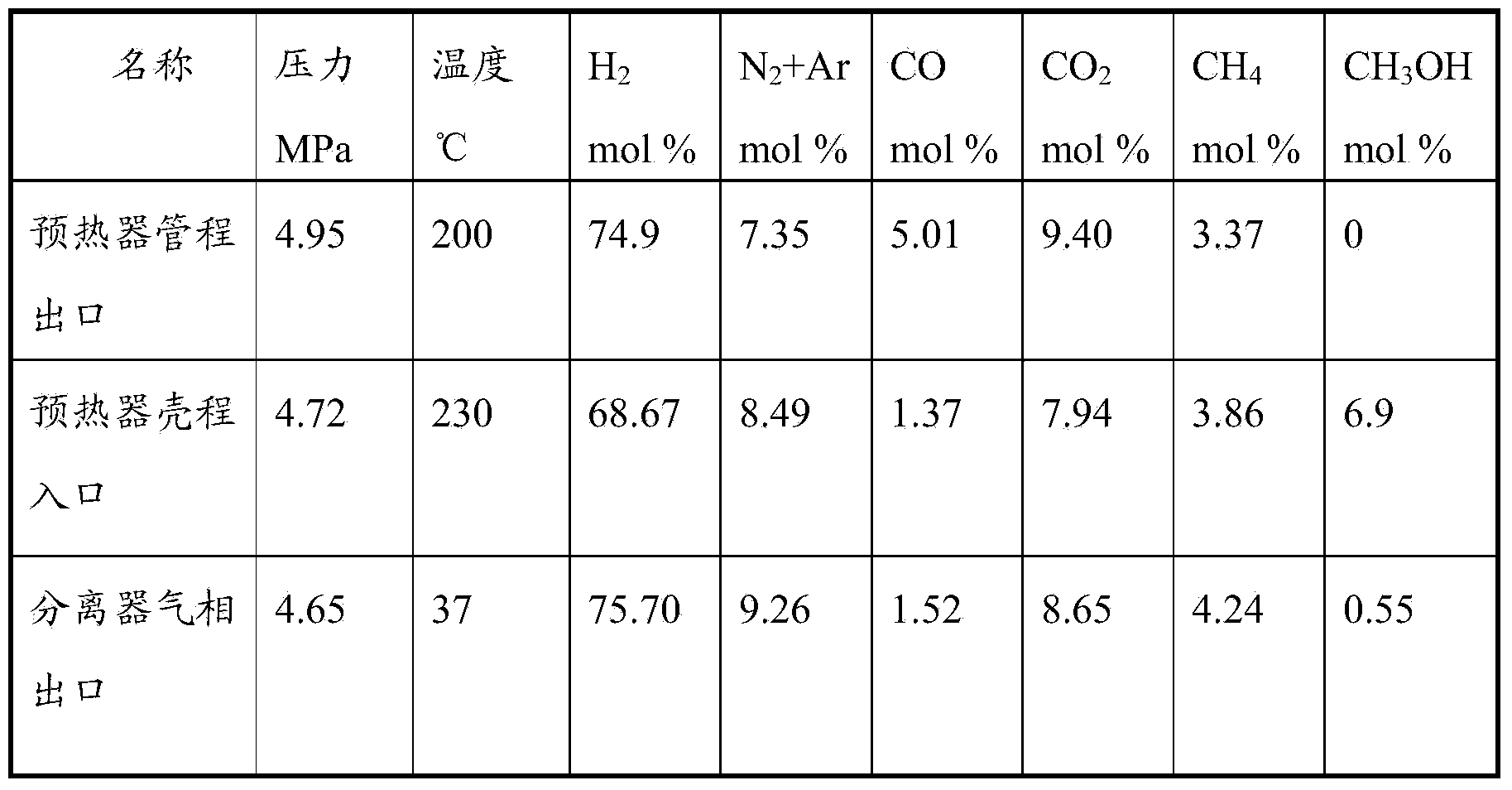

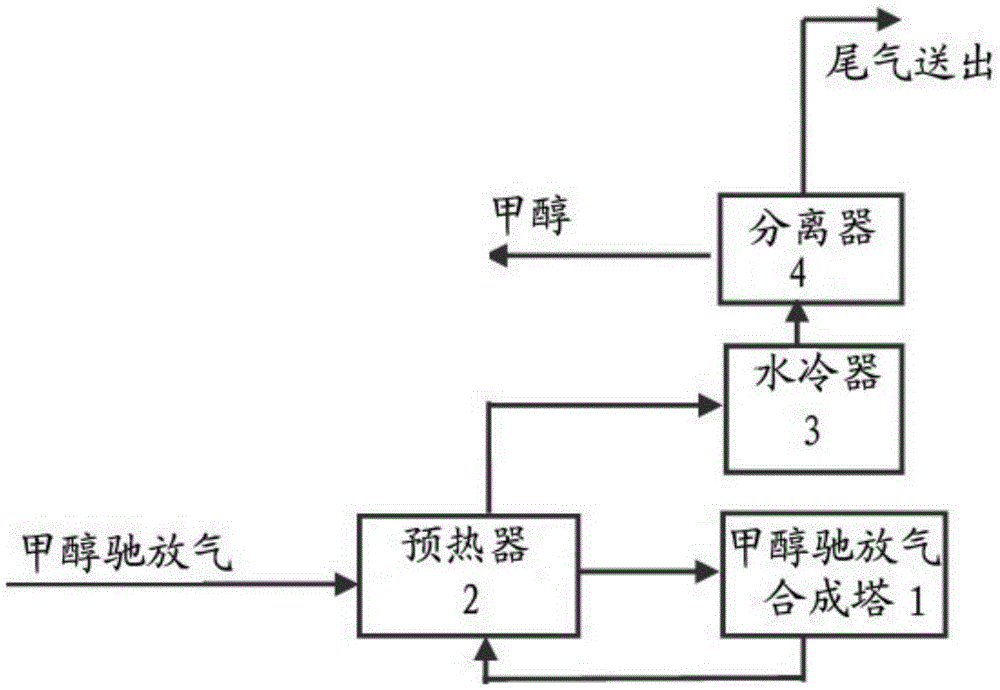

Utilization method of methanol purge gas

ActiveCN104211567AFully digestedEmission reductionOrganic compound preparationHydroxy compound preparationCombustionCoke oven

The invention discloses a utilization method of methanol purge gas. The method comprises the following steps: feeding the methanol purge gas to a methanol purge gas utilization unit; and preparing a reducing agent for reducing a desulfurizer in methanol by using tail gas of the methanol purge gas utilization unit as coke-oven gas. The invention further discloses a utilization method of methanol purge gas, wherein the reducing agent for reducing the desulfurizer in methanol is prepared by using the methanol purge as coke-oven gas. The method disclosed by the invention can be used for breaking through the boundary of conventional simple combustion and utilization in the aspect of utilizing the methanol purge gas, and further deeply synthesizing the methanol purge gas, so that the utilization ratio of carbon is improved and the greenhouse gas emission is reduced. Moreover, by replacing the coke-oven gas with the methanol purge gas or the tail gas of the methanol purge gas which is deeply synthesized as the reducing agent, not only is the system stable, but also the coke-oven gas can be better used for synthesizing methanol, and the economic efficiency is improved.

Owner:CHINA KINGHO ENERGY GRP +1

Process method for directly preparing olefin from synthesis gas

PendingCN112694377AIncrease conversion rate per passHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsPtru catalystProcess engineering

The invention discloses a process method for directly preparing olefin from synthesis gas, and the method comprises the following steps of: contacting a synthesis gas raw material with a catalyst, and carrying out reaction to obtain a product flow; separating the product flow to obtain carbon dioxide, an unreacted synthesis gas flow and a mixed hydrocarbon flow; and circulating at least part of the unreacted synthesis gas flow to the synthesis gas raw material to participate in reaction; wherein in the gas participating in the reaction, the methane content is less than 20% in terms of molar ratio. The method can inhibit the selectivity of CH4 to a certain extent while ensuring high selectivity and high conversion per pass of low-carbon olefins, can fully utilize the raw materials and improve the utilization rate of carbon in the raw material synthesis gas, and can be used for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

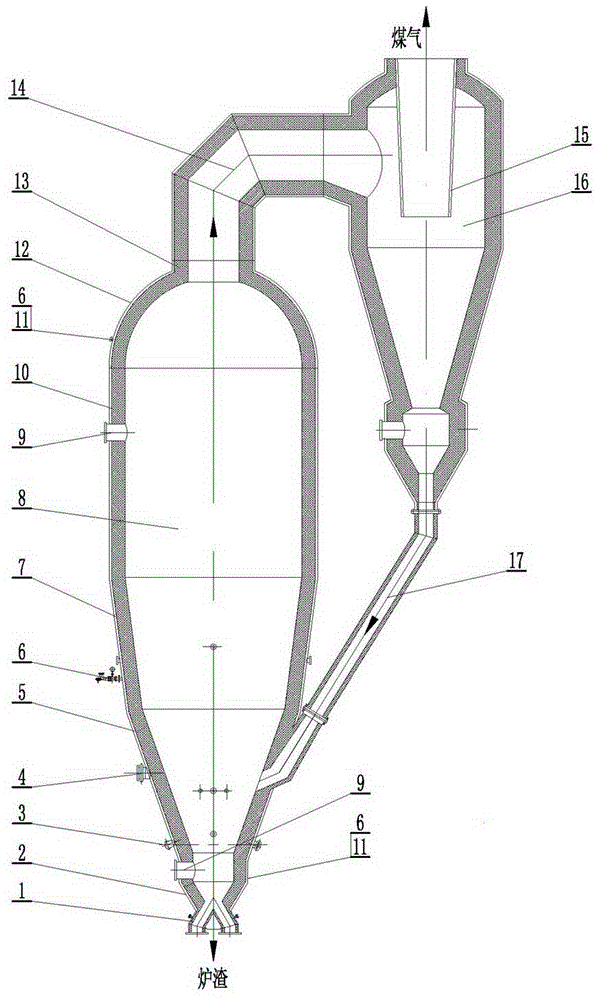

Low-high temperature combined normal-pressure powder coal gasification furnace and gasification technological method

InactiveCN104893760AReduce methane contentImprove carbon utilizationProductsReagentsSlagEconomic benefits

The invention discloses a low-high temperature combined normal-pressure powder coal gasification furnace and a gasification technological method. The low-high temperature combined normal-pressure powder coal gasification furnace adopts the structure that a high-temperature gasification furnace is communicated to the one end of a gas pipe of which the other end is communicated with a low-temperature gasification furnace; the high-temperature gasification furnace has a vertical cylindrical furnace body; a gas outlet pipe is arranged at the lower part of the cylindrical furnace body. As the low-temperature gasification furnace and the high-temperature gasification furnace are combined together, powder coal, which does not reacts at the moment and is carried by gas from the low-temperature gasification furnace, reacts with a gasifying agent again in the high-temperature gasification furnace, organic materials in coal gas are decomposed completely, and the vast majority of carbon dioxide in feed gas is converted into carbon monoxide, dust in the coal gas is dissolved completely, carbon in the dust is recovered almost completely. The content of effective gas in outlet coal gas of the high-temperature gasification furnace can reach 78 to 85 percent, the carbon content of slag is about 0.5 percent, the carbon use ratio is larger than or equal to 99 percent. The low-high temperature combined normal-pressure powder coal gasification furnace and the gasification technological method have the advantages that the coal gas cost is reduced greatly; the economic benefit is considerable; the environmental problem of dust pollution is solved thoroughly.

Owner:LIAONING ENDE ENG & CONSTR

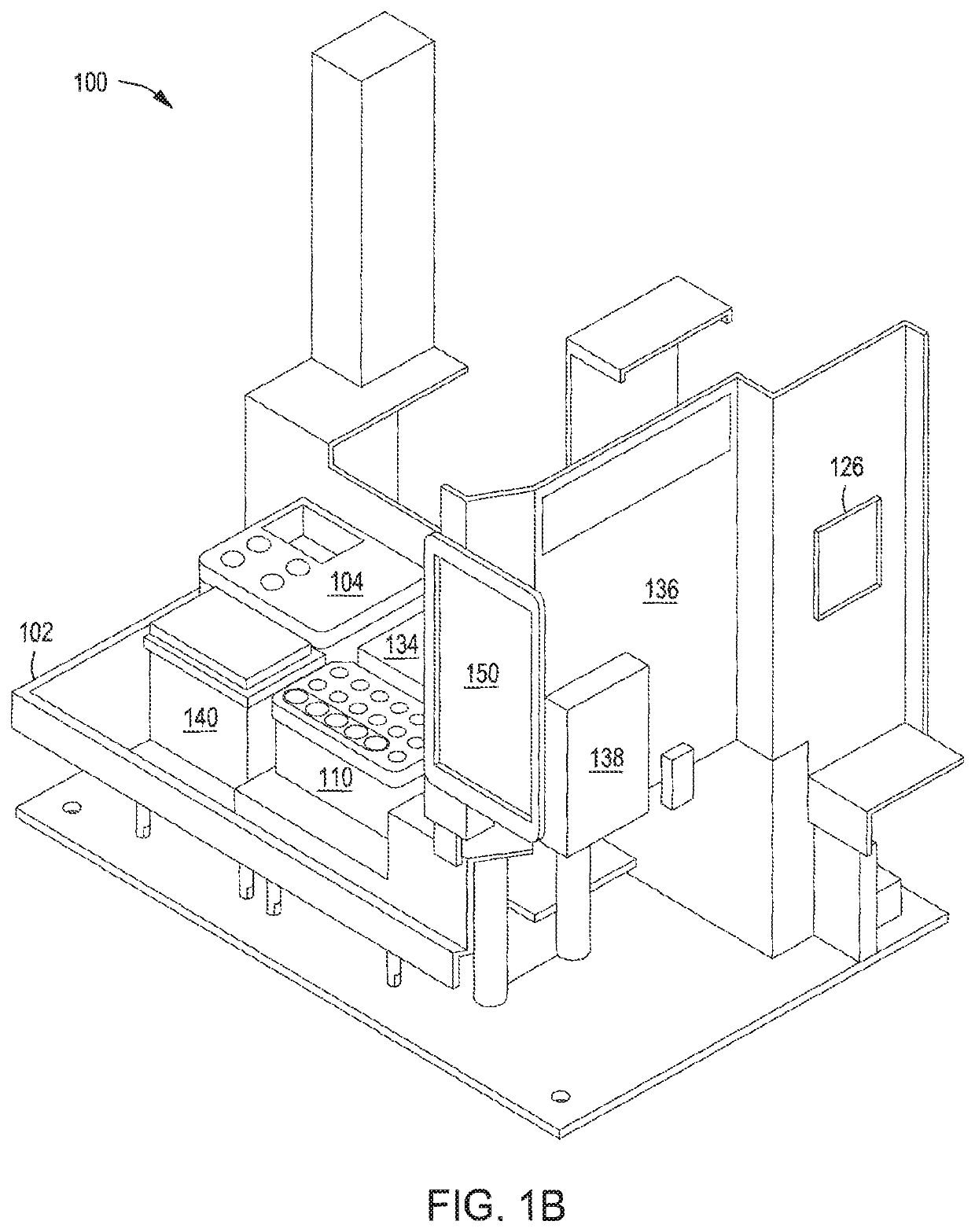

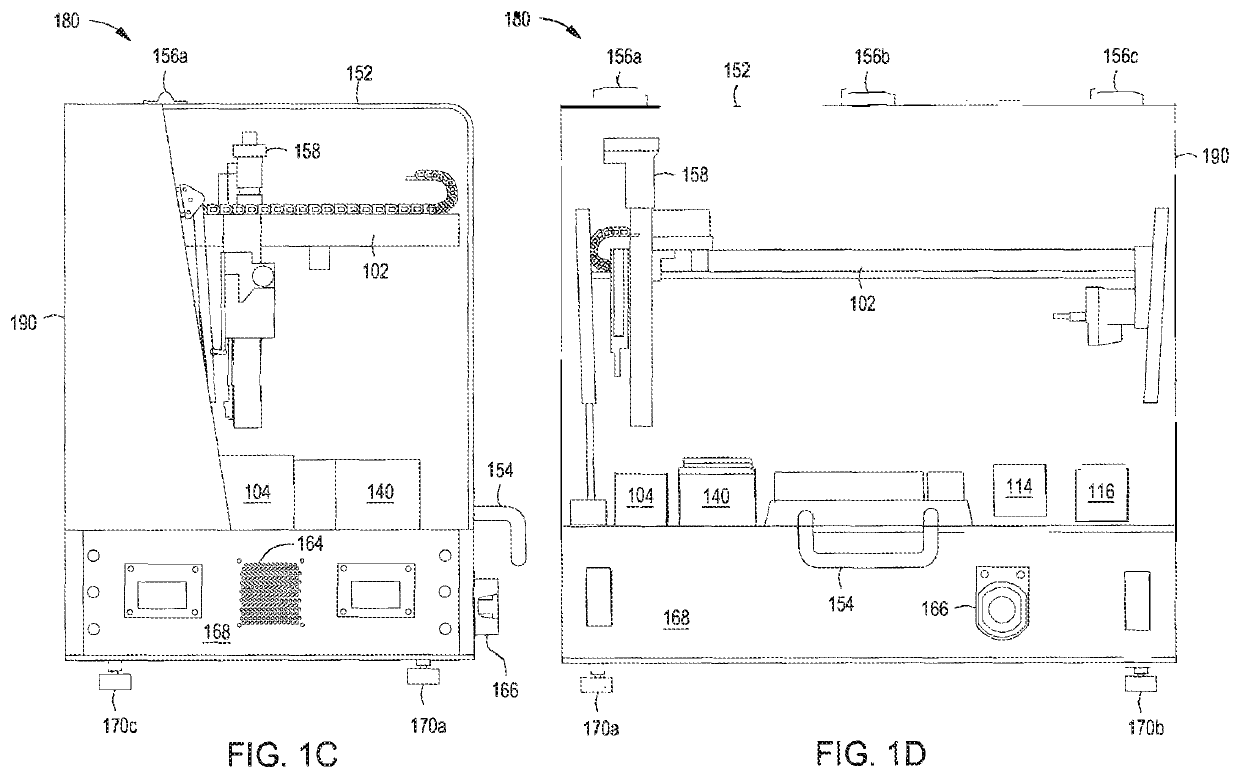

Integrated gasification and electrolysis process

ActiveUS10882800B2Improve carbon utilizationEfficient managementHydrocarbon from carbon oxidesGaseous fuelsThermodynamicsElectrolysis

Aspects of the invention relate to improvements in the flexibility with which oxygen and hydrogen, for example from electrolysis, may be supplied to processes having both gasification and methanation steps, as well as improvements in how such processes may be operated in response to variations in carbonaceous feeds. Offsets, between the ideal quantity of hydrogen and the quantity available from a given source may be compensated for by adjusting one or more operations of the process, and in particular such operation(s) that ultimately impact the quantity of CO and / or CO2 available downstream of the gasifier for conversion to methane in an RNG product stream.

Owner:GAS TECH INST

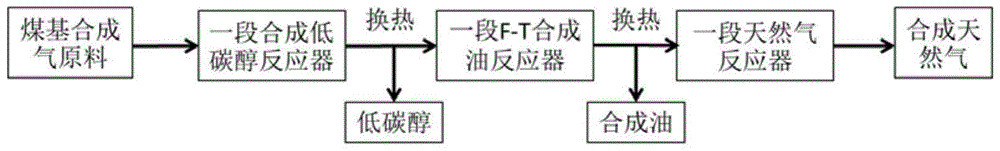

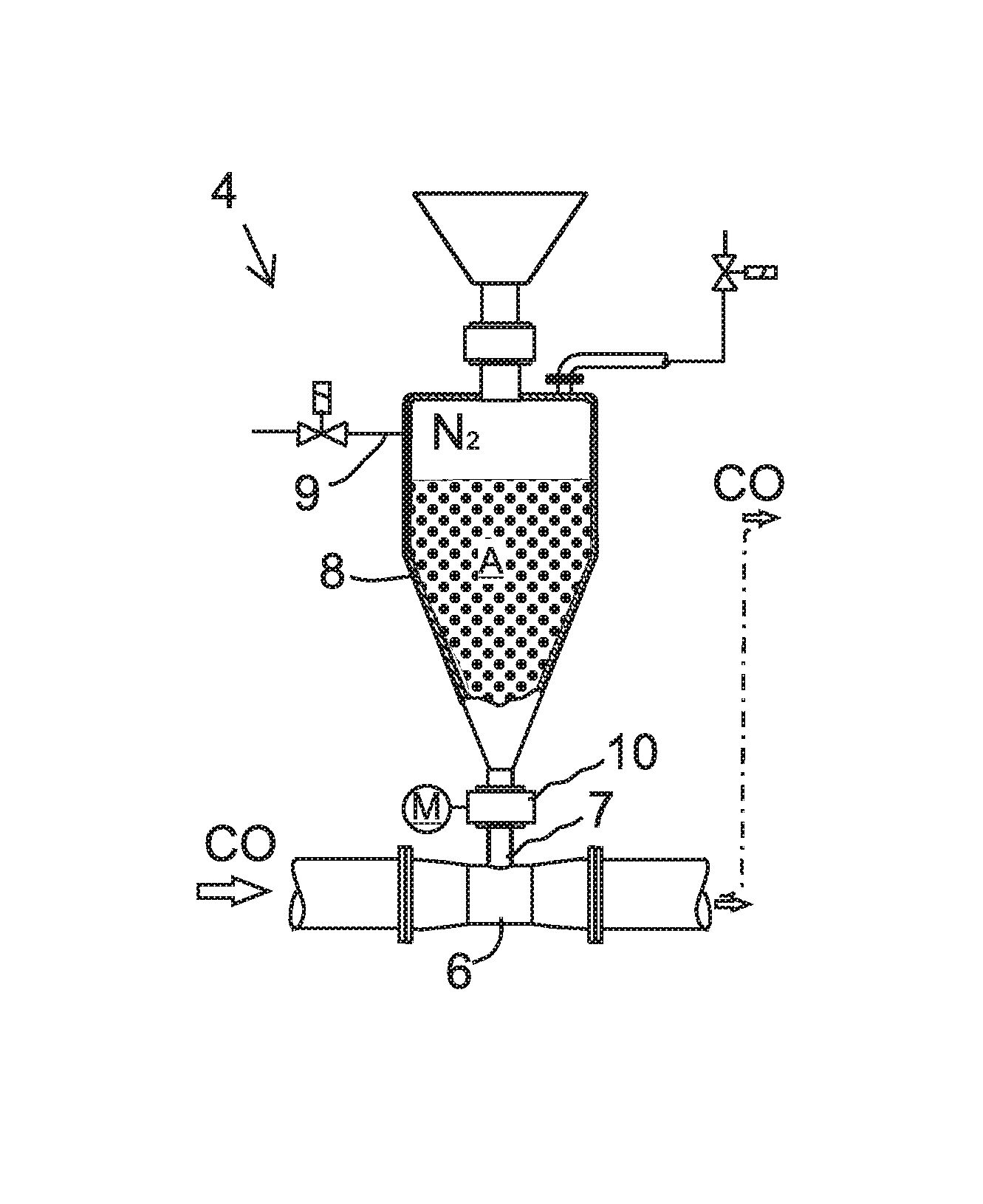

Method and arrangement for removing solid particles and tar component from carbon monoxide gas

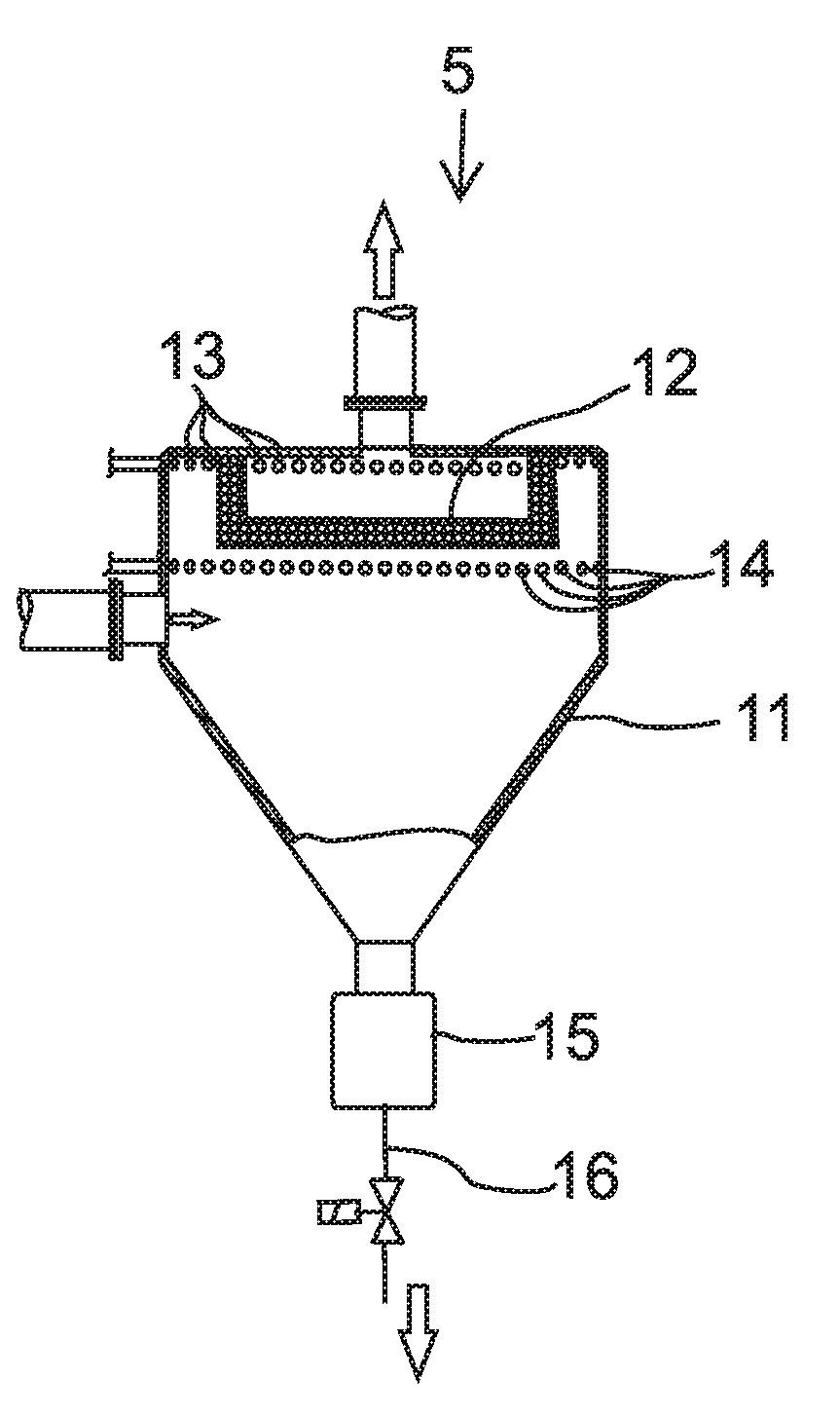

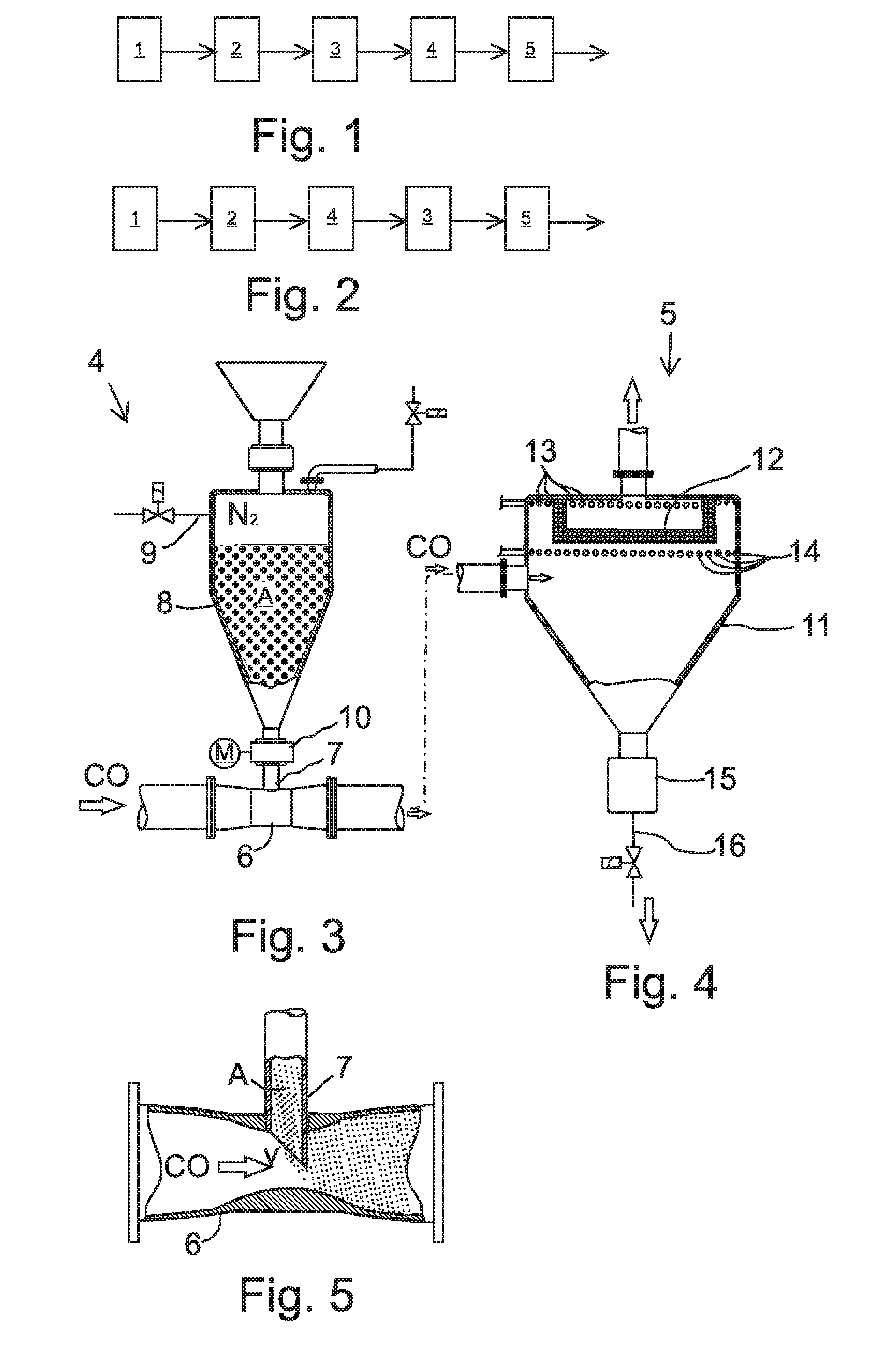

ActiveUS20110252967A1Efficient separationIncrease flow rateCombination devicesGas treatmentParticulatesLiquid medium

A method and arrangement for removing solid particles and tar component from carbon monoxide gas. In the method, carbon monoxide gas is conducted from a ferroalloy smelting furnace (1) to a gas scrubber (2), the carbon monoxide gas is scrubbed in the gas scrubber (2) by a liquid medium for removing part of the solid particles, the carbon monoxide gas is conducted from the gas scrubber to a blower (3), the flow rate of the carbon monoxide gas is increased by the blower (3), and the carbon monoxide gas is conducted to a particulate filter (5) and the remaining solid particles are essentially filtered in the particulate filter (5) from the carbon monoxide gas. Prior to conducting the carbon monoxide gas to the particulate filter (5), it is conducted to a particle feeder (4), where finely divided adsorbent particles (A) are fed in the carbon monoxide gas for adhering the tar component on the surface of the adsorbent particles, and the carbon monoxide gas flow containing adsorbent particles is conducted to the particulate filter (5), in which case the tar component adhered on the adsorbent particles is discharged in the particulate filter (5).

Owner:METSO OUTOTEC (FINLAND) OY

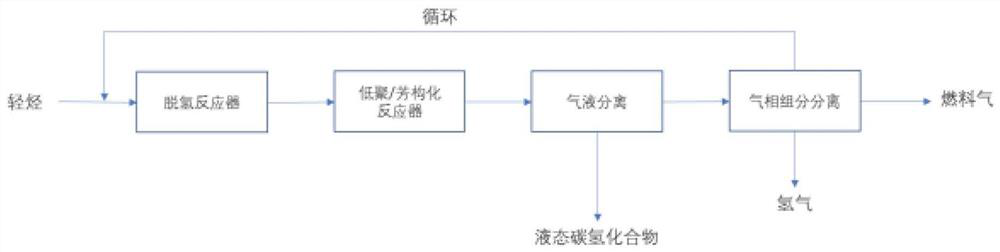

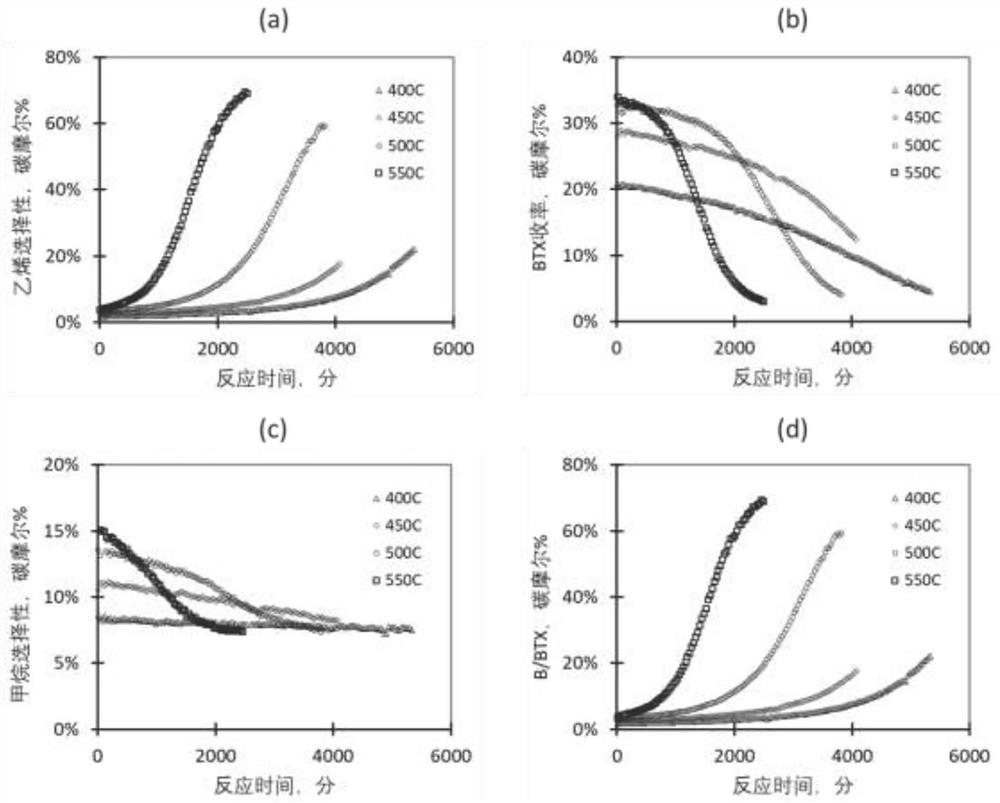

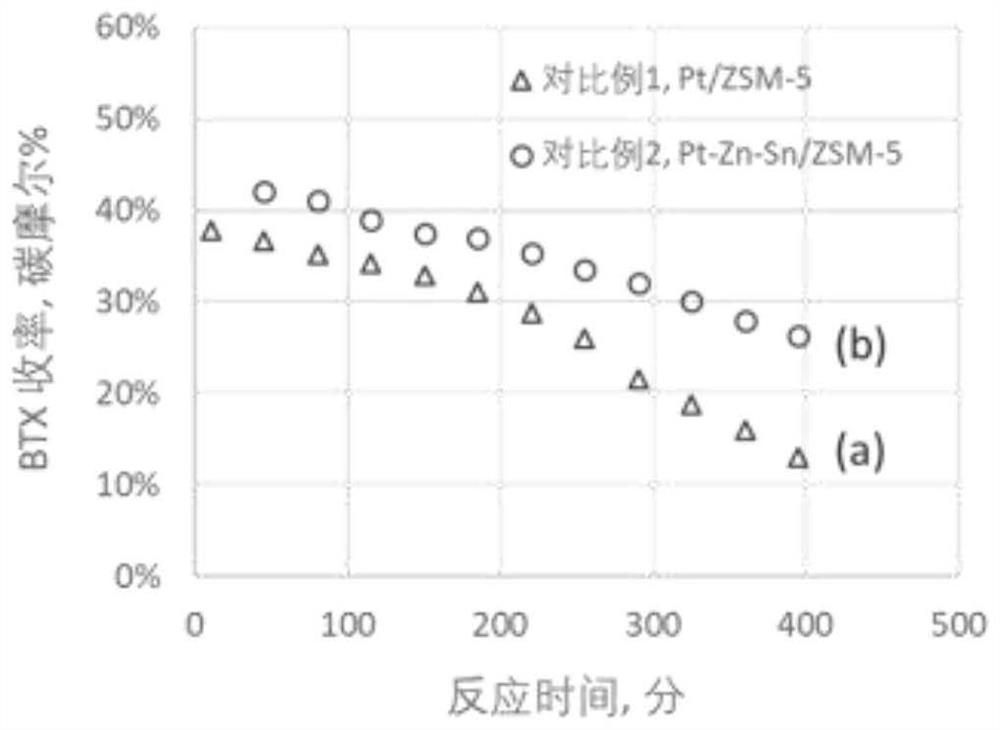

Method for producing aromatic hydrocarbons and/or liquid fuels from light hydrocarbons

ActiveCN113493699AImprove conversion rateLong life one wayMolecular sieve catalystLiquid hydrocarbon mixtures productionPtru catalystDehydrogenation

The invention provides a method for producing aromatic hydrocarbons and / or liquid fuels through light hydrocarbon dehydrogenation aromatization, which comprises the following steps: 1) under dehydrogenation reaction conditions, carrying out dehydrogenation reaction on light hydrocarbon material flow to obtain material flow containing olefin; and 2) under aromatization reaction conditions, contacting the material flow containing olefin with an aromatization catalyst, and carrying out oligomerization / aromatization reaction to obtain a material flow containing aromatic hydrocarbon and / or liquid fuel. According to the method, dehydrogenation and oligomerization / aromatization are separated and executed step by step under different conditions, a zeolite molecular sieve loaded with an active metal component is used as an aromatization catalyst, and under an optimal low-temperature aromatization condition, the high alkane conversion rate, the high carbon utilization rate and the high single-cycle aromatic hydrocarbon production capacity can be obtained through the method disclosed in the invention; and the catalyst is slow in deactivation, long in one-way service life, easy to regenerate and good in multi-cycle stability.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

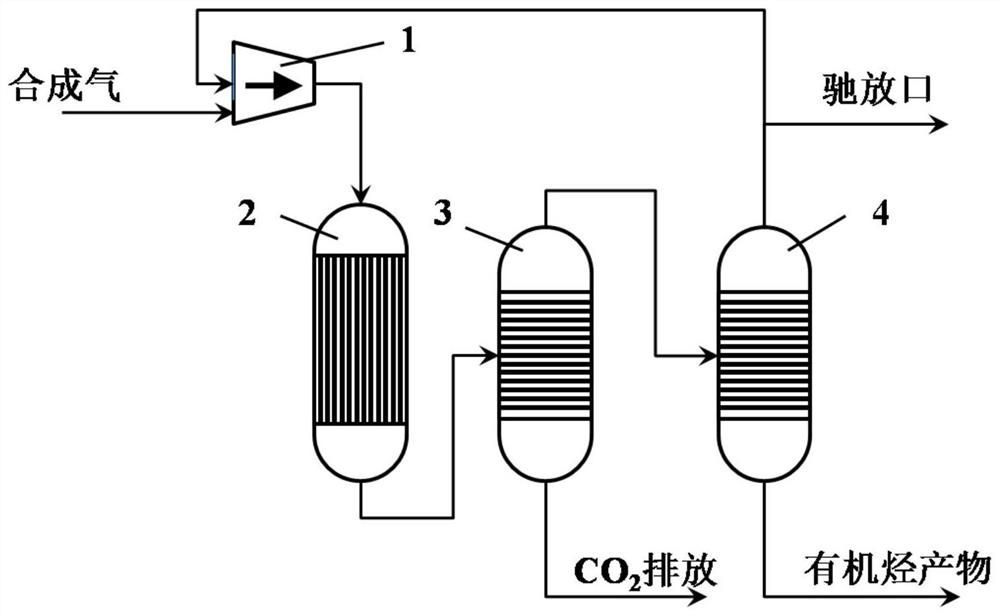

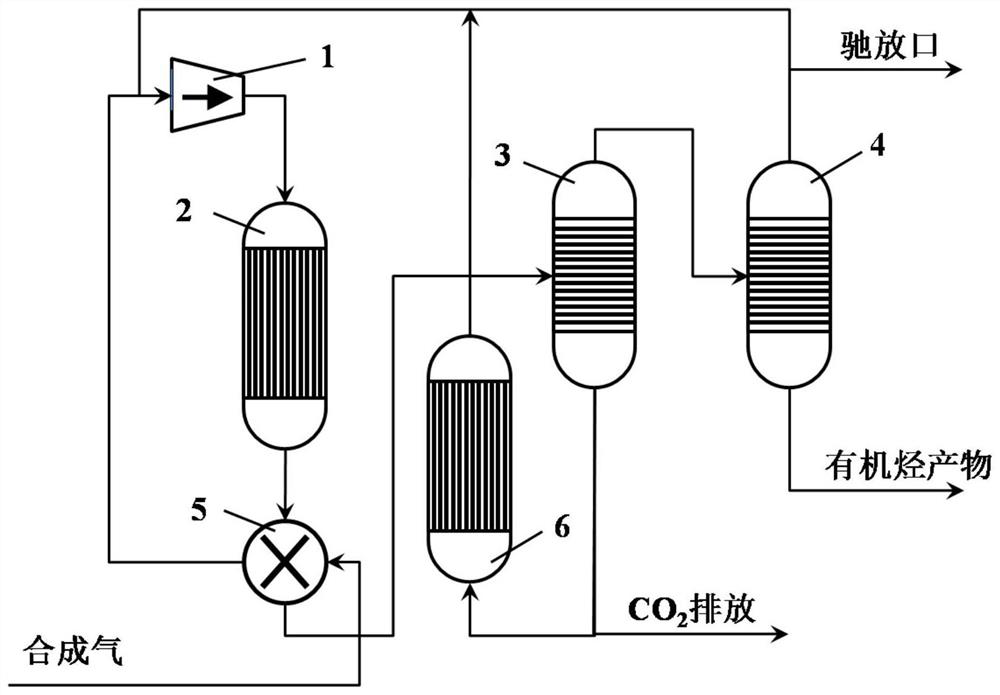

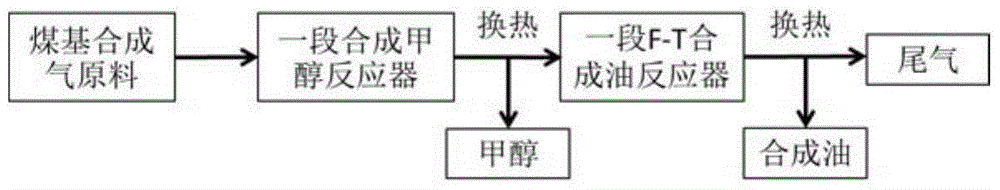

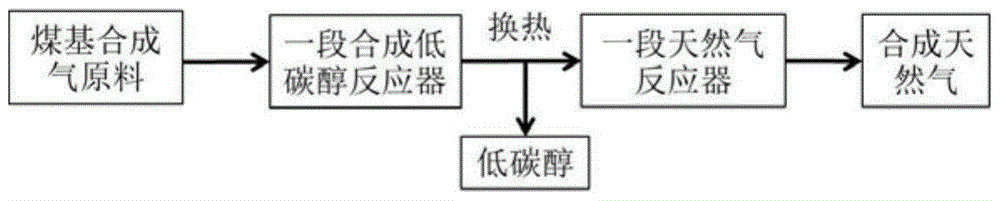

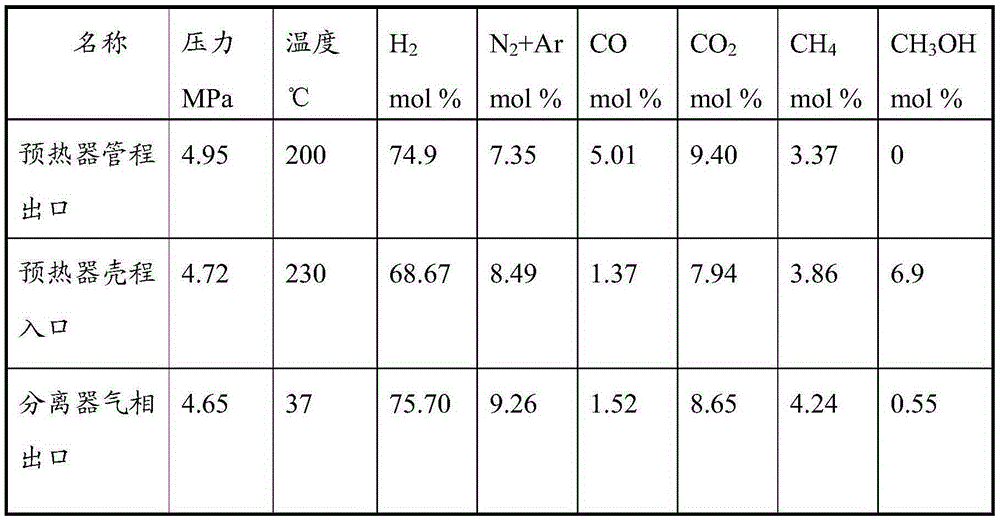

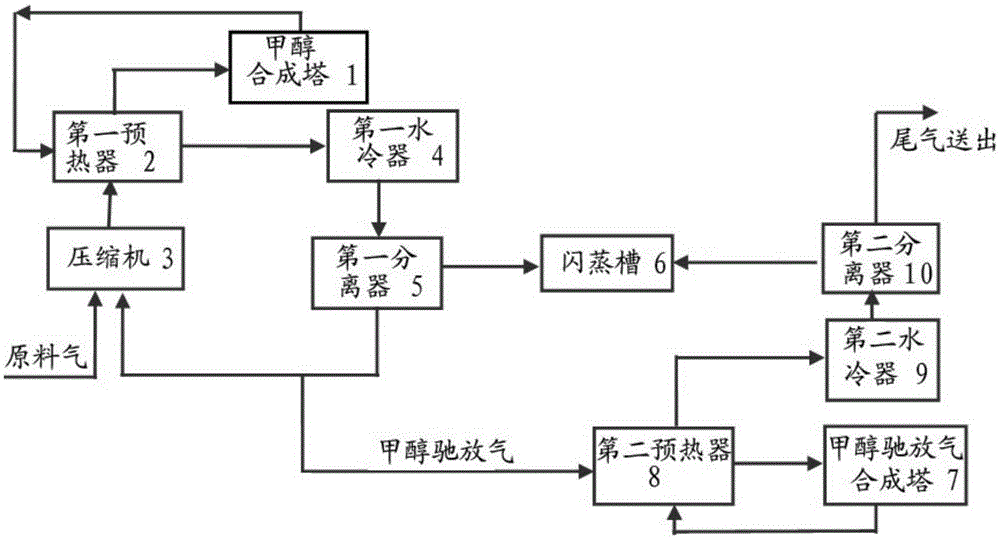

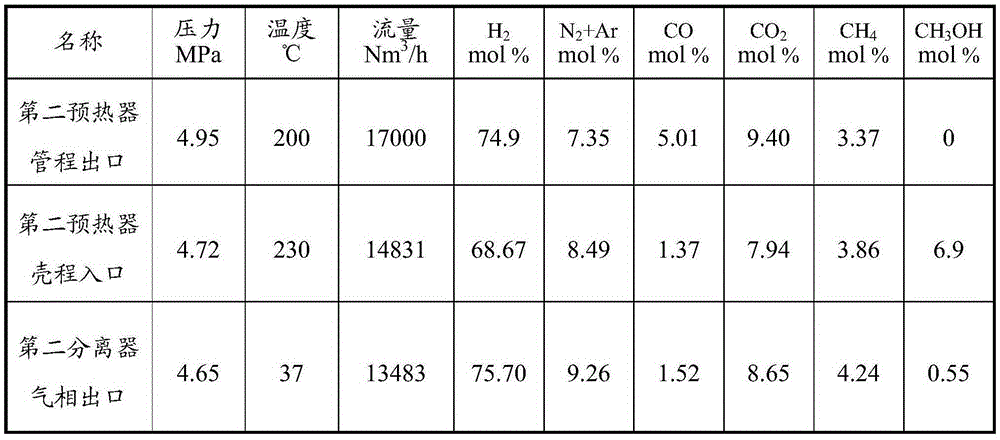

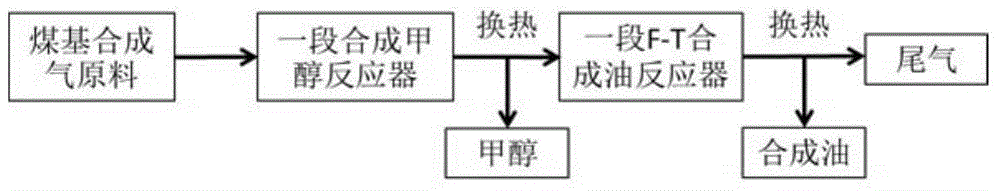

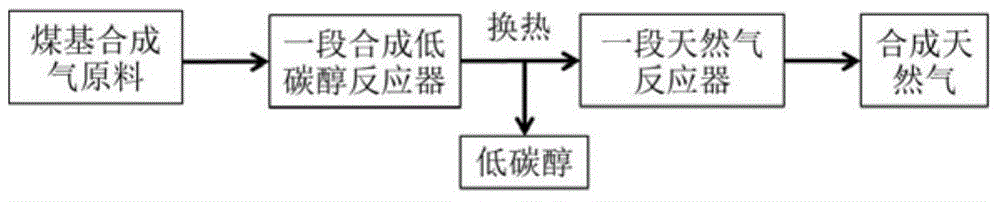

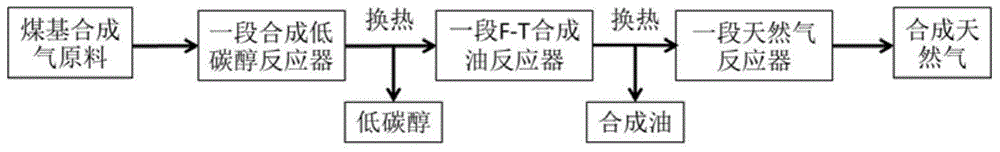

A method and system for comprehensive utilization of coal-based synthesis gas

ActiveCN104479723BImprove carbon utilizationEmission reductionSequential/parallel process reactionsOrganic compound preparationPtru catalystThermodynamics

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Method and arrangement for removing solid particles and tar component from carbon monoxide gas

ActiveUS8673058B2Improve carbon utilizationIncrease profitCombination devicesGas treatmentParticulatesLiquid medium

A method and arrangement for removing solid particles and tar component from carbon monoxide gas. In the method, carbon monoxide gas is conducted from a ferroalloy smelting furnace (1) to a gas scrubber (2), the carbon monoxide gas is scrubbed in the gas scrubber (2) by a liquid medium for removing part of the solid particles, the carbon monoxide gas is conducted from the gas scrubber to a blower (3), the flow rate of the carbon monoxide gas is increased by the blower (3), and the carbon monoxide gas is conducted to a particulate filter (5) and the remaining solid particles are essentially filtered in the particulate filter (5) from the carbon monoxide gas. Prior to conducting the carbon monoxide gas to the particulate filter (5), it is conducted to a particle feeder (4), where finely divided adsorbent particles (A) are fed in the carbon monoxide gas for adhering the tar component on the surface of the adsorbent particles, and the carbon monoxide gas flow containing adsorbent particles is conducted to the particulate filter (5), in which case the tar component adhered on the adsorbent particles is discharged in the particulate filter (5).

Owner:METSO METALS OY

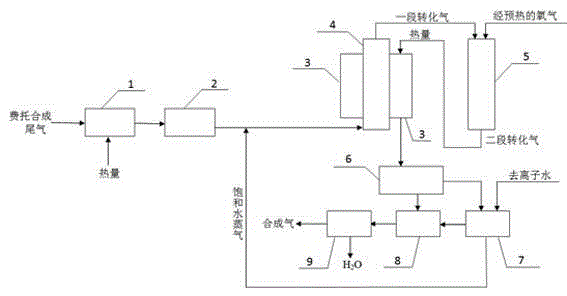

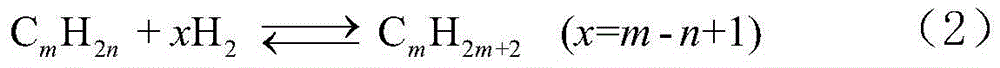

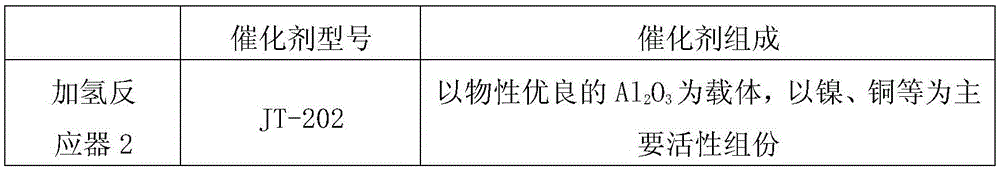

A method for converting Fischer-Tropsch synthesis tail gas into Fischer-Tropsch synthesis feed gas

ActiveCN104150441BTake advantage ofImprove carbon utilizationHydrogenChemical industrySteam reformingPartial oxidation

The invention relates to a method for converting a Fischer-Tropsch synthesis tail gas into a Fischer-Tropsch synthesis feed gas. The method comprises the following steps that: carrying out catalytic hydrogenation reaction on the Fischer-Tropsch synthesis tail gas in a hydrogenation reactor filled with a hydrogenation catalyst, so as to convert the Fischer-Tropsch synthesis tail gas into saturated hydrocarbon; then carrying out steam reforming and partial oxidation in a primary converter and a secondary converter, carrying out water gas shift reaction in an intermediate converter and finally carrying out gas-liquid separation, wherein a gas phase is the feed gas which meets the requirement for hydrogen carbon ratio required by Fischer-Tropsch synthesis. The method disclosed by the invention has the advantages of simple process and convenience for operation.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

Process for the preparation of aromatic hydrocarbons and compositions obtained by the process

ActiveCN106256812BReduce consumptionLow costHydrocarbon from oxygen organic compoundsBulk chemical productionCelluloseLevulinic acid

The invention relates to an aromatic hydrocarbon preparation method and a composition prepared by the aromatic hydrocarbon preparation method. The aromatic hydrocarbon preparation method comprises that a, acetylpropionic acid contacts with a hydrogenation catalyst under hydrogenation conditions and undergoes a reaction to produce a methyltetrahydrofuran flow and b, the methyltetrahydrofuran flow contacts with an aromatization catalyst under aromatization conditions and undergoes a reaction to produce an aromatic hydrocarbon flow containing benzene, toluene and xylene. The preparation method can be used for industrial production of aromatic hydrocarbons such as benzene, toluene and xylene from cellulose-containing biomass raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

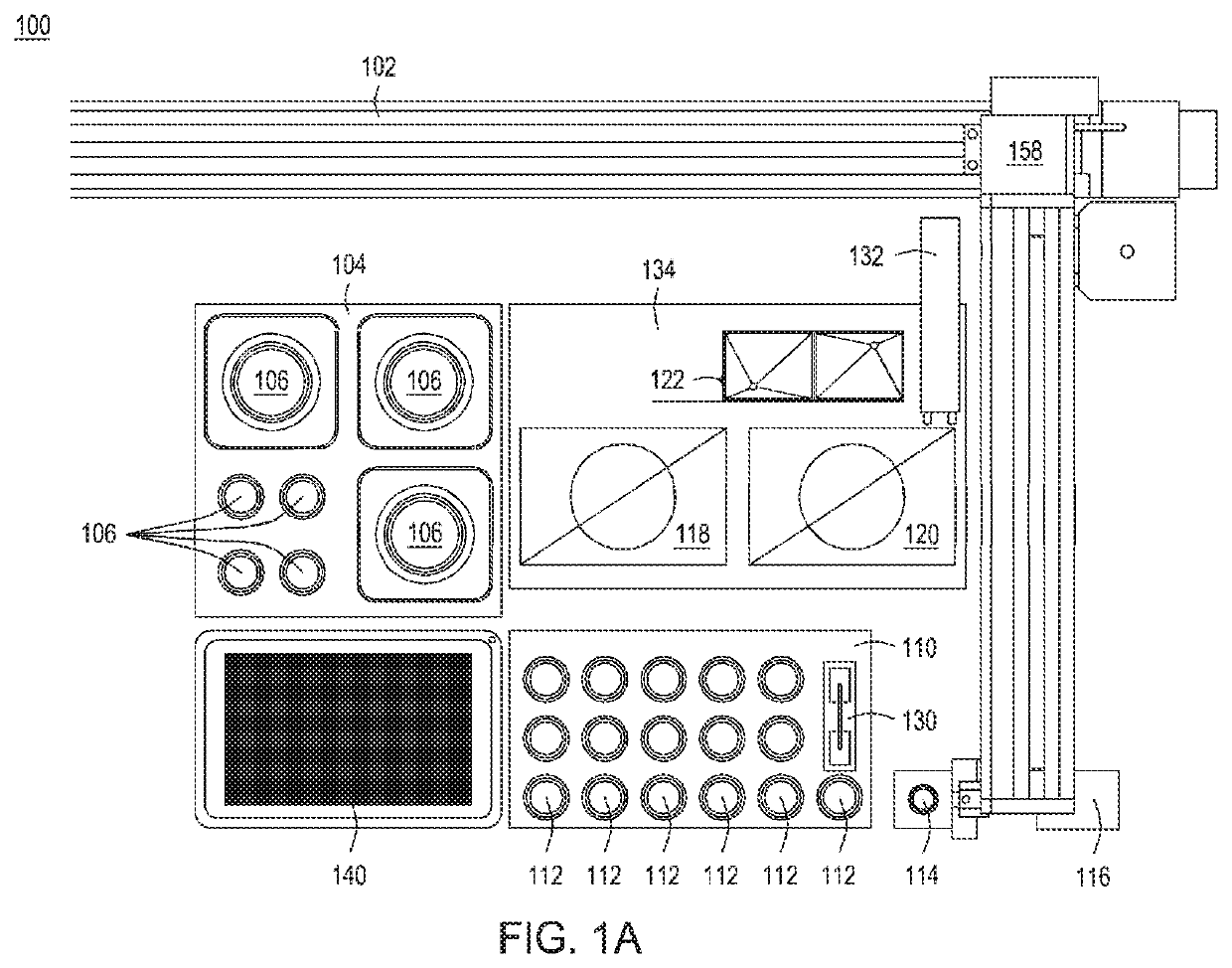

Multiplexed engineered cells and systems for biofuel production

PendingUS20220267812A1Increase productionImprove heat resistanceBacteriaHydrolasesBiotechnologyHeterologous

The present disclosure provides multiplexed engineered cells, automated multi-module instruments and methods of producing biofuel producing cells for enhanced production of biofuels. This platform empowers users to design genetic variant libraries of insertions, swaps, and / or deletions, that can be intentionally or randomly positioned across the entire genome to generate engineered cell populations with improved properties for several common biofuel applications including, but not limited to, improved tolerance to biomass inhibitors, increased thermo-tolerance, increased ethanol production and / or tolerance, expanded carbon utilization abilities, and increased utilization of heterologous proteins or pathways.

Owner:INSCRIPTA INC

Process for the production of aromatic hydrocarbons and compositions obtained by the process

ActiveCN106316738BImprove carbon utilizationReduce consumptionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionCelluloseLevulinic acid

The invention relates to a method for producing aromatic hydrocarbons and the compounds produced thereby. The method comprises the steps of contacting levulinic acid with aromatization catalysts, under aromizing conditions, to prepare the aromatic hydrocarbon mixture, which contains benzenes, methyl benzenes and xylenes. The method can be applied to the industrial production of aromatic hydrocarbons, including benzenes, methyl benzenes and xylenes, from biomass raw materials, which contain cellulose.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated gasification and electrolysis process

ActiveUS20210309586A1Improve carbon utilizationEfficient managementHydrocarbon from carbon oxidesGaseous fuelsThermodynamicsElectrolysis

Owner:GAS TECH INST

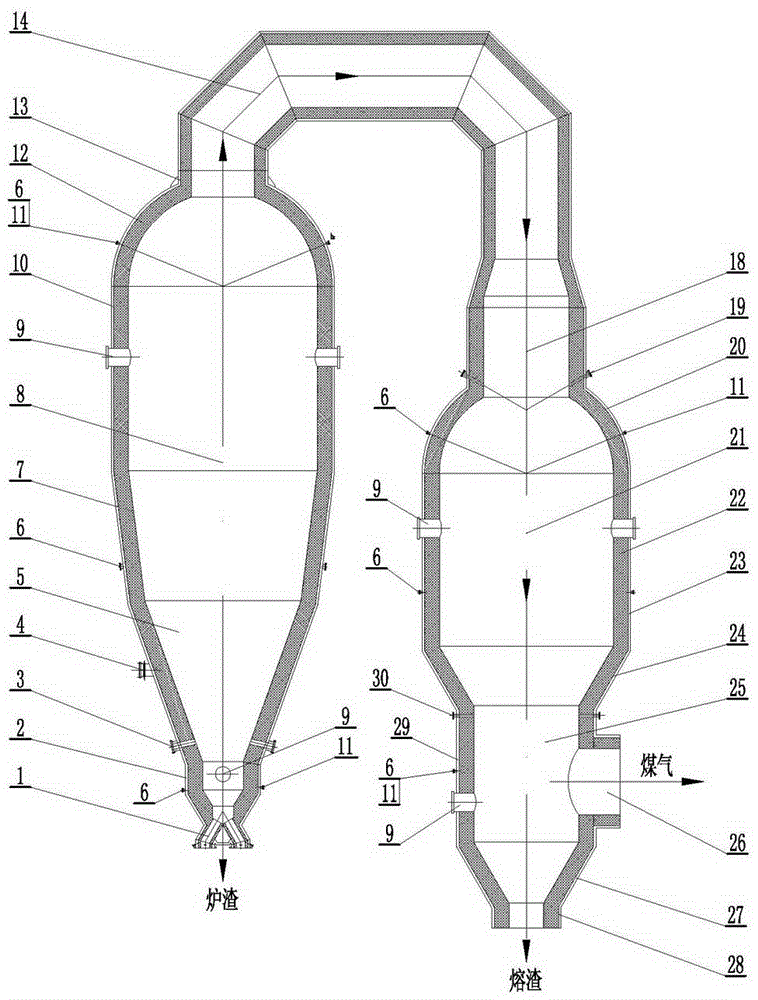

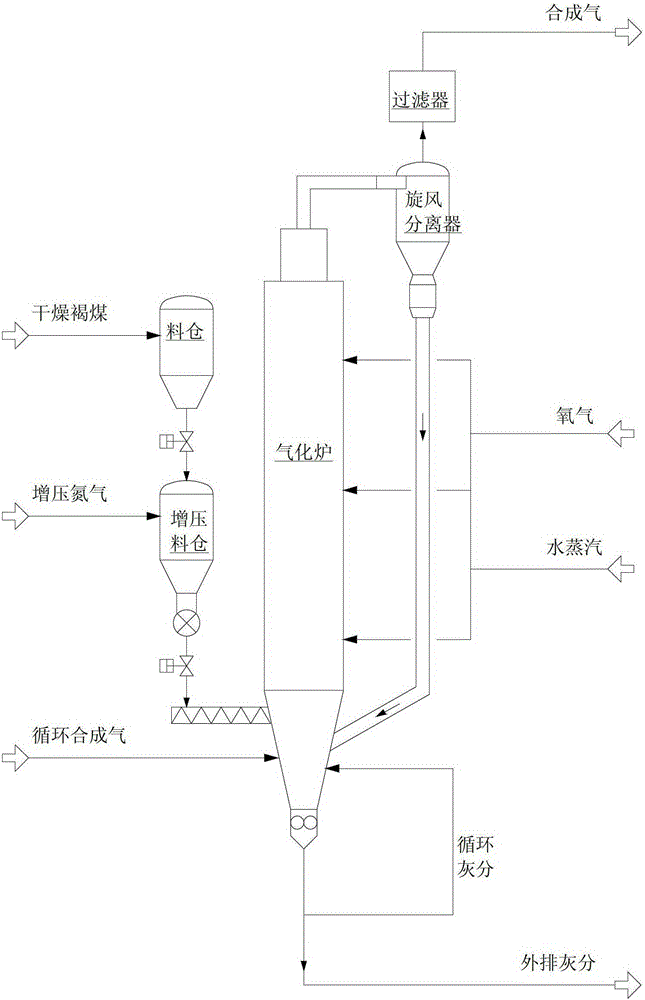

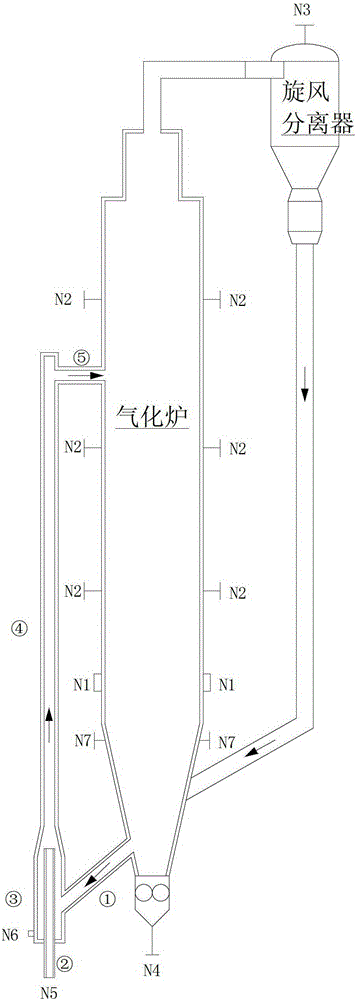

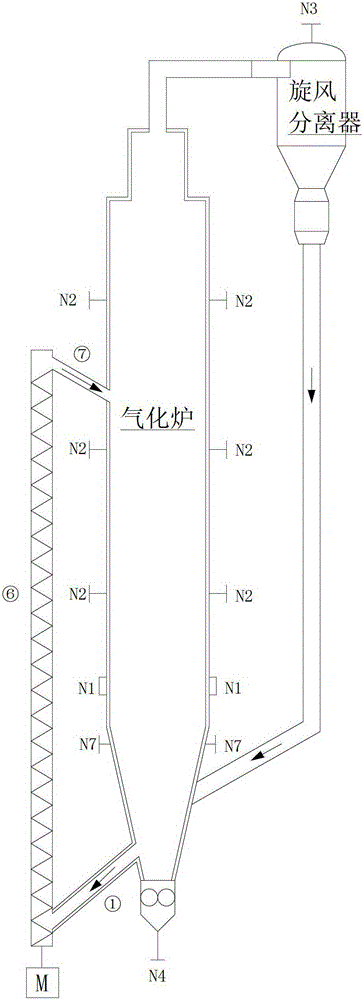

A Fluidized Bed Lignite Gasification Process with Ash Circulation

ActiveCN103450947BImprove conversion rateReduce carbon residueCombined combustion mitigationGranular/pulverulent flues gasificationSyngasBrown coal

The invention discloses a novel lignite gasification process by using a fluidized bed with ash circulation and equipment of the novel lignite gasification process. According to the novel lignite gasification process, a dried lignite raw material is put into a fluidized bed gasification furnace, a gasifying agent is put into the gasification furnace to perform mixed reaction with the lignite, a synthetic gas generated by the reaction between the lignite and the gasifying agent leaves the gasification furnace and flows to a downstream section after being separated and filtered, and separated fine powder returns to the gasification furnace through a pipeline; one part of the ash generated by lignite combustion is returned to the gasification furnace to perform further burning, and the other part of the ash is discharged from the bottom of the gasification furnace; the ash returned to the gasification furnace can be further burnt in two modes including a gas flow conveying mode and a mechanical conveying mode. According to the process disclosed by the invention, two ash circulating modes including the gas flow conveying mode and the mechanical conveying mode are used to ensure that the ash can be returned to the gasification furnace for continuous burning so as to reduce carbon residues on the ash and improve the carbon utilization ratio when the lignite raw material is converted into the synthetic gas. The process and the equipment are simple and reliable, can effectively reduce investment and increase the running reliability, and have environment-friendly effect and less in pollutant discharge.

Owner:CHINA TIANCHEN ENG +1

Utilization method of methanol purge gas

ActiveCN104211567BFully digestedEmission reductionOrganic compound preparationHydroxy compound preparationCombustionCoke oven

The invention discloses a utilization method of methanol purge gas. The method comprises the following steps: feeding the methanol purge gas to a methanol purge gas utilization unit; and preparing a reducing agent for reducing a desulfurizer in methanol by using tail gas of the methanol purge gas utilization unit as coke-oven gas. The invention further discloses a utilization method of methanol purge gas, wherein the reducing agent for reducing the desulfurizer in methanol is prepared by using the methanol purge as coke-oven gas. The method disclosed by the invention can be used for breaking through the boundary of conventional simple combustion and utilization in the aspect of utilizing the methanol purge gas, and further deeply synthesizing the methanol purge gas, so that the utilization ratio of carbon is improved and the greenhouse gas emission is reduced. Moreover, by replacing the coke-oven gas with the methanol purge gas or the tail gas of the methanol purge gas which is deeply synthesized as the reducing agent, not only is the system stable, but also the coke-oven gas can be better used for synthesizing methanol, and the economic efficiency is improved.

Owner:CHINA KINGHO ENERGY GRP +1

Aromatic hydrocarbon preparation method and composition prepared by aromatic hydrocarbon preparation method

ActiveCN106256812AReduce consumptionLow costHydrocarbon from oxygen organic compoundsBulk chemical productionCelluloseLevulinic acid

The invention relates to an aromatic hydrocarbon preparation method and a composition prepared by the aromatic hydrocarbon preparation method. The aromatic hydrocarbon preparation method comprises that a, acetylpropionic acid contacts with a hydrogenation catalyst under hydrogenation conditions and undergoes a reaction to produce a methyltetrahydrofuran flow and b, the methyltetrahydrofuran flow contacts with an aromatization catalyst under aromatization conditions and undergoes a reaction to produce an aromatic hydrocarbon flow containing benzene, toluene and xylene. The preparation method can be used for industrial production of aromatic hydrocarbons such as benzene, toluene and xylene from cellulose-containing biomass raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

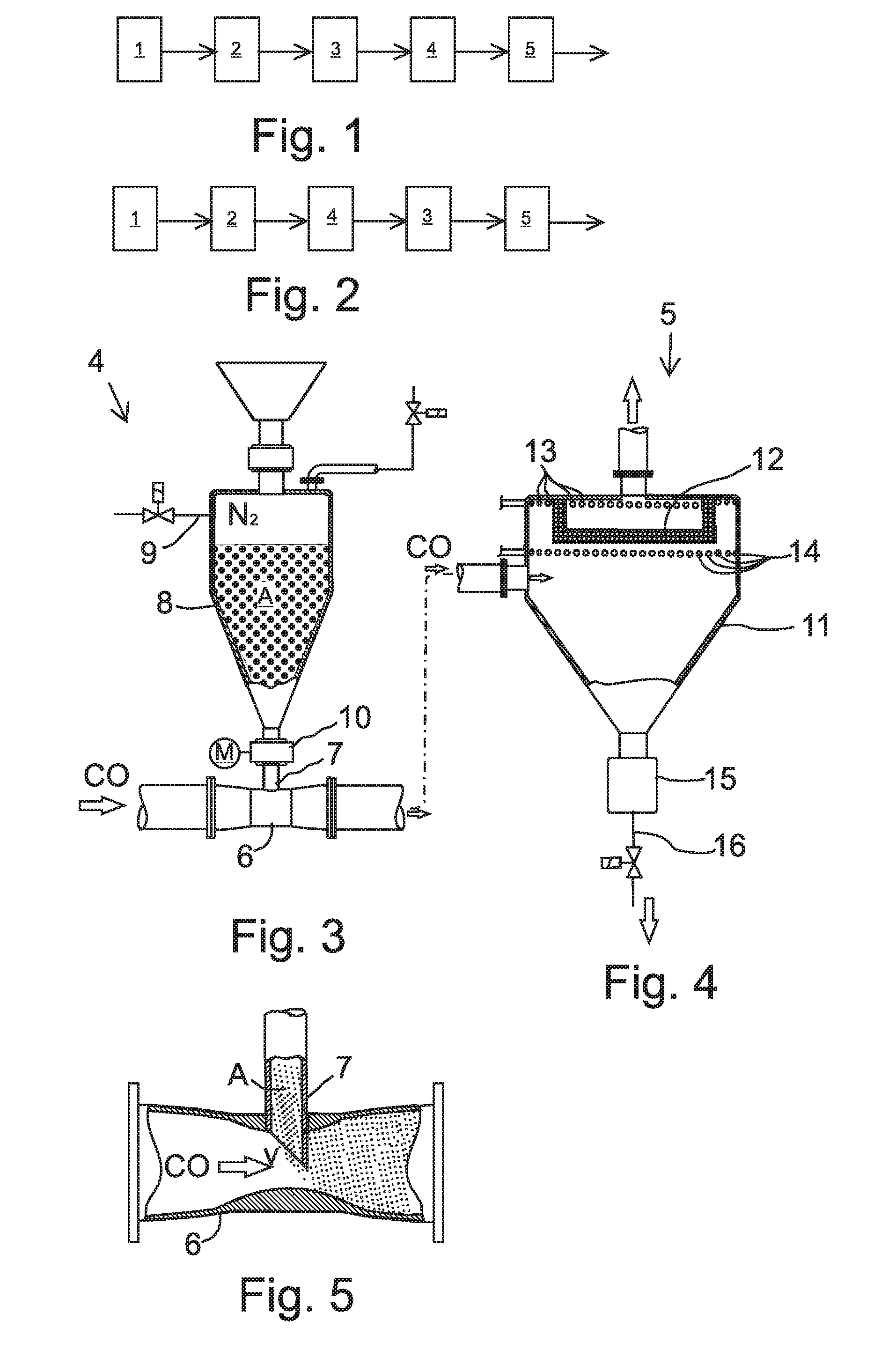

Technical method for preparing low-carbon mixed alcohol and natural gas by synthetic gas one-step method from coal

PendingCN112939734AIncrease production speedDisadvantages of low activityPhysical/chemical process catalystsOrganic compound preparationSyngasPtru catalyst

The invention provides a technical method for preparing low-carbon mixed alcohol by a synthetic gas one-step method from coal, which comprises the following specific steps that coal is gasified, the gas is purified, and desulfurizing is conducted by a chemical adsorption method to obtain synthetic gas consisting of hydrogen and carbon; then the synthetic gas is in contact with a Cu-based sulfide catalyst under the condition of high pressure for a catalytic reaction, the reacted gas is subjected to heat exchange, condensation and liquid separation, a liquid-phase component and tail gas are obtained, the liquid-phase component is low-carbon mixed alcohol, and the low-carbon mixed alcohol mainly containing alcohols and a small amount of C1-C4 gaseous hydrocarbon are generated through catalytic synthesis. According to the method, the coal is used as the raw material to synthesize the low-carbon mixed alcohol, the final products are the low-carbon mixed alcohol and the C1-C4 gaseous hydrocarbon, the low-carbon mixed alcohol is used as the chemical raw material, the C1-C4 gaseous hydrocarbon is used as the fuel, the final products are not wasted, and pollution is avoided. The Cu-based sulfide catalyst is used as the catalyst, such that the disadvantage of low activity of the existing catalyst is changed, and the production speed of the low-carbon mixed alcohol is improved.

Owner:山西华顿实业有限公司

A kind of coke oven gas to methanol system

ActiveCN103980091BFully digestedEmission reductionOrganic compound preparationHydroxy compound preparationCombustionEconomic benefits

The invention discloses a system for producing methanol by using coke oven gas. The system comprises a methanol synthesis unit and a methanol purge gas utilization unit, wherein the methanol purge gas utilization unit is used for synthesizing methanol by taking methanol purge gas from the methanol synthesis unit as a raw material. The invention also discloses a methanol purge gas utilization method. The traditional simple combustion utilization constraint is broken on the aspect of methanol purge gas utilization, and the methanol purge gas is further deeply synthesized to produce methanol, so that carbon in the methanol purge gas is more sufficiently digested, the extremely low carbon content of tail gas is difficult to reach by a conventional synthesis tower, the utilization ratio of carbon is increased, the discharged greenhouse gas is reduced, and meanwhile, the considerable economic benefit is further brought.

Owner:CHINA KINGHO ENERGY GRP +1

Comprehensive utilization method and comprehensive utilization system for coal-based synthesis gas

ActiveCN104479723AImprove carbon utilizationEmission reductionSequential/parallel process reactionsOrganic compound preparationAlcohol synthesisCoal

The invention provides a comprehensive utilization method and a comprehensive utilization system for coal-based synthesis gas. The method comprises the following steps, namely, a step of carrying out contact reaction on a gas and a catalyst for methanol synthesis and / or a step of carrying out contact reaction on the gas and a catalyst for low-carbon alcohol synthesis; a step of carrying out contact reaction on the gas and a catalyst for oil synthesis and / or a step of carrying out contact reaction on the gas and a catalyst for natural gas synthesis; and a step of reacting the coal-based synthesis gas according to a process formed by combining the previous steps. In addition, the invention also provides the comprehensive utilization system for coal-based synthesis gas. The system comprises one or a combination of a reactor for methanol synthesis and a reactor for low-carbon alcohol synthesis; and one or a combination of a reactor for oil synthesis and a reactor for natural gas synthesis. By the comprehensive utilization method and a comprehensive utilization system for coal-based synthesis gas provided by the invention, the economical efficiency of the device can be improved to a larger extent and the utilization rate of carbon resources in coal-based synthesis gas is increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com