Comprehensive utilization method and comprehensive utilization system for coal-based synthesis gas

A technology for coal-based synthesis gas and synthetic natural gas, applied in the field of coal chemical industry, can solve the problems of single raw material and evaluation conditions, poor product adjustment flexibility, unstable device operation, etc., and achieves improved anti-risk capability, obvious environmental protection effect, and good economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

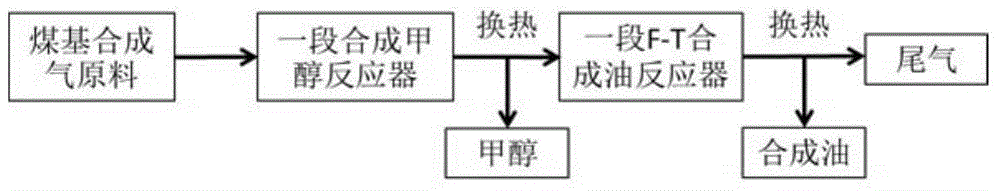

[0050] This embodiment provides a method for comprehensive utilization of coal-based synthesis gas, which uses a system in which a first-stage synthetic methanol reactor is connected to a first-stage F-T synthetic oil reactor, and its process is as follows figure 1 As shown, the method includes the following steps:

[0051] The flow rate of the purified coal-based syngas is 16Nm 3 / h, the molar composition (the sum of the contents of each component is 100%) is: CO 33.5%, H 2 54.3%, CO 2 0.9%, CH 4 11.2%, the rest is inert component N 2 and Ar;

[0052] The coal-based synthesis gas is fed into the first-stage methanol synthesis reactor to contact with the methanol synthesis catalyst for reaction. The reaction temperature is 230°C, the pressure is 2.0MPa, and the reaction space velocity is 1000h -1 , H 2 The / CO ratio is 1.6; the molar ratio of the metal elements of each component of the synthetic methanol catalyst is Cu:Zn:Ce:Al=40:25:6:29; the gas after the reaction is c...

Embodiment 2

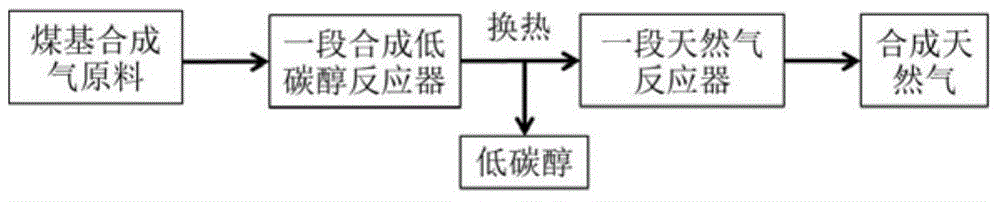

[0055] This embodiment provides a method for comprehensive utilization of coal-based synthesis gas, which uses a system in which a reactor for synthesizing low-carbon alcohols is connected to a reactor for synthesizing natural gas. The process flow is as follows figure 2 As shown, the method includes the following steps:

[0056] The flow rate of the purified coal-based syngas is 16Nm 3 / h, the molar composition (the sum of the contents of each component is 100%) is: CO 33%, H 2 53%, CO 2 0.8%, CH 4 12.7%, the rest is inert component N 2 and Ar;

[0057] The coal-based synthesis gas is fed into the first-stage low-carbon alcohol synthesis reactor to contact with the low-carbon alcohol synthesis catalyst for reaction. The reaction temperature is 200°C, the pressure is 2.0MPa, and the reaction space velocity is 1000h -1 , H 2 The / CO ratio is 1.6; the molar ratio of the metal elements of the components of the synthetic low-carbon alcohol catalyst is Cu:Cr:K:Zn=40:15:15:30...

Embodiment 3

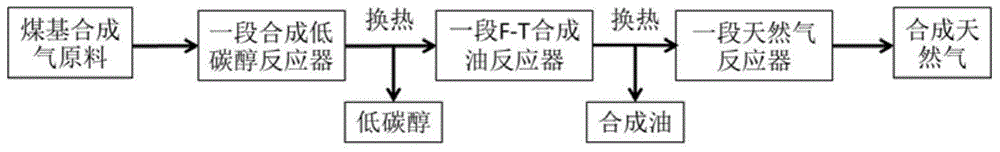

[0060] This embodiment provides a method for comprehensive utilization of coal-based synthesis gas, which uses a system in which a first-stage low-carbon alcohol synthesis reactor is connected to a first-stage F-T synthetic oil reactor, and a first-stage F-T synthetic oil reactor is connected to a first-stage synthetic natural gas reactor. The process flow is as follows image 3 As shown, the method includes the following steps:

[0061] The flow rate of the purified coal-based syngas is 16Nm 3 / h, the molar composition (the sum of the contents of each component is 100%) is: CO 31.2%, H 2 54.6%, CO 2 0.9%, CH 4 13.1%, the rest is inert component N 2 and Ar;

[0062] The coal-based synthesis gas is passed into the first-stage low-carbon alcohol synthesis reactor to contact with the low-carbon alcohol synthesis catalyst for reaction. The reaction temperature is 300°C, the pressure is 4.0MPa, and the reaction space velocity is 6000h -1 , H 2 The / CO ratio is 1.8; the molar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com