Patents

Literature

48results about How to "Good hole forming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

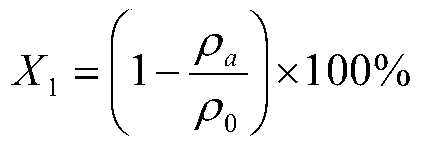

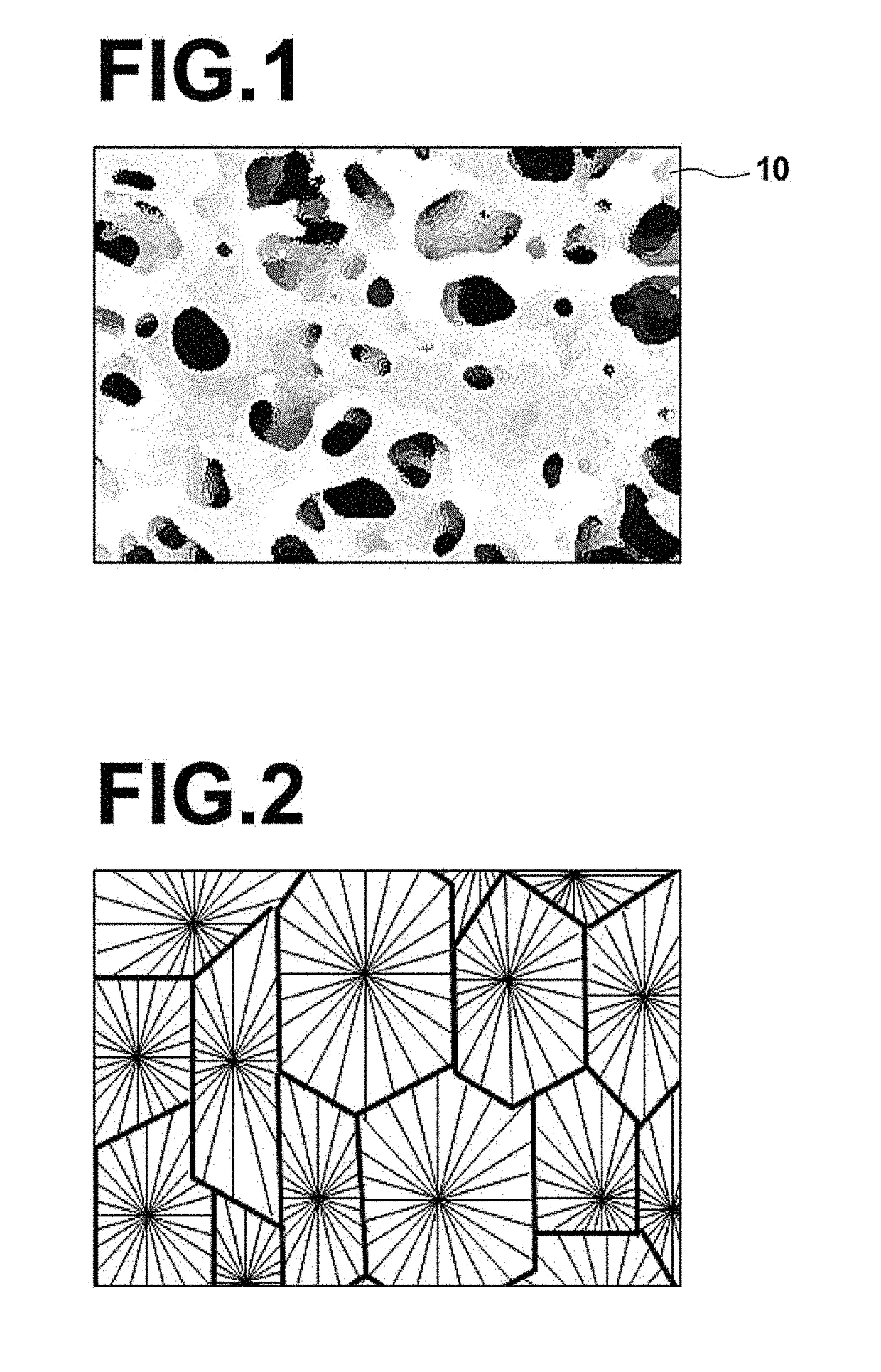

Improved microporous polymer film and preparation method thereof

The invention relates to an improved microporous polymer film and a preparation method thereof, and belongs to the field of chemistry. The improved microporous polymer film comprises the following compositions by weight percentage: 55% to 99.79% of polypropylene homopolymer, 0.01% to 5% of beta crystal nucleating agent, 0.1% to 20% of polymeric additive and 0.1% to 20% of inorganic modifier. The improved microporous polymer film is prepared by stretching a melt about 2 to 60 times at a speed of 1 m to 100 m / min in casting, calendering, extruding or film blowing process. Compared with the prior art, more beta crystals can be obtained within shorter time, the formed beta crystals have higher thermal stability, and have better film-forming stability and pore-forming properties, and the prepared microporous film has the characteristics of easiness in processing, higher permeability, excellent productivity, and strong mechanical properties and dimensional stability, and the porosity is further improved, and thereby the permeability of various media can be obviously improved.

Owner:CHENGDU WISEDONE TECH

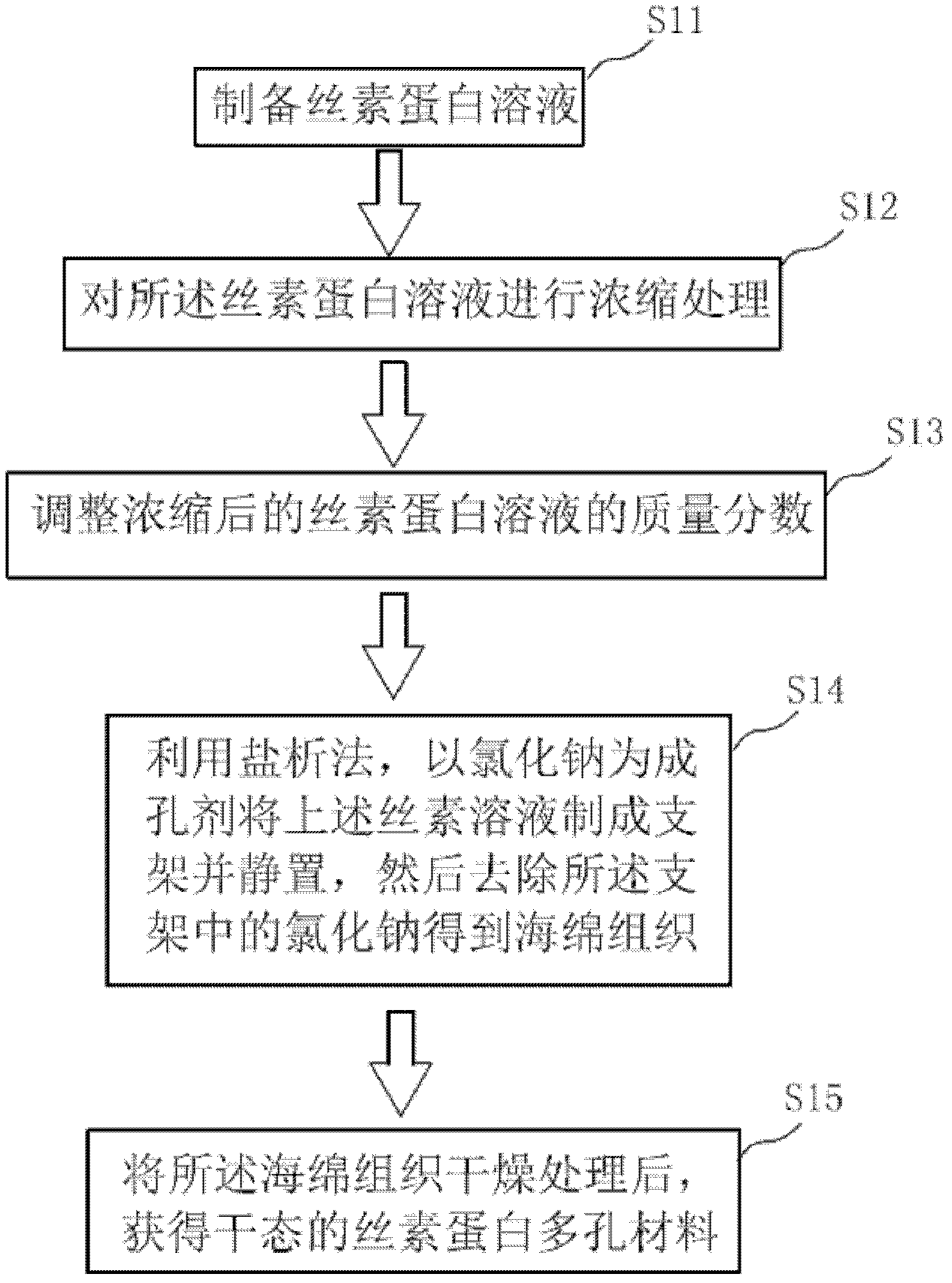

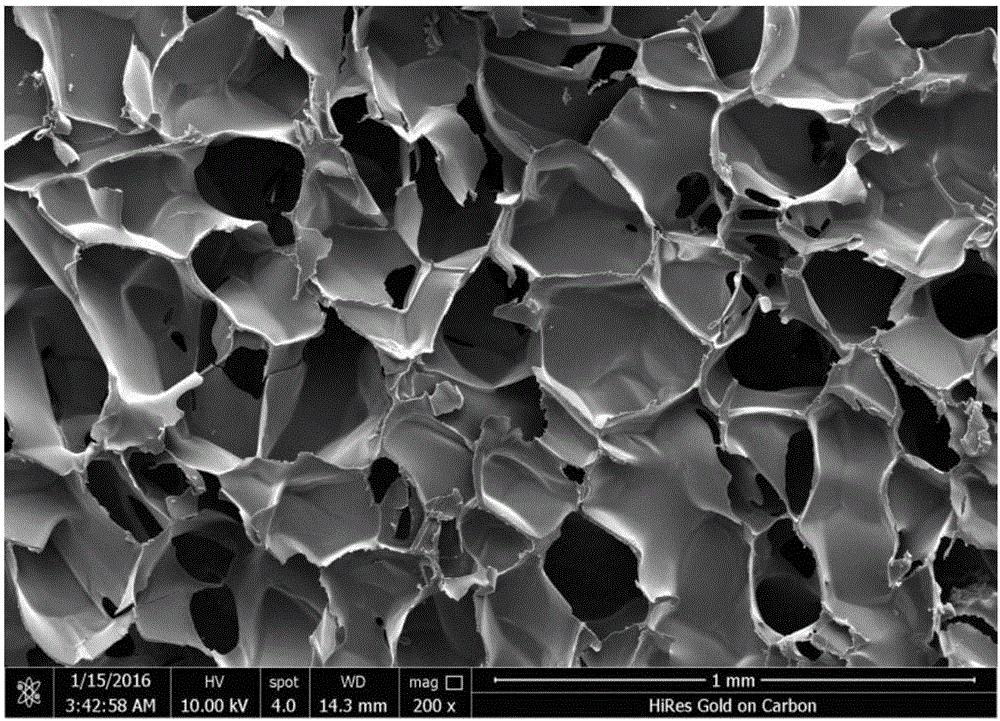

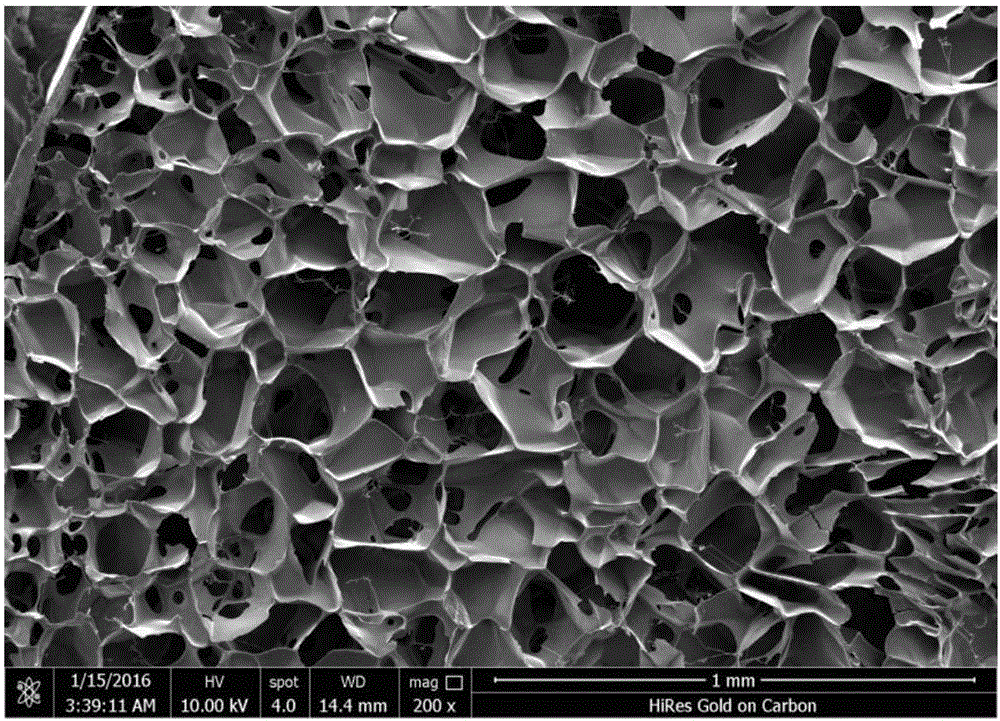

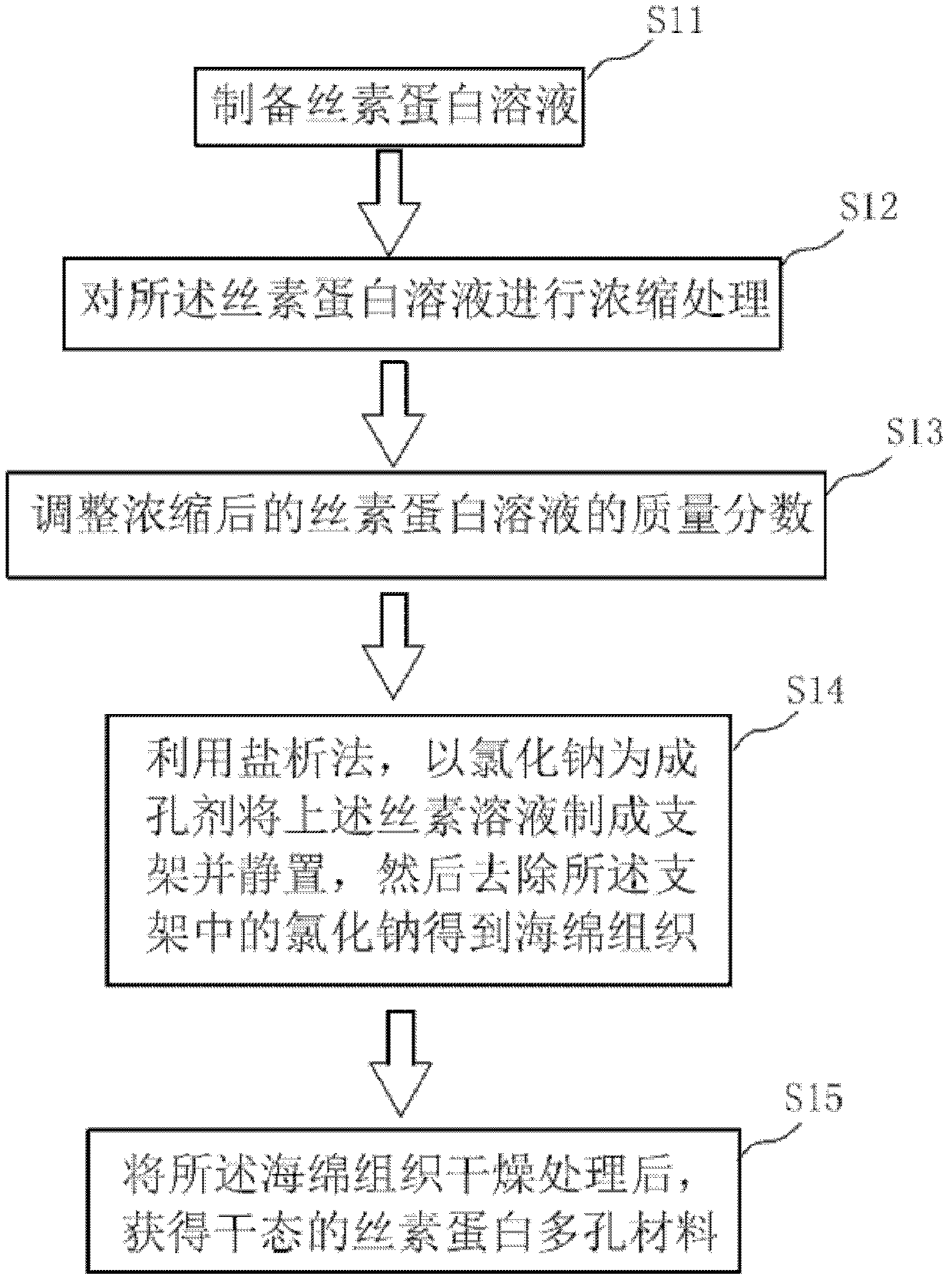

Preparation method of porous three-dimensional silk fibroin material

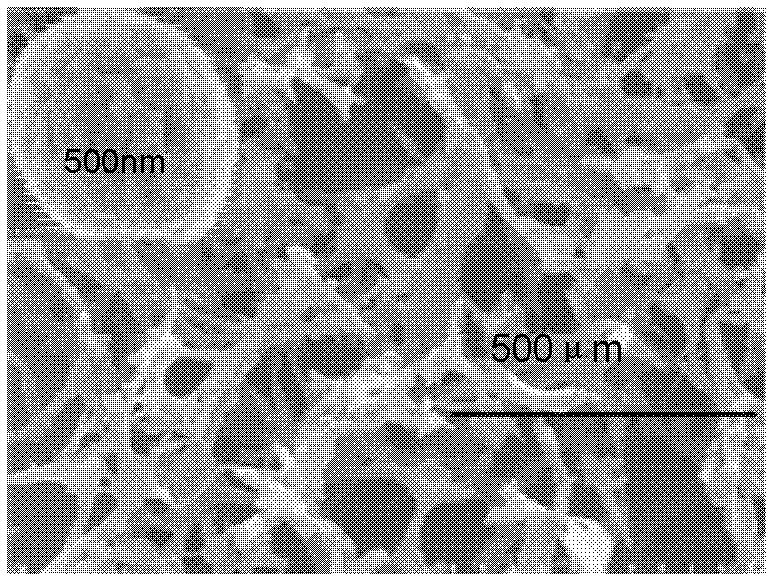

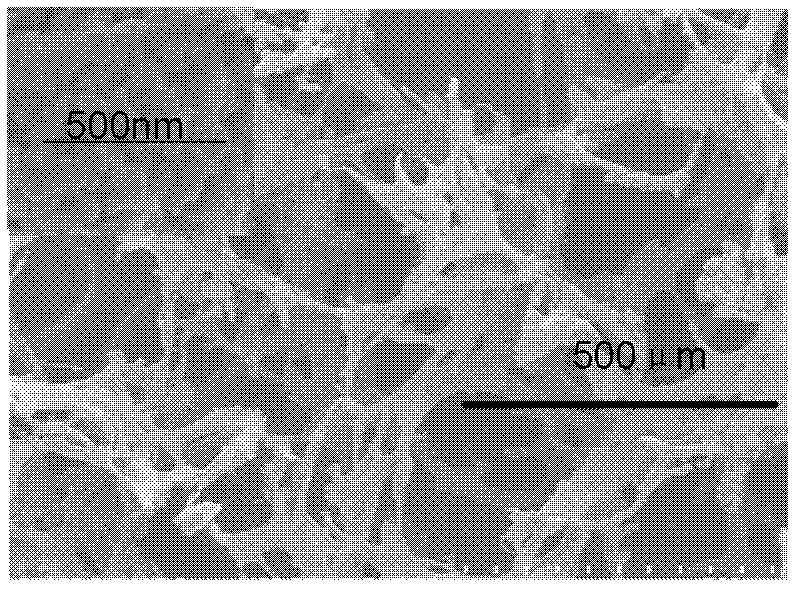

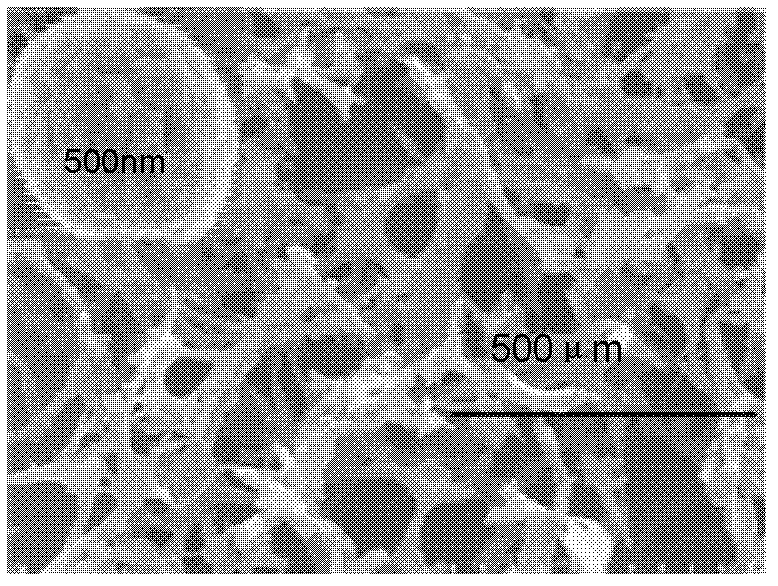

ActiveCN102512710AGood hole forming effectObvious fine structureProsthesisFine structureMaterials science

The invention provides a preparation method of porous three-dimensional silk fibroin material, comprising the following steps of concentrating a silk fibroin solution, and manufacturing a bracket by the processed silk fibroin solution through a salting out method. By utilizing the self-assembling behaviors of silk fibroin, a secondary structure of the silk fibroin is improved. Compared with other methods of obtaining porous brackets, not only can the pore-forming property be good but also the inner walls of pores are in a very obvious fine structure.

Owner:SUZHOU UNIV

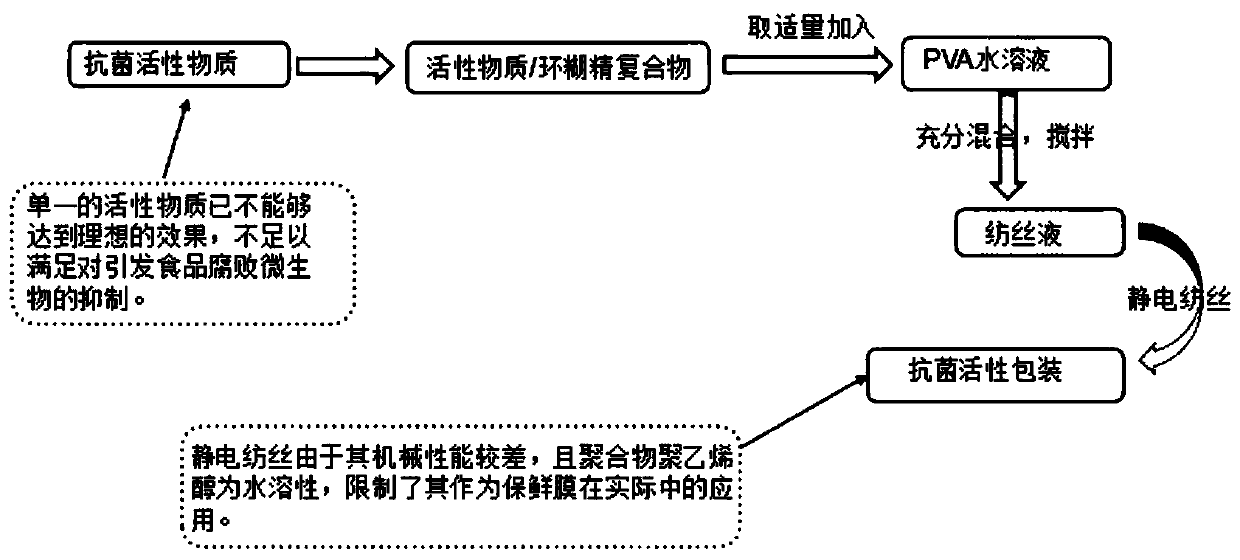

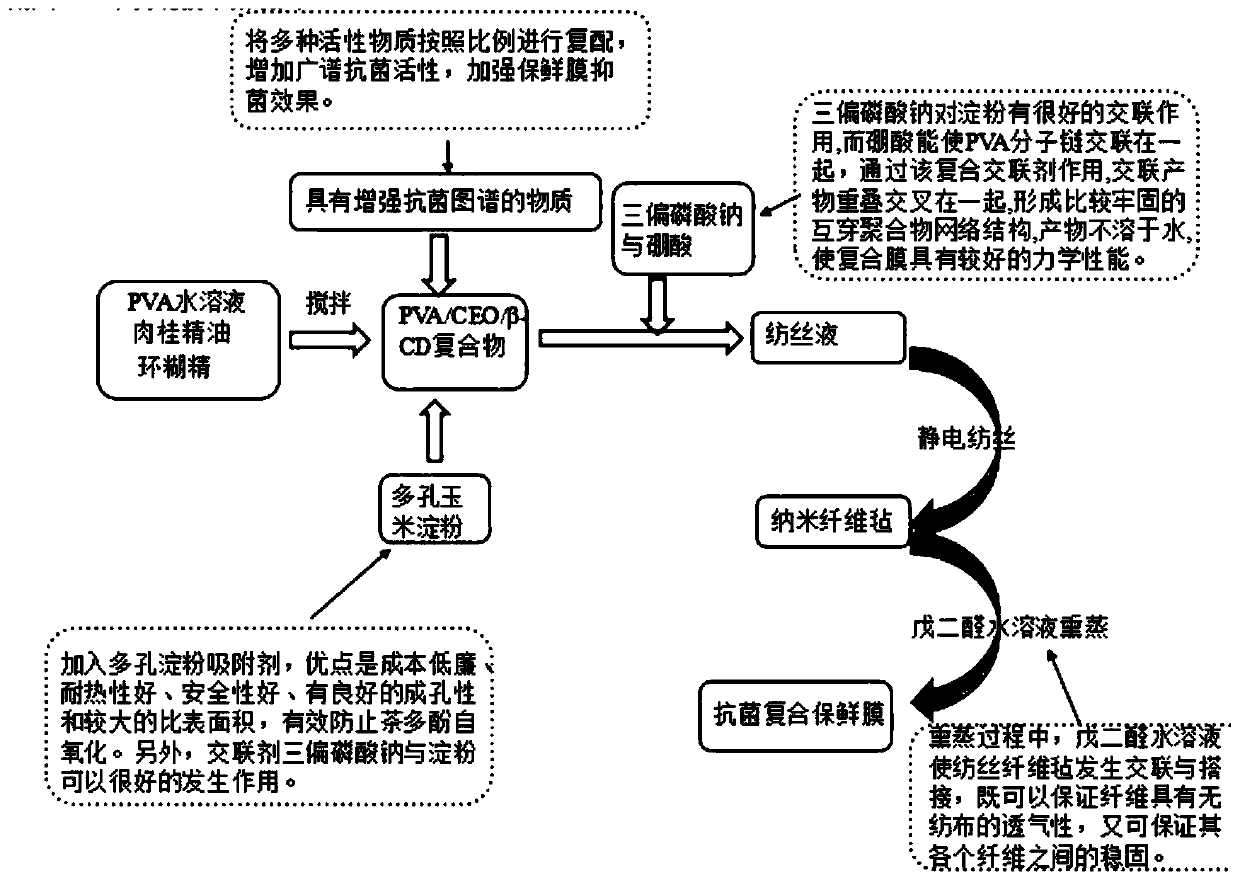

Preparation method of enhanced bacteriostatic and breathable composite fiber electrostatic spinning membrane

InactiveCN109881369AImprove the preservation effectExtended shelf lifeFibre typesMonocomponent synthetic polymer artificial filamentFiberCyclodextrin

The invention provides a preparation method of an enhanced bacteriostatic and breathable composite fiber electrostatic spinning membrane. The preparation method includes the following steps that 6-8 parts of polyvinyl alcohol are weighed and dissolved in 100 parts of 60-80 DEG C deionized water, and a PVA water solution is prepared; (2), 4 parts of active bacteriostatic substances are added into the PVC water solution, the active bacteriostatic substances are formed by mixing cinnamon essential oil, allicin, tea polyphenol and thyme essential oil according to the mass ratio of (2-4):(1-3):(0.5-2.5):(0.4-2.4), then 0.5-1.5 parts of cyclodextrin and 1-3 parts of corn porous starch are added, after the materials are fully mixed and stirred for 5-8 hours, 5-10 parts of sodium trimetaphosphateand boric acid complex are added for crosslinking, the sodium trimetaphosphate and boric acid complex is formed by compounding sodium trimetaphosphate and boric acid at the mass ratio of 4:5 until thesolution is uniform, and a spinning solution is obtained; (3), the spinning solution is arranged on an electrostatic spinning machine for spinning, and a spinning membrane is obtained; (4), the spinning membrane is subjected to glutaraldehyde fumigation crosslinking, and after the spinning membrane is dried in the air, the composite fiber electrostatic spinning membrane is obtained.

Owner:ZHEJIANG UNIV OF TECH

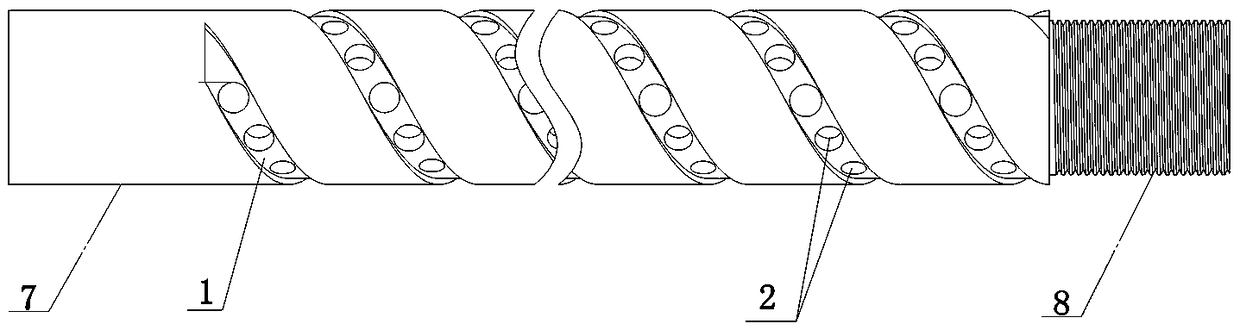

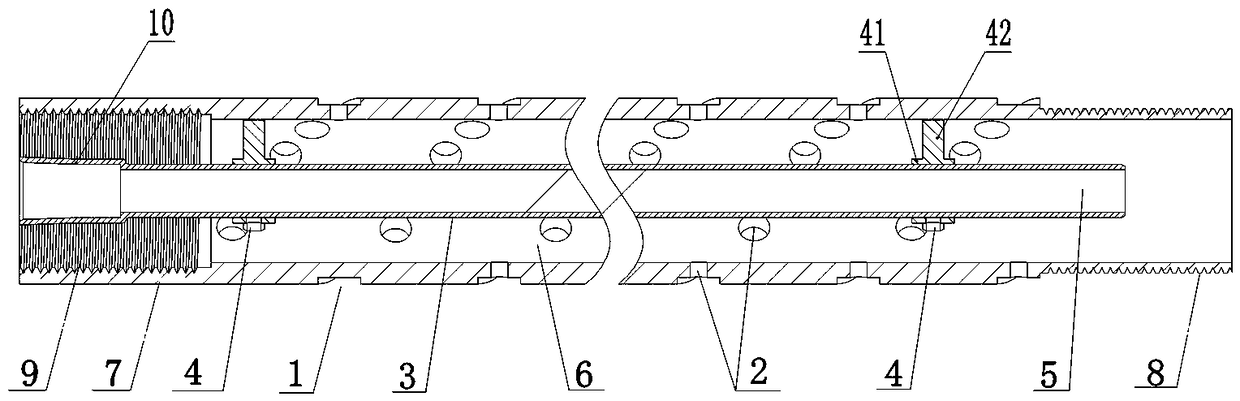

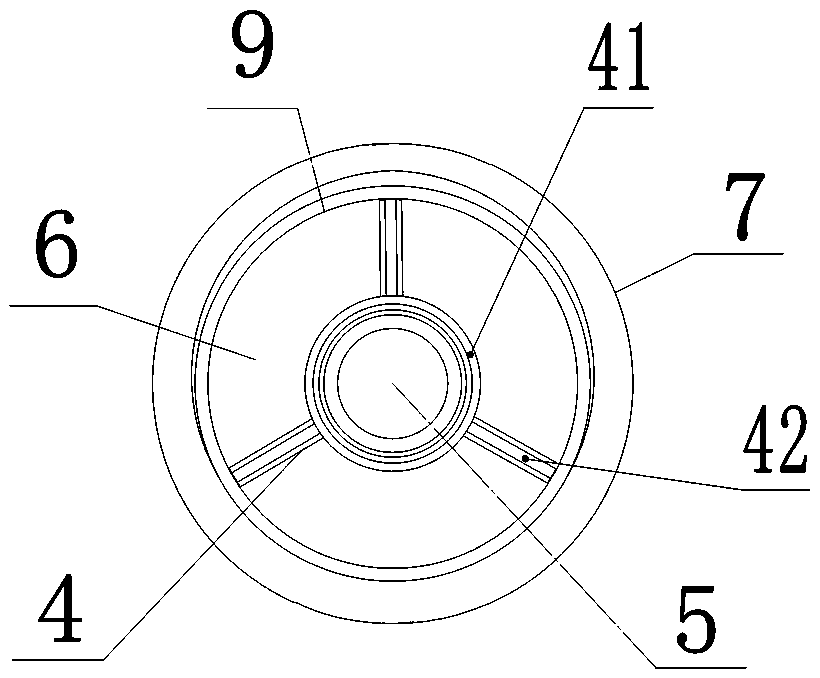

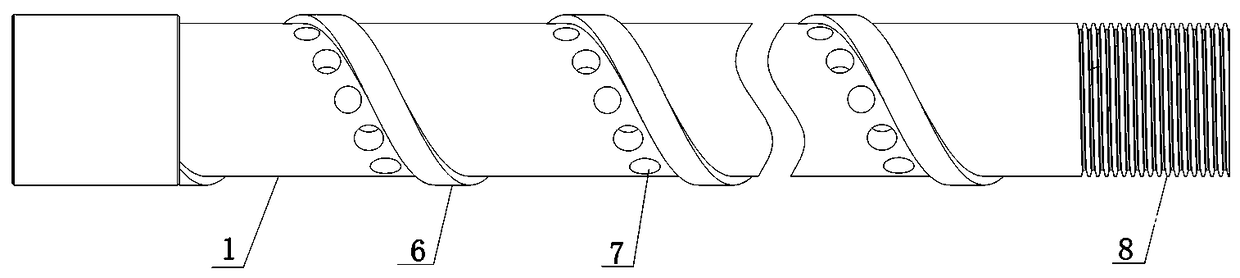

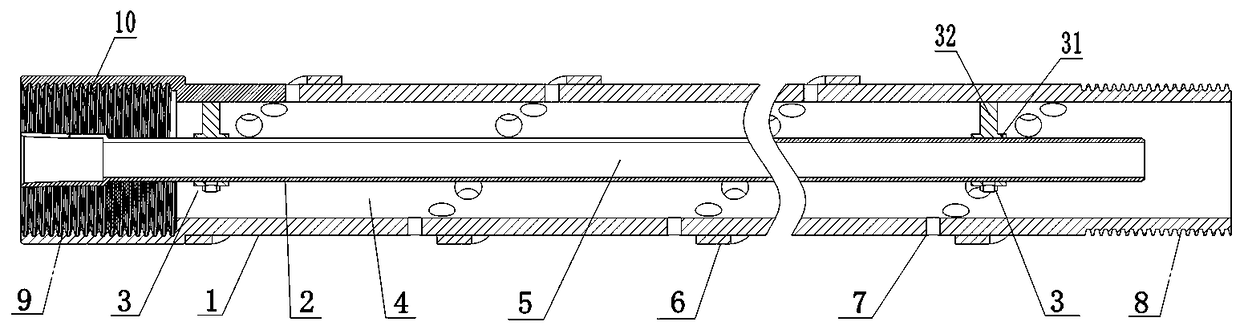

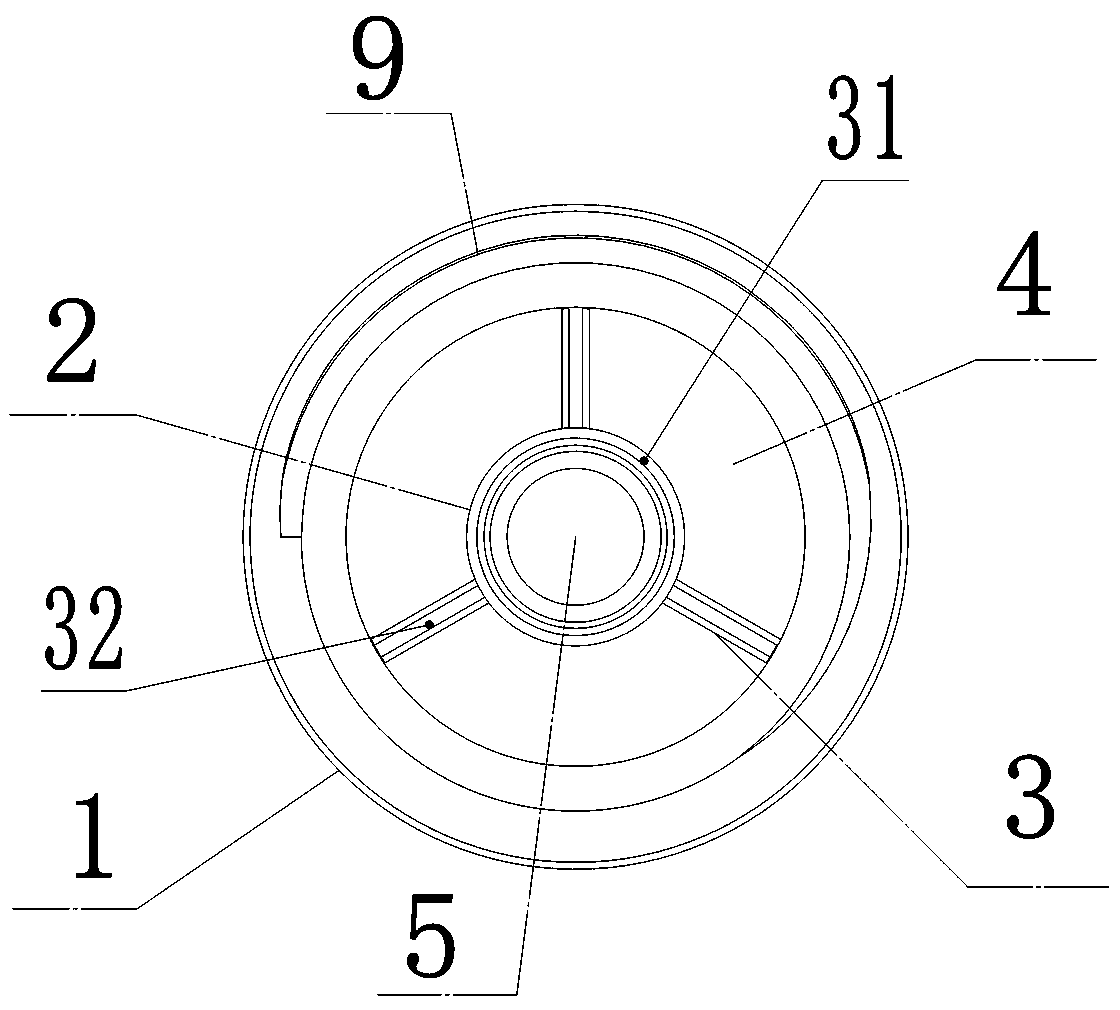

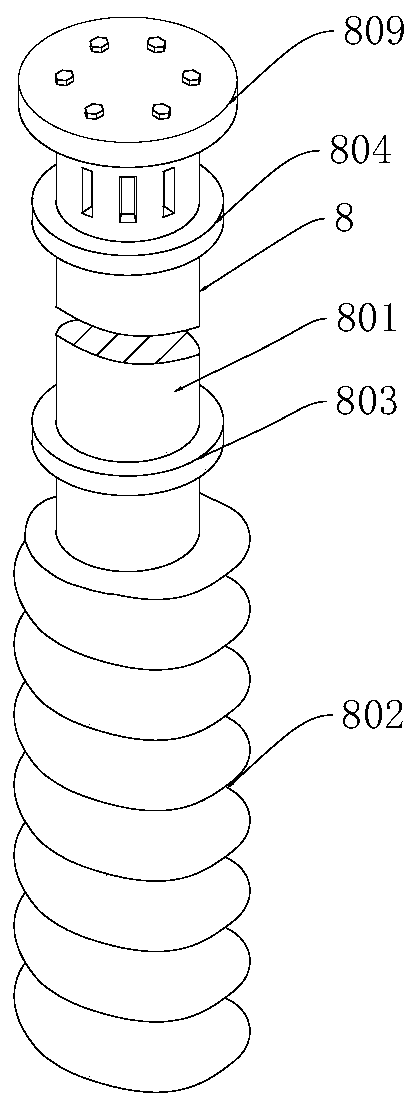

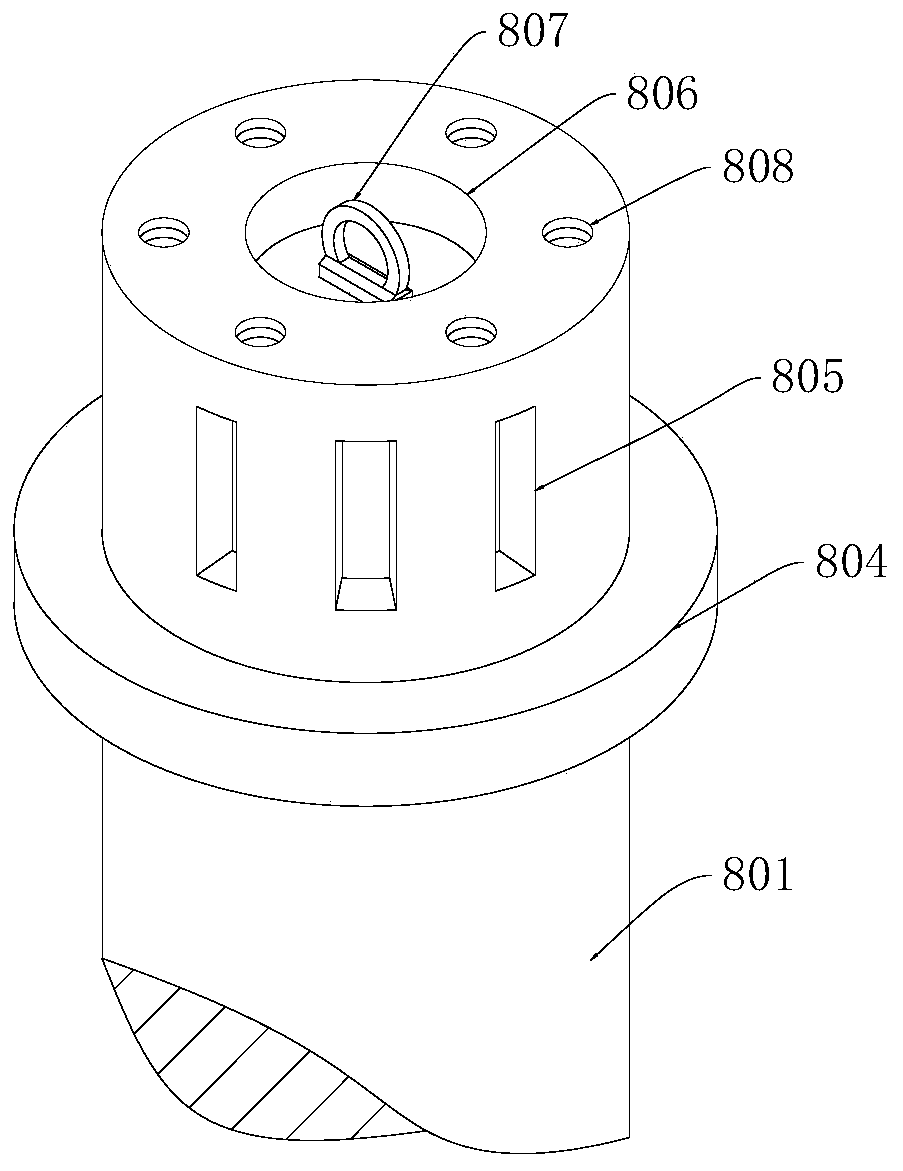

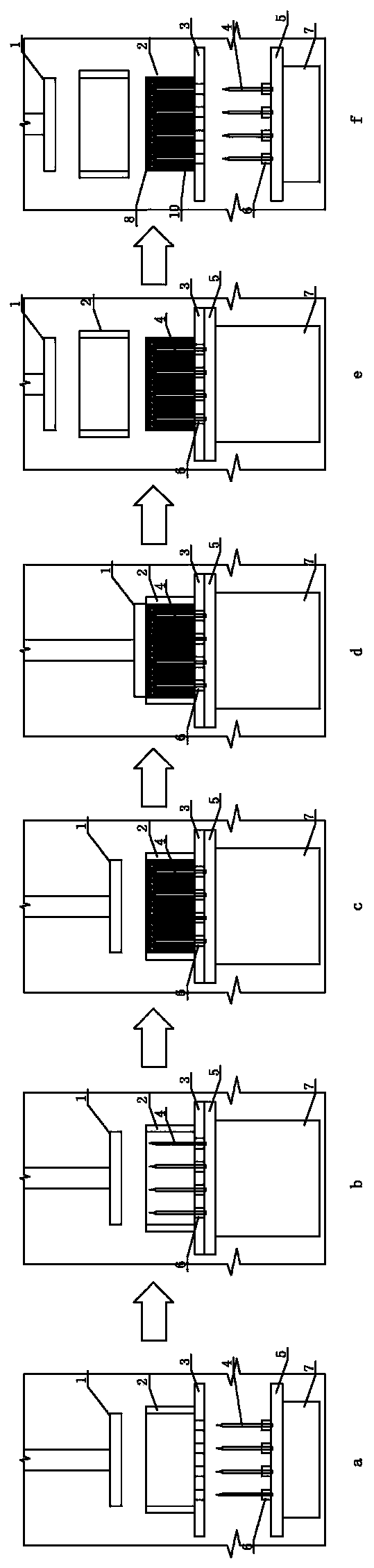

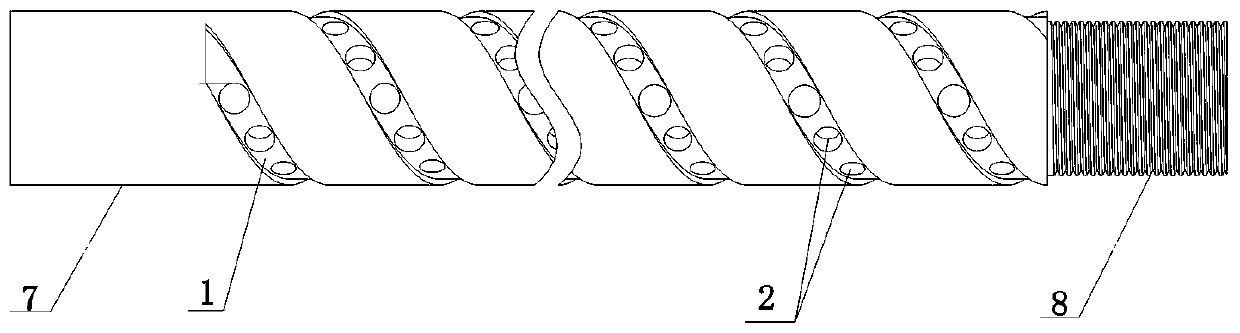

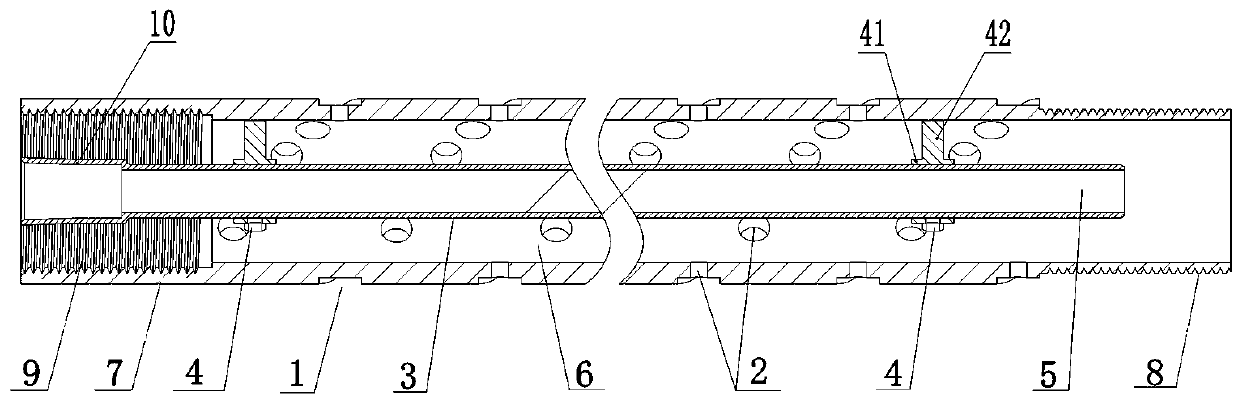

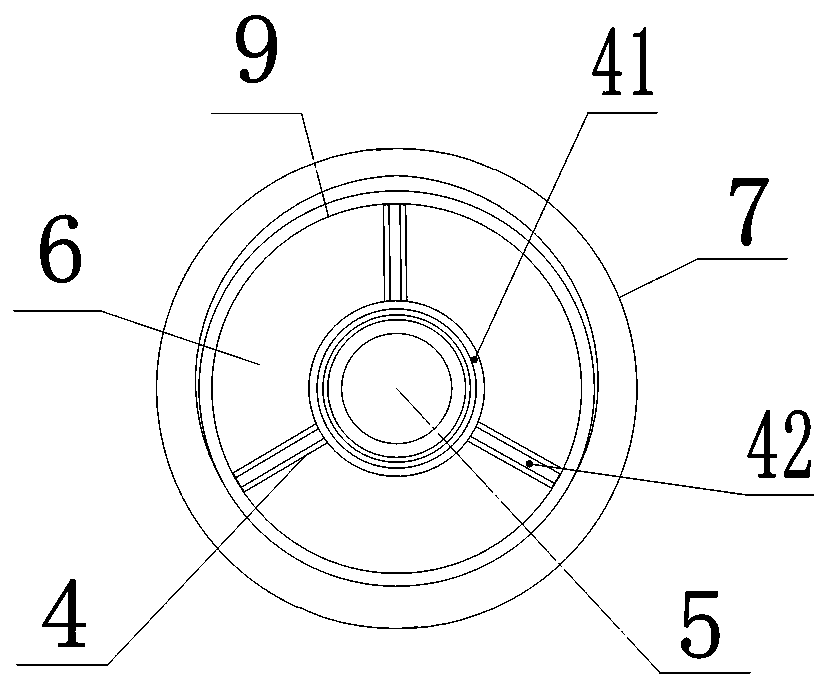

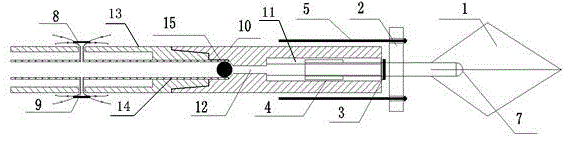

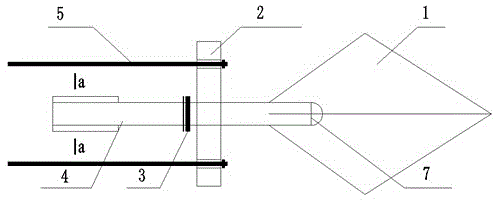

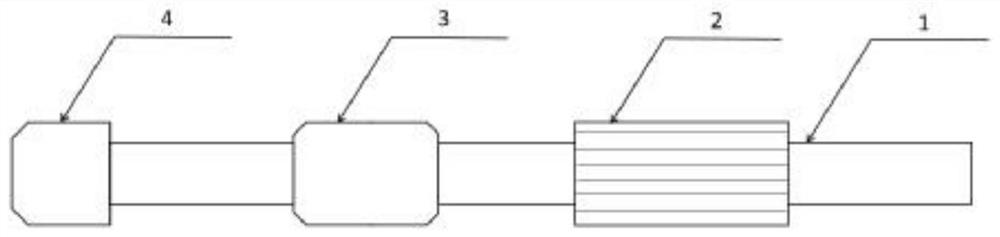

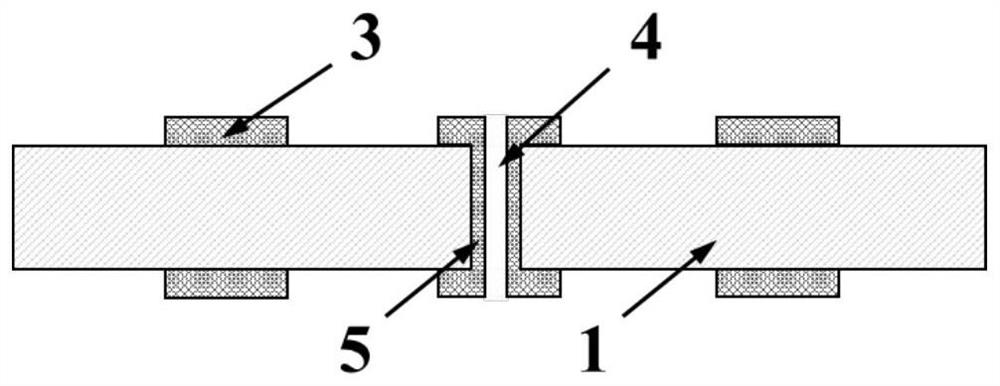

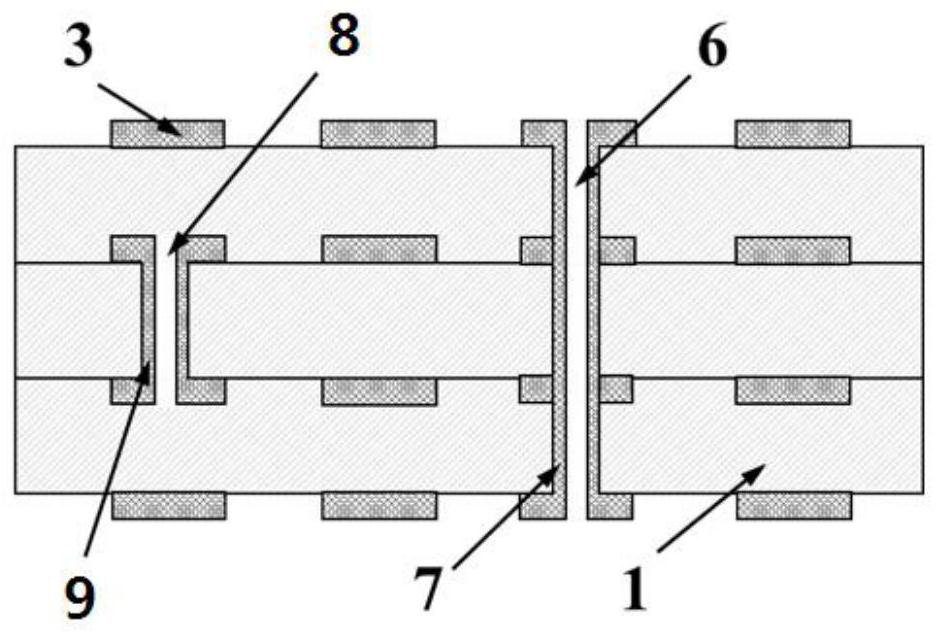

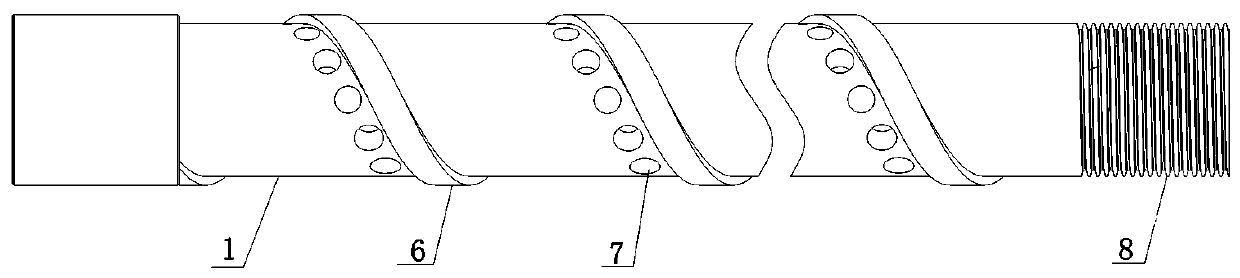

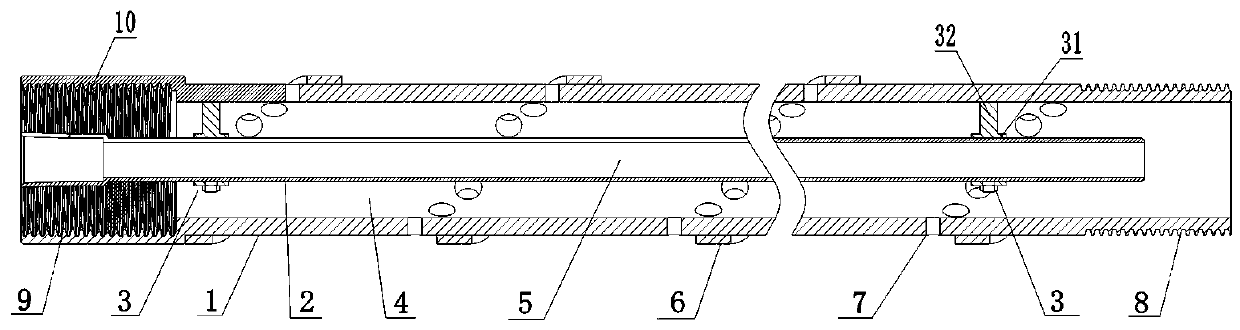

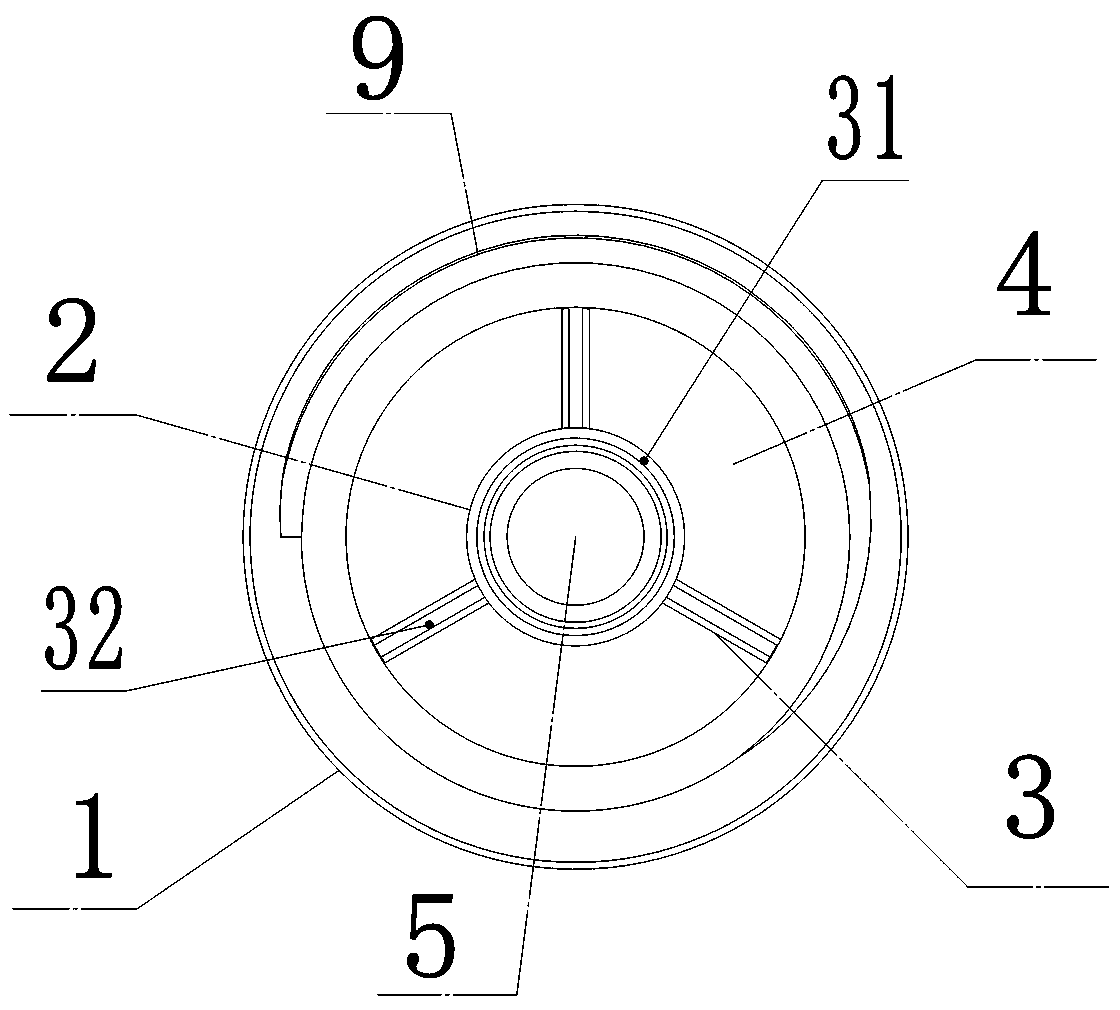

Drill rod with functions of hole protecting, pressure relief and internal slag discharging

ActiveCN108505955ASolve the problem of high drilling resistance and easy drill stickingReduce drilling resistanceDrilling rodsFlushingInlet channelSlag

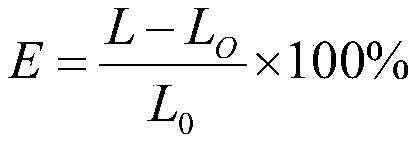

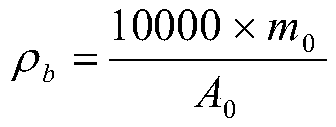

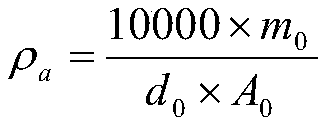

The invention discloses a drill rod with functions of hole protecting, pressure relief and internal slag discharging. The drill rod comprises hollow rod bodies, flow injecting pipes coaxially arrangedin the rod bodies, and supporting pieces connecting the rod bodies with the flow injecting pipes; slag discharging channels are formed between the inner walls of the rod bodies and the outer walls ofthe flow injecting pipes; the flow injecting pipes are internally provided with air inlet and water inlet channels; and with the direction opposite to the rotating direction during drilling of the drill rod bodies as the reverse direction, the outer cylindrical surfaces of the rod bodies are provided with spiral grooves rising in the reverse direction and in cylindrical spiral shapes, and a plurality of pressure relief holes communicating with inner cavities in the rod bodies are formed in the spiral grooves. During drilling of a soft coal seam and an outburst coal seam, the drill rod has theadvantages that the hole protecting ability is high, the slag discharging channels are not prone to being plugged, the hole forming effect is good, the slag discharging and temperature reducing abilities are high, and the hole collapse area is automatically dredged.

Owner:HENAN POLYTECHNIC UNIV

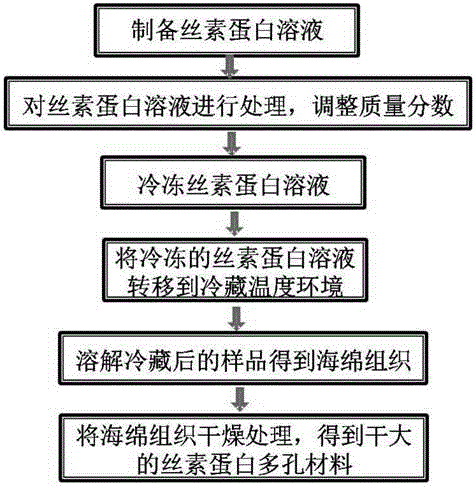

Preparation method of secondary structure controllable silk fibroin porous material with no need of organic solvent

InactiveCN105749343AGood hole forming effectSecondary structure is easy to controlPharmaceutical delivery mechanismProsthesisCross-linkFreeze-drying

Relating to the technical field of biological materials, the invention provides a preparation method of a silk fibroin three-dimensional porous material. The method includes: firstly subjecting a silk fibroin solution to freezing treatment, then conducting refrigeration treatment on a frozen sample, taking the sample out, performing thawing under room temperature condition to obtain a state wet three-dimensional porous material with stable structure, and conducting vacuum drying on the material by freeze-drying method so as to obtain a dried silk fibroin porous material. The technology can control the pore size, secondary structure composition, porosity and the like of the nano-porous material by changing the silk fibroin water solution concentration, freezing and refrigeration temperature, treatment time and other parameters. The preparation process involved in the invention is mild, has no need of any cross-linking agent, pore-forming agent or other toxic organic reagents, has green and controllable preparation conditions, and no waste residue, is green and pollution-free, and is easy for industrialization.

Owner:BEIHANG UNIV

Internal slag discharging drill rod provided with spiral convex ribs for cutting and holes for pressure relief

ActiveCN108798540AWith blockageSolve the problem of high drilling resistance and easy drill stickingDrilling rodsDrilling casingsInlet channelSlag

The invention discloses an internal slag discharging drill rod provided with spiral convex ribs for cutting and holes for pressure relief. The internal slag discharging drill rod comprises a hollow rod body, a flow injecting pipe coaxially arranged in the rod body, and a supporting piece for connecting the rod body with the flow injecting pipe. A slag discharging channel is formed between the inner wall of the rod body and the outer wall of the flow injecting pipe; an air inlet and water inlet channel is formed in the flow injecting pipe; with the direction opposite to the rotating direction of the drill rod body during drilling as the reverse direction, the spiral convex ribs ascending in a cylindrical spiral shape in the reverse direction are arranged on the outer cylindrical face of therod body; and the multiple pressure relief holes are formed in the outer cylindrical face of the rod body along one sides of the spiral convex ribs. If hole collapse occurs during drilling, coal slagcan enter the slag discharging channel through the pressure relief holes, the acting force of the coal slag on the drill rod is released, meanwhile, the spiral convex ribs have the hole raking capability, and thus the coal slag is in a loose state and enters the slag discharging channel through the pressure relief holes till the hole collapse area is smooth.

Owner:HENAN POLYTECHNIC UNIV

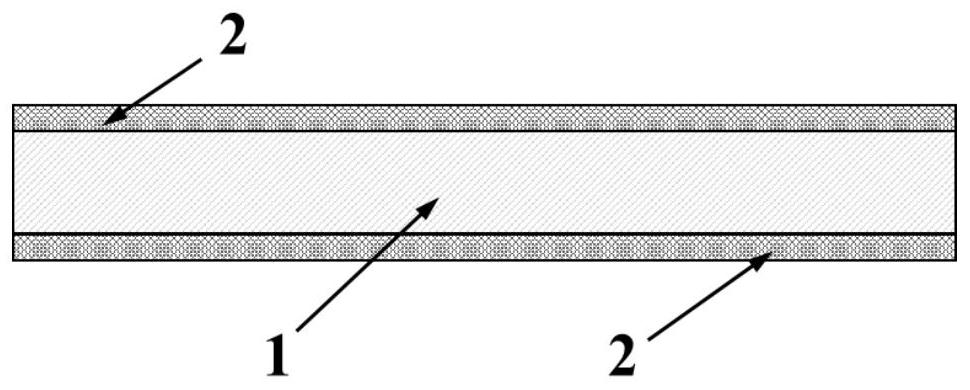

Electrolyte resistant wrinkle lithium ion battery diaphragm preparation method and prepared diaphragm

ActiveCN109702977AStress Reduction Phenomenon ResistanceAvoid wrinklesCell component detailsWrinkle skinPhysical chemistry

The invention provides an electrolyte resistant wrinkle lithium ion battery diaphragm preparation method. The electrolyte resistant wrinkle lithium ion battery diaphragm preparation method comprises the following steps that polypropylene raw materials are provided; the polypropylene raw materials are melted and extruded, a piece is made into a diaphragm by casting, and cooling is performed to obtain a diaphragm piece; heat treatment is performed on the diaphragm piece to make the diaphragm piece be perfect in crystallization, and then the cooling is performed; the diaphragm piece is subjectedto cold stretching to form microdefects, and then hot- stretching pore broadening is performed; heat shaping is performed on the stretched diaphragm piece; and natural cooling annealing is performed on the diaphragm piece after the heat shaping to obtain a lithium ion battery diaphragm finished product. According to the electrolyte resistant wrinkle lithium ion battery diaphragm preparation method, the melt index of the polypropylene raw materials is 0.8-1.8 g / 10min, the isotacticity is 98-99%, the number-average molar mass is 410000-480000, and in the stretching step, the cold stretching temperature is 80-100 DEG C, the cold stretching multiple ratio is 1.03-1.07, the hot stretching temperature is 135-145 DEG C, and the hot stretching multiple ratio is 3-5. The invention further providesan electrolyte resistant wrinkle lithium ion battery diaphragm obtained by the electrolyte resistant wrinkle lithium ion battery diaphragm preparation method.

Owner:深圳市博盛新材料有限公司

Porous hollow fiber membrane, method for producing the same, and filtration method

InactiveUS20190022601A1Good hole forming effectGood chemical resistanceSemi-permeable membranesMembranesFiberPhosphoric Acid Esters

A porous hollow fiber membrane includes at least a first solvent and a second solvent. The first solvent is at least one selected from sebacic acid esters, citric acid esters, acetyl citric acid esters, adipic acid esters, trimellitic acid esters, oleic acid esters, palmitic acid esters, stearic acid esters, phosphoric acid esters, C6-C30 fatty acids, and epoxidized vegetable oils. The second solvent is different from the first solvent, and is at least one selected from sebacic acid esters, citric acid esters, acetyl citric acid esters, adipic acid esters, trimellitic acid esters, oleic acid esters, palmitic acid esters, stearic acid esters, phosphoric acid esters, C6-C30 fatty acids, and epoxidized vegetable oils. The porous hollow fiber membrane has a three-dimensional network structure.

Owner:ASAHI KASEI KK

Preparation method of composite hollow fiber membrane

InactiveCN104667761AHigh initial fluxImprove mechanical propertiesSemi-permeable membranesFiberPhase conversion

The invention relates to a preparation method of a composite hollow fiber membrane. The preparation method is characterized by comprising the following steps: preparing a casting membrane solution; preparing a core solution and an external gel bath; spinning hollow fibers: injecting the core solution and the casting membrane solution into spinning nozzles together by utilizing dry-wet spinning equipment and extruding the core solution and the casting membrane solution from the spinning nozzles together to prepare hollow fiber membrane silk; and after the hollow fiber membrane silk obtained in the above step passes through a 0-35cm dry spinning path, enabling the hollow fiber membrane silk to enter a first gel bath and a second gel bath to undergo gel phase conversion, thus forming the polymer hollow fiber porous membrane with microchannels. The composite hollow fiber membrane prepared by the method is a hydrophilic hollow membrane material, has higher membrane flux under low pressure, has good pollution resistance and also has better mechanical strength due to the complementarity of the raw materials.

Owner:WATER CODE MEMBRANE TECH CO LTD

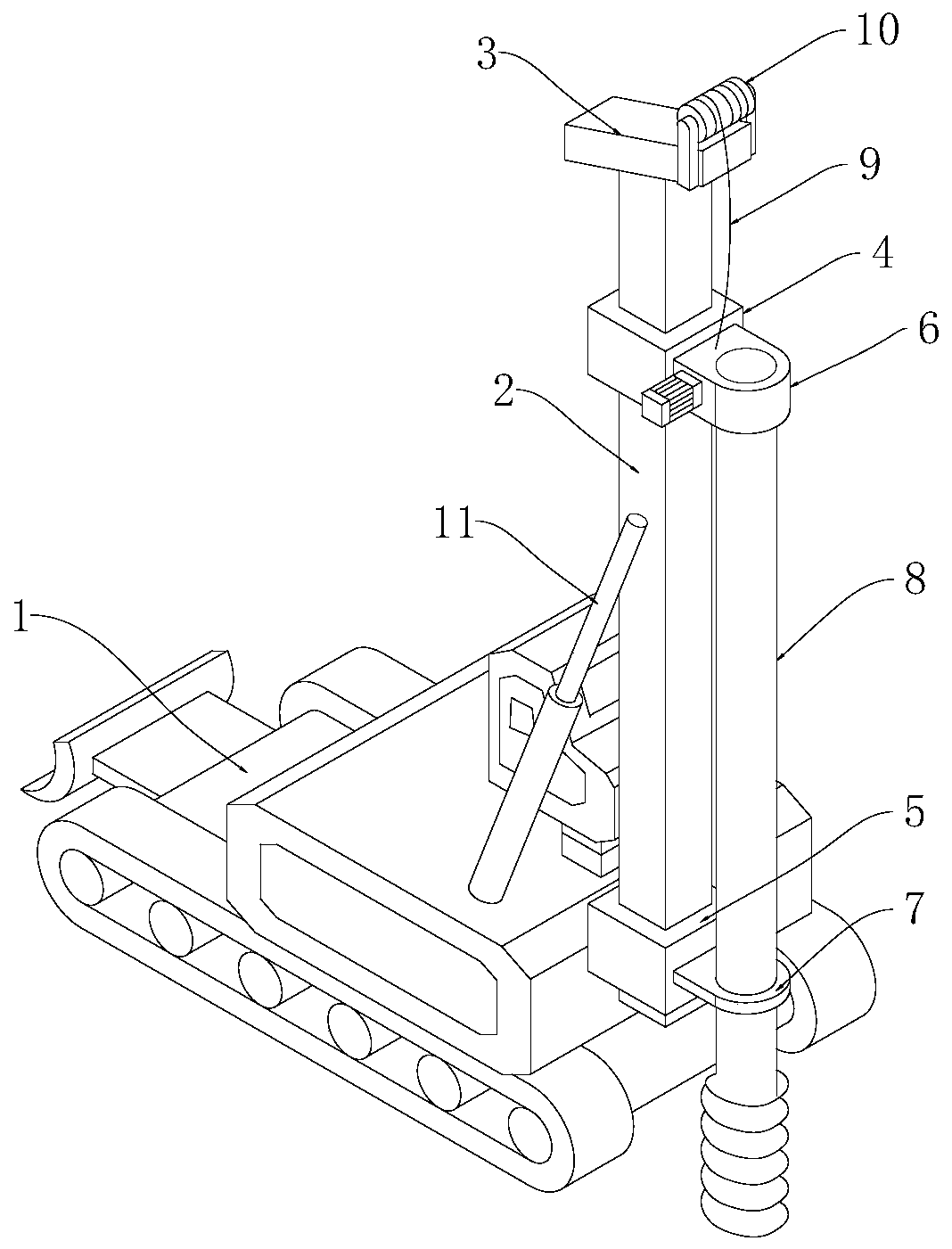

Drill rod spiral composite drilling machine for building

ActiveCN109779523AReduce power loadGood hole forming effectSpadesDrilling rodsEngineeringDrilling machines

The invention discloses a drill rod spiral composite drilling machine for a building. The machine comprises a cart body; a stand column is arranged on the vehicle body; a limiting sleeve is arranged on a fixing block; the middle part of the limiting sleeve is sleeved with a screw mechanism; a rod body is movably inserted into the middle part of the limiting sleeve; a rotary excavating drilling bit, a first baffle ring, a second baffle ring, the limiting groove and the groove are sequentially formed in the surface of the rod body from bottom to top; a lifting ring is arranged in the groove; a threaded hole is formed in the surface of the top end of the rod body; the top of the rod body is fixedly connected with a cover plate through the threaded hole and the connecting screw rod in the threaded hole; when the rotary excavating drill bit and the rod body with the structure are used for forming a hole, the hole can be drilled; the soil body at the bottom is loose; when concrete is pouredthrough external concrete filling equipment, loose soil moves upwards under the spiral effect, so that the hole wall is smooth and firm, the hole forming effect is very good, hole collapse is avoided,and the hole wall is smooth under the effect of underground water; when the concrete is poured through the external concrete filling equipment, the friction resistance is very small when the rod bodydrives the soil upwards, and the power load of the driving motor is greatly reduced.

Owner:LIAOCHENG YELLOW RIVER ENG BUREAU

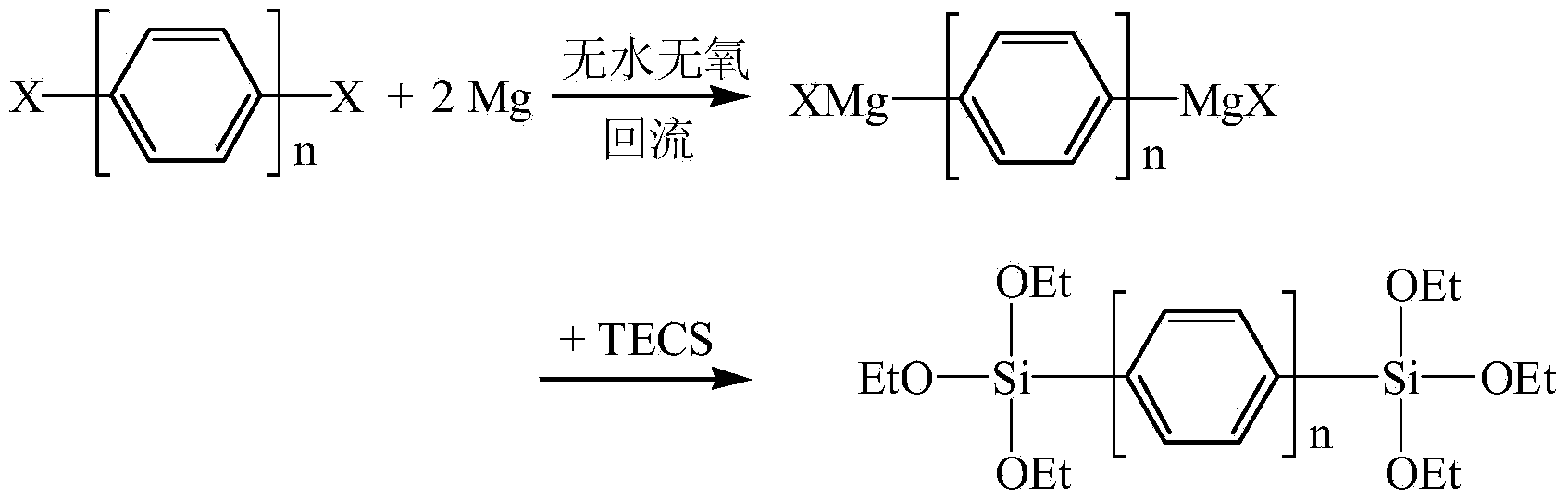

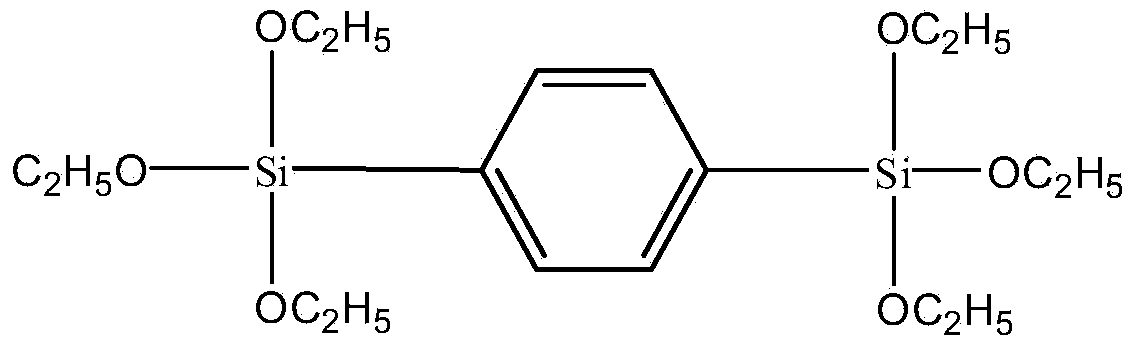

Aryl bridged silsesquioxane monomer and preparation method thereof

InactiveCN103450247AGood hole forming effectImprove high temperature resistanceGroup 4/14 element organic compoundsGrignard reagentGrignard reaction

The invention discloses a preparation method of an aryl bridged silsesquioxane monomer. The preparation method comprises the following steps: performing Grignard reaction on dihalogenated arene and metal magnesium to prepare a Grignard reagent; performing nucleophilic substitution reaction on the Grignard reagent and triethoxychlorosilane to produce the aryl bridged silsesquioxane monomer. In the reaction, triethoxychlorosilane serves as a reaction raw material, so the reaction has low activation energy and strong specificity, the yield of the aryl bridged silsesquioxane monomer is high, and aryl bridged polysilsesquioxanes prepared from the prepared aryl bridged silsesquioxane monomer through hydrolysis-polycondensation has excellent pore-forming property and high-temperature resistance.

Owner:HEFEI UNIV

Preparation method of porous three-dimensional silk fibroin material

ActiveCN102512710BGood hole forming effectObvious fine structureProsthesisFine structureMaterials science

Owner:SUZHOU UNIV

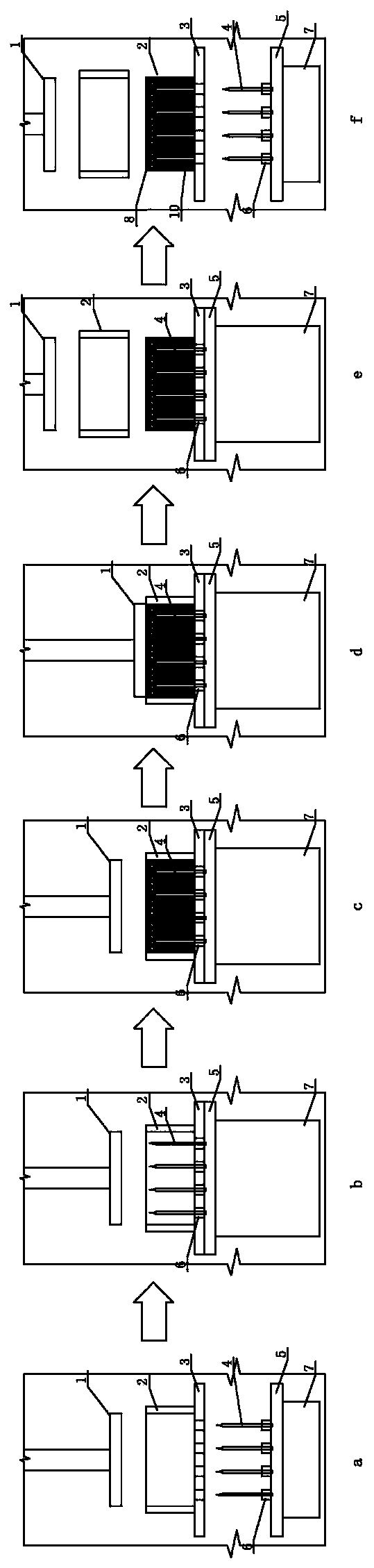

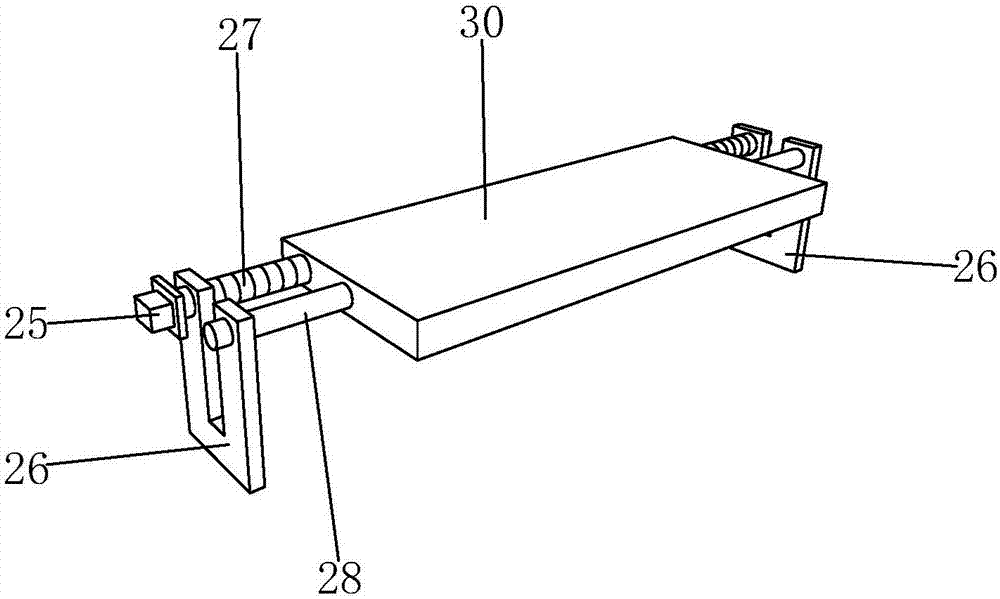

Tray hole piercing and guiding device and guide hole permeable brick preparation method

PendingCN109910136ASimple installationGood hole forming effectMouldsShaping press ramHole makingBiomedical engineering

The invention provides a tray piercing guide hole device and a guide hole permeable brick preparation method. The guide hole device is composed of a chassis, guide hole needles and a lifting system. The guide hole needles are distributed on the chassis according to a certain arrangement spacing, tips of the needles are vertical and upward, and the lifting system is arranged under the chassis. According to the distribution of the guide hole needles on the guide hole device, a tray is pre-pierced, the guide hole device enables the guide hole needles to penetrate through the tray until the chassis is attached closely to the piercing tray by lifting the lifting system, and permeable bricks are formed by twice material distributing and one time compacting; and finally, the lifting device drivesthe chassis down, the guide hole needles are pulled out from the permeable bricks, guide hole permeable hole channels are formed in structural layers, and the permeable bricks of tray piercing guideholes are manufactured. The permeable bricks use artificial hole making, the pore connectivity is good, and the problem that the strength and permeability of traditional permeable bricks are incompatible is solved; and the guide hole device is suitable for any brick machines as an independent whole, and the hole forming effect can be achieved without the modification of the brick machines.

Owner:CHINA UNIV OF MINING & TECH

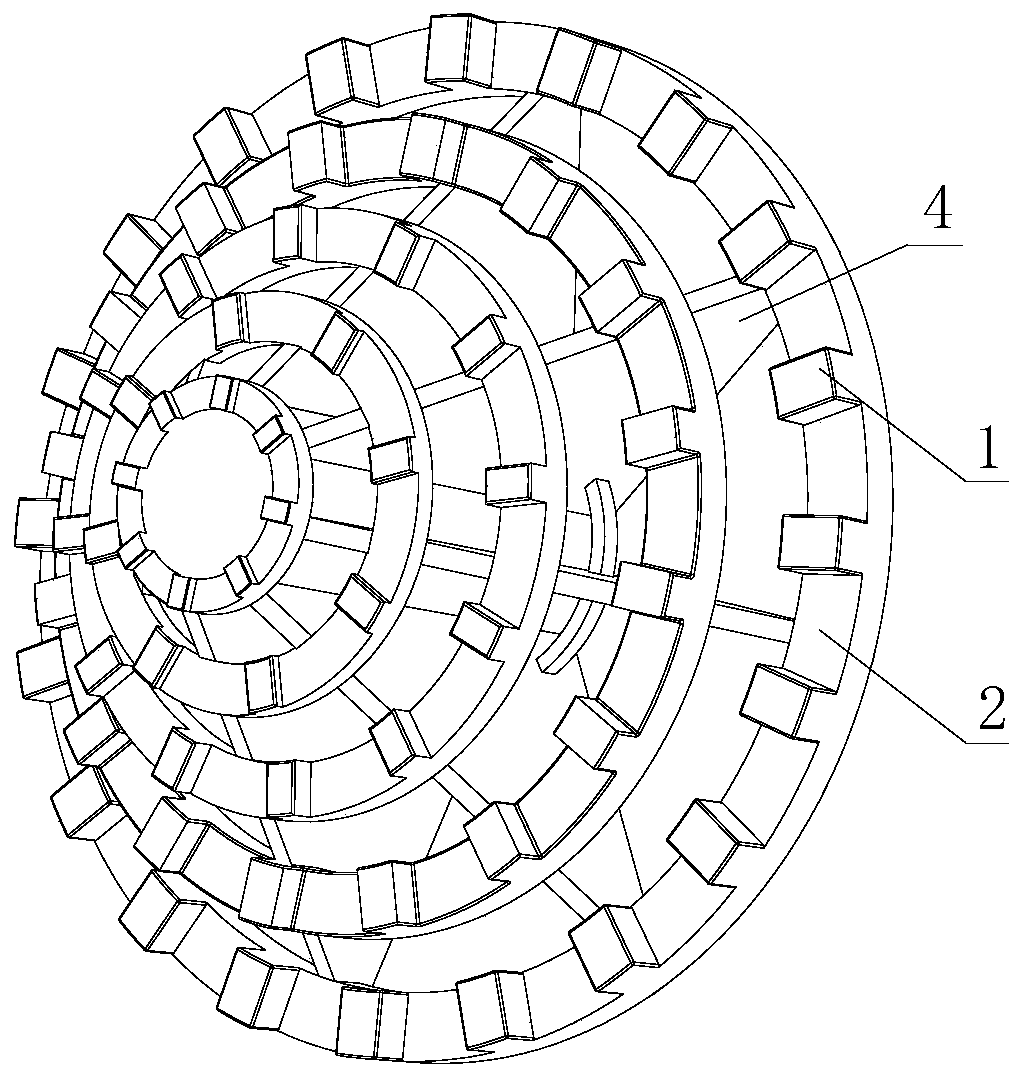

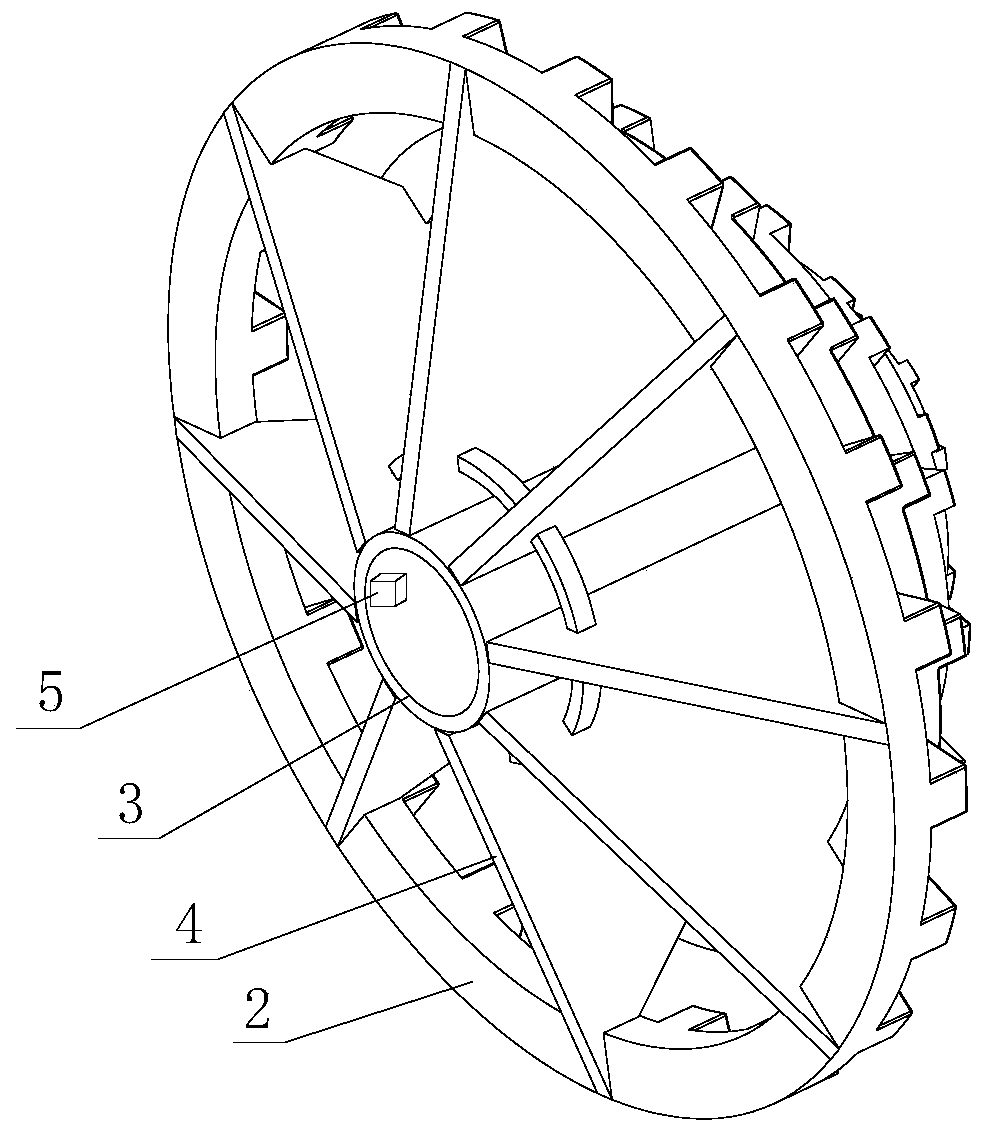

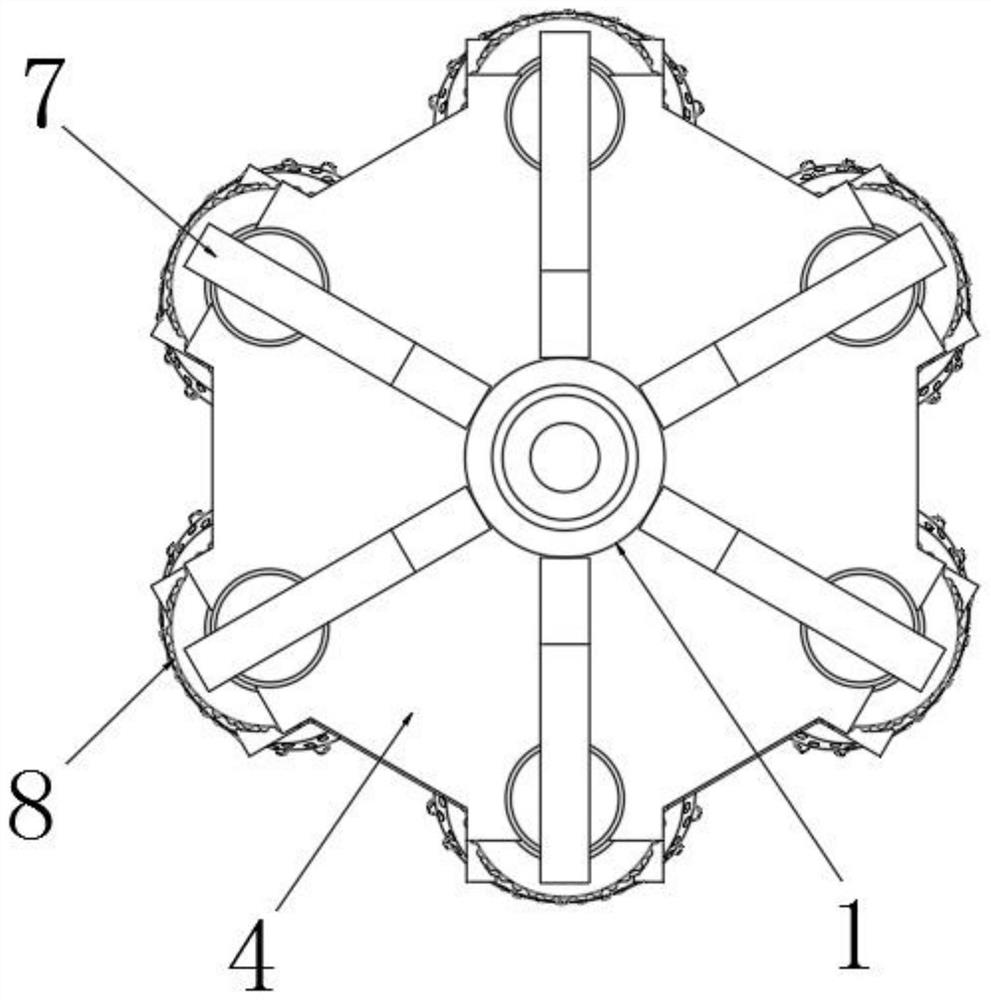

Hollow impact drill

InactiveCN110259387AAvoid smashingImprove punching efficiencyDrill bitsBridge erection/assemblyEngineeringDrill

The invention relates to a hollow impact drill, and belongs to the field of civil engineering and bridge pile foundation construction. The hollow impact drill comprises a gravity cylinder, a plurality of gravity plates and a plurality of annular gravity rings of different diameters, the gravity cylinder is located in the center of the hollow impact drill, and the circular gravity rings and the gravity cylinder are coaxially arranged; the annular gravity rings of the different diameters are arranged stepwise in the length direction of the gravity cylinder from small to large, and gaps exist between the every adjacent two annular gravity rings, and a plurality of hammer teeth are arranged on the working faces of the annular gravity rings. The working faces are in contact with the ground when the hollow impact drill works; the gravity cylinder and the annular gravity rings are fixed by the gravity plates, and the gravity plates are evenly distributed on the periphery of the gravity cylinder. According to the hollow impact drill, the one-time hole forming effect is enabled to be better in the piling process, the probability of the hole shifting is reduced, and the piling efficiency is improved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +2

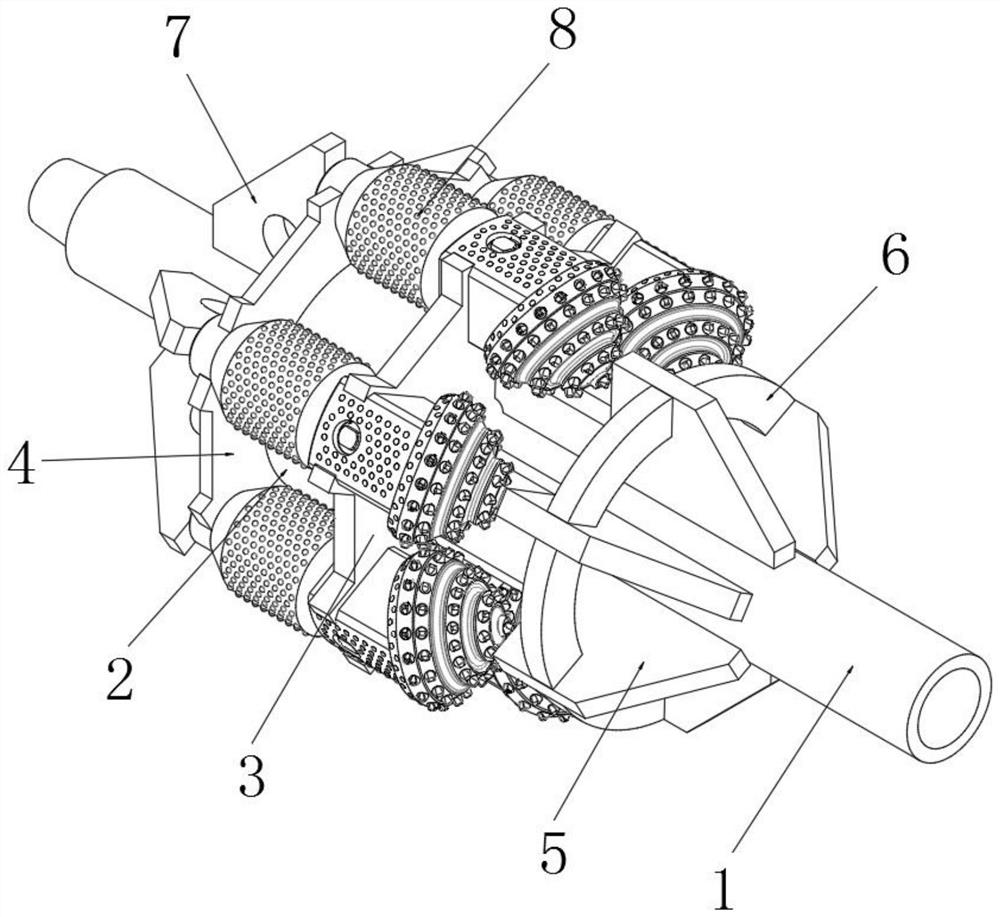

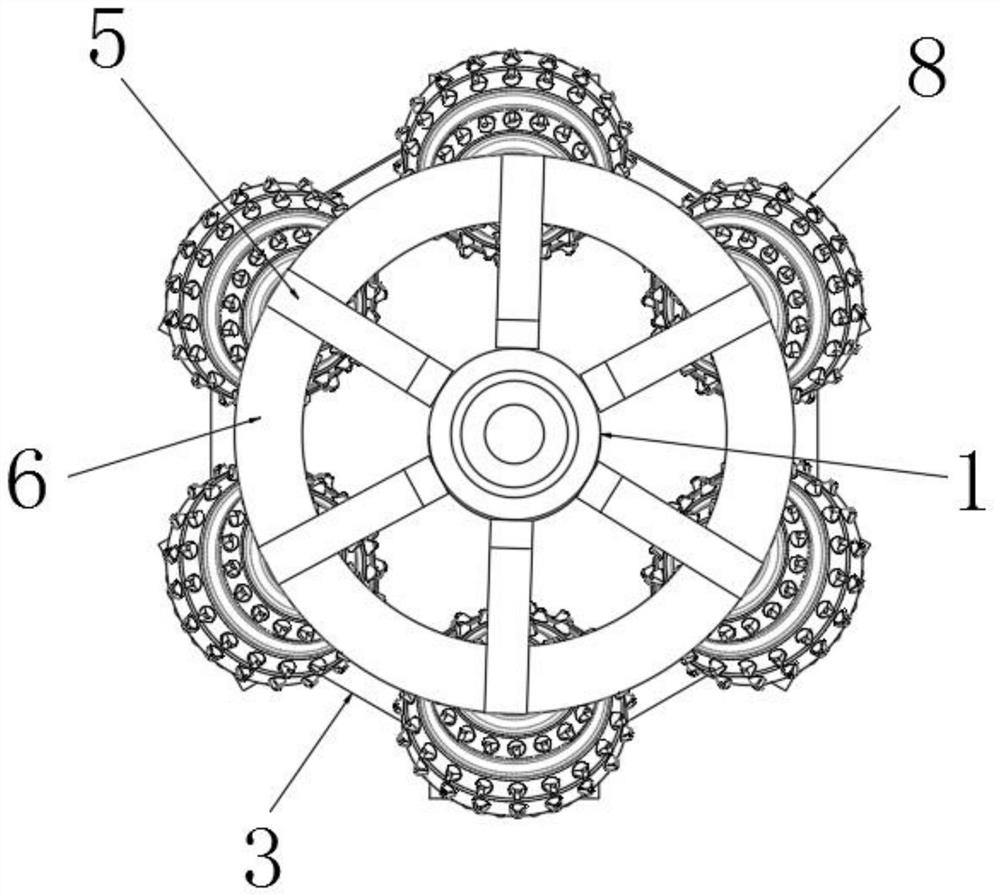

Pure rolling supporting and cutting integrated reamer bit

PendingCN113279698AExtended service lifePlay a protective effectDrill bitsDrilling rodsStructural engineeringReamer

The invention discloses a pure rolling supporting and cutting integrated reamer bit, and relates to the technical field of pipeline crossing construction. The reamer bit comprises a reamer bit body and further comprises a plurality of cutting units; the cutting units are arranged in the circumferential direction of the reamer bit body; the cutting units are arranged on the reamer bit body in a double-fulcrum supporting mode; the reamer bit body comprises a mandrel; a cylinder is sleeved on the mandrel; an upper cover plate is arranged on one side of the cylinder; and a lower supporting plate is arranged on the other side of the cylinder. According to the pure rolling supporting and cutting integrated reamer bit, the multiple cutting units are directly arranged on the reamer bit body, so that the installation of a centralizer is omitted, and the reamer bit and the centralizer are combined into a whole; and sliding friction between a drilling tool and the bottom of a hole is changed into pure rolling, so that the overall weight of a reaming drilling tool combination and the jumping in the cutting process are reduced, torque is reduced, the cutting units are fixed on the reamer bit body in a double-fulcrum supporting mode, the stability is better, the service life of the cutting units is prolonged, and the production cost is saved.

Owner:天津博为中天钻具有限公司

Composite hollow fiber membrane

ActiveCN103463996AHigh initial fluxImprove mechanical propertiesSemi-permeable membranesHollow fibrePorous membrane

The invention relates to a composite hollow fiber membrane. The composite hollow fiber membrane is characterized by comprising the following steps: preparing a membrane casting solution; preparing a core solution and an outer gel bath; utilizing a dry-wet spinning device to inject the core solution and the membrane casting solution into a spinneret together for hollow fiber spinning, and extruding from the spinneret together to prepare a hollow fiber membrane wire; and enabling the hollow fiber membrane wire obtained in the step to pass a dry spinning path of 0-35cm and sequentially enter a first gel bath and a second gel bath for gel phase inversion to form the high polymer hollow fiber porous membrane with a microprous pore canal. The composite hollow fiber membrane prepared by the method disclosed by the invention is a hydrophilic hollow membrane material and has higher membrane flux and good pollution resistance at low pressure; simultaneously, the hollow fiber membrane has better mechanical strength due to the complementary property of the raw materials.

Owner:5ELEM HI TECH CORP

A hole protection drill pipe for pressure relief and internal slag discharge

ActiveCN108505955BSolve the problem of high drilling resistance and easy drill stickingReduce drilling resistanceDrilling rodsFlushingThermodynamicsSlag

The invention discloses a drill rod with functions of hole protecting, pressure relief and internal slag discharging. The drill rod comprises hollow rod bodies, flow injecting pipes coaxially arrangedin the rod bodies, and supporting pieces connecting the rod bodies with the flow injecting pipes; slag discharging channels are formed between the inner walls of the rod bodies and the outer walls ofthe flow injecting pipes; the flow injecting pipes are internally provided with air inlet and water inlet channels; and with the direction opposite to the rotating direction during drilling of the drill rod bodies as the reverse direction, the outer cylindrical surfaces of the rod bodies are provided with spiral grooves rising in the reverse direction and in cylindrical spiral shapes, and a plurality of pressure relief holes communicating with inner cavities in the rod bodies are formed in the spiral grooves. During drilling of a soft coal seam and an outburst coal seam, the drill rod has theadvantages that the hole protecting ability is high, the slag discharging channels are not prone to being plugged, the hole forming effect is good, the slag discharging and temperature reducing abilities are high, and the hole collapse area is automatically dredged.

Owner:HENAN POLYTECHNIC UNIV

Preparation method of composite hollow fiber membrane

ActiveCN104689725AHigh initial fluxImprove mechanical propertiesSemi-permeable membranesHollow fibre membranePhase conversion

The invention relates to a preparation method of a composite hollow fiber membrane. The preparation method is characterized by comprising the following steps: preparing membrane casting liquid; preparing core liquid and external gel bath; injecting the core liquid and the membrane casting liquid together into a spinning nozzle by utilizing a dry-wet spinning device, and extruding together from the spinning nozzle so as to prepare a hollow fiber membrane filament; carrying out dry spinning on the hollow fiber membrane filament prepared in the previous step in a dry spinning path of 0-35cm, and carrying out gel phase conversion sequentially in first gel bath and second gel bath so as to form a macromolecule hollow fiber porous membrane with a micro duct. The composite hollow fiber membrane prepared by the invention is a hydrophilic hollow membrane material, has relatively high membrane flux at low pressure, is good in pollution resistance, and meanwhile has relatively good mechanical intensity because of complementarity of raw materials.

Owner:徐州洁诚环保科技有限公司

Preparation method of composite hollow fiber membrane

InactiveCN104667760AHigh initial fluxImprove mechanical propertiesSemi-permeable membranesFiberPhase conversion

The invention relates to a preparation method of a composite hollow fiber membrane. The preparation method is characterized by comprising the following steps: preparing a casting membrane solution; preparing a core solution and an external gel bath; spinning hollow fibers: injecting the core solution and the casting membrane solution into spinning nozzles together by utilizing dry-wet spinning equipment and extruding the core solution and the casting membrane solution from the spinning nozzles together to prepare hollow fiber membrane silk; and after the hollow fiber membrane silk obtained in the above step passes through a 0-35cm dry spinning path, enabling the hollow fiber membrane silk to enter a first gel bath and a second gel bath to undergo gel phase conversion, thus forming the polymer hollow fiber porous membrane with microchannels. The composite hollow fiber membrane prepared by the method is a hydrophilic hollow membrane material, has higher membrane flux under low pressure, has good pollution resistance and also has better mechanical strength due to the complementarity of the raw materials.

Owner:广州市宇艺包装材料有限公司

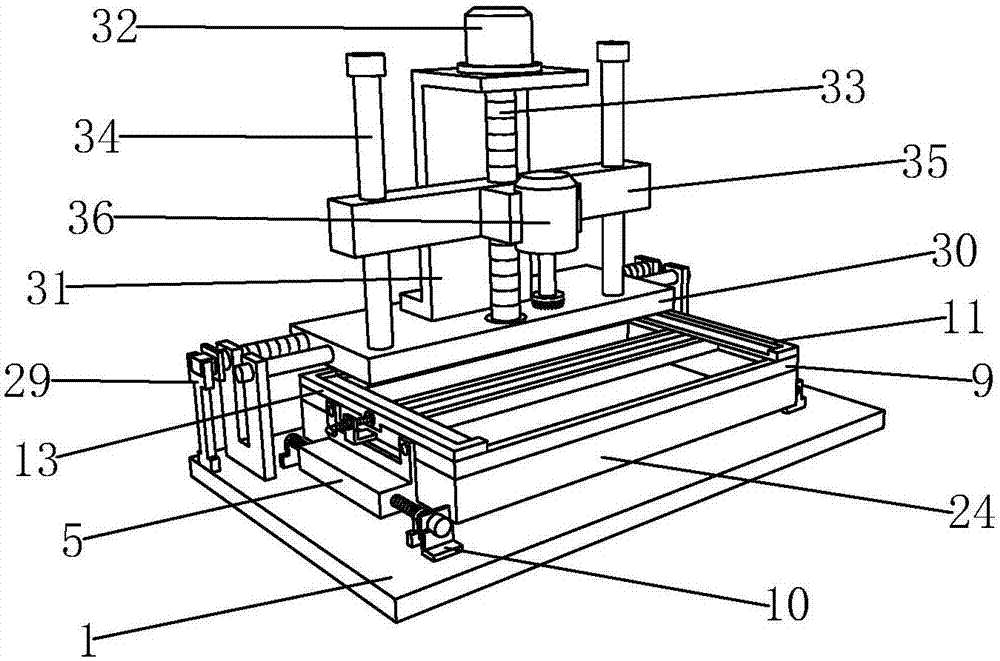

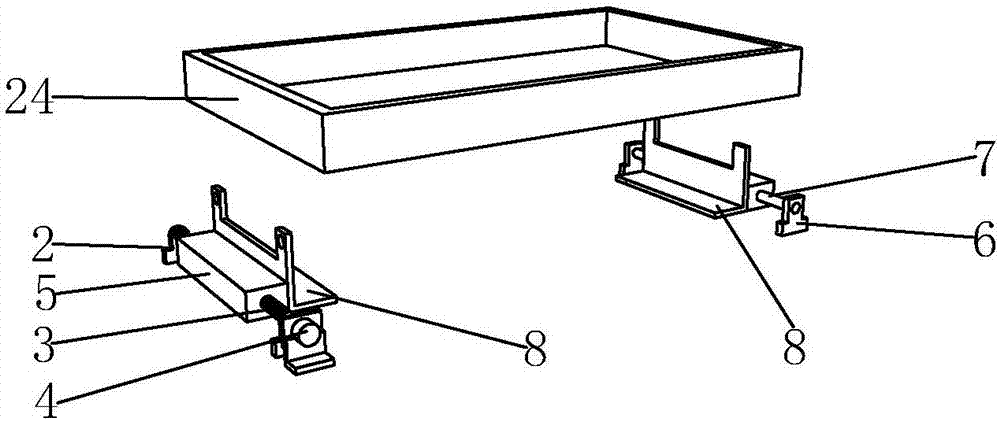

Drilling device for laminated glass production

InactiveCN106956371AGuaranteed to collect completelyImprove work efficiencyWorking accessoriesFine working devicesElectric machineryWorking environment

The invention discloses a drilling device for the production of laminated glass, which comprises a working platform, on which a driving mechanism, a screw mechanism and a fixing mechanism are respectively arranged, and a supporting block is arranged on the screw mechanism and the fixing mechanism, and the supporting block There is a storage table between them, a receiving box is movably connected between the L-shaped support parts, a sliding seat is provided on the driving mechanism, a support frame is provided on the sliding seat, a stepping motor is provided on the top of the supporting frame, and the stepping motor and the A first screw is provided between the sliding seats, a fixed rod is provided on the sliding seat, a support plate is provided between the fixed rod and the first screw, a drilling motor is provided on the support plate, and a drilling shaft is connected to the drilling motor. One end of the drilling shaft is provided with a drill piece, and drill teeth are distributed around the bottom of the drill piece. The invention has the advantages of simple structure, strong flexibility, large drilling range, and can complete rows of drilling in the horizontal direction, with high working efficiency, simple collection of waste materials, and protection of the working environment.

Owner:嵊州市赫利玻璃制品有限公司

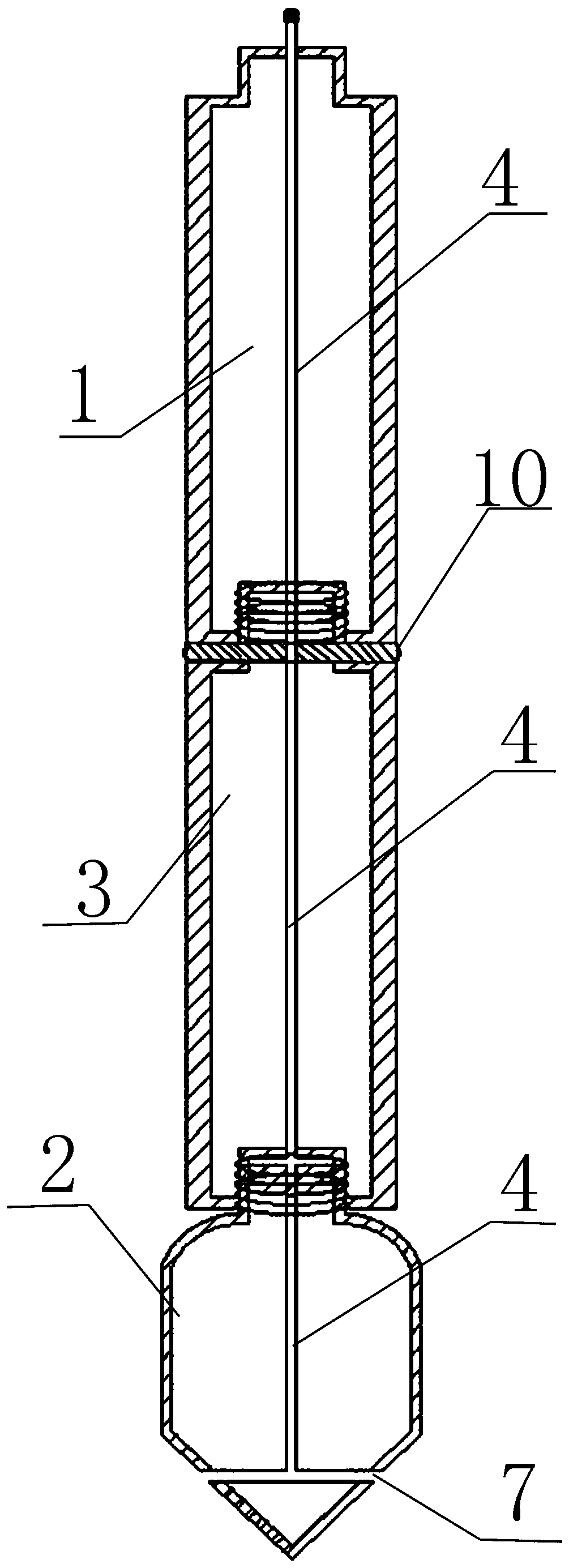

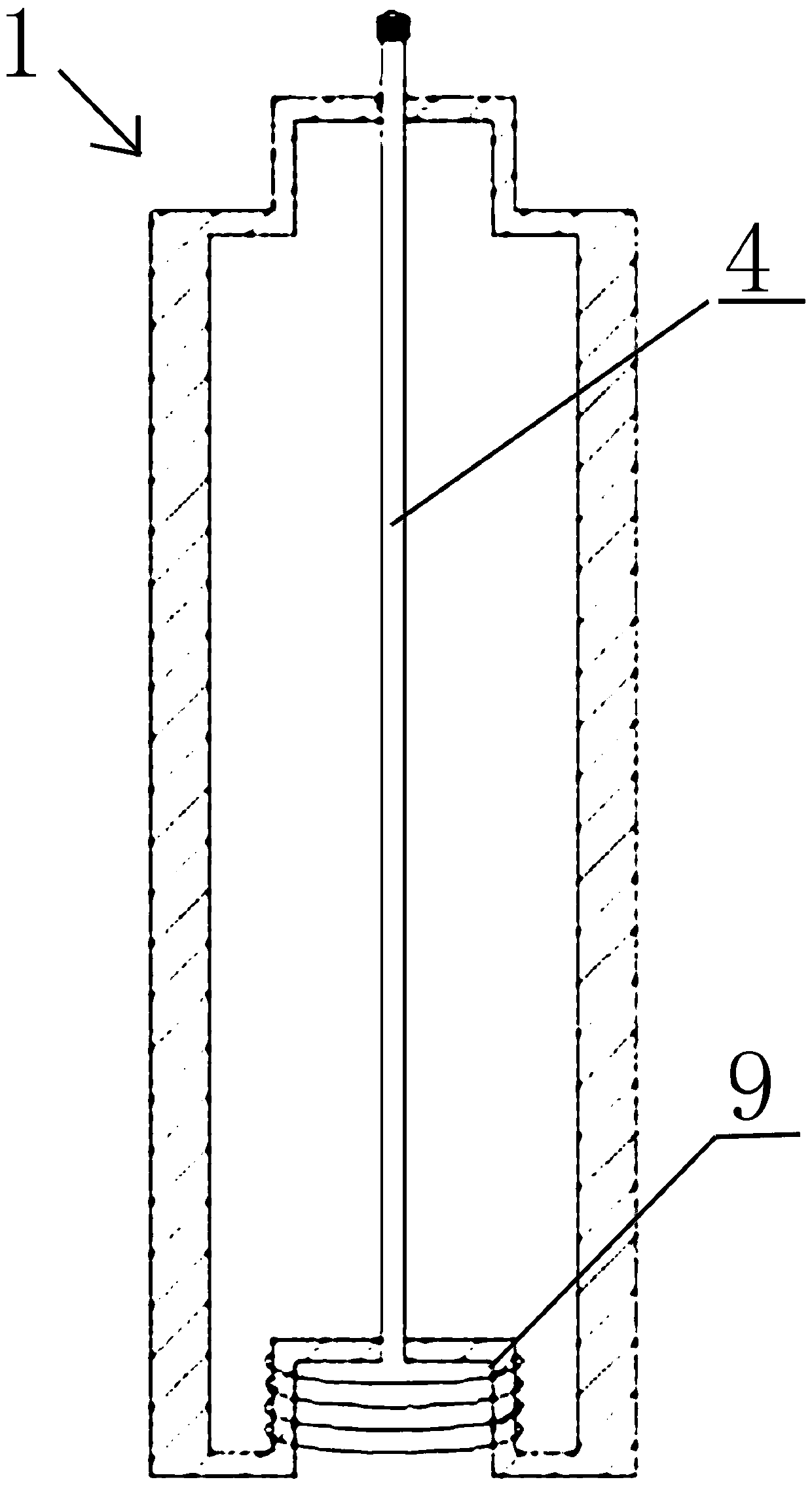

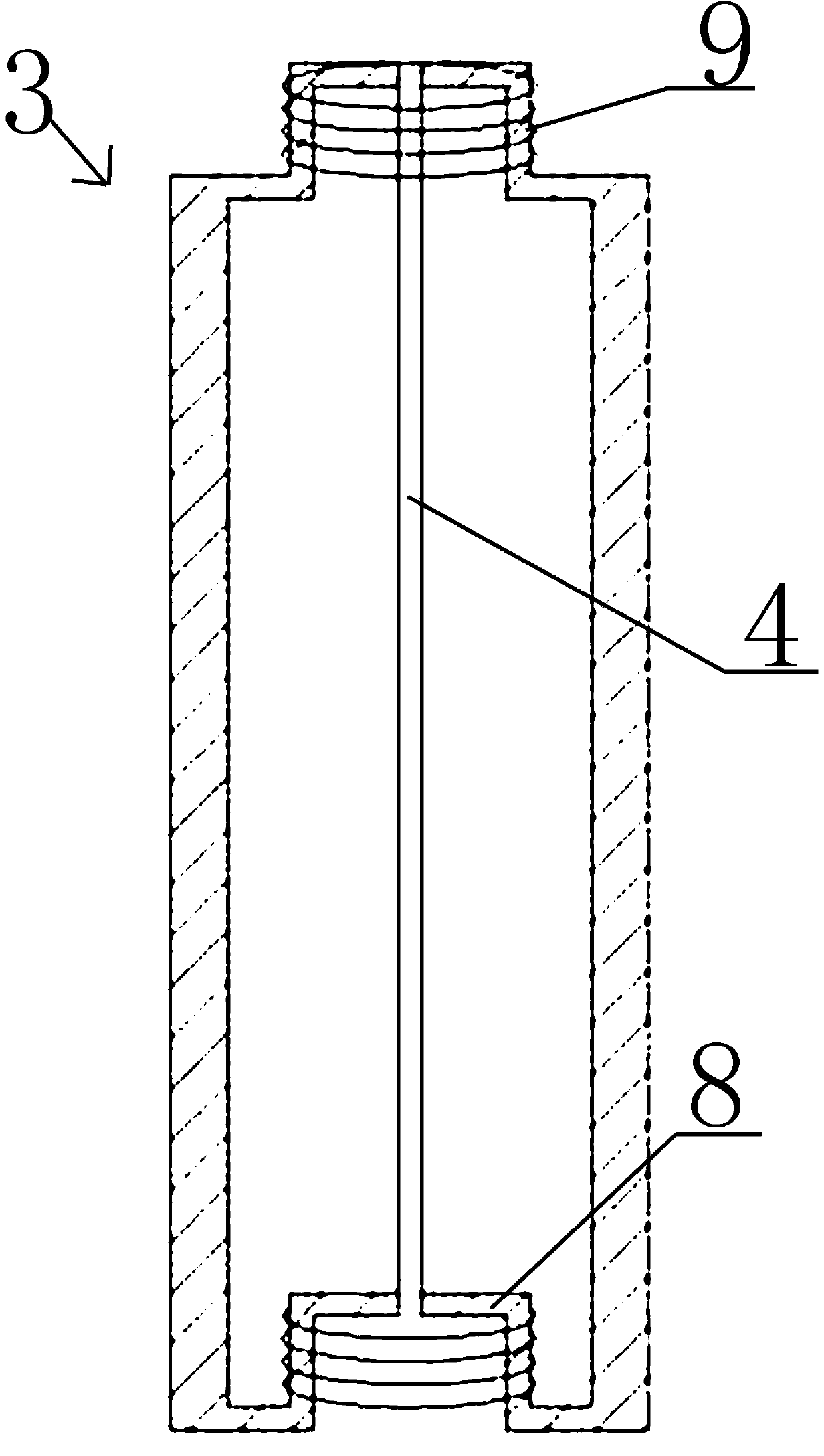

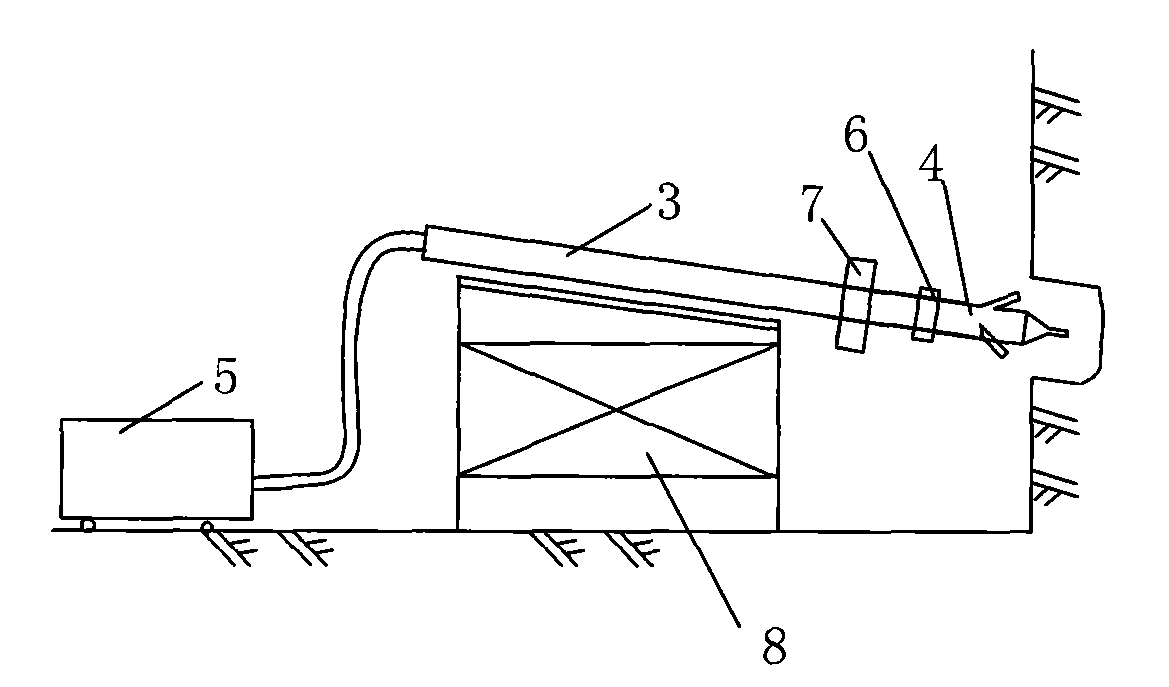

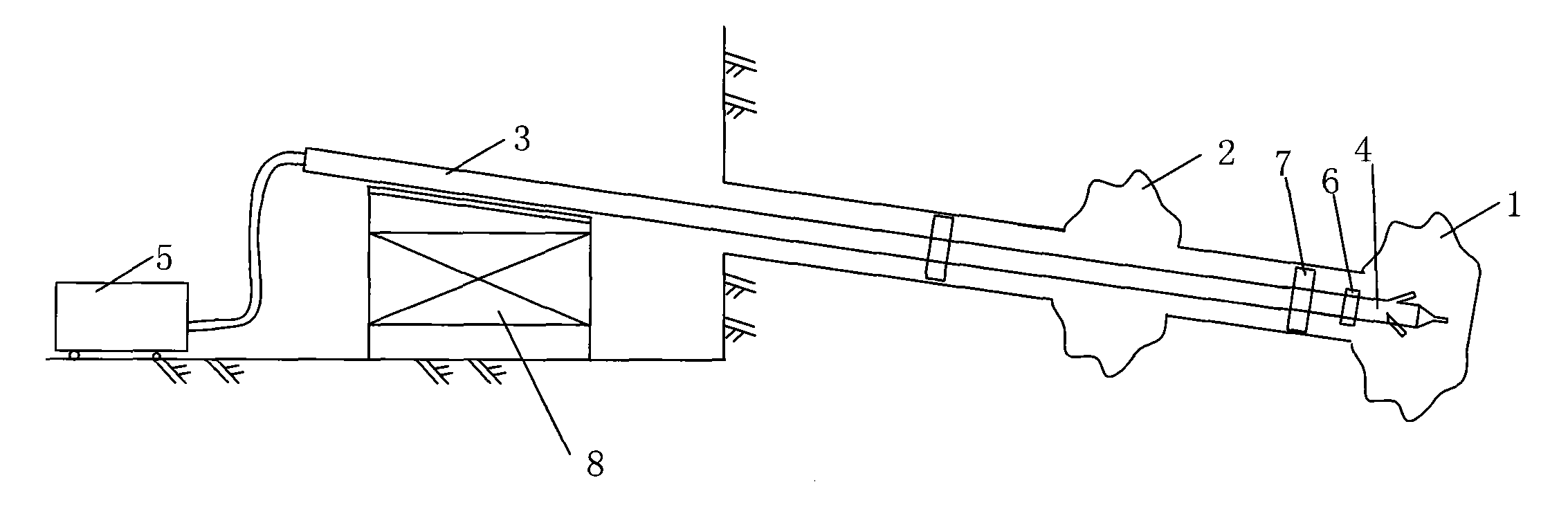

A rotary grouting anchor cable drill body and construction technology of rotary grouting anchor cable

ActiveCN104563106BSimple and effective high-pressure rotary sprayImprove construction efficiencyDrill bitsDrilling rodsSteel ballDrill hole

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

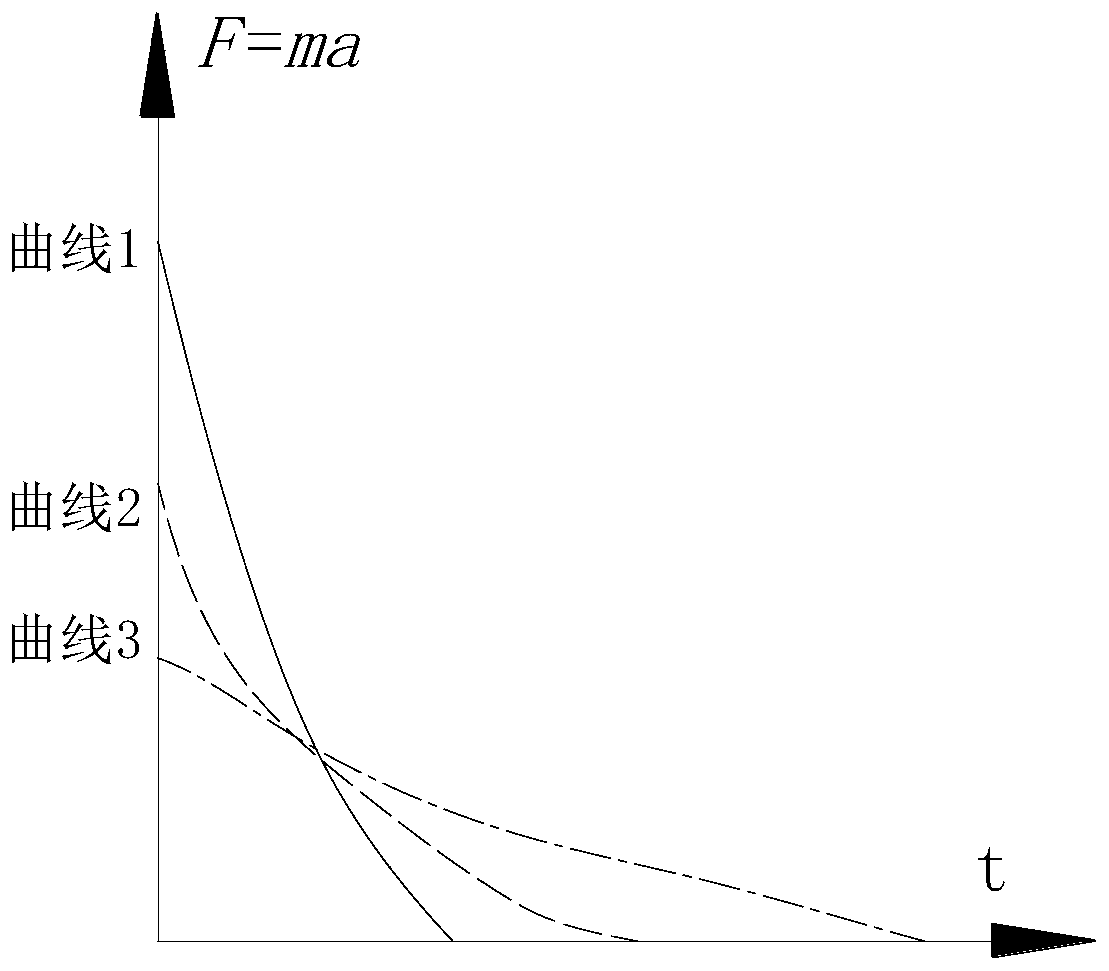

Unstable stratum variable-diameter casing pipe hole-protecting drilling process

ActiveCN111677448ASolve the problem of collapsed holesSolve problems such as shrinkageDrill bitsDirectional drillingPipeMechanical engineering

The invention discloses an unstable stratum variable-diameter casing pipe hole-protecting drilling process. The unstable stratum variable-diameter casing pipe hole-protecting drilling process can realize hole-protecting directional drilling in an unstable stratum, and solves the problems of hole collapse, hole shrinkage and the like in unstable stratum drilling, under the hole protection effect ofa variable-diameter casing pipe, the situations of hole collapse, hole shrinkage and the like in an unstable stratum hole section during subsequent drilling are avoided, drill jamming and drill falling accidents are avoided, smoothness of a directional drilling channel is guaranteed due to the hole protection effect of the variable-diameter casing pipe 2 in the unstable stratum hole section, therequirements of a mine for gas control, water damage prevention and the like are met, and the method is good in effect in the construction process, high in stability, high in unstable stratum hole protection drilling efficiency and good in hole forming performance.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Method for preparing flexible circuit board based on liquid crystal polymer film

ActiveCN112351592AExcellent pore forming performanceGood bending resistanceConductive material chemical/electrolytical removalPhysicsThin membrane

The invention discloses a method for preparing a flexible circuit board based on a liquid crystal polymer film, and the method comprises the steps: firstly, preparing a metal foil, and preparing a prefabricated film of a liquid crystal polymer material with the tensile modulus of 0.5-6.0 GPa and the bending modulus of 1.0-11.0 GPa; adjusting the tensile modulus of the prefabricated film from 0.5-6.0 GPa to 1.8-3.5 GPa through the modulus adjusting procedure; besides, adjusting the bending modulus of the prefabricated film to 2.0-8.0 GPa from 1.0-11.0 GPa through the modulus adjusting procedure, and obtainng a finished film, wherein the modulus adjustment process comprises the following steps: carrying out heat treatment on the prefabricated film under the condition of temperature T, cooling the prefabricated film, and controlling the heat treatment time t and the cooling rate vt; then, enabling the metal foil and the finished film to be subjected to hot press molding, and obtaining a molded metal-clad plate; and finally, etching a circuit on the metal conductive layer coated with the metal plate according to the circuit design drawing, and carrying out hole turning and electroplating on the circuit to obtain the flexible circuit board. The problem that in the prior art, a metal-clad plate has the hole forming defect can be solved.

Owner:UNIV OF SCI & TECH OF CHINA

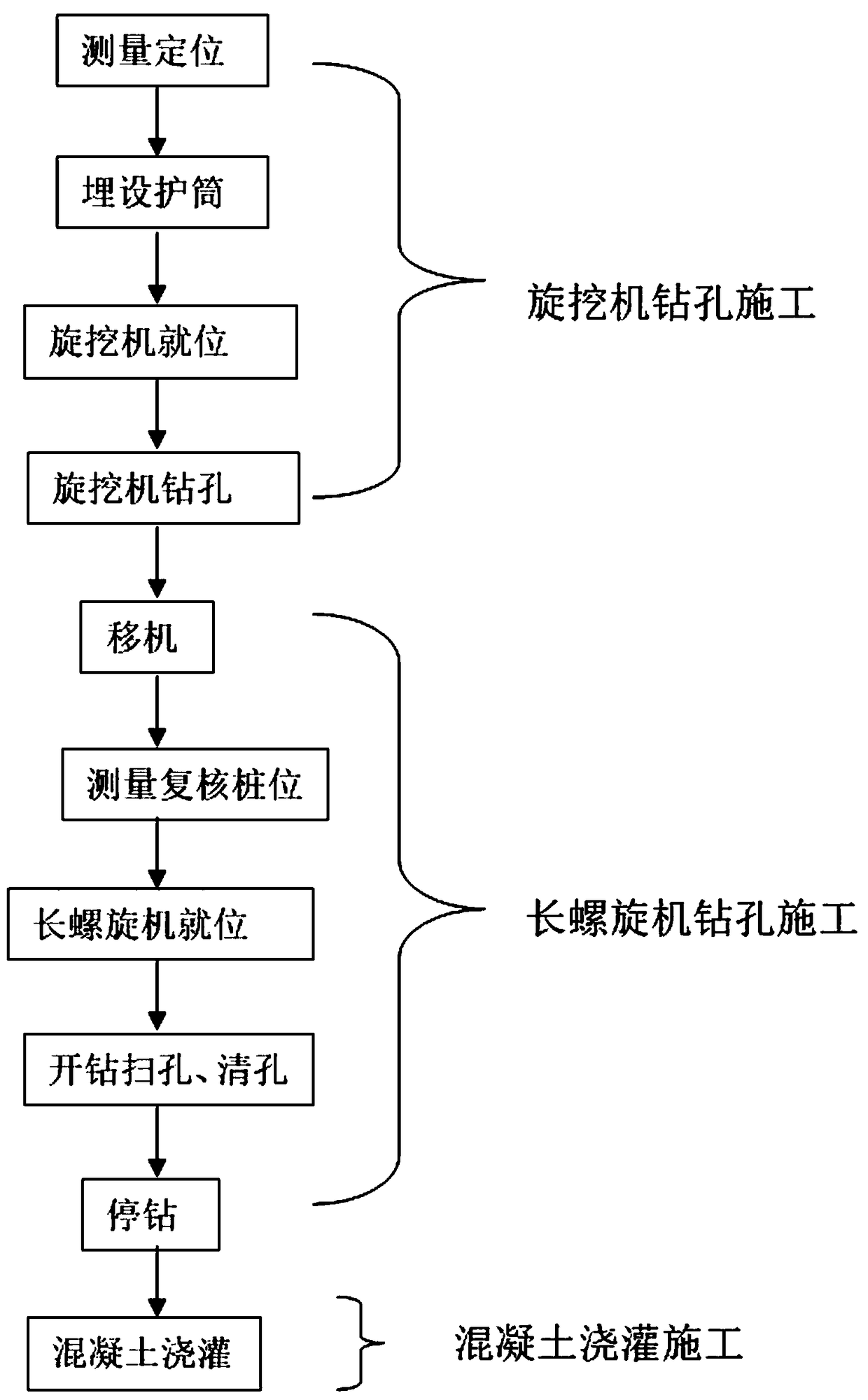

CFG pile implanting construction method suitable for composite soft and hard geology

InactiveCN109371975AStrong targetingMeet the construction period requirementsBulkheads/pilesSocial benefitsArchitectural engineering

The invention discloses a CFG pile implanting construction method suitable for the composite soft and hard geology. Firstly, a rotary excavating machine is used for drilling a hard stratum, then a long spiral machine is used for conducting repeated drilling till the designed elevation is achieved, and finally concrete pouring is conducted; and the interval time of drilling of the rotary excavatingmachine and drilling of the long spiral machine is controlled to be within 1 hour. By means of the CFG pile implanting construction method, the mechanical degree is high, the labor intensity is low,mature supporting measures are achieved on the construction quality and safety, the construction noise is low, construction materials are few, equipment for use is simple, the equipment transfer costis low, the construction speed is high, and the social benefits are obvious.

Owner:广西建工集团土木工程有限公司

Method for preparing wastewater heavy metal adsorbing material by using ionothermal system

InactiveCN107497395AWide variety of sourcesHigh adsorption rateOther chemical processesWater contaminantsWater bathsBromoethane

The invention relates to a method for preparing a wastewater heavy metal adsorbing material by using an ionothermal system. The method comprises the following steps: mixing 2-methylimidazole with bromoethane, and carrying out stirring, heating and an evaporating reaction to obtain bromide ionic liquid; uniformly mixing urea with choline chloride and uniformly heating for melting to obtain a deep-eutectic solvent; mixing and stirring the bromide ionic liquid, the deep-eutectic solvent, aluminum nitrate and sodium silicate, putting a mixture into a reaction still, and then putting into a baking oven; after the reaction ends, taking out a reactant for cooling, filtering, washing and drying to obtain a primary solid; adding the primary solid into a solution containing sodium hydroxide and then stirring the solution under the condition of water bath heating; filtering the stirred solution to obtain a final solid; cooling the final solid; drying the cooled final solid and then grinding the dried final solid to obtain a zeolite adsorbing material. The method disclosed by the invention has the advantages of being simple in preparation technology, environment friendly and low in energy consumption; reaction conditions are easy to meet; the zeolite adsorbing material has high purity and good adsorbing effect.

Owner:长沙埃比林环保科技有限公司

Spiral convex rib cutting hole pressure relief internal slag discharge drill pipe

ActiveCN108798540BWith blockageSolve the problem of high drilling resistance and easy drill stickingDrilling rodsDrilling casingsThermodynamicsSlag

The invention discloses an internal slag discharging drill rod provided with spiral convex ribs for cutting and holes for pressure relief. The internal slag discharging drill rod comprises a hollow rod body, a flow injecting pipe coaxially arranged in the rod body, and a supporting piece for connecting the rod body with the flow injecting pipe. A slag discharging channel is formed between the inner wall of the rod body and the outer wall of the flow injecting pipe; an air inlet and water inlet channel is formed in the flow injecting pipe; with the direction opposite to the rotating direction of the drill rod body during drilling as the reverse direction, the spiral convex ribs ascending in a cylindrical spiral shape in the reverse direction are arranged on the outer cylindrical face of therod body; and the multiple pressure relief holes are formed in the outer cylindrical face of the rod body along one sides of the spiral convex ribs. If hole collapse occurs during drilling, coal slagcan enter the slag discharging channel through the pressure relief holes, the acting force of the coal slag on the drill rod is released, meanwhile, the spiral convex ribs have the hole raking capability, and thus the coal slag is in a loose state and enters the slag discharging channel through the pressure relief holes till the hole collapse area is smooth.

Owner:HENAN POLYTECHNIC UNIV

Synchronous water injection and humidification device for lime-soil compaction pile

InactiveCN110820789AAchieve uniform moisturizing effectGood hole-forming effectBulkheads/pilesSoil preservationArchitectural engineeringWater resources

The invention belongs to the technical field of civil engineering foundation treatment equipment, in particular to a synchronous water injection and humidification device for a lime-soil compaction pile. The device solves the technical problem in the background technology. The device comprises a top section pile pipe, a bottom pile tip and a plurality of standard section pile pipes, wherein the top section pile pipe, the standard section pile pipes and the bottom pile tip are coaxially arranged from top to bottom and are sequentially connected, water injection pipes are arranged on a central axis of the top section pile pipe and central axes of the standard section pile pipes, the bottom pile tip comprises a cylindrical upper part and an inverted cone-shaped tip end, a water injection pipeis arranged on a central axis of the bottom pile tip, a plurality of water outlet holes are uniformly distributed in the circumferential direction of the side wall of the inverted cone-shaped tip end, and the water outlet holes communicate with the bottom end of the water injection pipe in the bottom pile tip. According to the device, synchronous water injection can be achieved in a punching process, too-little water injection does not occur, water resources are not wasted, the effect of uniform humidification of a surface layer and a deep layer of a pile hole is achieved, a construction period can be shortened, and the pore-forming extrusion effect is good, and the breakthrough of processing depth doubling is achieved.

Owner:TAIYUAN UNIV OF TECH

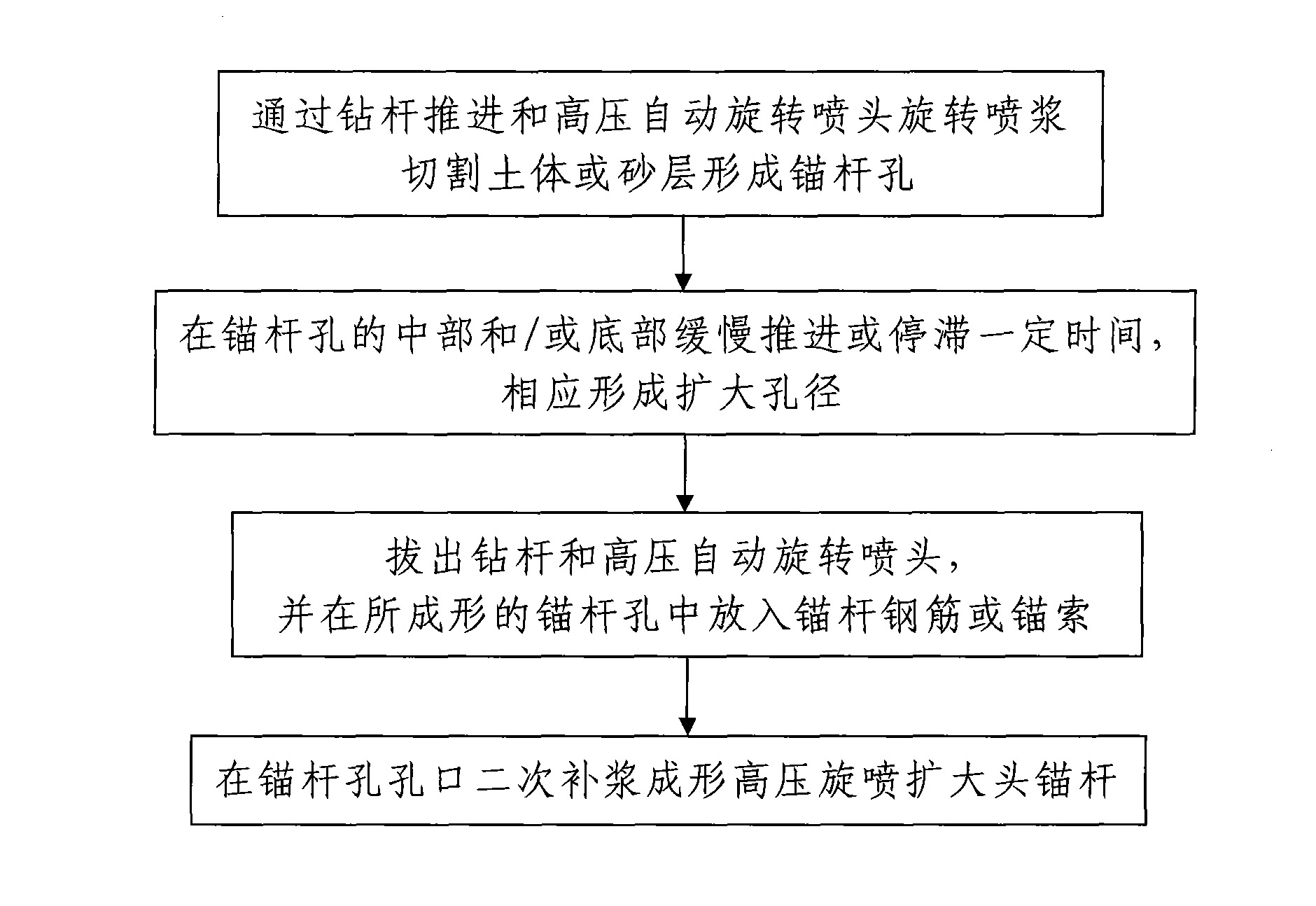

High-pressure jet grouting enlarged footing anchor rod and construction method thereof

ActiveCN101575854BFully mobilize the pulling forceImprove pullout forceExcavationsBulkheads/pilesRebarHigh pressure

The invention discloses a high-pressure jet grouting enlarged footing anchor rod and a construction method thereof. The anchor rod comprises an anchor rod body and a partial enlarged footing and / or a bottom enlarged footing which are arranged on the anchor rod body. The construction method comprises the following steps: firstly, cutting a soil body or a sand layer to form an anchor rod hole through the propulsion by a drilling rod and the rotary grouting by a high-pressure auto-rotating spray head; secondly, propelling slowly or stagnating for certain time at the middle part and / or the bottomof the anchor rod hole so as to form a partially enlarged aperture and / or a bottom enlarged aperture correspondingly; thirdly, pulling out the drilling rod and the high-pressure auto-rotating spray head, and putting an anchor rod reinforcing steel bar or an anchor cable in the formed anchor rod hole; and fourthly, performing secondary grouting at the orifice of the anchor rod hole to form the high-pressure jet grouting enlarged footing anchor rod. The construction method has the advantages of simple steps, low construction cost and good construction effect, and the formed high-pressure jet grouting enlarged footing anchor rod has the advantages of reasonable structure, large drawing force and low manufacturing cost.

Owner:陕西中机岩土工程有限责任公司

Preparation method of composite hollow fiber membrane

ActiveCN103464002BHigh initial fluxImprove mechanical propertiesSemi-permeable membranesPorous membraneUltimate tensile strength

The invention relates to a preparation method of a composite hollow fiber membrane. The preparation method is characterized by comprising the following steps: preparing a membrane casting solution; preparing a core solution and an outer gel bath; utilizing a dry-wet spinning device to inject the core solution and the membrane casting solution into a spinneret together for hollow fiber spinning, and extruding from the spinneret together to prepare a hollow fiber membrane wire; and enabling the hollow fiber membrane wire obtained in the step to pass a dry spinning path of 0-35cm and sequentially enter a first gel bath and a second gel bath for gel phase inversion to form the high polymer hollow fiber porous membrane with a microprous pore canal. The composite hollow fiber membrane prepared by the method disclosed by the invention is a hydrophilic hollow membrane material and has higher membrane flux and good pollution resistance at low pressure; simultaneously, the hollow fiber membrane has better mechanical strength due to the complementary property of the raw materials.

Owner:启东市天汾电动工具技术创新中心

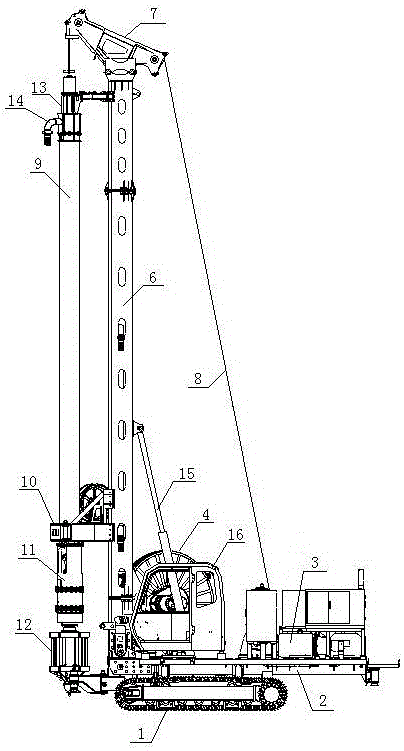

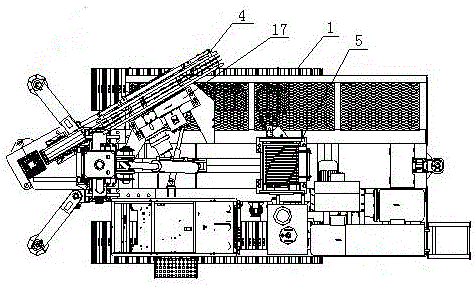

diving rig

ActiveCN104295230BHigh output speedReduce the number of peopleConstructionsRotary drillingWinchSubmersible drilling rig

Owner:SHANGHAI JINTAI ENG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com