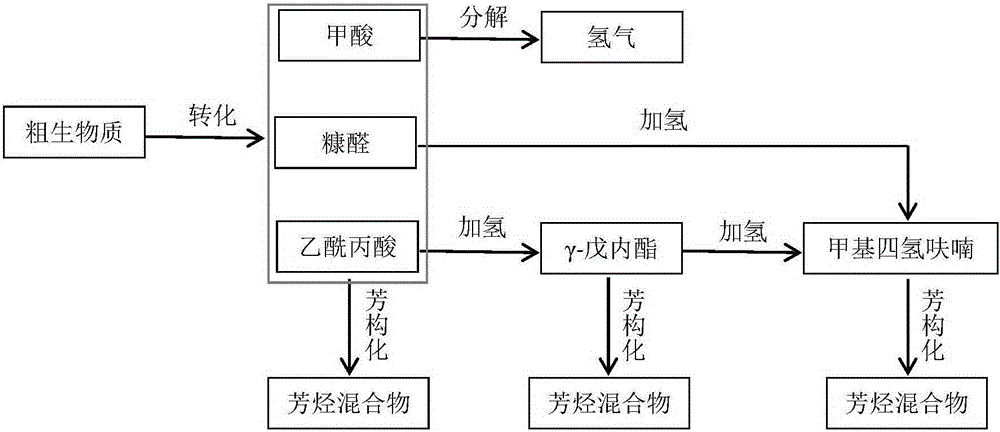

Method for producing aromatic hydrocarbon from biomass and composition product thereof

A biomass and biomass raw material technology, applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve the problems of low carbon utilization rate, high hydrogen consumption, high raw material cost, etc., and achieve the effect of low total consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The raw material is 1 ton of papermaking sludge, with a dry base cellulose content of 61%. The papermaking sludge was fully stirred and mixed with 3.5 tons of 3% sulfuric acid aqueous solution, and the acid hydrolysis process was completed by stirring and reacting at 3.0 MPa and 205°C for 25 minutes. After the liquid phase product was separated, 275 kg of levulinic acid and 104.5 kg of formic acid. 104.5 kg of formic acid can be decomposed to obtain 4.5 kg of hydrogen.

[0047] In 25%Cu / 70%SiO 2 -5%Al 2 o 3 On the catalyst, the reaction pressure is 2.0MPa, the reaction temperature is 182°C, the molar ratio of hydrogen / levulinic acid is 30, and the space velocity of levulinic acid is 0.3h -1, the conversion rate of levulinic acid is 100%, the molar selectivity of γ-valerolactone is 96.8%, and the molar selectivity of methyl tetrahydrofuran is 2.1%. 275 kg of levulinic acid undergoes a hydrogenation reaction to generate 229 kg of γ-valerolactone and 4.3 kg of methyl ...

Embodiment 2

[0052] The raw material is 1 ton of bagasse, the dry base cellulose content is 52%, and the hemicellulose content is 27%. After fully pulverizing the bagasse, stir and mix with 3.5 tons of 1.5% hydrochloric acid aqueous solution, then add 1.2 kg of ferric chloride, and keep the mixed solution at 1.0 MPa and 180°C for 10 minutes under microwave heating conditions to complete the acid reaction. During the hydrolysis process, the liquid phase product can obtain 248 kilograms of levulinic acid, 95 kilograms of formic acid and 135 kilograms of furfural after separation. 95 kg of formic acid can be decomposed to obtain 4.1 kg of hydrogen.

[0053] On 0.5% Ru / C catalyst, the reaction pressure is 1.2MPa, the reaction temperature is 130°C, the molar ratio of hydrogen / levulinic acid is 10, and the space velocity of levulinic acid is 0.3h -1 , the conversion rate of levulinic acid was 89%, the molar selectivity of γ-valerolactone was 4.5%, and the molar selectivity of methyl tetrahydrof...

Embodiment 3

[0058] The raw material is 1 ton of municipal waste paper, and the dry base cellulose content is 92.1%. After these municipal waste papers are fully pulverized, they are stirred and mixed with 3.5 tons of 3.5% sulfuric acid aqueous solution, and then 13 kg of sodium sulfite is added, and the mixed solution is kept at 3.0 MPa and 205°C for 30 minutes under stirring conditions to complete the acidolysis process. After separation of the phase products, 503.5 kg of levulinic acid and 197.6 kg of formic acid were obtained. 197.6 kg of formic acid can be decomposed to obtain 8.5 kg of hydrogen.

[0059] In 0.1%Pd-15%Ni / 84.9%SiO 2 On the catalyst, the reaction pressure is 9.0MPa, the reaction temperature is 240°C, the hydrogen / levulinic acid molar ratio is 20, and the levulinic acid space velocity is 0.8h -1 , the conversion rate of levulinic acid was 93.9%, the molar selectivity of γ-valerolactone was 98.2%, and the molar selectivity of methyl tetrahydrofuran was 0.3%. 503.5 kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com