Patents

Literature

60results about How to "Long life one way" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for preparing propylene by propane dehydrogenation as well as preparation and application thereof

InactiveCN101411978AThe content of any component is easy to controlLarge specific surface areaHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementPtru catalyst

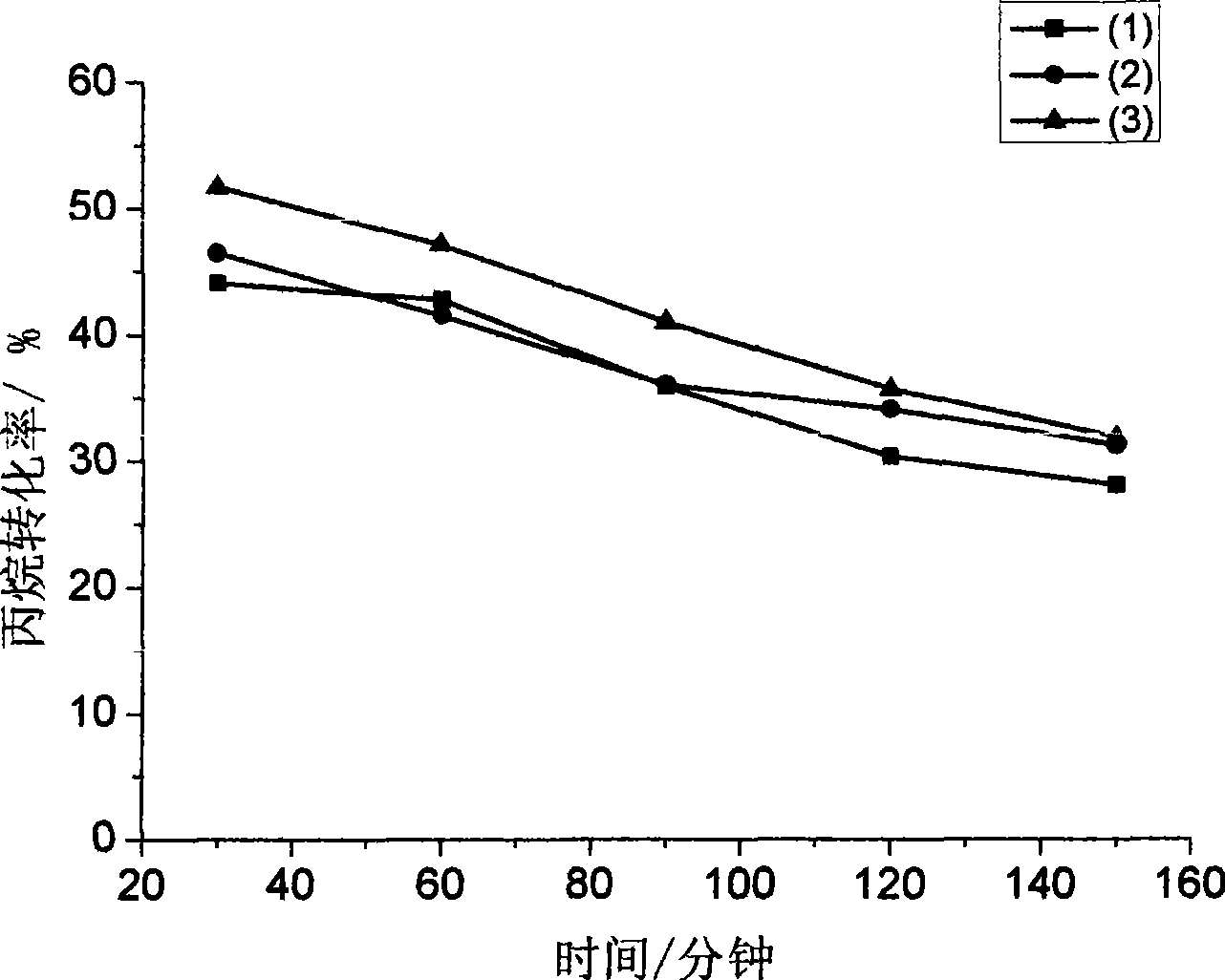

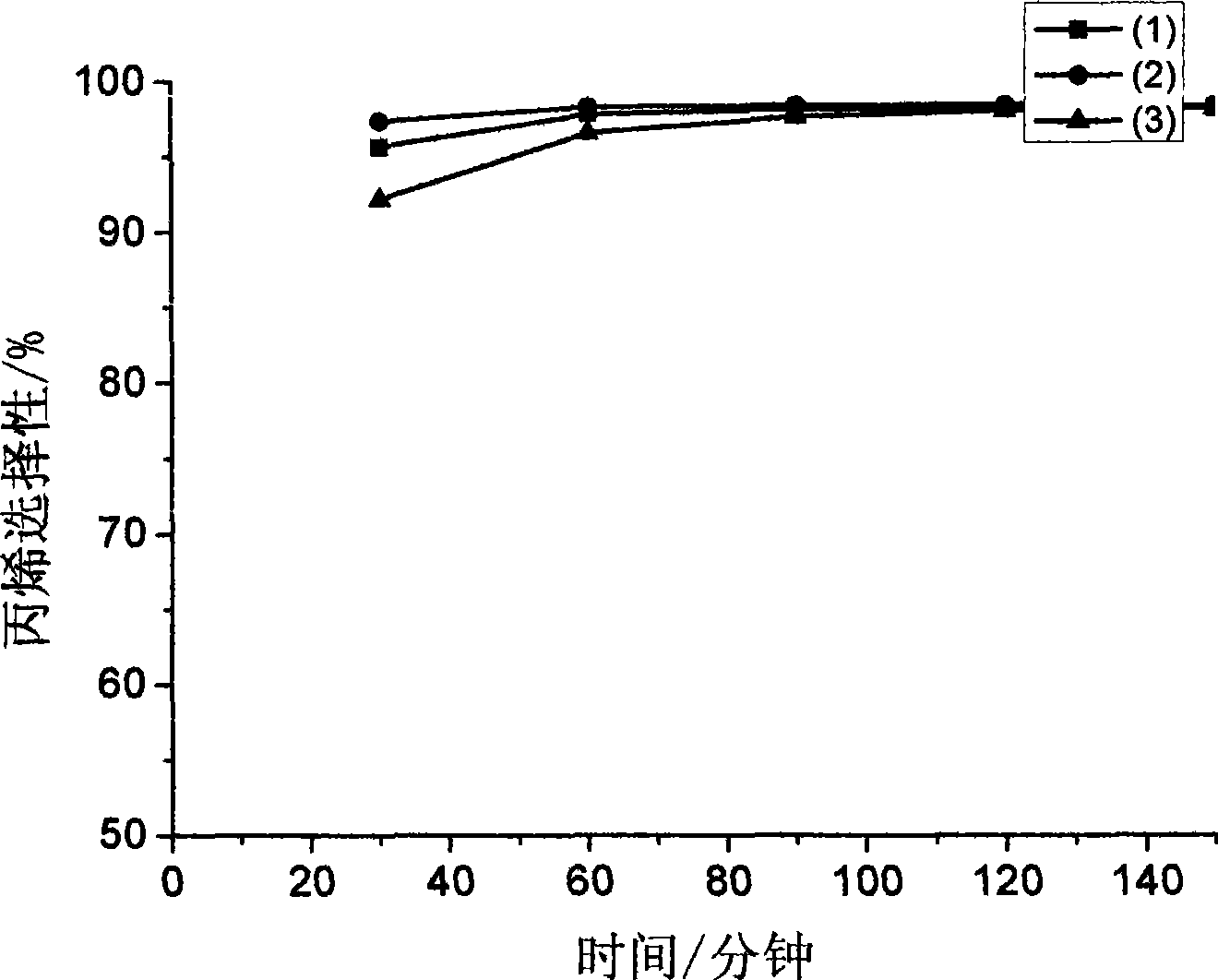

The invention relates to the field of organic chemistry, in particular to a catalyst for dehydrogenating propane to prepare propylene. The catalyst for dehydrogenating propane to prepare propylene uses gamma-Al2O3 as a carrier, platinum metal and tin metal as main catalysts and a zinc metal element and a rare earth metal element as additives. The mass percentage of platinum is between 0.01 and 2 percent; the mass percentage of Sn is between 0.1 and 5 percent; the mass percentage of zinc in the catalyst is between 0.1 to 5 percent; and the mass percentage of rare earth metal elements is between 0.1 and 5 percent. The invention discloses a method for preparing the catalyst and an application method. The catalyst has the advantages that the catalyst with four compositions is prepared by adopting a continuous isometric dipping method; and the content of any composition is easy to control. The prepared catalyst has high specific surface area and high catalytic activity; propane has high transformation rate; and propylene has good selectivity. The catalyst has long one-way service life and good industrial application prospect.

Owner:NANKAI UNIV +1

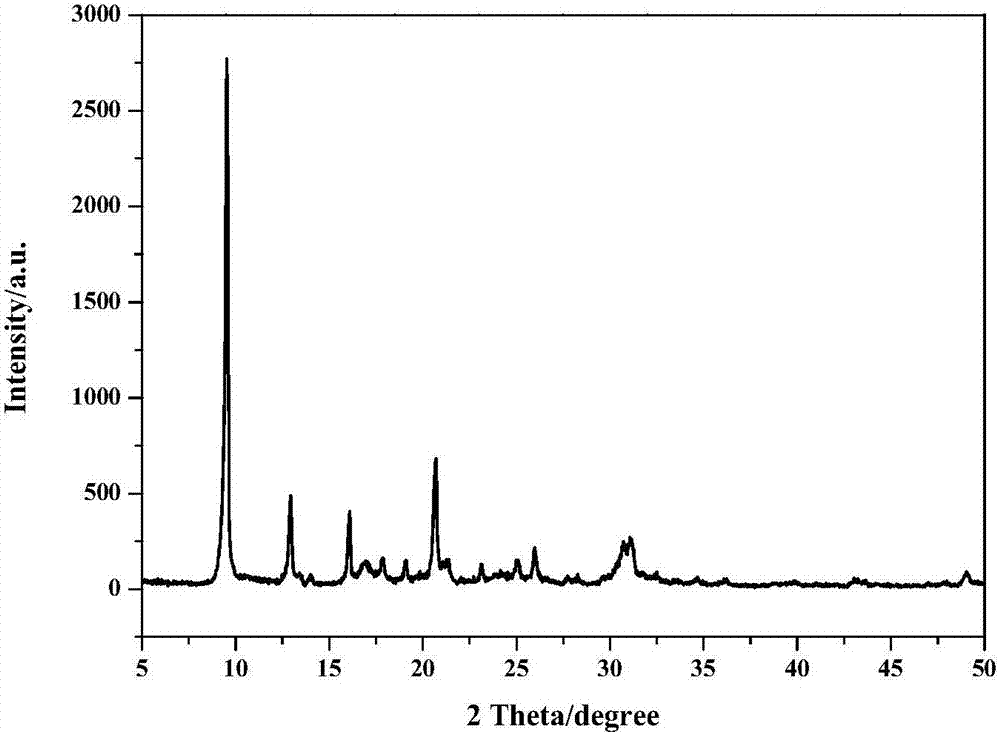

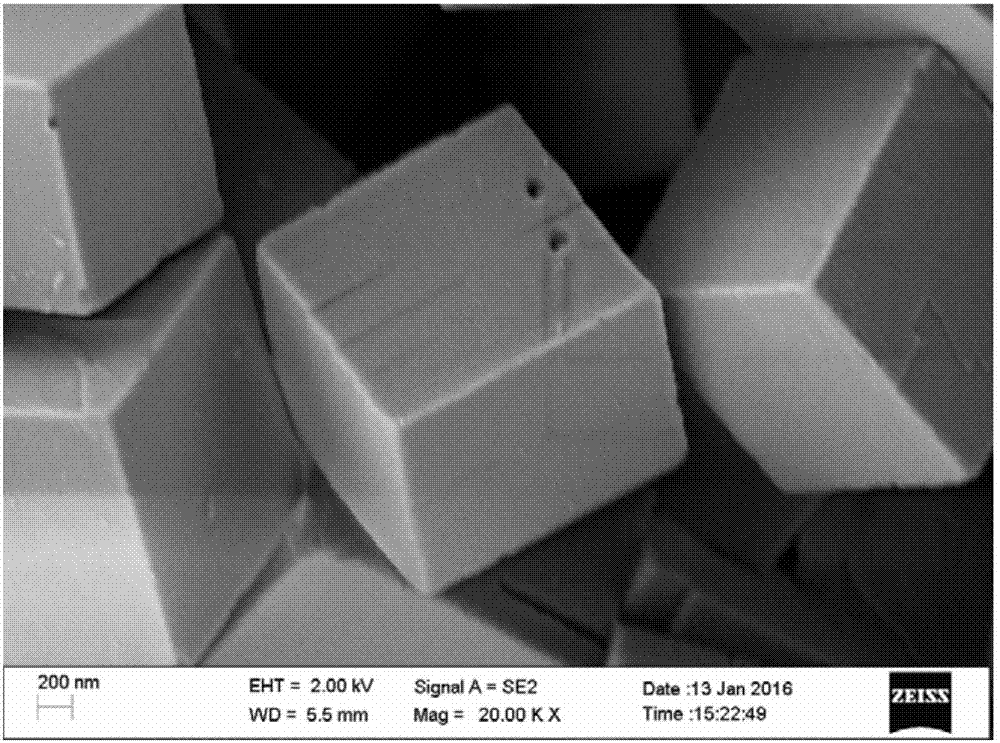

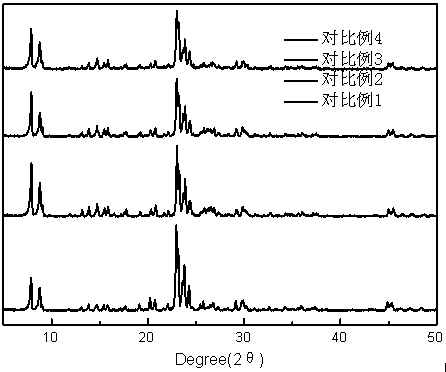

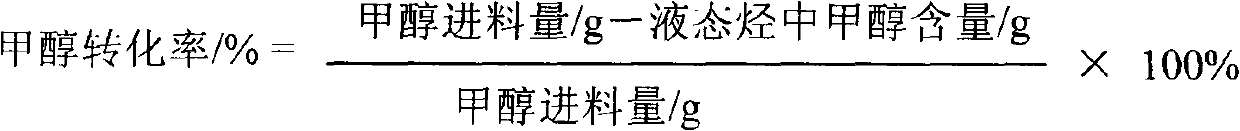

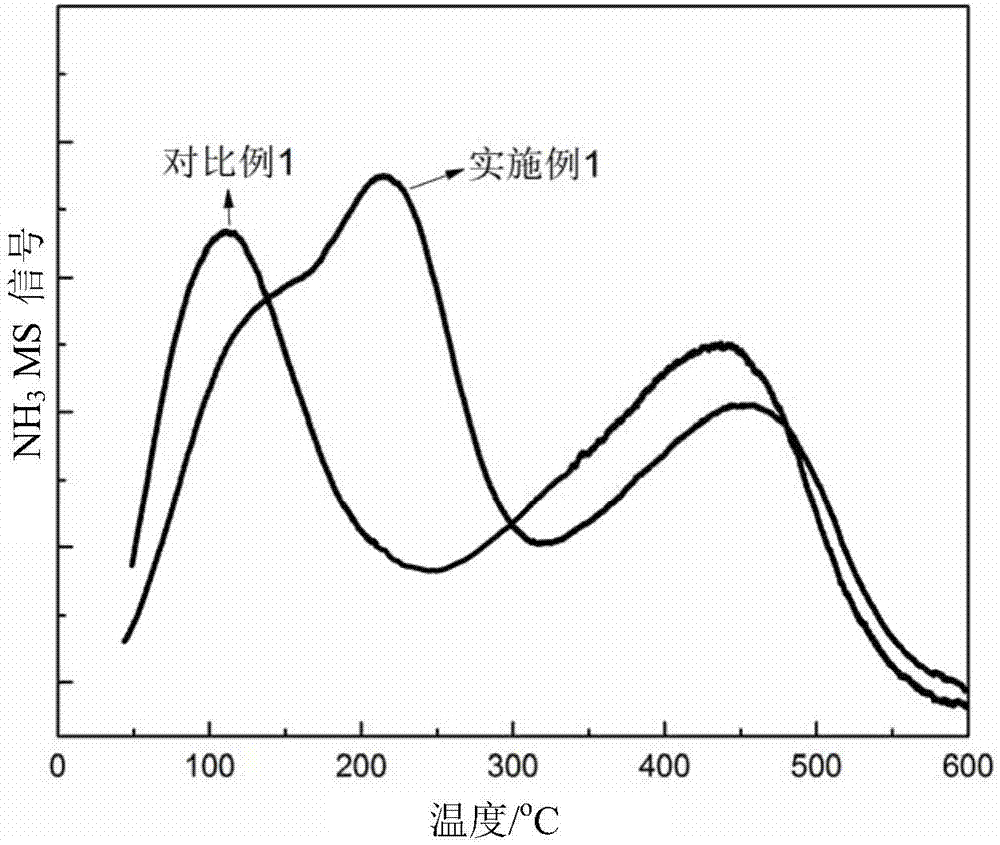

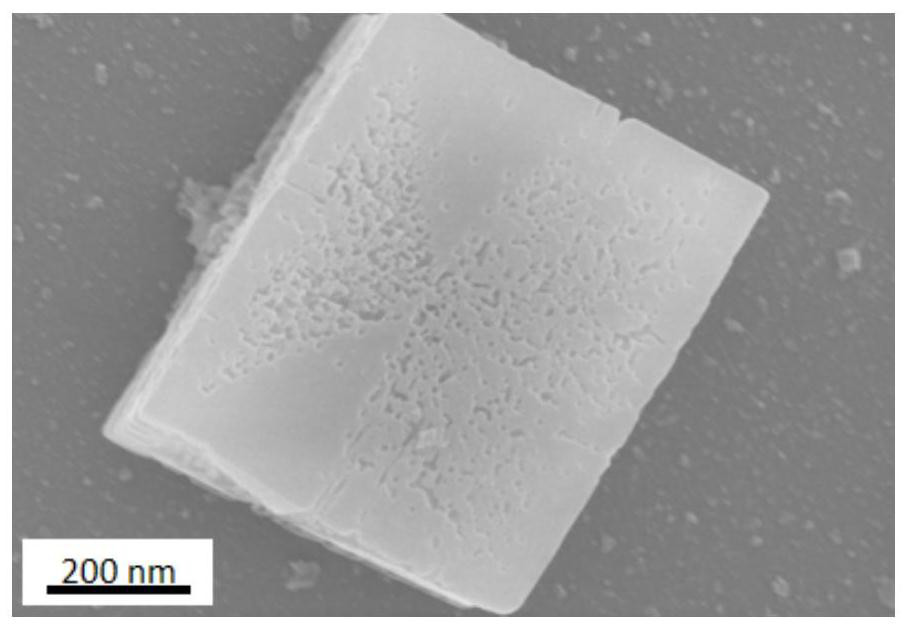

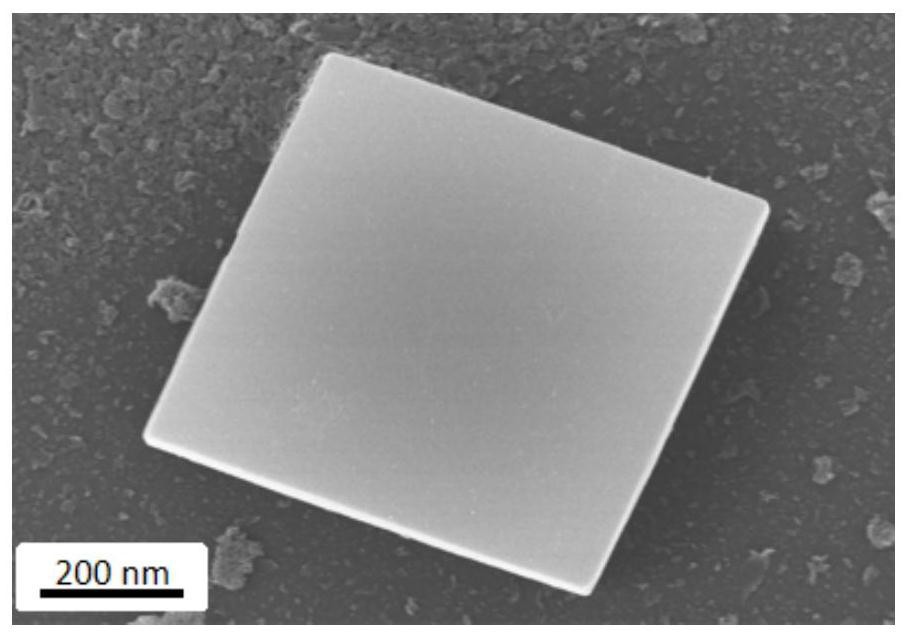

Method for synthesizing hierarchical-pore SAPO-34 molecular sieve through post-treatment of solid acid

ActiveCN107285342AEmission reductionReduce pollutionMolecular-sieve and base-exchange phosphatesMolecular sieveSolid acid

The invention discloses a method for synthesizing a hierarchical-pore SAPO-34 molecular sieve through post-treatment of solid acid, which relates to the field of synthesis of molecular sieves. The method comprises the following steps: uniformly smashing and mixing raw powder of a SAPO-34 molecular sieve and the solid acid, and performing a reaction on an obtained mixture at the temperature of 20-120 DEG C for 2-12h, so as to obtain the hierarchical-pore SAPO-34 molecular sieve. According to the method, water or other solvents is / are not used in a treatment process, so that the discharge of effluents is reduced, the cost is saved, the pollution is reduced, and the method has the potential economic value and social value; the obtained hierarchical-pore SAPO-34 molecular sieve can realize hierarchical-pore compounding and is good in the degree of crystallinity, and the catalytic performance can be greatly improved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

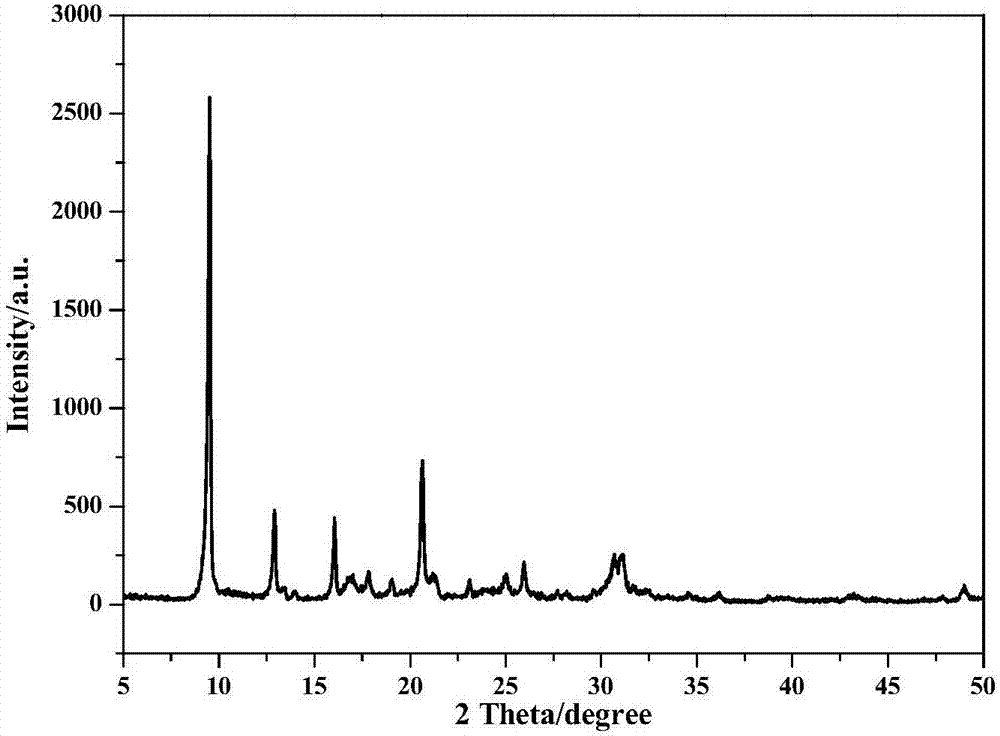

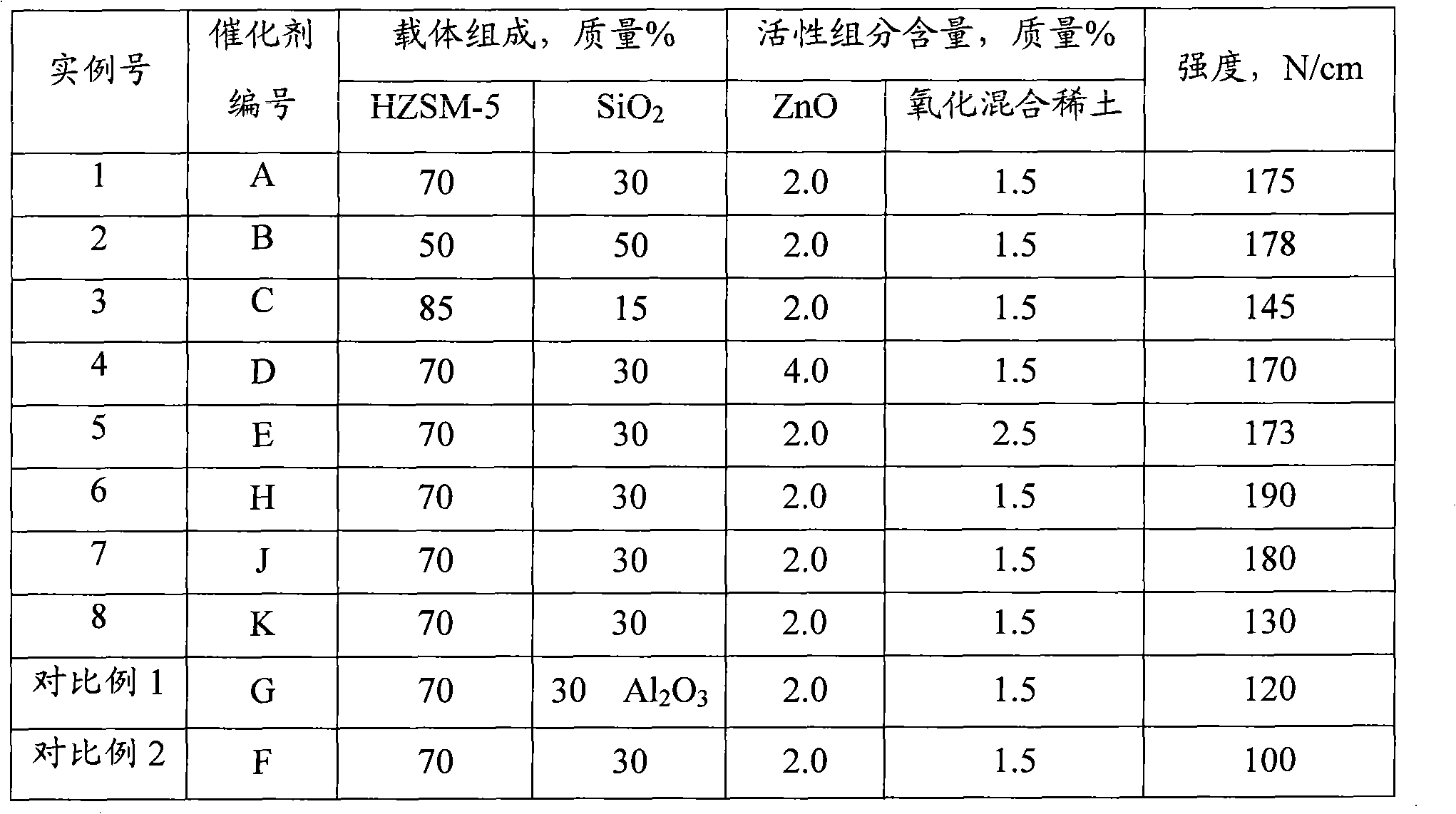

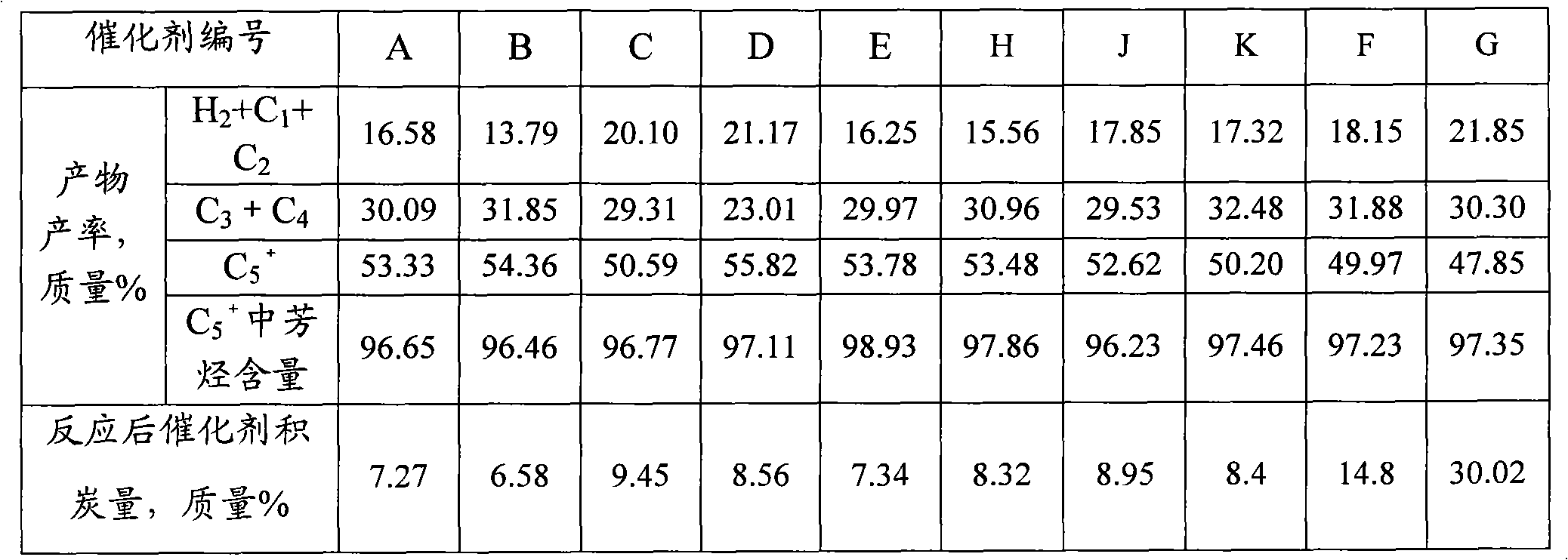

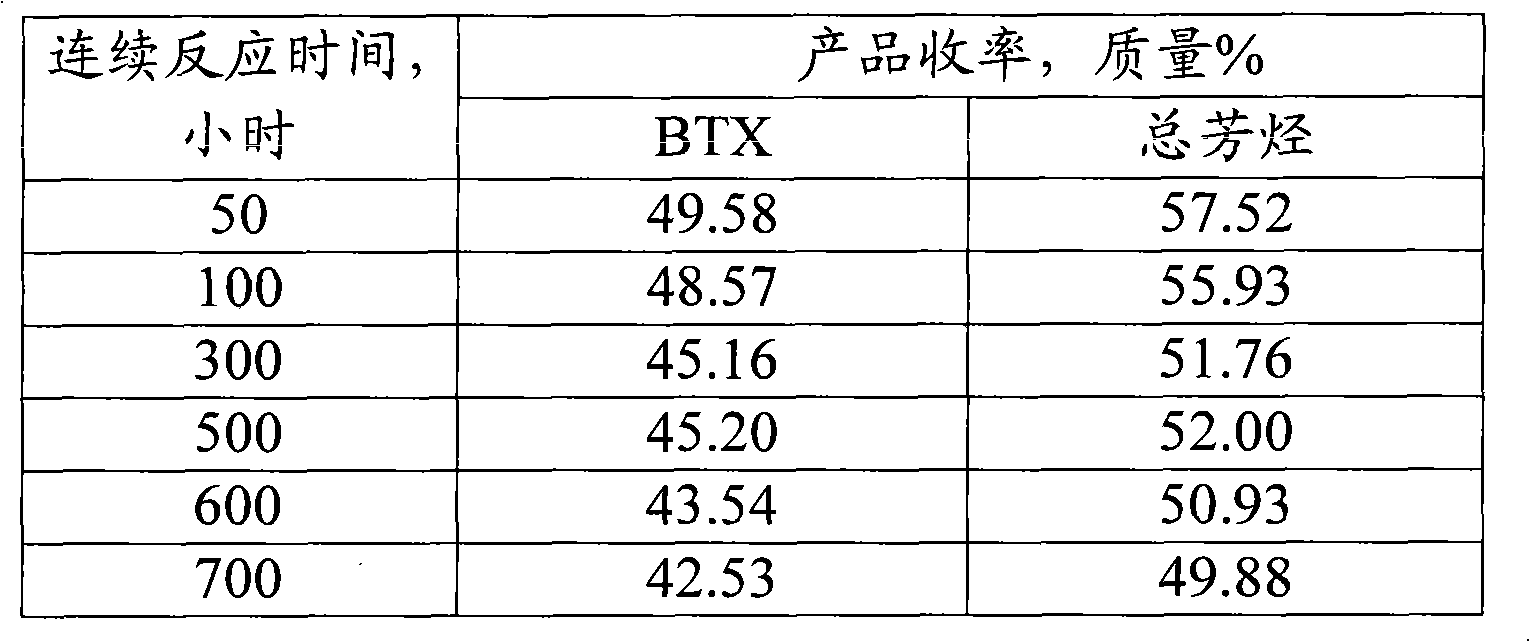

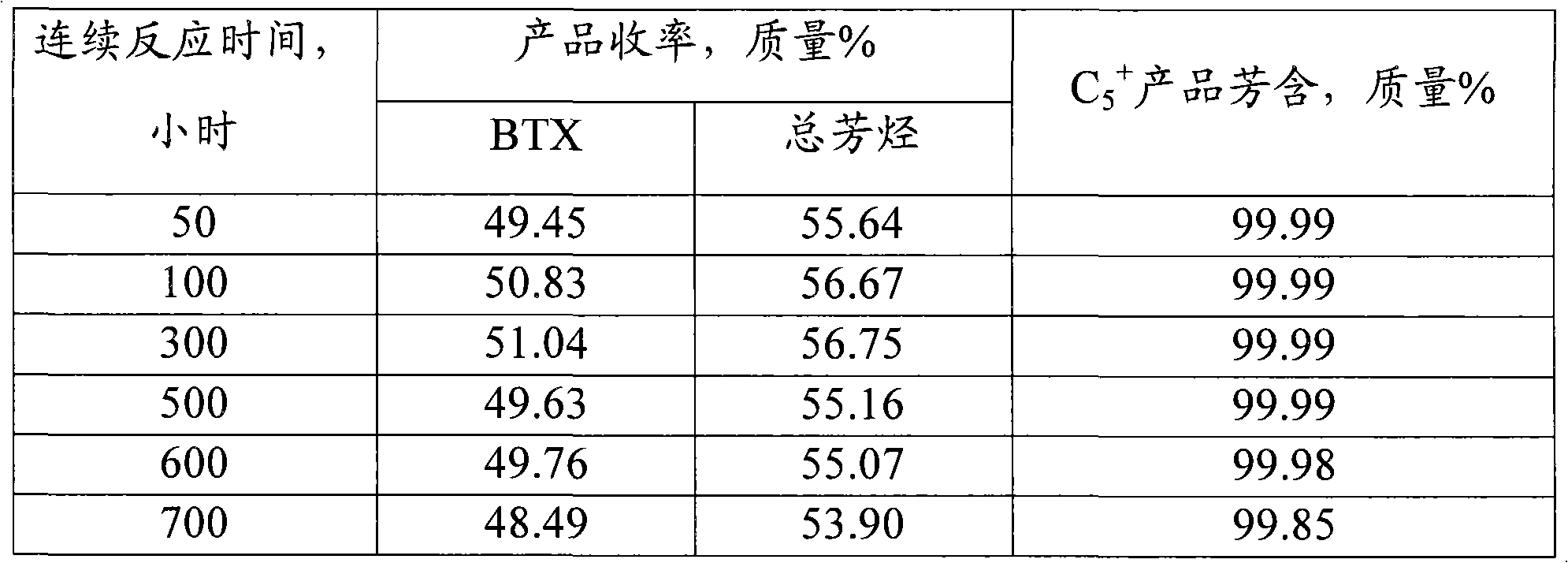

Light hydrocarbon aromatization catalyst and preparation method thereof

InactiveCN102078819ALong life one wayReduce carbon depositionMolecular sieve catalystsHydrocarbon oils refiningAromatizationRare earth

The invention provides a light hydrocarbon aromatization catalyst which comprises a composite carrier and modified components, wherein the modified components comprise the following compositions which are calculated based on the carrier in mass percentage by mass percent: 1.0-10.0% of ZnO, 0.5 to 10.0% of rare earth oxide; the composite carrier comprises 10 to 90% of H zeolite socony mobile-5 (HZSM-5) and 10 to 90% of silica. The catalyst preparation is simple and has high aromatization activity and selectivity on light hydrocarbon, and the carbon-depositing amount of the catalyst after reaction is less. With mixed C4 as a raw material for aromatization reaction, the yield of aromatics reaches 50 % by mass and the one-way service life of the catalyst lasts as long as 700 hours.

Owner:CHINA PETROLEUM & CHEM CORP +1

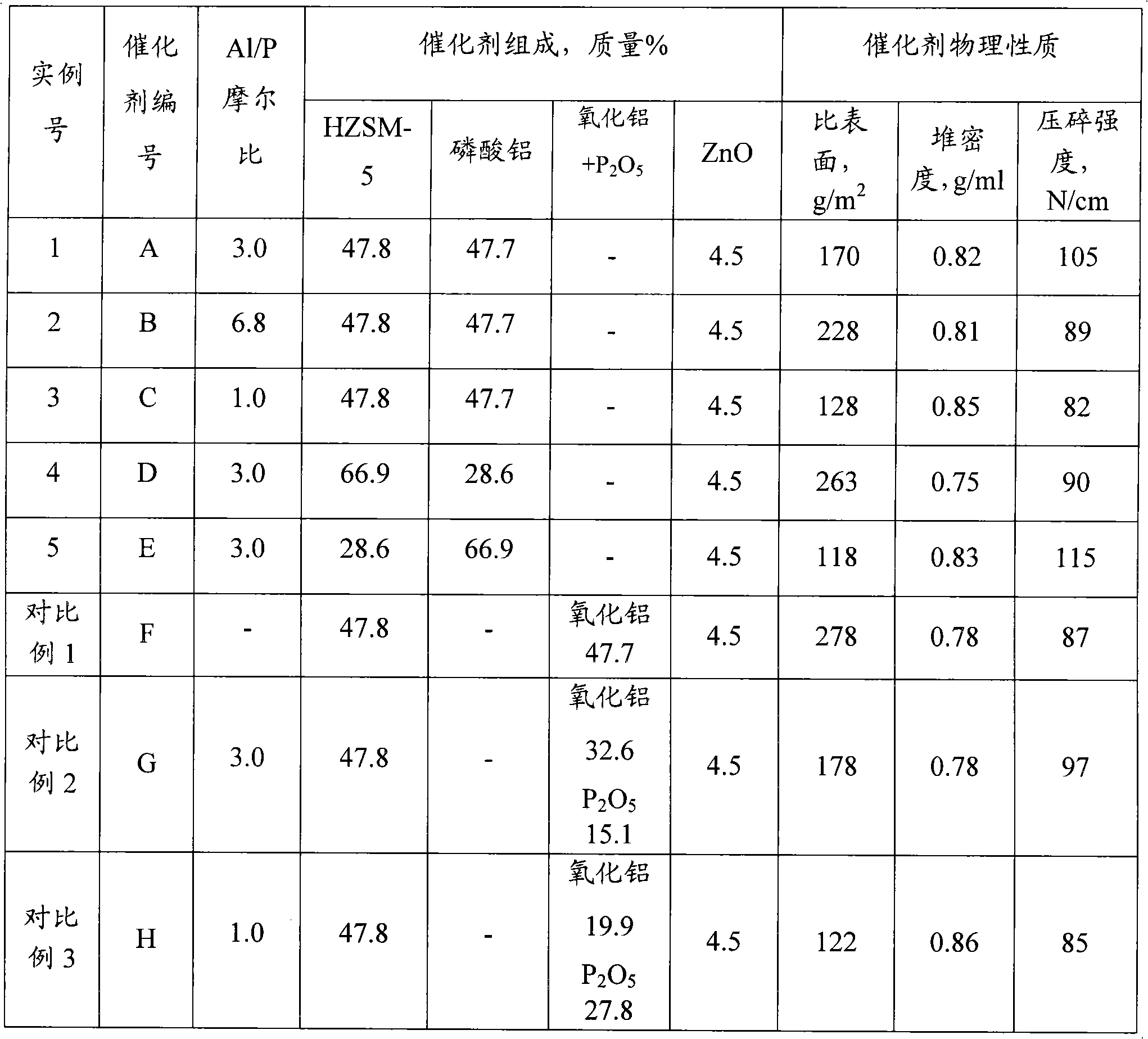

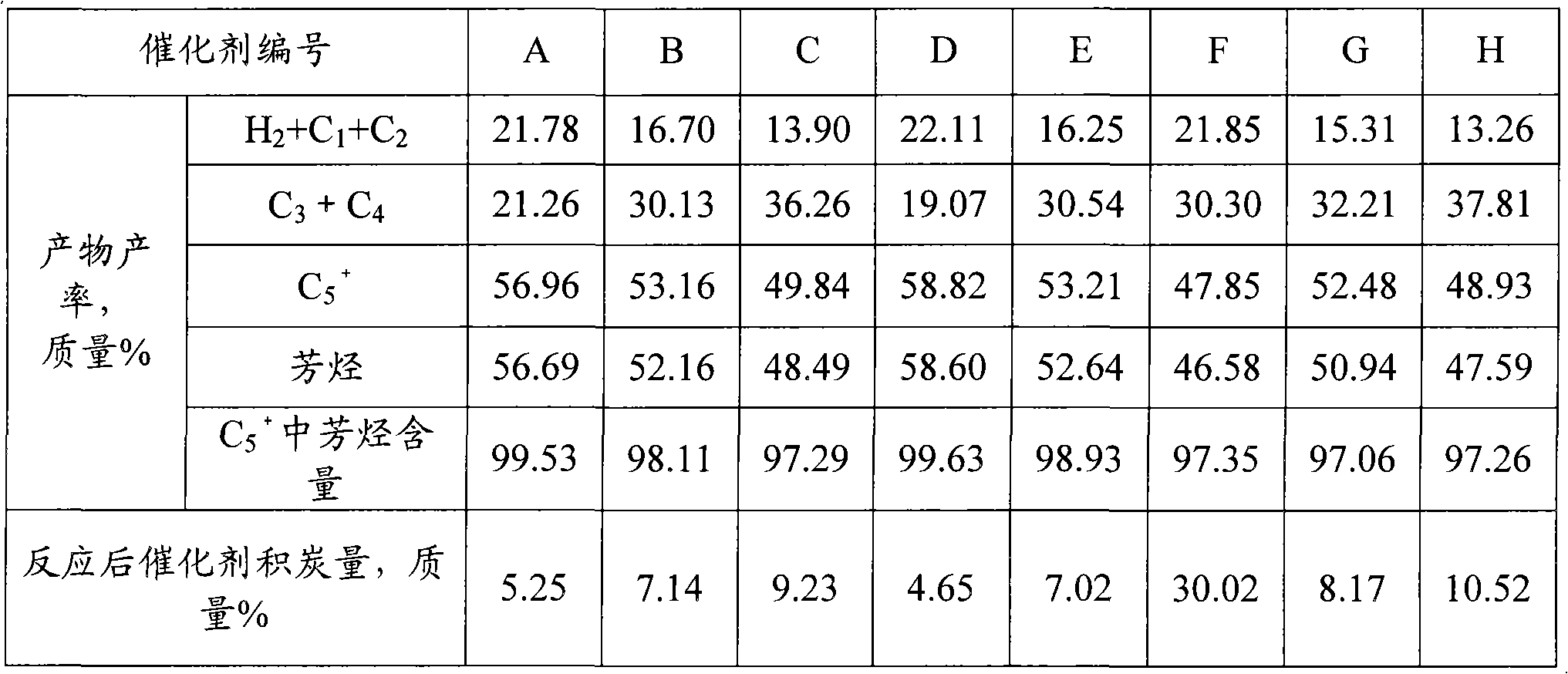

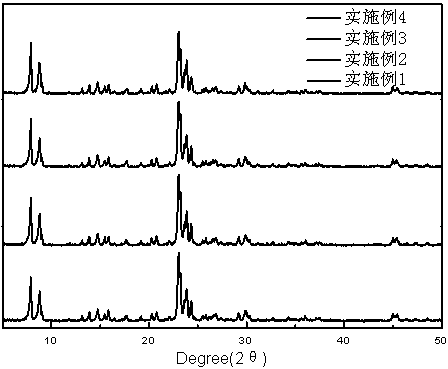

Light-hydrocarbon aromatized catalyst and preparation method thereof

ActiveCN101596461AIncrease aromatics yieldLong life one wayMolecular sieve catalystsHydrocarbon oils refiningPhosphoric acidOxide

The invention relates to a light-hydrocarbon aromatized catalyst which comprises the following components according to the mass percent: 20-75 percent of zeolite with MFI structure, 20-75 percent of aluminum phosphate and 0.5-8.0 percent of zinc oxide. The catalyst is used for the light-hydrocarbon aromatization reaction and has better aromatization activity, low carbon deposition rate in the reaction and long one-way service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multistage porous ZSM-5 molecular sieve and preparation method thereof as well as method for preparing PX catalyst using same

ActiveCN108178164AThe synthesis process is simpleReduce economic costsMolecular sieve catalystsMolecular sieve catalystSeed crystalMolecular sieve

The invention relates to a multistage porous ZSM-5 molecular sieve. The molecular sieve comprises the following raw materials: a silicon source, an aluminum source, a template agent, water, an alkalisource, polyether polyol, a seed crystal, a cosolvent and a mineralizer. The invention provides a preparation method of the multistage porous ZSM-5 molecular sieve with a high silicon-aluminum ratio.The synthesis process is simple, and cheap template agent and porous agent are adopted, so that the economic cost of the molecular sieve is reduced. The ZSM-5 molecular sieve obtained by the method has a multistage pore channel structure, the relative crystallinity is higher than 90%, and the specific surface area is greater than 420m<2> / g.

Owner:REZEL CATALYSTS CORP

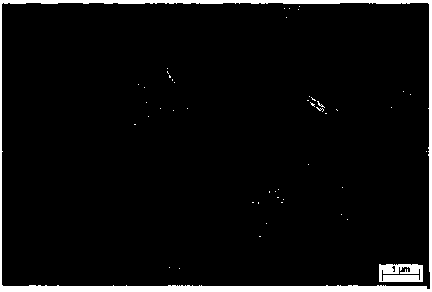

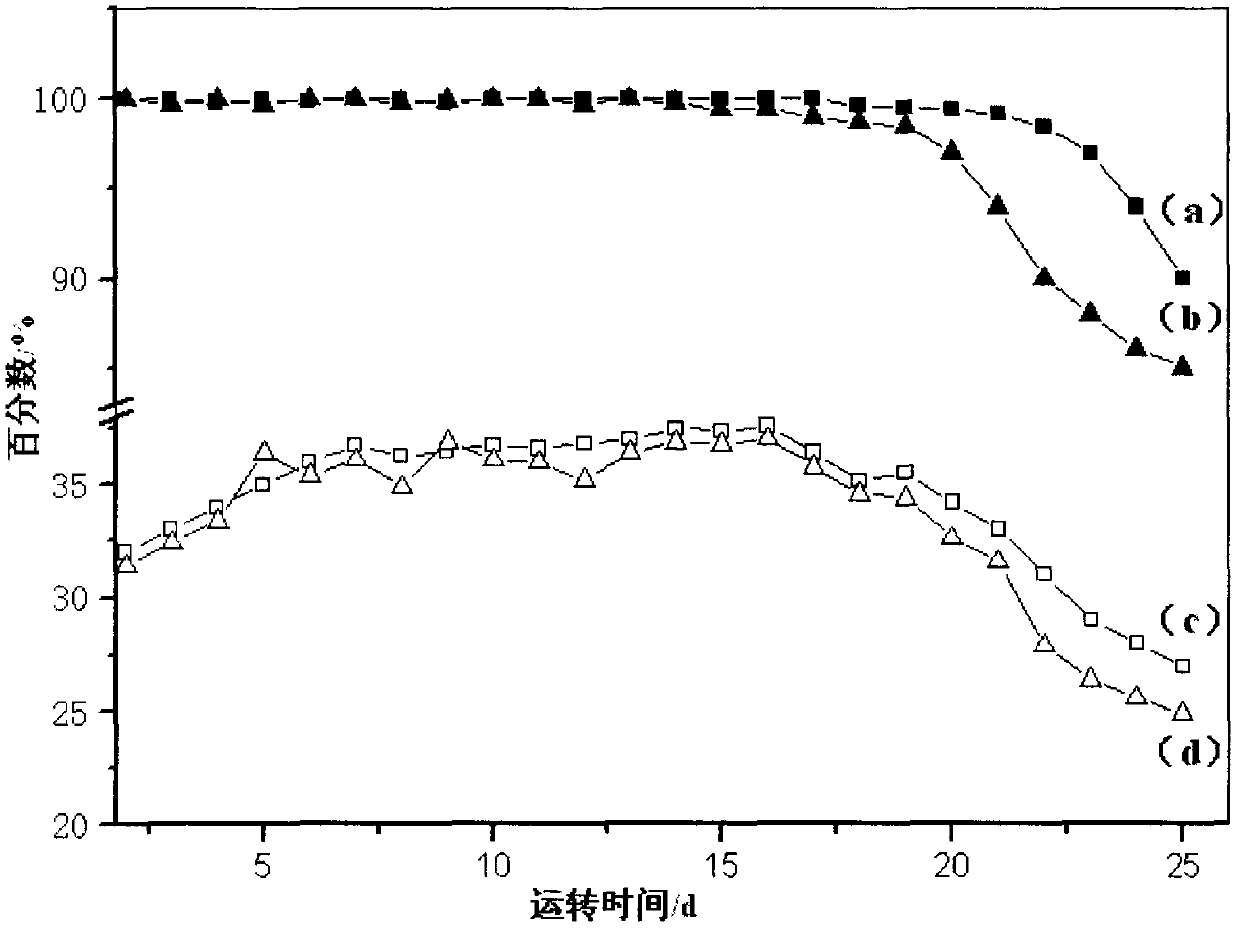

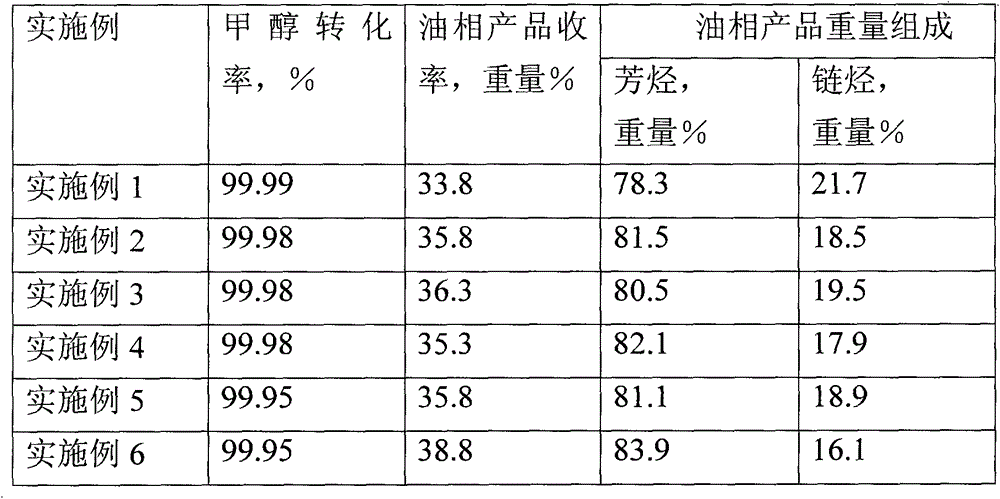

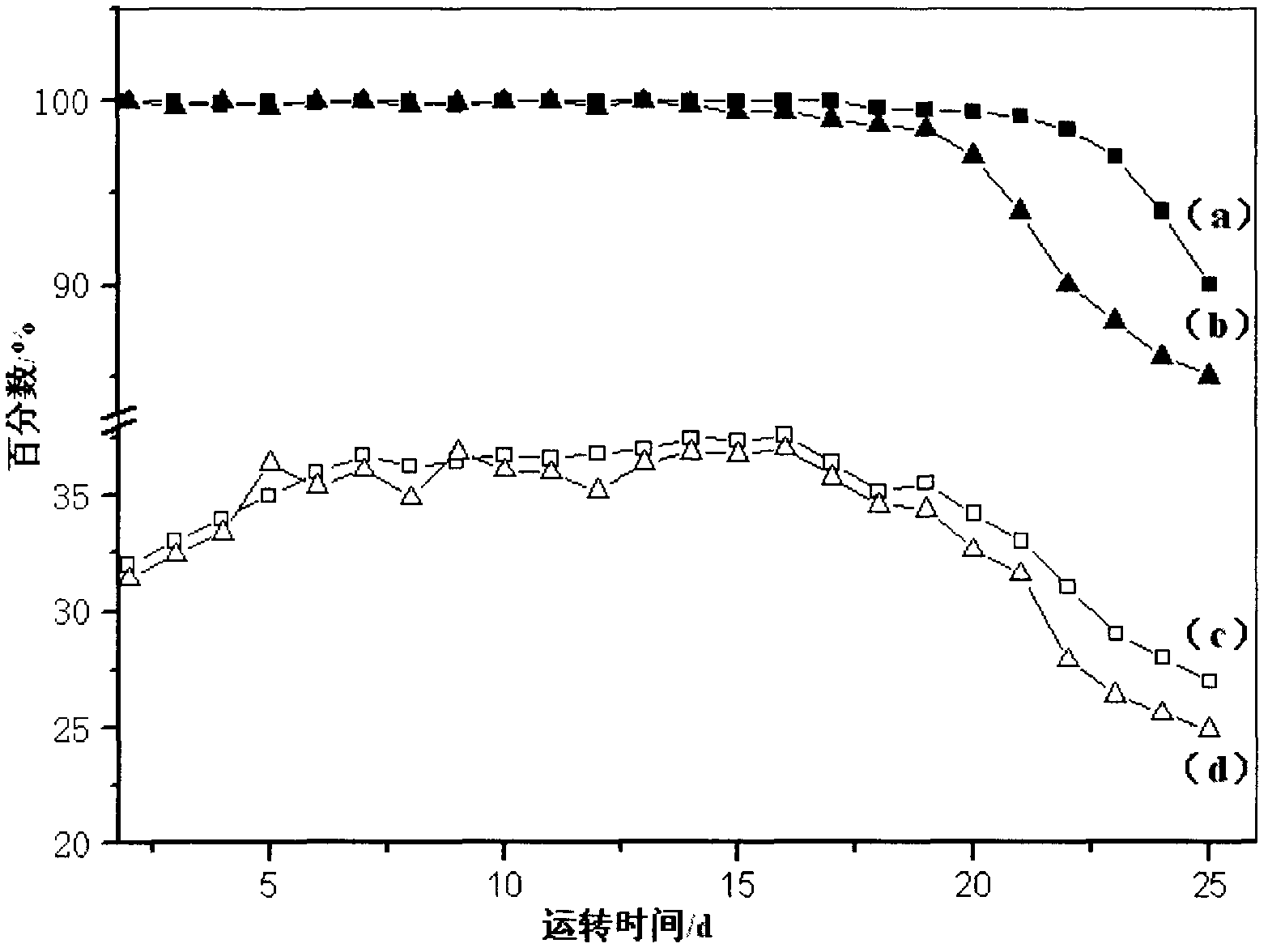

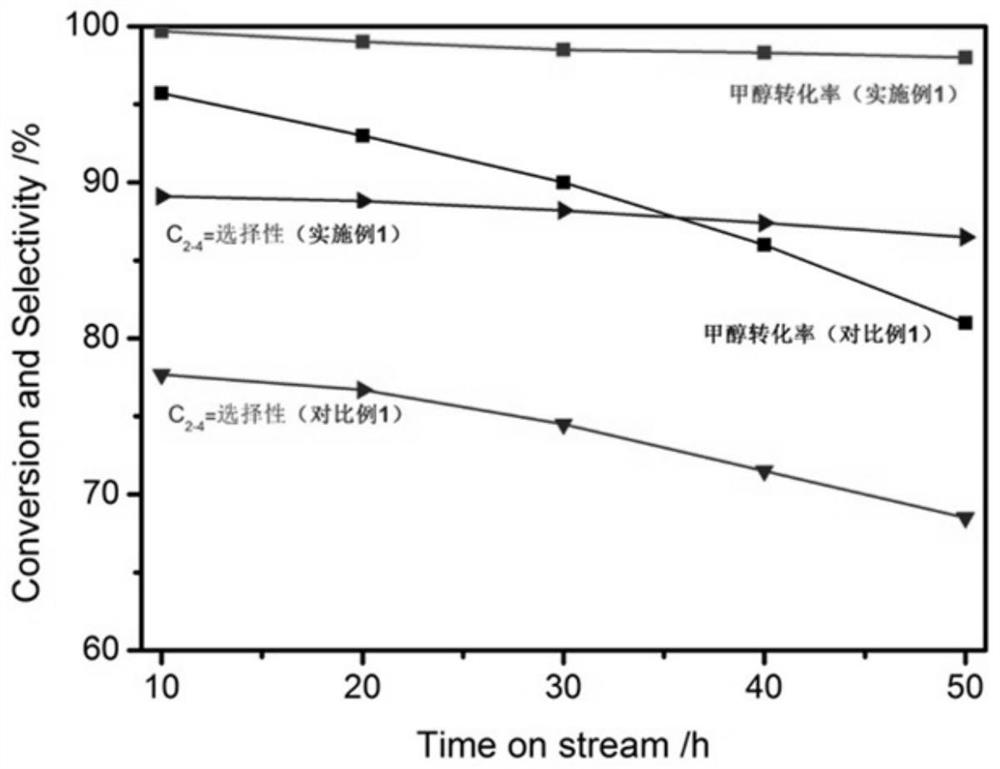

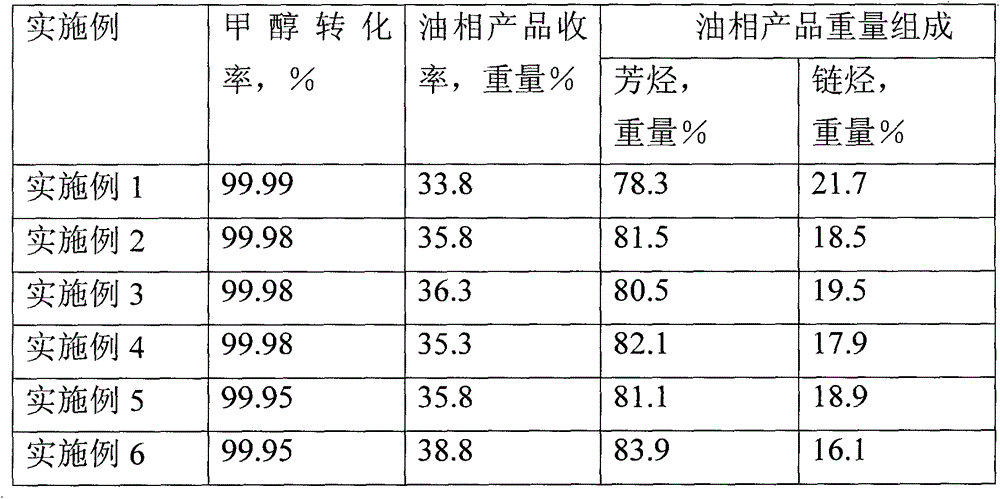

Preparation method for preparing gasoline catalyst with methanol

ActiveCN102513142AIncrease the areaHigh pore volumeMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sieveFixed bed

The invention relates to a preparation method for preparing a gasoline catalyst with methanol. The preparation method is characterized by comprising the following steps of: before molding the catalyst, performing aluminum-removing and silicon replenishing treatment on a catalyst matrix nanoscale ZSM-5 molecular sieve with an acid solution to adjusting the acidic property of the molecular sieve; and after the catalyst is molded, pretreating the catalyst by using a hydrothermal aging device to enhance the gasoline selectivity and stability of the catalyst. When the catalyst prepared with the method is applied to a reaction for preparing gasoline with methanol on a section of fixed bed, the gasoline yield is up to 36-37 percent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Boron-modified ferrierite molecular sieve catalyst as well as preparation method and application thereof

ActiveCN107265478AHigh activityLong life one wayFerrierite aluminosilicate zeoliteHydrocarbon by isomerisationPtru catalystIon exchange

The invention provides a boron-modified ferrierite molecular sieve catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: adding an alkali source, an aluminum source and a boron source into water, and stirring to form a uniform solution; adding a ferrierite molecular sieve seed crystal, a silicon source and a template agent into the uniform solution, and stirring until a sol solution is formed; crystallizing the sol solution under a hydrothermal condition, and carrying out filtration, drying and roasting, so as to obtain boron-modified sodium-type ferrierite molecular sieve raw powder; carrying out ion exchange on the boron-modified sodium-type ferrierite molecular sieve raw powder and an ammonium salt water solution or diluted hydrochloric acid, filtering, and drying, so as to obtain hydrogen-type molecular sieve raw powder; and mixing the hydrogen-type molecular sieve raw powder with a binder and water, carrying out extrusion formation, drying, and roasting, so as to obtain the boron-modified ferrierite molecular sieve catalyst. The boron-modified ferrierite molecular sieve catalyst prepared by virtue of the preparation method has the advantages of high activity, long single pass life, strong anti-carbon property and low liquid phase yield.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Methanol aromatization technology

ActiveCN104098418AImprove stabilityLong life one wayHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionLiquid productLiquid gas

The invention disclose a methanol aromatization technology which includes following steps: 1) feeding methanol into a tube side of a reactor to enable the methanol to contact with a tube-side catalyst with an operation temperature being 400-450 DEG C and an operation pressure being 0.1-5 Mpa, wherein a liquid space velocity of the raw material methanol is 0.5-7.0 h<-1>; 2) feeding a reaction product out of the tube side into a shell side of the reactor to enable the reaction product to contact with a shell-side catalyst with an operation temperature being 330-380 DEG C, an operation pressure being 0.1-3.5 Mpa and an operation space velocity being 0.4-4.0 h<-1>; performing a catalytic convention reaction in the shell side to obtain C5+ hydrocarbon liquid products and performing a rectification separation process to obtain aromatic hydrocarbons and non-aromatic hydrocarbons; and performing a separation process to gas products in shell-side products, wherein low-carbon olefins are fed back to the shell side of the reactor for being subjected to a reaction continuously. By means of the technology, utilization of the methanol can be increased, a complex reaction can be simplified, selectivity of the low-carbon olefins is enhanced and generation of dry gas and liquefied gas can be reduced.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Catalyst for preparing ethylbenzene by reacting ethylene with benzene, and preparation method and application of catalyst

ActiveCN103801389AReduce manufacturing costReduce pollutionMolecular sieve catalystsHydrocarbonsMolecular sieveRare earth

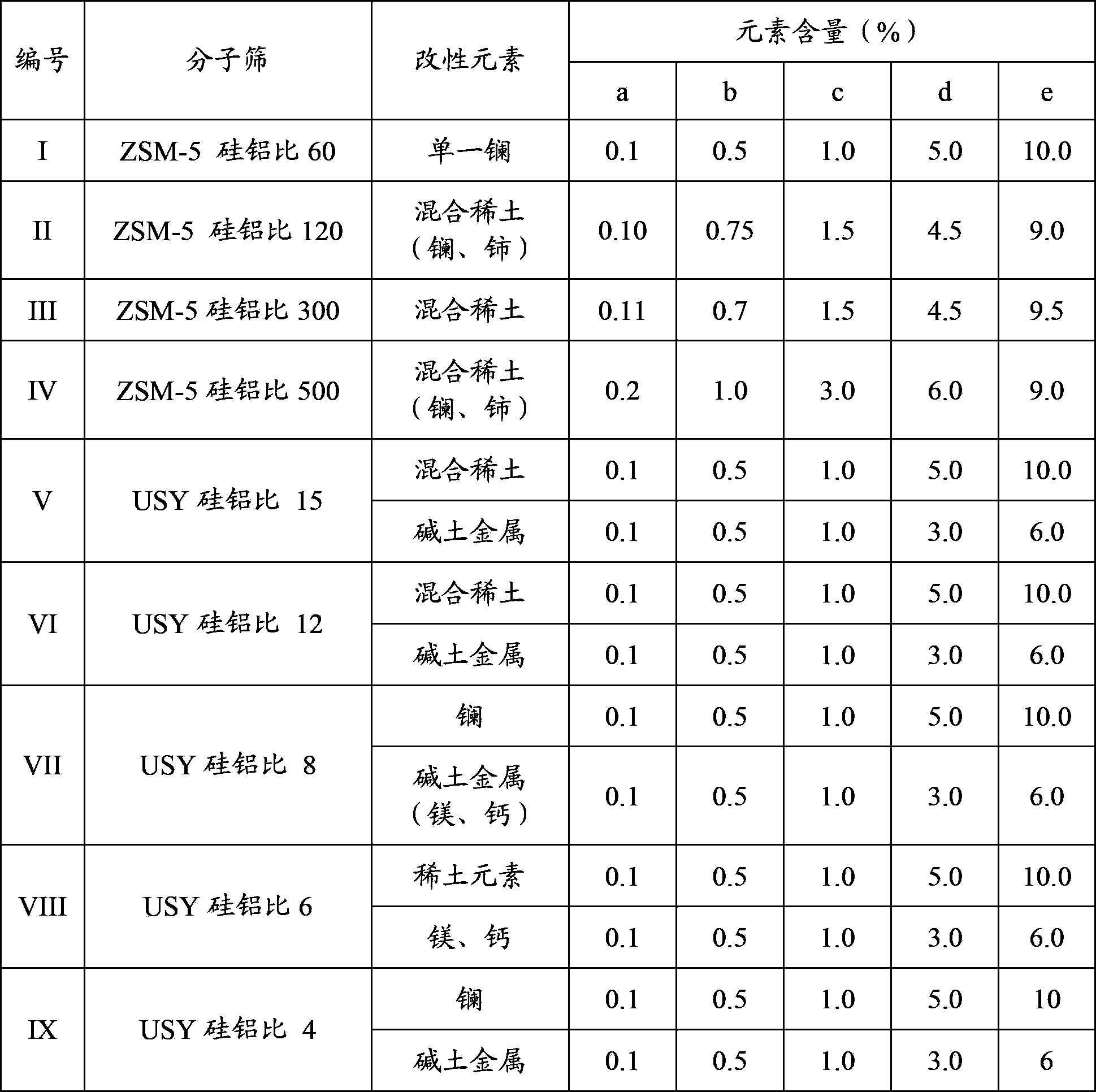

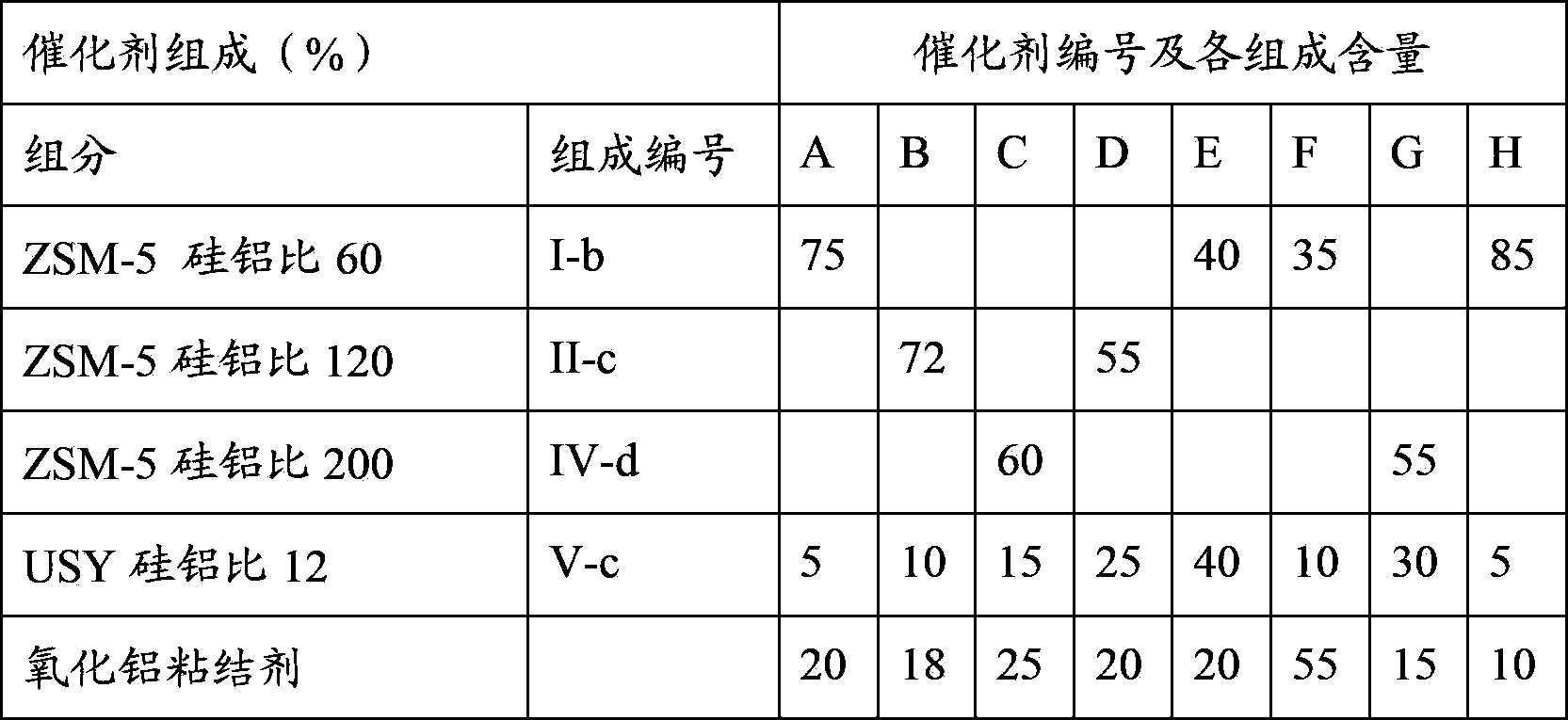

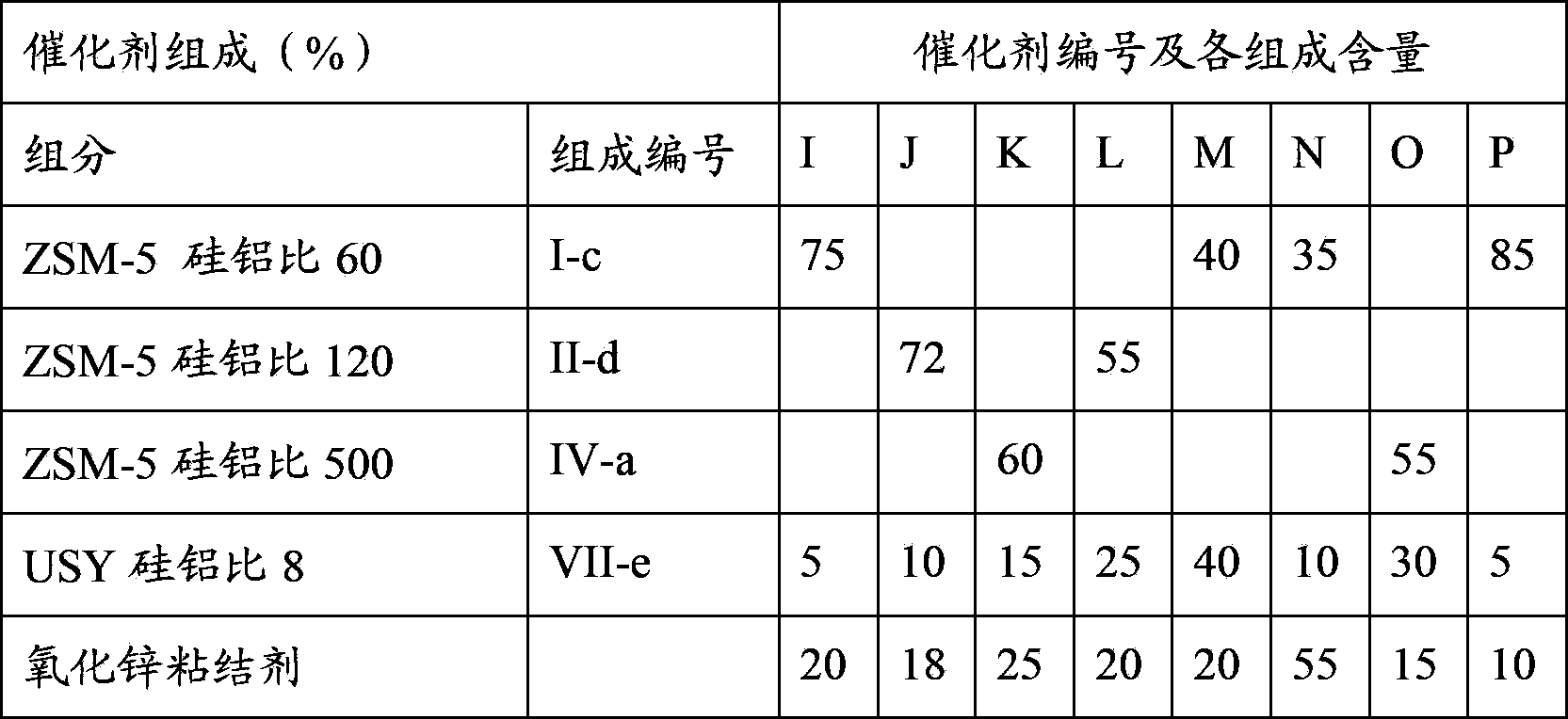

The invention discloses a catalyst for preparing ethylbenzene by reacting ethylene with benzene. The catalyst comprises a modified ZSM-5 molecular sieve, a modified ultrastable Y-type molecular sieve and an inorganic oxide, wherein the modified ZSM-5 molecular sieve consists of a ZSM-5 molecular sieve and 0.1wt%-10wt% of rare earth metal oxide which is supported on the ZSM-5 molecular sieve; a mole ratio of SiO2 to Al2O3 in the ZSM-5 molecular sieve is 30-500; the modified ultrastable Y-type molecular sieve consists of an ultrastable Y-type molecular sieve, 0.1wt%-6wt% of alkaline earth metal oxide and 0.1wt%-10wt% of rare earth metal oxide; a mole ratio of SiO2 to Al2O3 in the ultrastable Y-type molecular sieve is 4-15; the alkaline earth metal oxide and the rare earth metal oxide are supported on the ultrastable Y-type molecular sieve; the inorganic oxide is one or a mixture of more than two of aluminium oxide, zinc oxide and silicon oxide; a weight ratio of the modified ZSM-5 molecular sieve to the modified ultrastable Y-type molecular sieve and the inorganic oxide is (35%-85%):(5%-40%):(10%-55%).

Owner:洛阳市科创石化科技开发有限公司

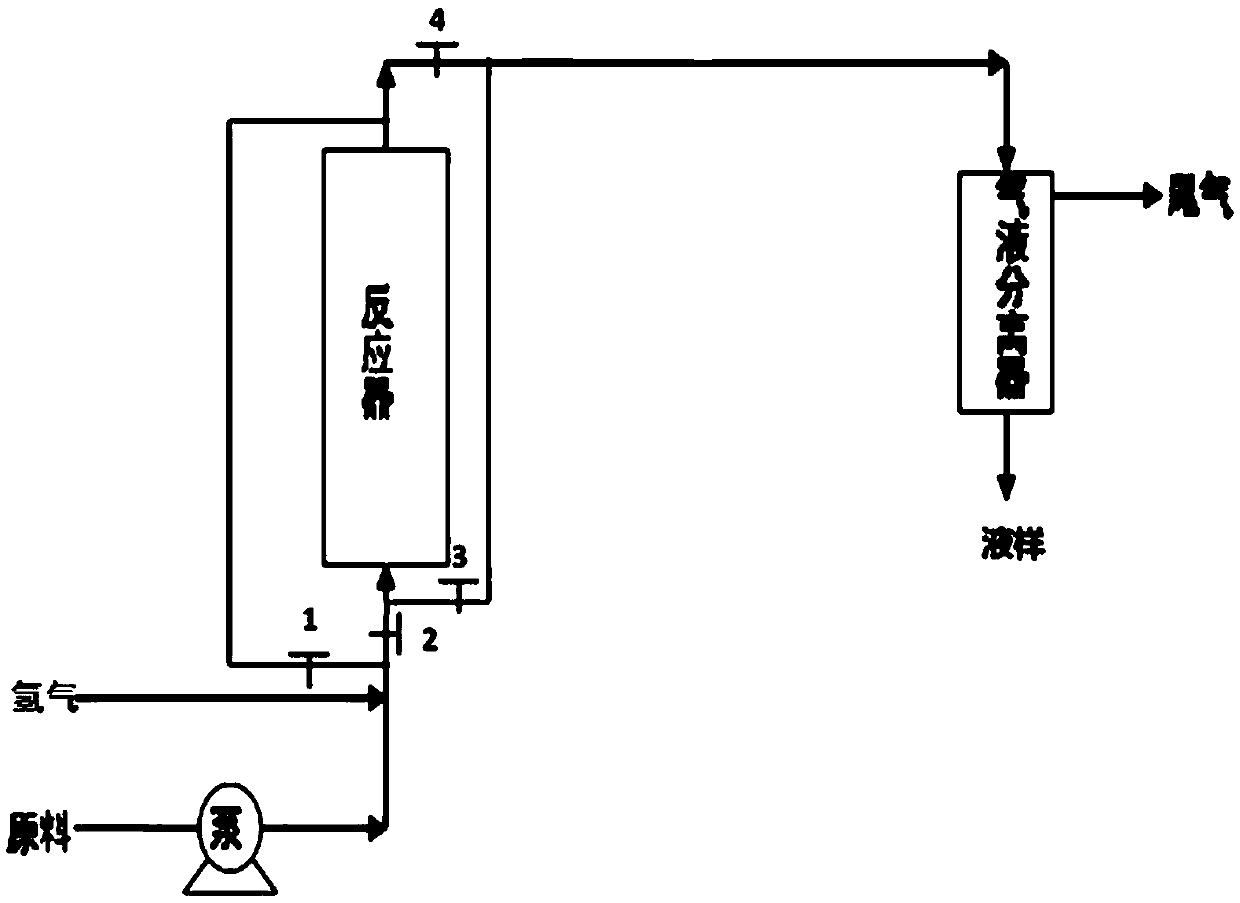

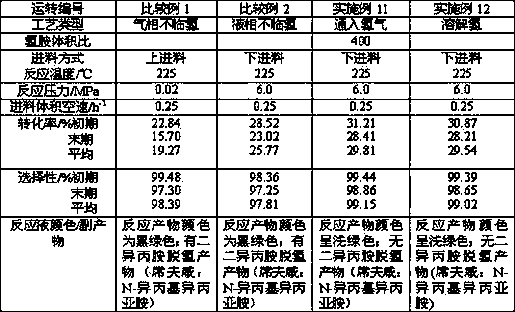

Method for continuously synthesizing diphenylamine by utilizing phenylamine

ActiveCN103044270ALong life one wayThe amount of hydrogen used in the reaction is reducedAmino compound preparation by condensation/addition reactionsProcess engineeringSystems engineering

The invention discloses a method for continuously synthesizing diphenylamine by utilizing phenylamine. Phenylamine raw material contacts with hydrogen before entering into a reactor, the hydrogen is dissolved into the phenylamine raw material, the phenylamine raw material with the dissolved hydrogen enters into a reactor used for continuously synthesizing diphenylamine by virtue of phenylamine, the phenylamine raw material with the dissolved hydrogen passes through a catalyst bed layer, and a diphenylamine synthesizing reaction by virtue of the phenylamine is carried out, wherein the catalyst bed layer contains no gas-phase hydrogen. Compared with the prior art, the method disclosed by the invention has the advantage that the dissolved hydrogen substitutes for massive gas-phase recycled hydrogen while conversion rate of the reaction, selectivity of a target product and service life of a catalyst are guaranteed, so that equipment investment and operation energy consumption are greatly reduced, and reduction of production cost can be facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

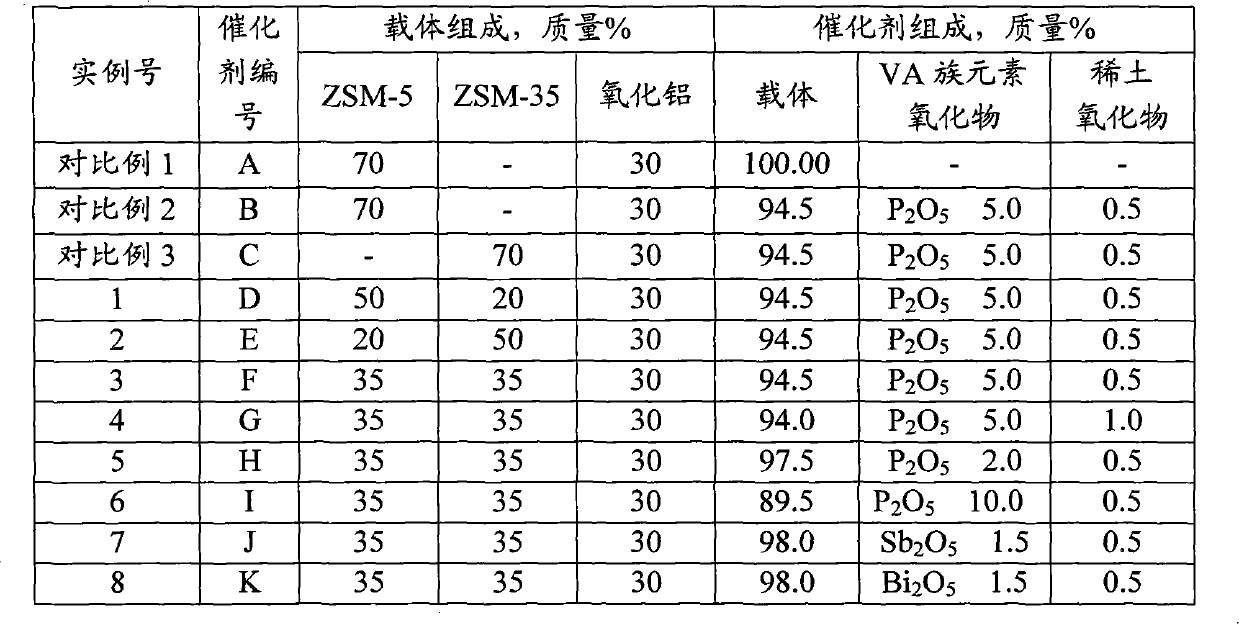

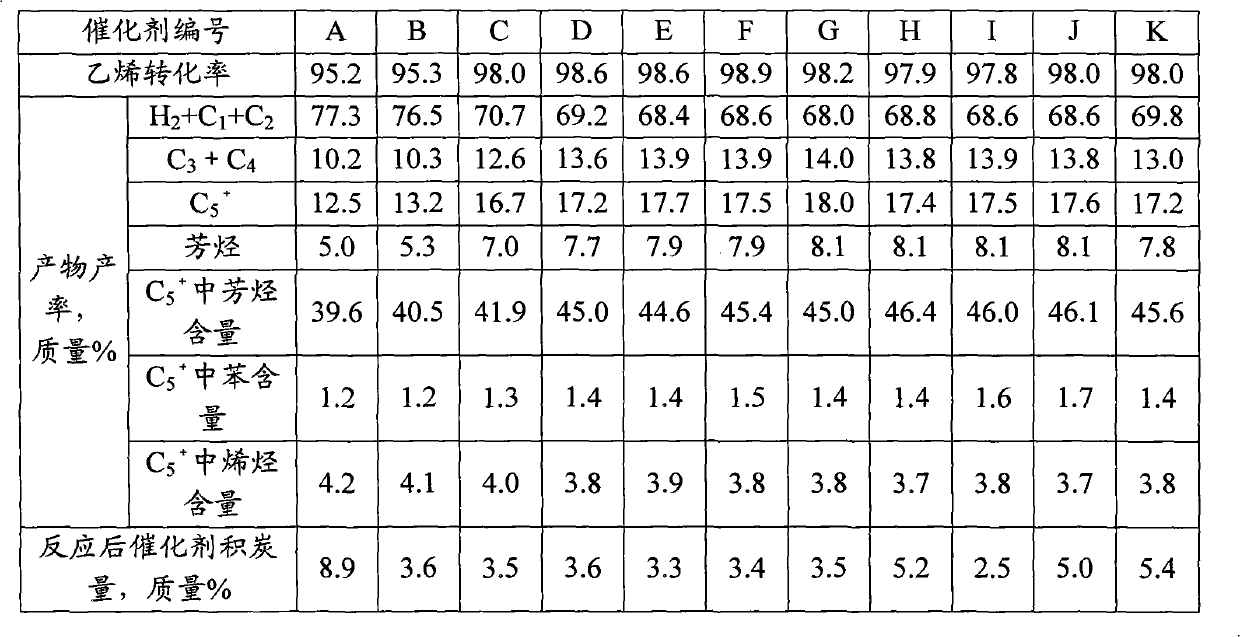

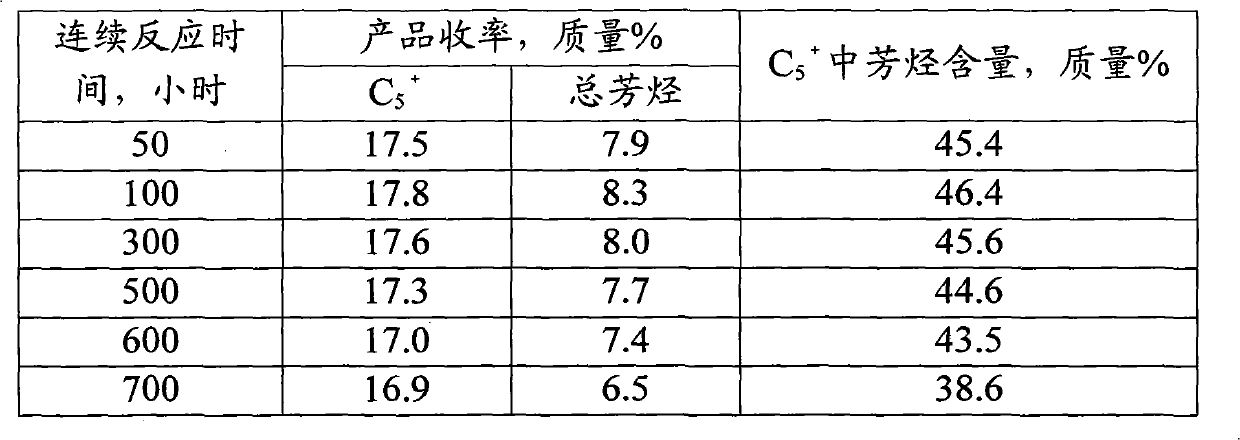

Catalyst for producing gasoline by refinery dry gas and preparation method thereof

ActiveCN102950017AHigh gasoline yieldLong life one wayMolecular sieve catalystsLiquid hydrocarbon mixtures productionZSM-5 zeoliteOxide

A catalyst for producing gasoline by refinery dry gas comprises 1.0-13.0 m% of VA-group element oxides, 0.1-5.0 m% of rare earth oxide, and 86-98.9 m% of a composite carrier; the composite carrier comprises 15-75 m% of ZSM-5 zeolite, 15-75 m% of ZSM-35, and 10-70 m% of a binder.

Owner:CHINA PETROLEUM & CHEM CORP +1

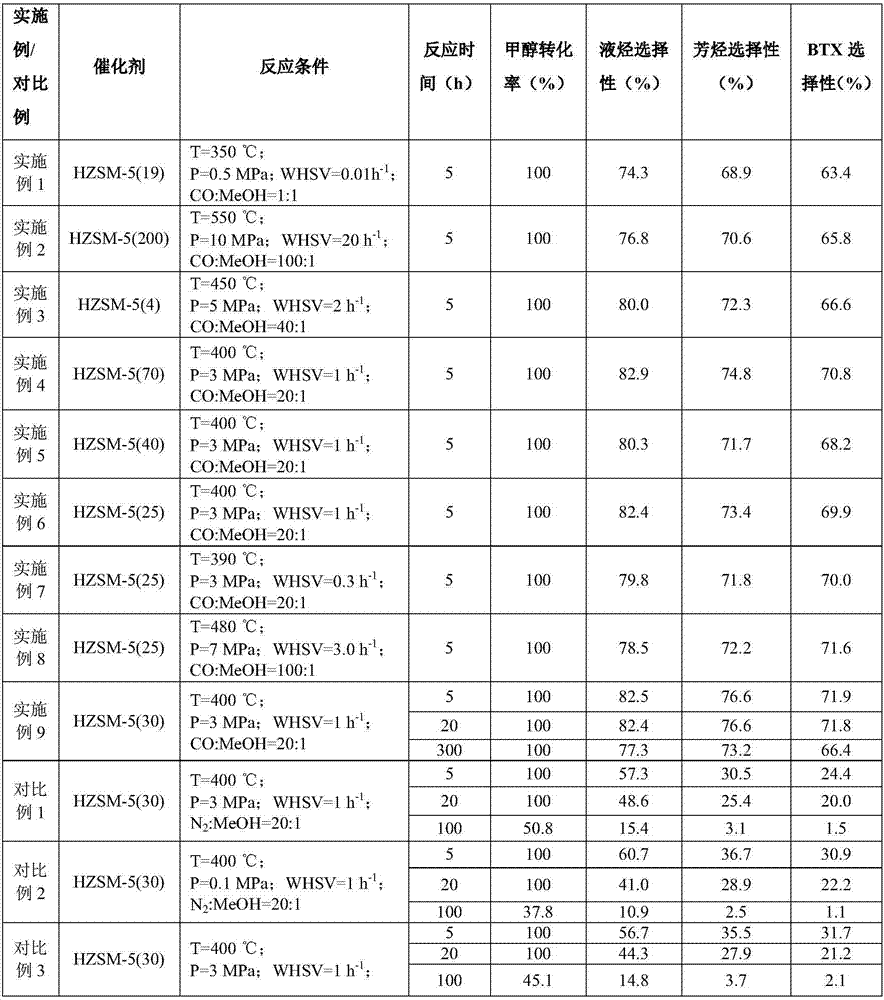

Method for preparing aromatic hydrocarbons

ActiveCN107973679AImprove and stabilize selectivityLong life one wayMolecular sieve catalystsMolecular sieve catalystMolecular sieveAromatization

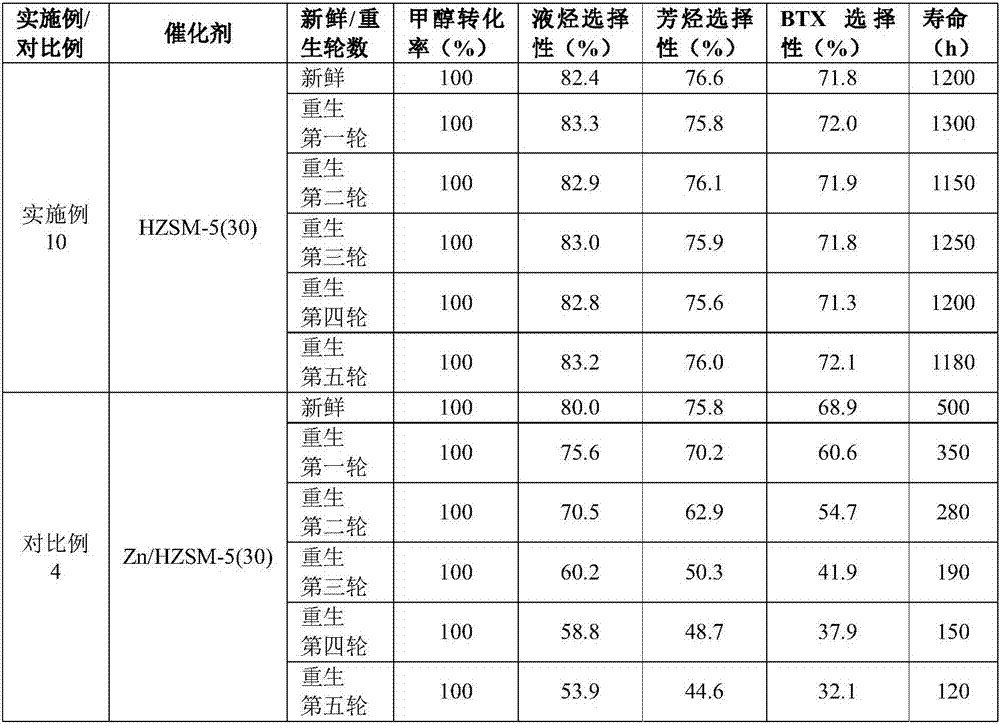

The invention discloses a method for preparing aromatic hydrocarbons, and particularly relates to a method for preparing the above aromatic hydrocarbons by using methanol and carbon monoxide to pass through a reactor carrying an acidic ZSM-5 molecular sieve catalyst free of a metal auxiliary agent under reaction conditions. Compared with the prior art, the method provided by the invention adds thecarbon monoxide in a methanol aromatization reaction, so that the selectivity of the aromatic hydrocarbons, especially BTX, can be improved and stabilized, and the single-pass service life of the catalyst is prolonged; after the deactivated catalyst is subject to regeneration for a plurality of times, the performance is not significantly reduced; and the catalyst preparation process omits the step of adding the metal auxiliary agent, so that the process is simplified, the costs are greatly saved, and the method is beneficial for environmental protection.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for removing aldehyde and ketone in HPPO process by molecular sieve catalytic reaction

ActiveCN110003138ASimple processModification process is simpleOrganic chemistryMolecular sieve catalystsCooking & bakingMolecular sieve

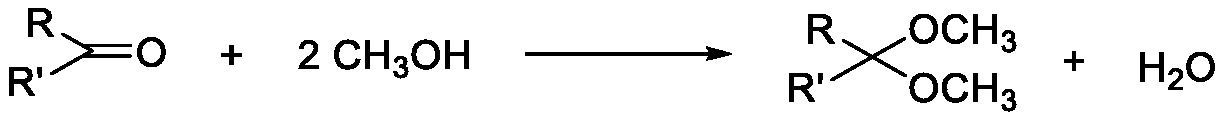

The invention provides a method for removing aldehyde and ketone in a HPPO process recycling methanol by using a molecular sieve catalytic reaction. A molecular sieve is modified by an ion exchange method, the recycling methanol containing the aldehyde and ketone impurities from the HPPO process is pumped at a certain airspeed in a fixed bed reactor with a modified molecular sieve, the modified molecular sieves catalyze the reaction of the aldehyde and ketone with the methanol at a certain temperature and pressure to form corresponding acetals and ketals, and the purified recycling methanol for removing the aldehyde and ketone impurities is obtained. The process for removing the aldehyde and ketone impurities is simple, and does not produce nitrogen-containing wastewater, and the modifiedmolecular sieve catalyst can be regenerated by simple high-temperature baking.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Light oil non-hydroaromatization catalyst as well as preparation method and application thereof

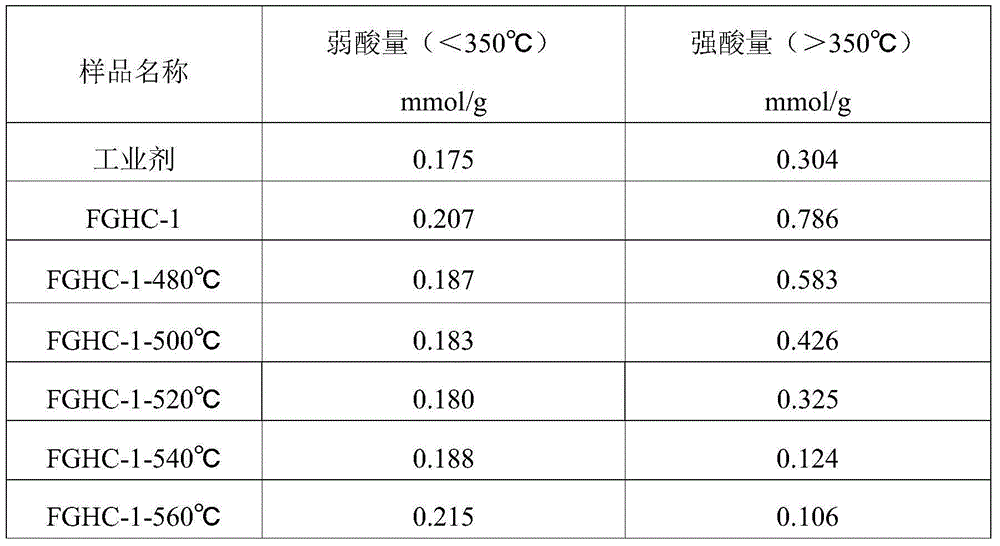

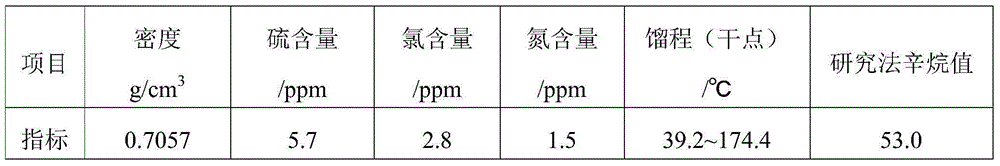

InactiveCN104923288AReduce manufacturing costReduce one-step roasting processMolecular sieve catalystsNaphtha reformingReaction temperatureTransition metal

The invention relates to a light oil aromatization catalyst, in particular to a non-hydrogen modified catalyst suitable for producing a high-octane gasoline blending component as well as a preparation method and application of the non-hydrogen modified catalyst. According to the catalyst, a catalyst active component is loaded on a carrier containing a modified molecular sieve. The catalyst is characterized in that the active component is transition metal oxide and the loading capacity is 0.5-5.0 wt%. The preparation method comprises the following specific steps: 1), molecular sieve modification; 2), carrier preparation; 3), preparation of a dipping solution; 4) catalyst preparation; 5), steam treatment. The application of the catalyst is that the catalyst is used in light oil non-hydroaromatization reaction, and is characterized in that the aromatization reaction conditions are that reaction pressure is 0.1-1.0 MPa, the reaction temperature is 280-420 DEG C and the liquid hourly space velocity is 0.5-2.0 h<-1>. According to the invention, the transition metal element with relatively cheap price is used as the active component for preparation of the light oil aromatization catalyst which is high in activity and good in stability, the catalyst can replace an industrial modifier in the prior art, an octane value of the gasoline is further increased and the liquid yield is increased.

Owner:SHANDONG JINCHENG HEAVY OIL RES INST OFCHEM TECH

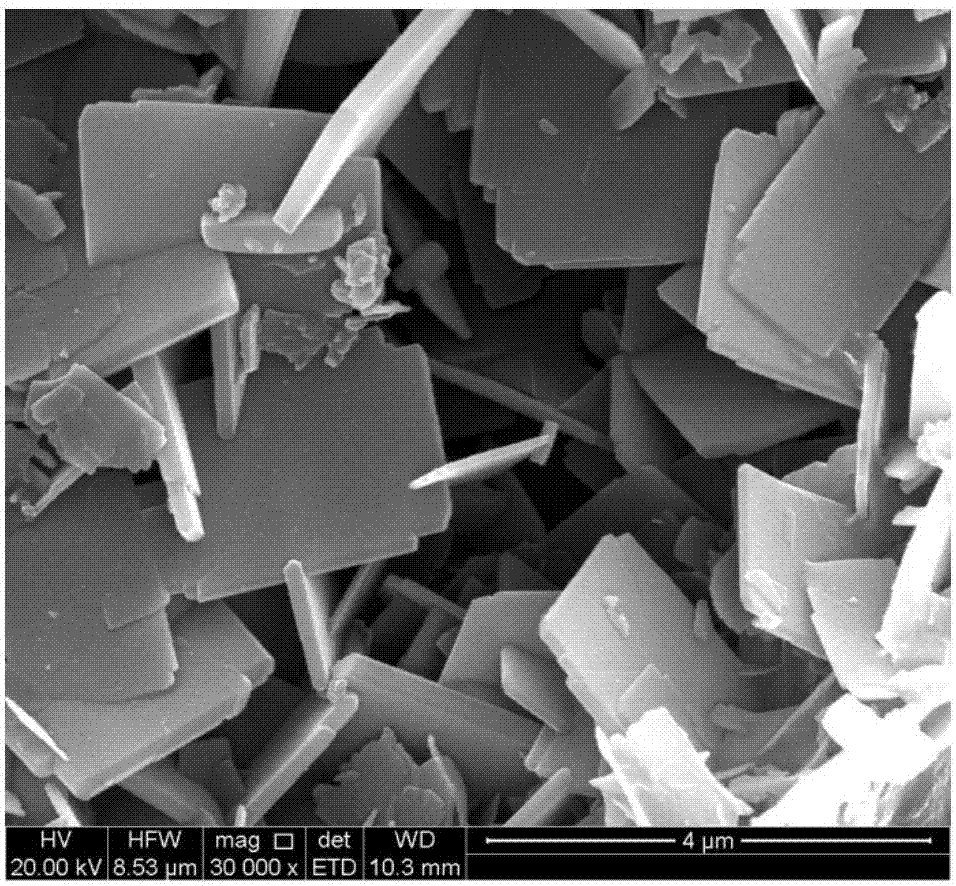

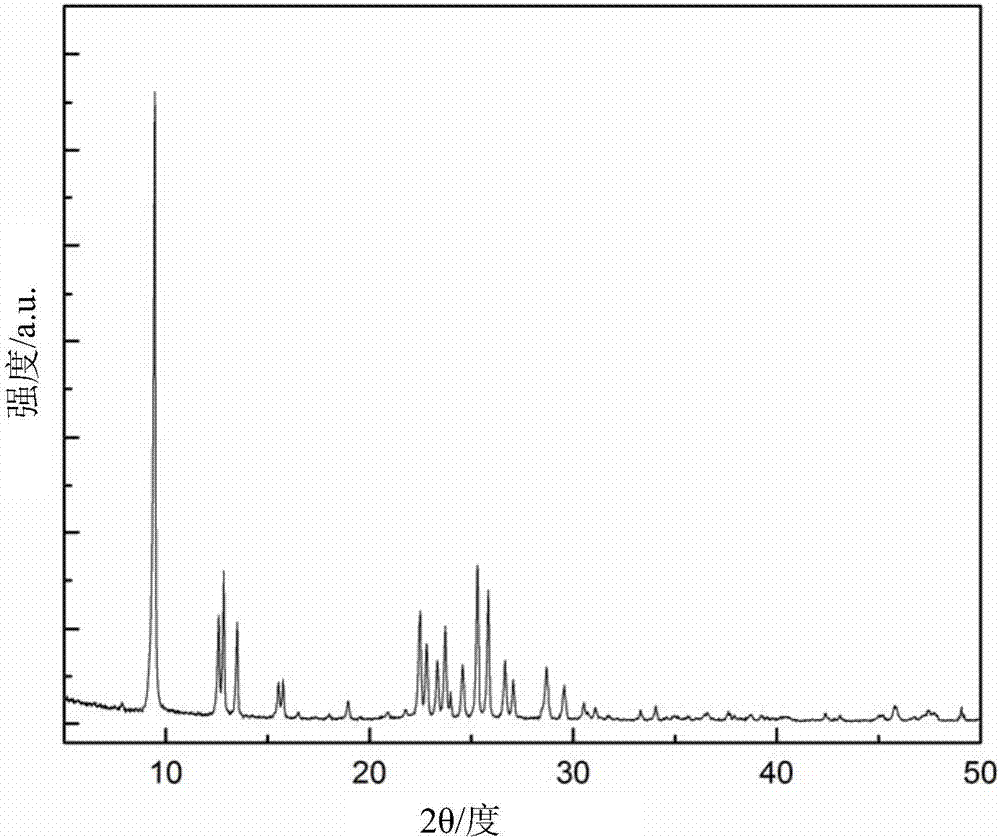

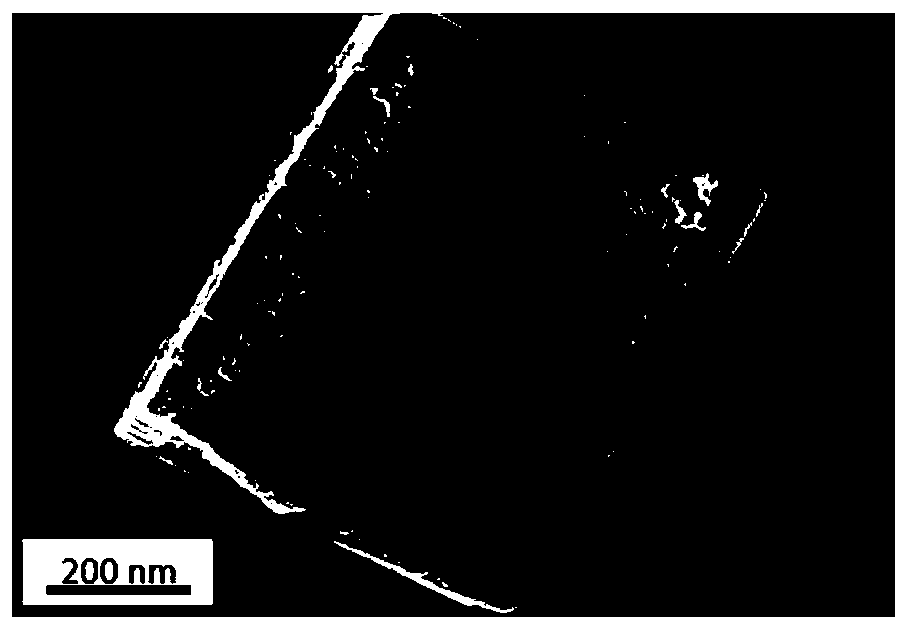

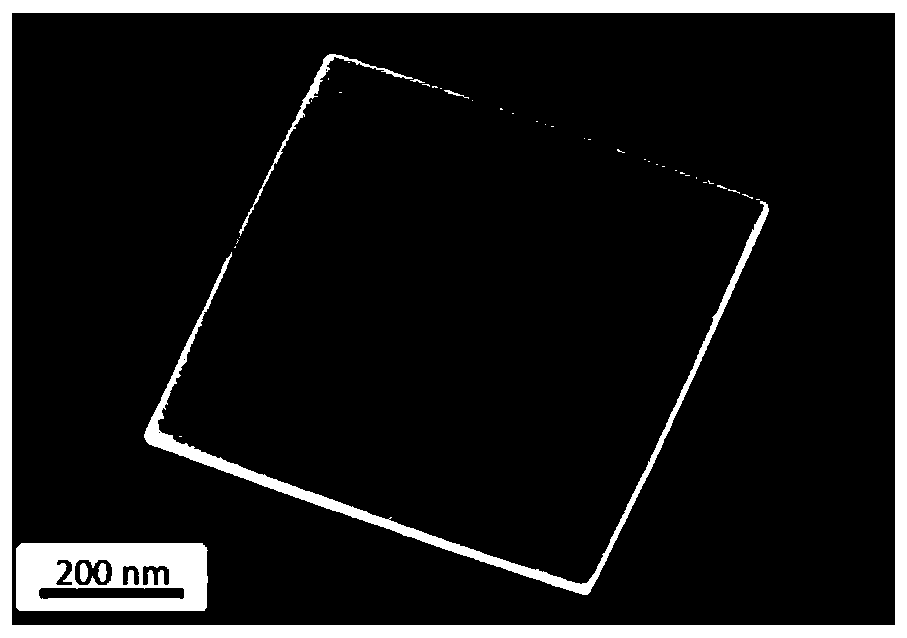

Hierarchical pore nanometer SAPO-34 molecular sieve, preparation method and applications thereof

ActiveCN110589847AHigh selectivityImprove catalytic performanceMaterial nanotechnologyMolecular sieve catalystsMolecular sieveChemistry

The invention discloses a hierarchical pore nanometer SAPO-34 molecular sieve, a preparation method and applications thereof, and relates to the field of catalysis, wherein the hierarchical pore nanometer SAPO-34 molecular sieve is a nanometer flaky molecular sieve with a thickness of 10-100 nm, an average particle size of 300-1000 nm, a micropore size of 0.38-0.5 nm, a mesopore size of 2-30 nm, aspecific surface area of 400-600 m<2> / g, and a pore volume of 0.3-0.6 cm<3> / g. According to the present invention, the hierarchical pore nanometer SAPO-34 molecular sieve is obtained through co-treatment with HF and NH4F; and with the application of the hierarchical pore nanometer SAPO-34 molecular sieve in MTO reactions, the selectivity of low-carbon olefins can be improved, the content of C5<+>is low, and the one-way service life of the catalyst is prolonged.

Owner:XIAMEN UNIV

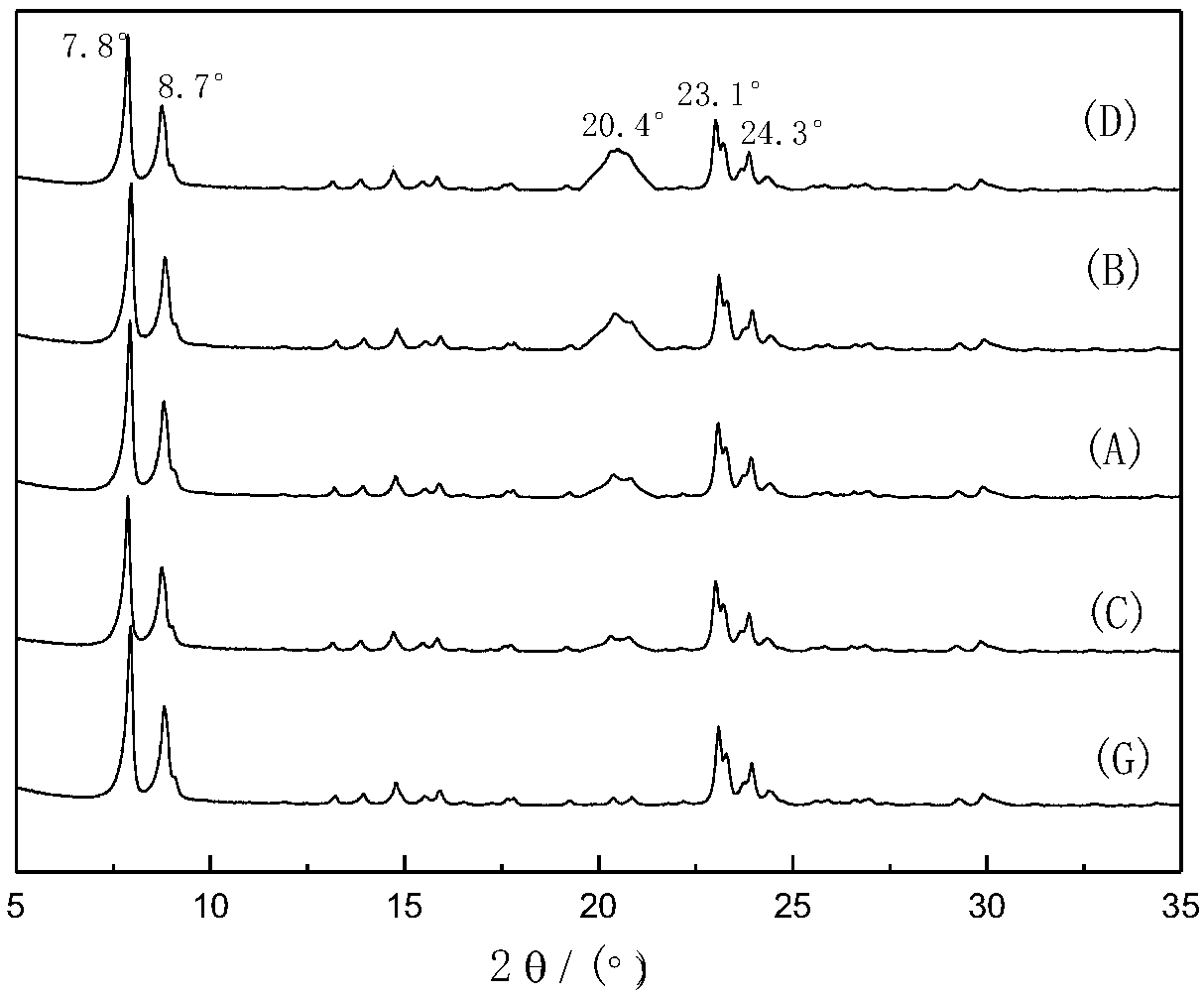

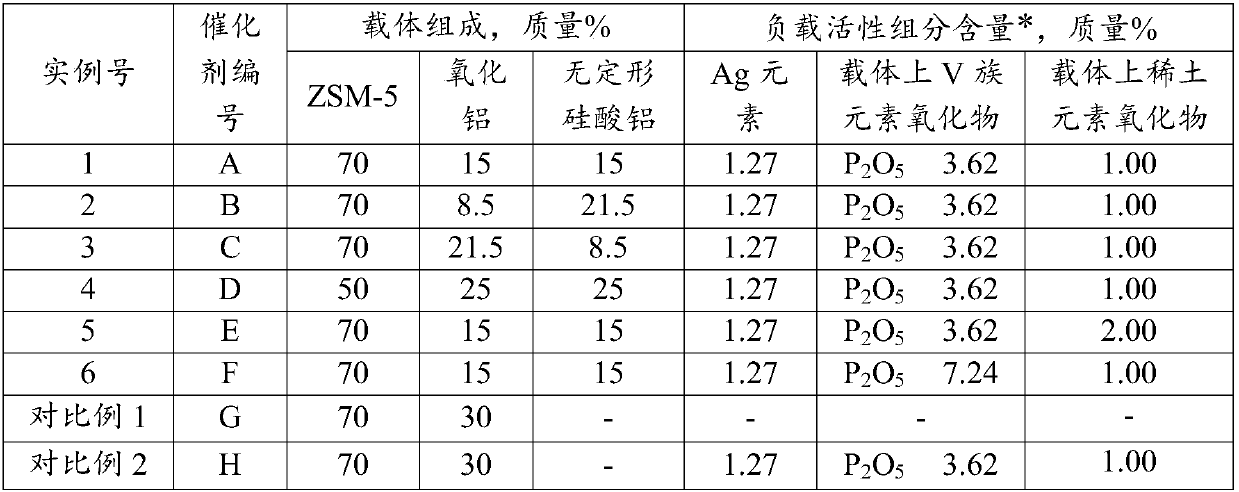

Catalyst for producing gasoline component by naphtha and methanol, and preparation method and application thereof

ActiveCN109569703ALong life one wayLess carbon depositMolecular sieve catalystsCatalyst activation/preparationRare-earth elementAluminum silicate

A catalyst for producing a gasoline component by aromatization of naphtha and methanol includes a carrier and active components having contents calculated based on the carrier as follows: 0.1-5.0% bymass of Ag, 1.0-15.0% by mass of a VA group element oxide, 0.1-3.0% by mass of a rare earth element oxide; and the carrier includes 40-80% by mass of ZSM-5 zeolite, 3-30% by mass of aluminum oxide, and 5-30% by mass of amorphous aluminum silicate. The catalyst can promote the naphtha and the methanol to produce a co-aromatization reaction to form the gasoline component with a high-octane value, and can produce a high-quality liquefied gas by side.

Owner:CHINA PETROLEUM & CHEM CORP +1

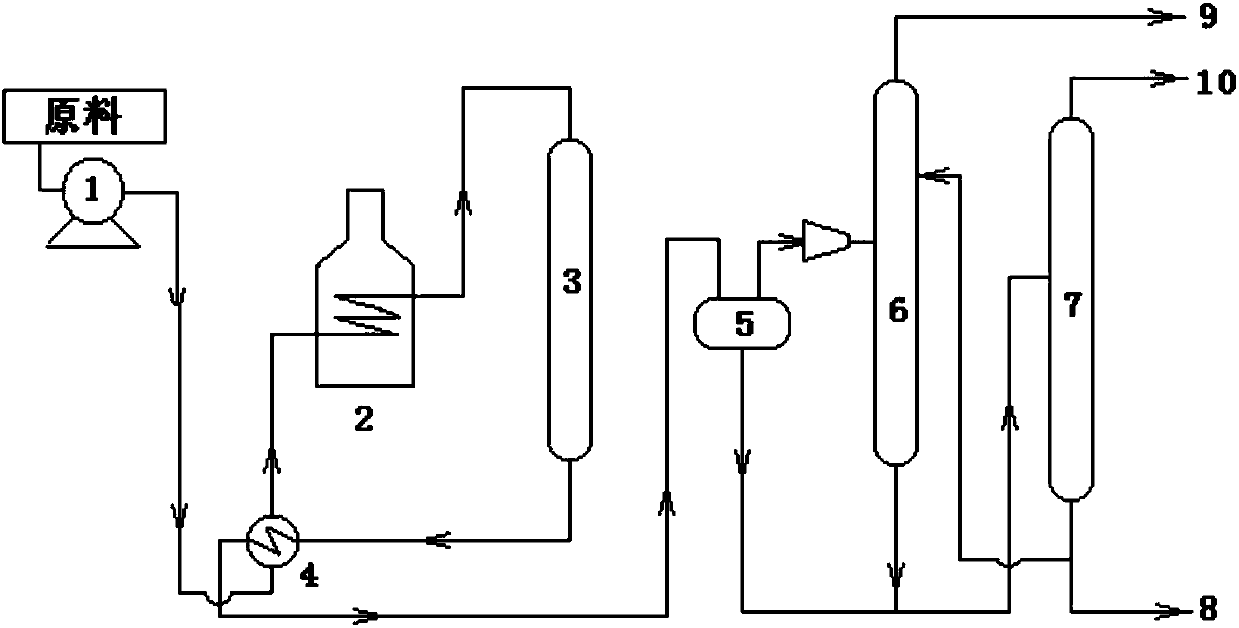

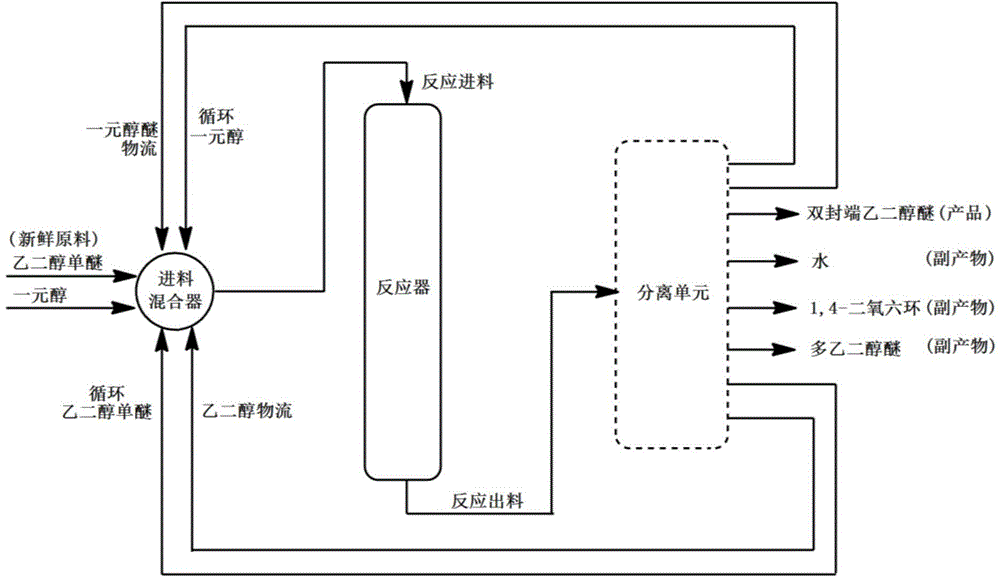

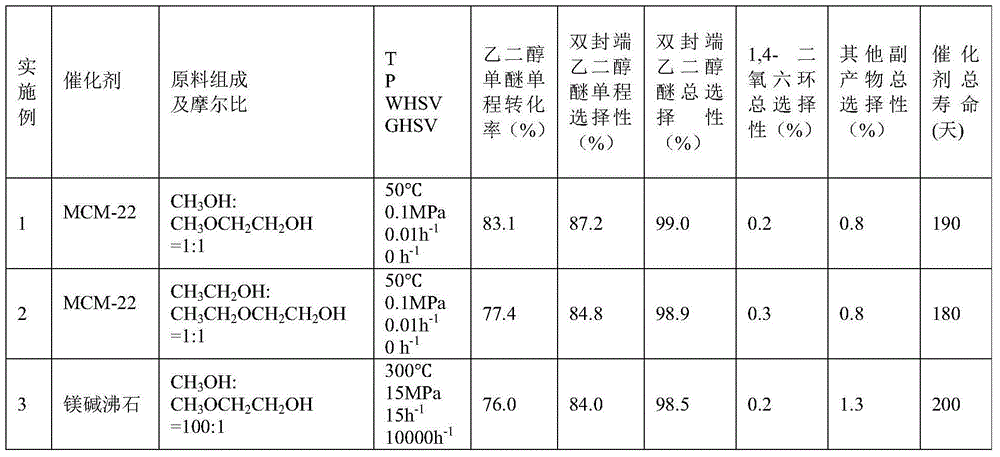

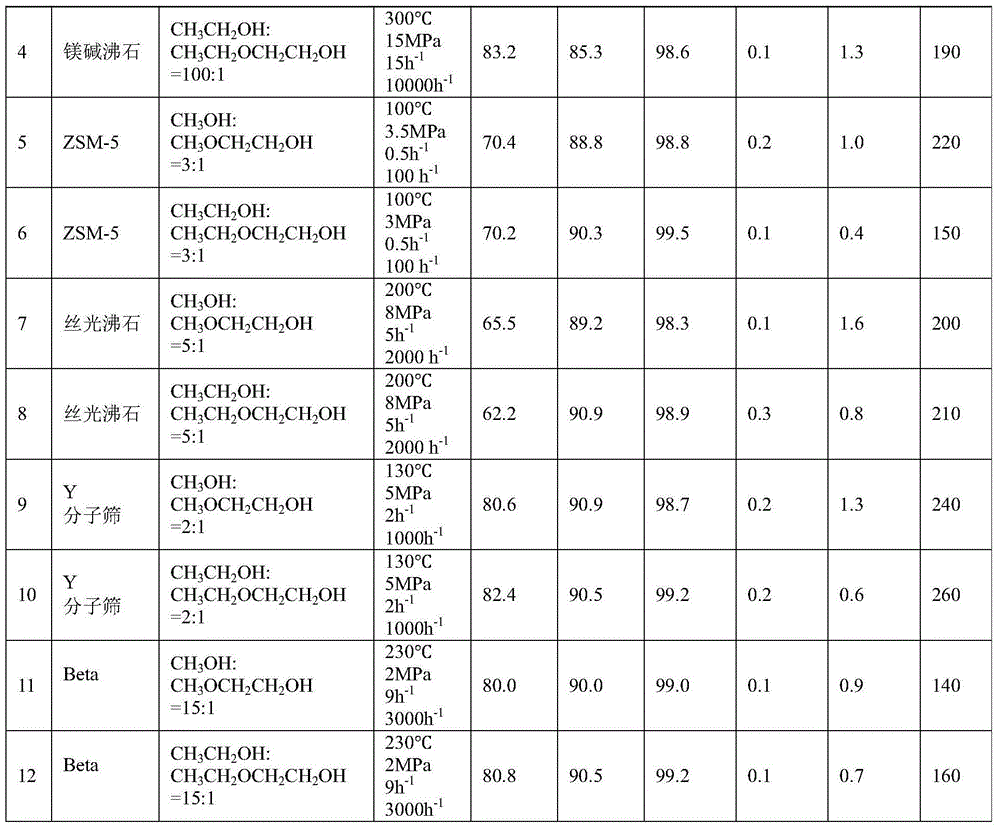

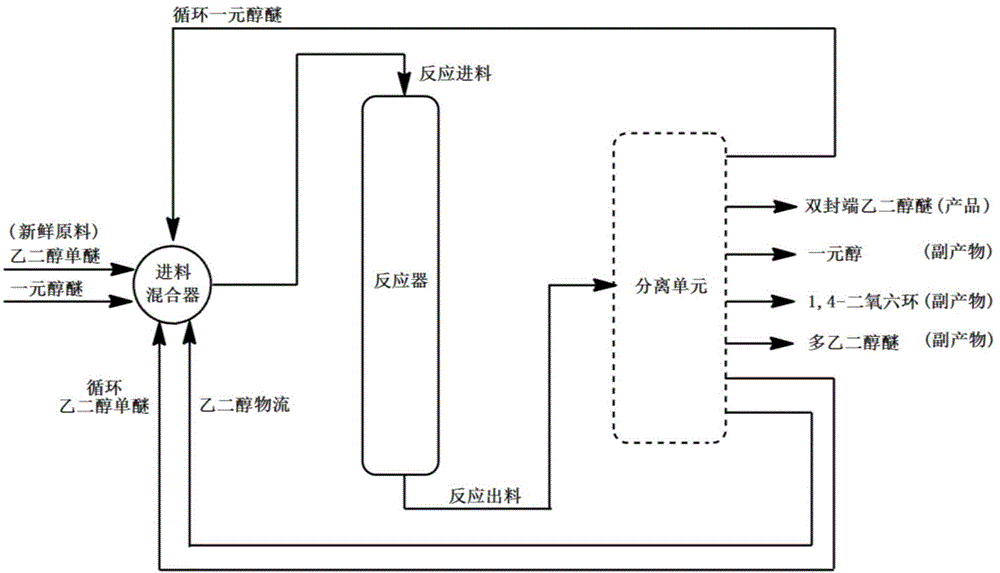

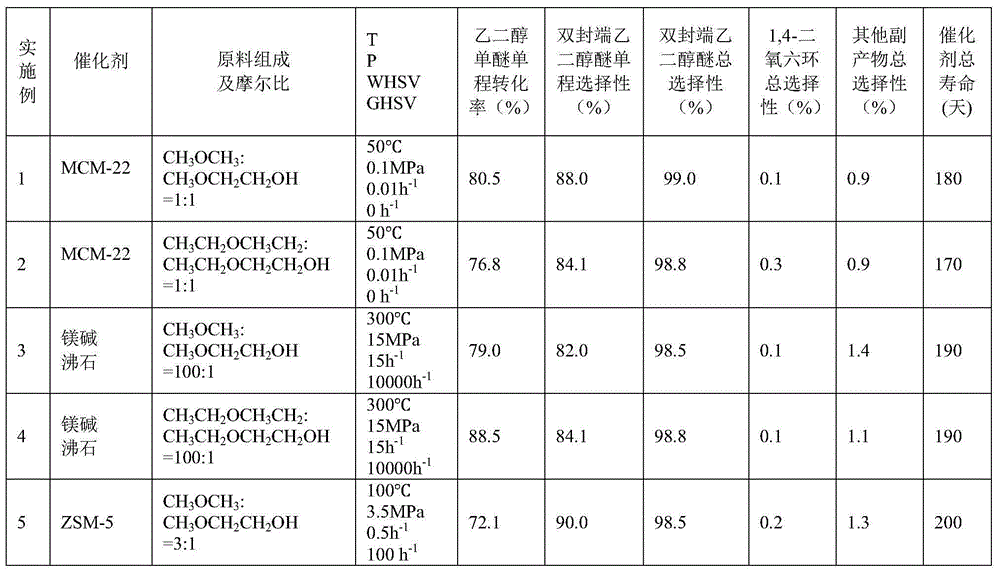

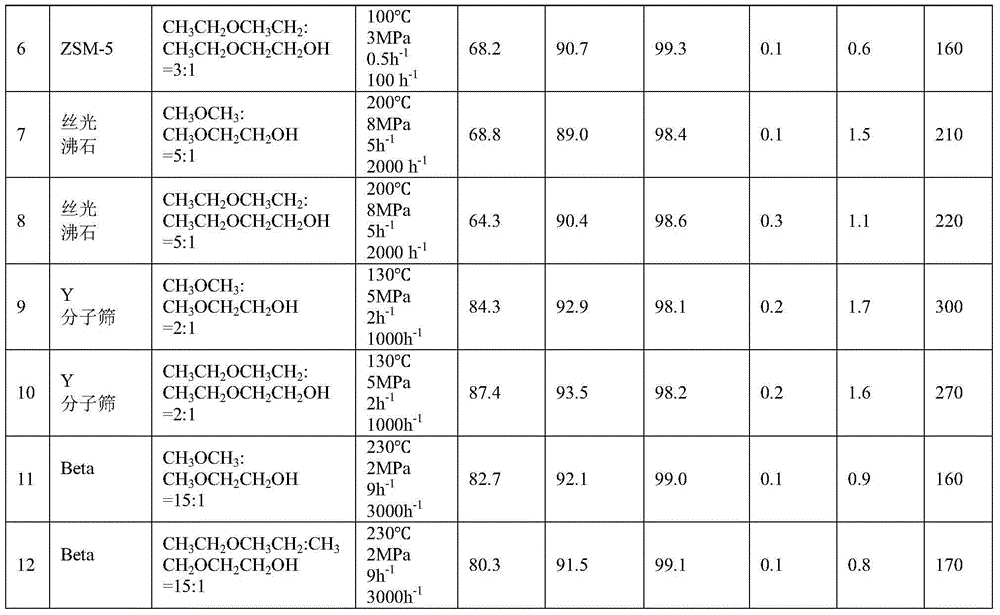

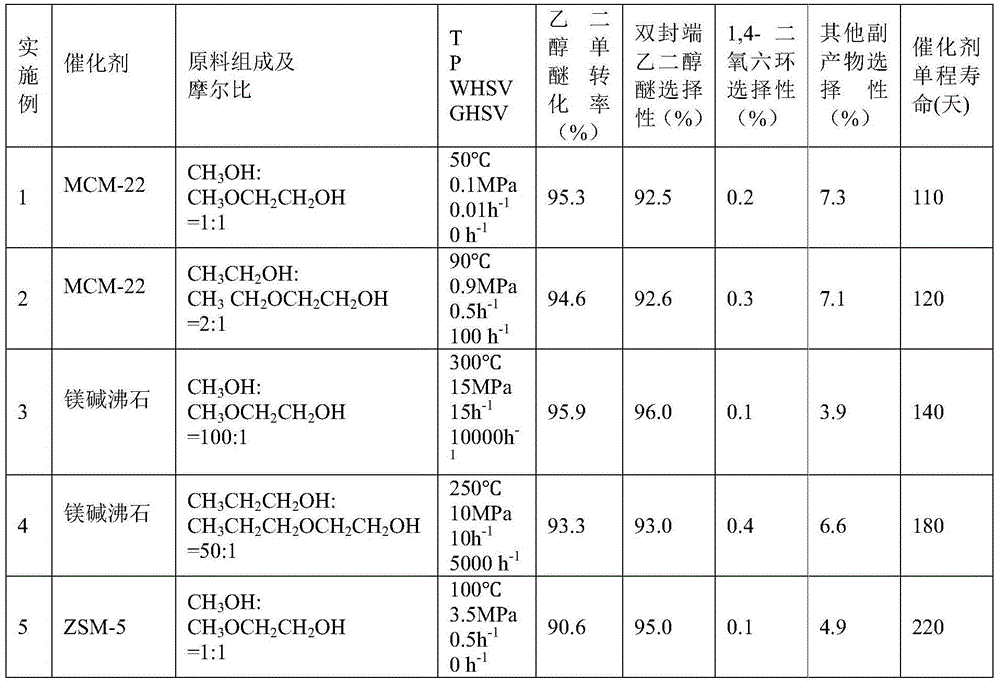

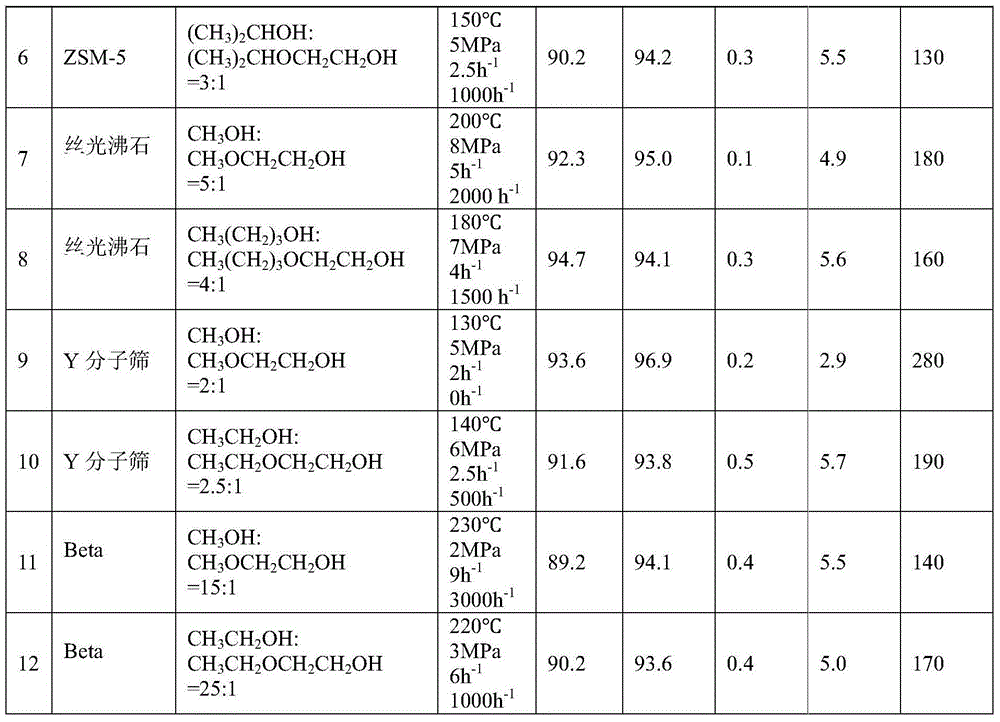

Preparation method for double-terminated glycol ether

InactiveCN105777504AWide variety of sourcesLong life one wayEther preparation by compound dehydrationMolecular sieveAlcohol

The invention discloses a preparation method for double-terminated glycol ether. The preparation method comprises the following steps: a) introducing raw materials containing glycol monoether and monohydric ether alcohol into a reactor for contact and reaction with an acidic molecular sieve catalyst under the conditions that reaction temperature is 50 to 300 DEG C, reaction pressure is 0.1 to 15 MPa, the mass space velocity of the glycol monoether in the raw materials is 0.01 to 15.0 / h, and a mol ratio of monohydric ether alcohol to glycol monoether in the raw materials is 1-100: 1, and separating obtained products so as to obtain a double-terminated glycol ether product, unreacted glycol monoether and monohydric ether alcohol, by-product components and other components; and b) returning the unreacted glycol monoether and monohydric ether alcohol and the by-product components obtained in the step a) to the reactor. The preparation method has the advantages that the catalyst has long single-pass life; the target product, i.e., double-terminated glycol ether has high yield and selectivity; energy consumption in separation of the products is low; by-products have high economic value; production scale can be large or small; and application of the method is flexible.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method for double-terminated glycol ether

InactiveCN105777503ALong life one wayIncrease profitEther preparation by compound dehydrationMolecular sieveAlcohol

The invention discloses a preparation method for double-terminated glycol ether. The preparation method comprises the following steps: a) introducing raw materials containing glycol monoether and monohydric ether alcohol into a reactor for contact and reaction with an acidic molecular sieve catalyst under the conditions that reaction temperature is 50 to 300 DEG C, reaction pressure is 0.1 to 15 MPa, the mass space velocity of the glycol monoether in the raw materials is 0.01 to 15.0 / h, and a mol ratio of monohydric ether alcohol to glycol monoether in the raw materials is 1-100: 1, and separating obtained products so as to obtain a double-terminated glycol ether product, unreacted glycol monoether and monohydric ether alcohol, by-product components and other components; and b) returning the unreacted glycol monoether and monohydric ether alcohol and the by-product components obtained in the step a) to the reactor. The preparation method has the advantages that the catalyst has long single-pass life; the target product, i.e., double-terminated glycol ether has high yield and selectivity; energy consumption in separation of products is low; by-products have high economic value; production scale can be large or small; and application of the method is flexible.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

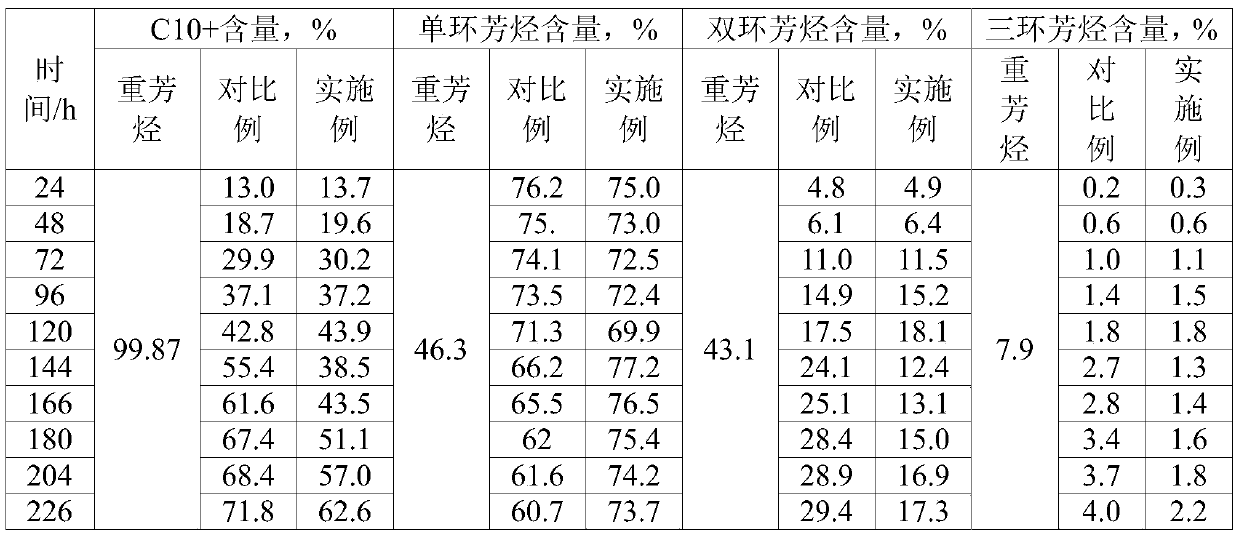

A method for improving the stability of catalysts for lightening heavy aromatics

ActiveCN104447175BImprove stabilityLong life one wayHydrocarbonsBulk chemical productionMolecular sieveHydrogen

Owner:CHINA NAT OFFSHORE OIL CORP +2

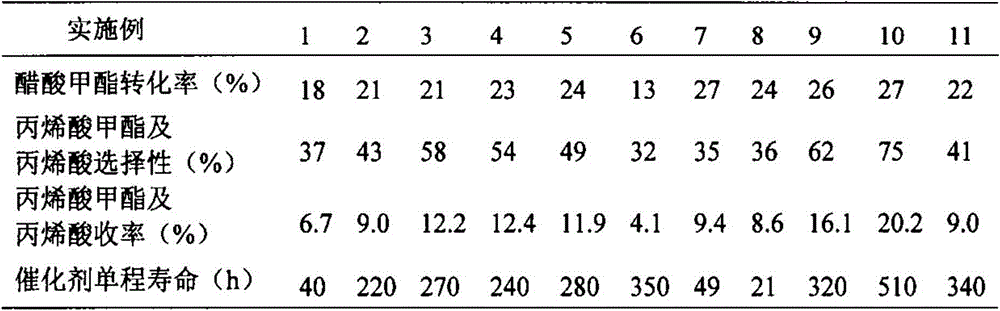

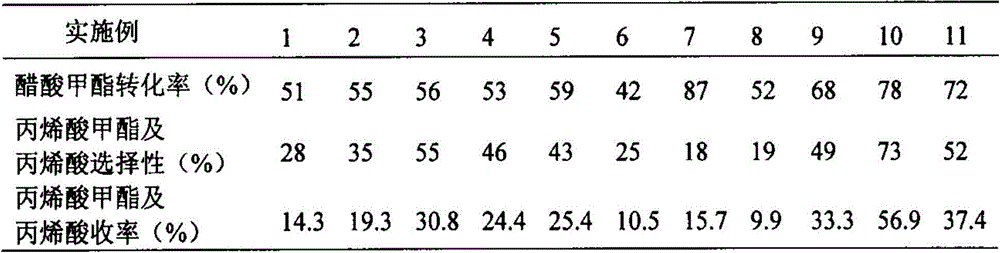

Catalyst, preparation method and application of methyl acrylate and formaldehyde for producing methyl acrylate

ActiveCN103506107BHigh selectivityHigh activityOrganic compound preparationCarboxylic acid esters preparationCaesium oxidePtru catalyst

Owner:SHANGHAI PUJING CHEM NEW MATERIALS

Process for synthesizing diisopropylamine from isopropylamine

ActiveCN103787892ASmall scaleReduce manufacturing costOrganic compound preparationAmino compound preparationGas phaseReaction temperature

The invention provides a process for synthesizing diisopropylamine from isopropylamine. Isopropylamine passes through a catalyst bed layer in the presence of hydrogen for a reaction so as to realize synthesis of diisopropylamine from isopropylamine. Reaction of isopropylamine in the presence of hydrogen is realized through the following two manners: 1, hydrogen is introduced into a reactor, and gas phase hydrogen is allowed to exist in the catalyst bed layer; 2, an isopropylamine raw material contacts with hydrogen before entering the reactor, hydrogen is dissolved in the isopropylamine raw material, then the isopropylamine raw material with dissolved hydrogen enters the reactor used for synthesis of diisopropylamine from isopropylamine, and gas phase hydrogen does not exist in the catalyst bed layer. Reaction conditions for synthesis of diisopropylamine from isopropylamine are as follows: reaction pressure is 1.0 to 8.0 MPa, reaction temperature is 150 to 350 DEG C, and liquid hour space velocity is 0.1 to 1.0 / h. The process greatly prolongs the service life of a catalyst and reduces reaction temperature while maintaining high selectivity and a high conversion rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for preparing gasoline catalyst with methanol

ActiveCN102513142BIncrease the areaHigh pore volumeMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sievePtru catalyst

The invention relates to a preparation method for preparing a gasoline catalyst with methanol. The preparation method is characterized by comprising the following steps of: before molding the catalyst, performing aluminum-removing and silicon replenishing treatment on a catalyst matrix nanoscale ZSM-5 molecular sieve with an acid solution to adjusting the acidic property of the molecular sieve; and after the catalyst is molded, pretreating the catalyst by using a hydrothermal aging device to enhance the gasoline selectivity and stability of the catalyst. When the catalyst prepared with the method is applied to a reaction for preparing gasoline with methanol on a section of fixed bed, the gasoline yield is up to 36-37 percent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Catalyst for preparing butene/butadiene by dehydrogenation of butane and application of catalyst

PendingCN107537462AImprove conversion rateReduce carbon depositionCatalyst carriersCatalyst activation/preparationIridiumDehydrogenation

The invention relates to a catalyst for preparing butene / butadiene by dehydrogenation of butane and an application of the catalyst, and mainly solves the problems of low butane conversion rate, and poor single-pass stability and regeneration stability in conventional preparation technologies. According to the invention, firstly, zirconia, chromium oxide and oxides of at least one element selectedfrom a group consisting of IIIA, IVA, VA and IIB in the periodic table of elements are introduced into an aluminum oxide carrier by a dry mixing method to obtain a composite metal-oxide carrier; thenthe loading of iridium (Ir) and ruthenium (Ru) components is performed by an impregnation method, that is, water solutions of soluble salts of iridium (Ir) and ruthenium (Ru) are employed for impregnation; and the catalyst is obtained after drying and calcination. The problems are well solved with the technical scheme that n-butane is used as a raw material, under the conditions that the reactiontemperature is in a range of 530-650 DEG C, the reaction pressure is in a range of 0.1-0.4 MPa, the mass space velocity of the n-butane is in a range of 0.1-6.0 h<-1>, and the volume ratio of H<2>O toC<n>H<2n+2> is in a range of 0.1-16, the raw material contacts with the catalyst and reacts to form the butene / butadiene. The technical scheme can be used in the industrial preparation of the catalyst for preparing butene / butadiene by the dehydrogenation of n-butane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing hydrocarbons from oxygen-containing compounds, and preparation method and application thereof

InactiveCN104923285AHigh selectivityLong life one wayMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sieveOxygen

The invention discloses a catalyst for preparing hydrocarbons from oxygen-containing compounds, and a preparation method and application thereof. The catalyst, on a basis of total weight, comprises 35-84% of ZSM-5 molecular sieve, 15-60% of a binder and 0.1- 15% of modified elements. The catalyst is prepared by preparing modified ZSM-5 molecular sieve, mixing the ZSM-5 molecular sieve with the binder and performing extrusion molding, and post-processing. The catalyst is used for preparing hydrocarbons from oxygen-containing compounds, is high in catalytic activity, good in hydrocarbon selectivity, long in single pass life and simple in preparation process.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

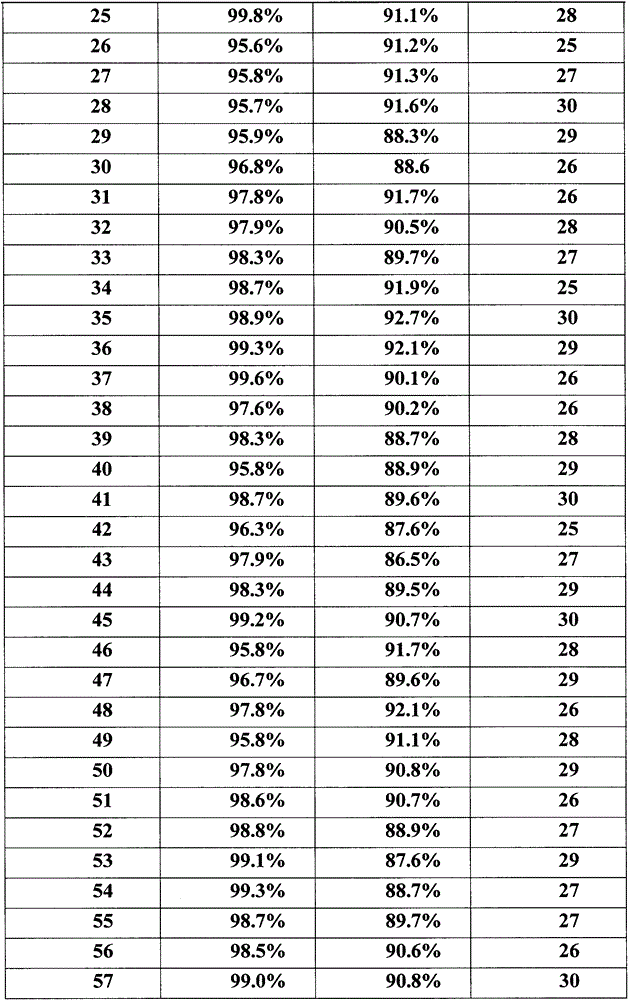

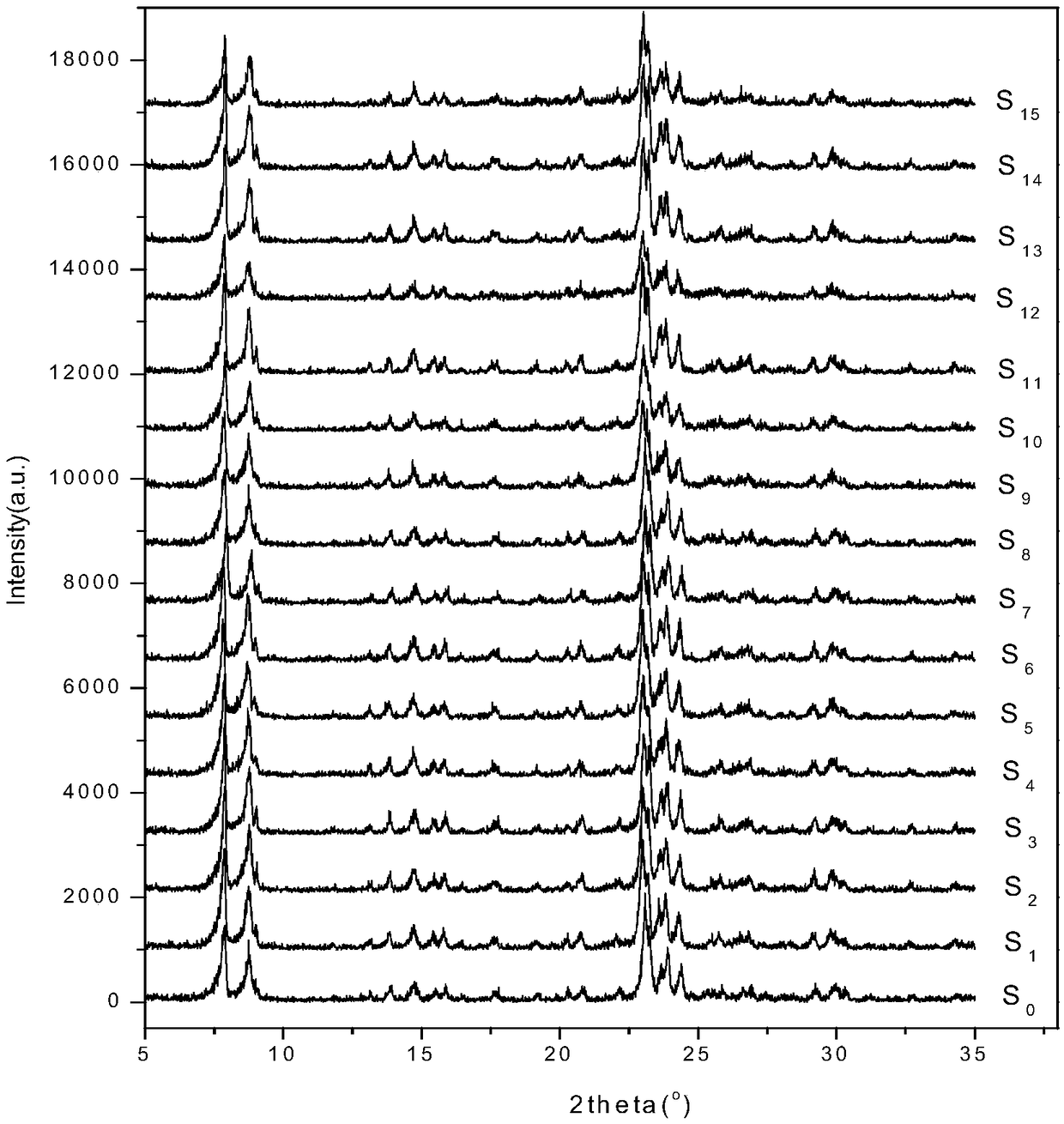

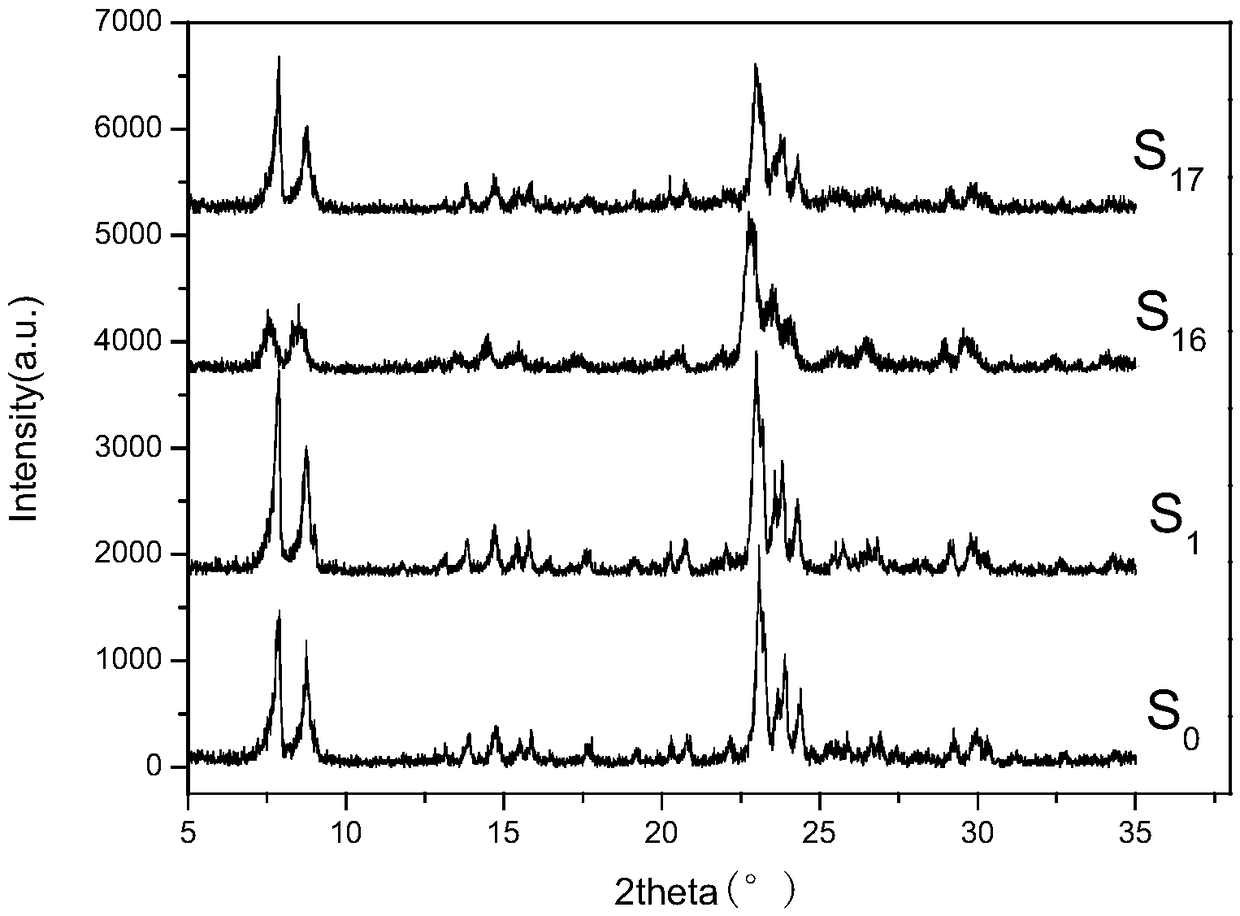

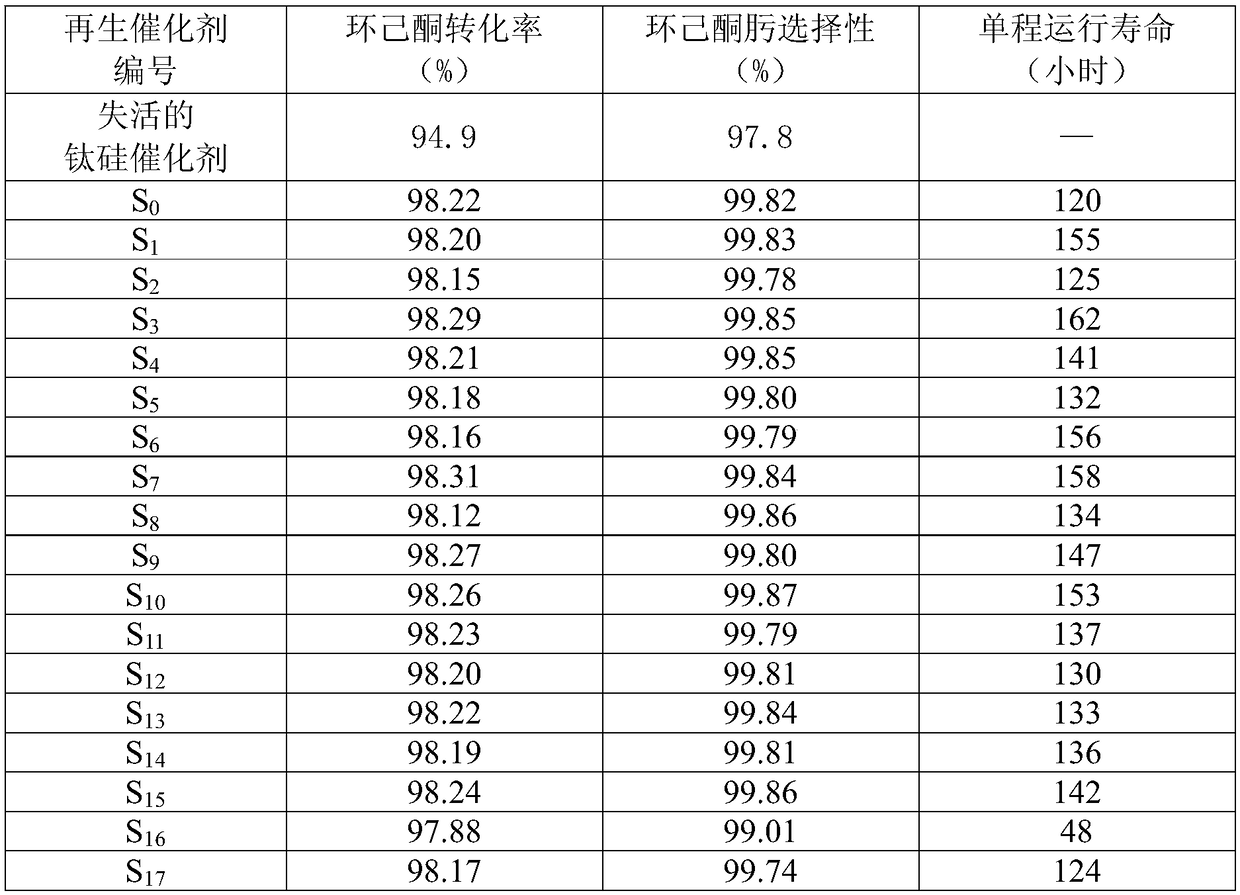

Regeneration method of deactivated titanium-silicon catalyst, regenerated catalyst and application thereof

ActiveCN109465032AReduce lossesReduce generationMolecular sieve catalystsCatalyst regeneration/reactivationCyclohexanoneWastewater

The invention discloses a regeneration method of a deactivated titanium-silicon catalyst. The method comprises the following steps: (1) mixing a deactivated titanium-silicon catalyst wet material withregenerated mixed liquid, and grinding the mixture by adopting a colloid mill to obtain a uniform material; (2) performing hydrothermal crystallization on the uniform material obtained in the step (1) to obtain a crystallized product; and (3) filtering, washing and calcining the crystallized product obtained in the step (2) to obtain a regenerated catalyst, wherein the mass ratio of the deactivated titanium-silicon catalyst wet material to the regenerated mixed liquid is 1:(1-10). The obtained regenerated catalyst, prepared with the regeneration method of the deactivated titanium-silicon catalyst provided by the invention, has the advantages that the activity is recovered to a fresh agent level, the single-path life is obviously prolonged when the catalyst is used for cyclohexanone ammoximation reaction, only once washing is required during the entire regeneration process, the loss of the catalyst and the generated wastewater are less, the regeneration process is short, the regeneration cost is low, and industrial amplification is easy.

Owner:SHANGHAI NOVEL CHEM TECH

A kind of hierarchical porous nano sapo-34 molecular sieve and its preparation method and application

ActiveCN110589847BHigh selectivityImprove catalytic performanceMaterial nanotechnologyMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a multi-level porous nanometer SAPO-34 molecular sieve and its preparation method and application, relating to the field of catalysis. The multi-stage porous nano-SAPO-34 molecular sieve is a nano-sheet molecular sieve with a thickness of 10-100nm and an average particle size of 300-1000nm. 600m 2 / g, the pore volume is 0.3~0.6cm 3 / g. The hierarchical porous nanometer SAPO-34 molecular sieve adopts HF and NH 4 F co-processed, applied to the MTO reaction, can improve the selectivity of light olefins, while C 5 + With less content, the one-way life of the catalyst is also extended.

Owner:XIAMEN UNIV

A methanol aromatization process

ActiveCN104098418BImprove stabilityLong life one wayHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionLiquid productDistillation

The invention discloses a methanol aromatization process. The steps are: 1) Methanol enters the tube side of the reactor to contact with the tube side catalyst, the operating temperature is 400-450°C, the operating pressure is 0.1-5Mpa, and the liquid space velocity of the raw material methanol is 0.5-7.0h -1 ; 2) The reaction product from the tube side enters the shell side of the reactor to contact with the catalyst on the shell side, the operating temperature is 330-380°C, the operating pressure is 0.1-3.5Mpa, and the operating space velocity is 0.4-4.0h -1 , converted to C through shell-side catalysis 5 + Hydrocarbon liquid products are separated by rectification to obtain aromatics and non-aromatics. After the gas products in the shell side products are separated, the low carbon olefins return to the shell side of the reactor to continue the reaction. The use of the invention can improve the utilization rate of methanol, simplify complex reactions, increase the selectivity of low-carbon olefins, and reduce the generation of dry gas and liquefied gas.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

Preparation method of double terminated glycol ether

InactiveCN105777501AWide variety of sourcesLong life one wayChemical recyclingEther preparation by compound dehydrationMolecular sieveAlcohol

The invention relates to a preparation method of double terminated glycol ether. According to the preparation method, raw materials, which contain glycol mono-ether and monohydric alcohol, are introduced into a reactor and then contacted with an acidic molecular sieve catalyst to carry out reactions so as to produce double terminated glycol ether; the reaction temperature is 50 to 300 DEG C, the reaction pressure is 0.1 to 15 MPa; the mass space velocity of glycol mono-ether is 0.01 to 15.0 h<1>; and the mole ratio of monohydric alcohol to glycol mono-ether is 1-100:1. The provided method has the advantages that the single pass service life of catalyst is long, the catalyst can be repeatedly regenerated, the yield and selectivity of target product are high, the energy consumption for separating products is low, the economic value of byproducts is high, the production scale can be large or small, and the application is flexible.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

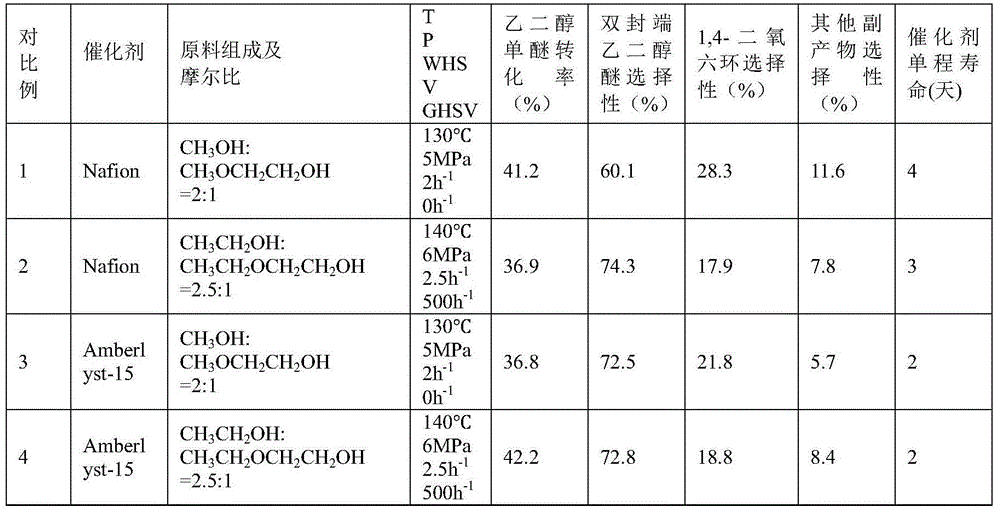

Carrier of catalyst for preparing low-carbon alkene by dehydrogenation of low-carbon alkane and application of carrier

ActiveCN107537584AReduce carbon depositionLong life one wayCatalyst carriersHydrocarbonsAlkaneMolecular sieve

The invention relates to a carrier of a catalyst for preparing low-carbon alkene by dehydrogenation of low-carbon alkane and an application of the carrier, and mainly solves problems that in the priorpreparation art, a carbon deposit quantity of a catalyst is large, in a usage process, performance decline is quick, and regeneration is frequent. The carrier adopted by the invention comprises a Nb2O5.b MoO3.c MxOy.d SiO2, wherein M is one or more selected from Ge, Sn and Pb, SiO2 is at least one selected from diatomite, silicon oxide and a high-silicon Y type molecular sieve; and the carrier comprises the following components calculated by an oxide, by weight: 15-35.0% of Nb2O5; 5.0-15.0% of MoO3; 1.0-10.0% of MxOy; and 50-70% of SiO2, when the above technical scheme is used for preparing the low-carbon alkene by dehydrogenation of the low-carbon alkane, the problems are better solved, and the carrier can be used in industrial preparation of the catalyst for preparing the low-carbon alkene by dehydrogenation of the low-carbon alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

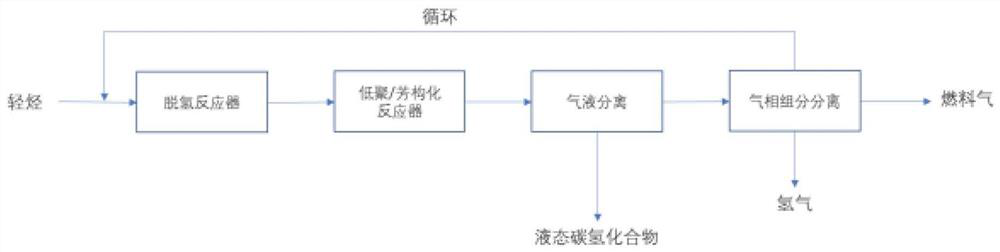

Method for producing aromatic hydrocarbons and/or liquid fuels from light hydrocarbons

ActiveCN113493699AImprove conversion rateLong life one wayMolecular sieve catalystLiquid hydrocarbon mixtures productionPtru catalystDehydrogenation

The invention provides a method for producing aromatic hydrocarbons and / or liquid fuels through light hydrocarbon dehydrogenation aromatization, which comprises the following steps: 1) under dehydrogenation reaction conditions, carrying out dehydrogenation reaction on light hydrocarbon material flow to obtain material flow containing olefin; and 2) under aromatization reaction conditions, contacting the material flow containing olefin with an aromatization catalyst, and carrying out oligomerization / aromatization reaction to obtain a material flow containing aromatic hydrocarbon and / or liquid fuel. According to the method, dehydrogenation and oligomerization / aromatization are separated and executed step by step under different conditions, a zeolite molecular sieve loaded with an active metal component is used as an aromatization catalyst, and under an optimal low-temperature aromatization condition, the high alkane conversion rate, the high carbon utilization rate and the high single-cycle aromatic hydrocarbon production capacity can be obtained through the method disclosed in the invention; and the catalyst is slow in deactivation, long in one-way service life, easy to regenerate and good in multi-cycle stability.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com