Utilization method for CO2 in biomass pyrolysis tail gas

A biomass pyrolysis and biomass technology, which is applied in the fields of biofuels, carbon monoxide, special forms of dry distillation, etc., can solve problems such as applications that do not involve the improvement of reaction performance, reduce investment in storage and treatment, improve economy and environmental protection, Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

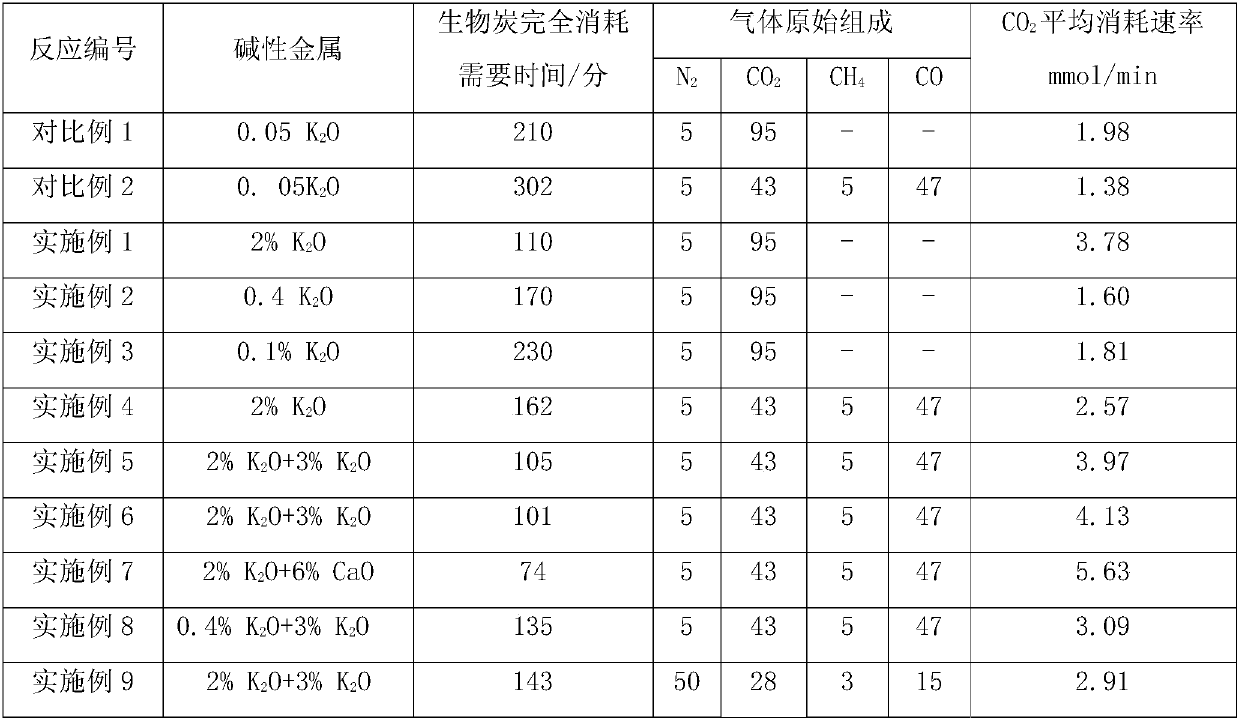

Embodiment 1

[0021] Weigh 5g of biochar produced by the rapid pyrolysis of corncobs and fill it into the middle of the fixed-bed reactor, and feed it with N 2 Purge at room temperature for 10 minutes to remove the air in the system, and then raise the temperature to 900°C. After the reactor bed reached the target reaction temperature, the N 2 Switch to 95% CO 2 -5%N 2 Mixed gas, gas chromatographic detection of tail gas changes. The test results are shown in Table 1.

Embodiment 2

[0023] Weigh 5g of biochar produced by rapid pyrolysis of rice husk and fill it into the middle of the fixed-bed reactor, and feed N 2 Purge at room temperature for 10 minutes to remove the air in the system, and then raise the temperature to 1200°C. After the reactor bed reached the target reaction temperature, the N 2 Switch to 95% CO 2 -5%N 2 Mixed gas, gas chromatographic detection of tail gas changes. The test results are shown in Table 1.

Embodiment 3

[0025] Weigh 5g of biochar produced by the rapid pyrolysis of rice straw and fill it into the middle of the fixed-bed reactor. 2 Purge at room temperature for 10 minutes to remove the air in the system, and then raise the temperature to 700°C. After the reactor bed reached the target reaction temperature, the N 2 Switch to 95% CO 2 -5%N 2 Mixed gas, gas chromatographic detection of tail gas changes. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com