System for producing natural gas by electrolytic hydrogen production and gas synthesis from coal

A coal-to-synthesis gas and natural gas technology, applied in the field of natural gas, to achieve the effects of improving carbon utilization, reducing production load, and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

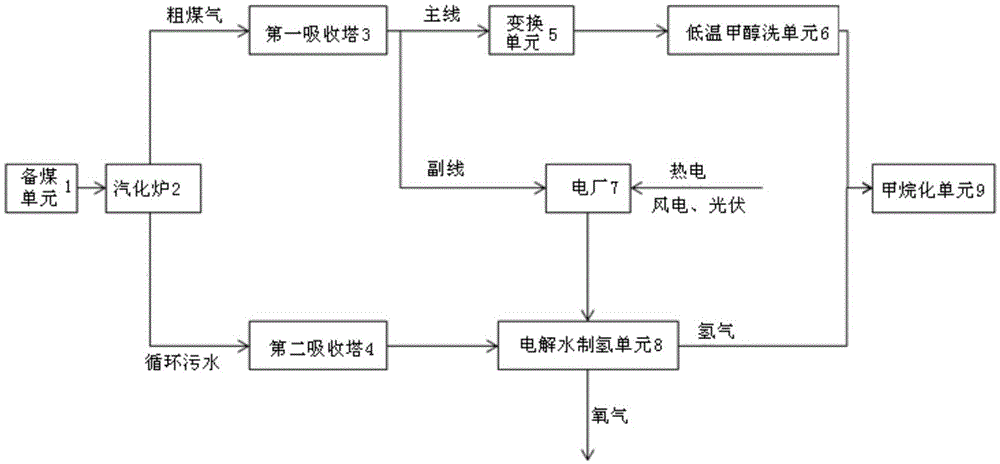

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Referring to the accompanying drawings, a system for electrolytic hydrogen production and coal-to-synthetic gas to natural gas comprises a coal preparation unit 1, the outlet of the coal preparation unit 1 is connected to the inlet of the gasifier 2, and the crude gas outlet at the upper end of the gasifier 2 is connected to the first The inlet of the first absorption tower 3 is connected, and the outlet of the first absorption tower 3 is divided into two lines, the main line and the auxiliary line. Line 1 is connected to the power plant 7, and the electric energy generated by the power plant 7 through thermoelectricity, wind power, and photovoltaics is directly supplied to the electrolytic water hydrogen production unit 8; the outlet of the lower end of the gasifier 2 is connected to the inlet of the second absorption tower 4, and the second absorption tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com